Design, Synthesis, and Characterization of Lightweight Medium/High Entropy Alloys—A Review

Funding: The authors received no specific funding for this work.

ABSTRACT

Lightweight medium/high-entropy alloys (MEAs/HEAs) are an emerging class of materials with exceptional properties, including low density, high strength, and enhanced thermal stability. This review explores their design, synthesis, and characterization, emphasizing their potential for high-performance applications in aerospace and automotive industries. HEAs, typically composed of five or more principal elements in near-equimolar ratios, form stable solid solution phases due to high configurational entropy, preventing the formation of complex intermetallic compounds. To achieve lightweight yet strong alloys, elements like Al, Mg, Li, and Ti are carefully selected. Computational tools and thermodynamic models play a crucial role in predicting phase stability and optimizing compositions. Various fabrication techniques are employed, including solid-state processing methods such as mechanical alloying and spark plasma sintering, as well as liquid processing routes such as vacuum induction melting and arc melting with electromagnetic stirring. Advanced additive manufacturing techniques like direct laser fabrication (DLF) and selective laser sintering (SLM) are also effective in producing these alloys. Characterization studies confirm the superior mechanical and thermal properties of HEAs, allowing them to maintain strength and stability even at high temperatures. While these alloys show great promise as replacements for conventional materials, further research and development are needed to fully exploit their potential.

1 Introduction

High entropy alloys (HEAs) represent a revolutionary class of materials that challenge the conventional alloy design strategy. Conventional alloys usually have a basic element with small amounts of additional elements added to enhance certain qualities [1]. HEAs are a class of advanced materials made up of five or more primary elements in substantial or nearly equal amounts [1, 2]. A special set of qualities, such as high strength, resistance to corrosion, and thermal stability, are produced by this compositional complexity [2].

HEAs can be categorized into many types according to aspects like their functionality, chemical makeup, physical characteristics, and crystal structure. The crystal structures of HEAs might be mixed-phase, face-centered cubic (FCC), body-centered cubic (BCC), or hexagonal close-packed (HCP). BCC HEAs, such as AlCoCrFeNi, offer greater strength but less ductility; FCC HEAs, like the CoCrFeMnNi alloy, are renowned for their ductility and resistance to corrosion [3]. HCP HEAs, like TiZrHf alloys, offer exceptional strength and resistance to wear, and some HEAs have mixed-phase structures, which combine the advantages of FCC and BCC phases [3]. The physical characteristics of HEAs can also be used to categorize them. High-temperature HEAs like HfNbTaTiZr maintain performance in extremely hot conditions; high-strength HEAs like NbTaMoW are utilized for demanding structural applications; lightweight HEAs like AlLiMgScTi are made for low density and high strength; and magnetic HEAs like CoFeNiCu are helpful in electronic and magnetic applications [4-6]. Chemically, HEAs can include oxidation-resistant alloys like AlCrCoNi, carbide or nitride-forming HEAs with extreme hardness (like TiVCrAl nitrides), and refractory elements like Mo, W, and Ta for high-temperature applications (like NbMoTaW). Some HEAs incorporate non-metals, such as boron, for enhanced properties, as in FeCrAlNiMoBC alloys [4, 7, 8]. Functionally, superconducting HEAs like HfNbTaTiZr are useful at low temperatures; shape memory HEAs such as TiZrHf can return to their original shape after deformation; and catalytic HEAs like CoCrFeNiCu are used in chemical reactions. Lastly, the non-crystalline structure of amorphous HEAs, or metallic glasses like AlFeCuCrNi, provides excellent strength and resilience to wear [9, 10].

Recent developments have concentrated on creating lightweight HEAs because of the growing need for materials that combine great strength and low weight, especially in industries like aerospace, automotive, and energy sector [3, 11]. These alloys have the potential to take the place of more conventional materials like steel and aluminium alloys because of their lower density, which minimizes energy consumption and carbon emissions while providing better performance in demanding situations [8]. Aluminium (Al), magnesium (Mg), titanium (Ti), and lithium (Li) are examples of elements with lower atomic masses that are used in lightweight HEAs to achieve low density without compromising strength [12-14]. These HEAs are useful for applications that demand both performance and weight reduction despite their reduced weight because of their superior mechanical qualities, such as high strength, hardness, and occasionally even good ductility [3]. Lightweight HEAs retain mechanical qualities even at elevated temperatures, which is beneficial for parts in the automotive and aerospace industries [3, 12]. Many of them are also made to withstand corrosion, which makes them appropriate for long-term usage in challenging conditions [12]. AlLiMgScTi-based alloys, which have low densities and high specific strengths; AlCrTiV-based alloys, which balance strength and wear resistance; and Mg-based HEAs, which combine the light weight of magnesium with respectable mechanical qualities, are examples of common lightweight HEAs [14, 15]. The main industries that use these alloys are aerospace (for enhancing flight performance and fuel economy), automotive engineering (for increasing vehicle efficiency and range), defense (for creating lightweight but robust armor and components), and energy (for creating energy-efficient systems) [5, 11, 16]. However, creating lightweight HEAs necessitates careful optimization to strike a balance between performance and low density, and continuous research attempts to enhance their manufacturability and mechanical characteristics. The next generation of lightweight HEAs is anticipated to be driven by developments in alloy design and fabrication processes like additive manufacturing [17].

Lightweight high entropy alloys (HEAs) are created by choosing and combining several elements in equiatomic or nearly equiatomic ratios to balance mechanical stability, high strength, and low density [18]. The most common methods for creating these alloys are advanced metallurgical processes, including additive manufacturing, powder metallurgy (PM), arc melting, and vacuum induction melting [14, 15, 19]. Each technique allows for the fine-tuning of attributes by providing control over composition, microstructure, and performance [14]. While mechanical alloying enables alloys with significantly different melting points, methods such as arc melting guarantee homogeneous mixing [19, 20]. Vacuum induction melting and PM are helpful for reducing contamination and material waste [21]. Additive manufacturing allows for the production of complicated geometries [22]. The characteristics of lightweight HEAs are further improved by post-synthesis procedures including heat treatment and surface coatings [11]. Researchers can create lightweight HEAs with specialized qualities for applications with high performance in sectors including aerospace, automotive, and defense by streamlining these procedures.

Although there has been a lot of advancement in the design, synthesis, and characterization of lightweight HEAs, there are still several gaps that present chances for more research. The lack of information on the effects of combinations of lightweight elements (such as Al, Mg, Ti, and Li) on alloy characteristics is a significant problem in the database for elemental selection and combinatorial exploration. It is still difficult to optimize synthesis methods like arc melting, mechanical alloying, and additive manufacturing, especially when it comes to distributing elements uniformly, managing porosity, and avoiding contamination. Furthermore, little is known about phase formation and stability in lightweight HEAs, especially when it comes to forecasting whether crystal structures FCC, BCC, HCP, or mixed phases will form in various scenarios. Finally, to guarantee sustainable alloy design, more focus needs to be placed on recycling and environmental impact, especially regarding resource availability and HEAs' capacity to be recycled. The full potential of lightweight HEAs for industrial applications will be unlocked by resolving these issues.

This study examines the most recent developments in the design, synthesis, and characterization of lightweight HEAs to shed light on their potential uses in sectors that require high performance with weight efficiency. The paper will also discuss the challenges and opportunities that lie ahead for further optimizing these alloys for practical use.

2 Design of Lightweight HEAS

To design lightweight HEAs, elements must be carefully chosen, and their composition optimized to produce alloys with high strength, low density, and desired mechanical qualities. The procedure necessitates a thorough comprehension of thermodynamics, alloy phase development, and material science concepts [23]. Achieving a high strength-to-weight ratio while preserving mechanical stability is the major objective while constructing lightweight HEAs [24]. Lightweight elements like aluminium (Al), magnesium (Mg), titanium (Ti), and lithium (Li) are frequently added to alloy compositions to reduce density [25, 26]. These elements help make the alloy lightweight because of their small atomic masses. In HEAs, Al tends to encourage the development of body-centered cubic (BCC) phases [27]. Its high atomic radius and substantial negative mixing enthalpy with several transition metals are primarily responsible for this [10, 27]. Increasing the Al content in several HEAs can change dual-phase or face-centered cubic (FCC) structures into single BCC phases, which typically have lower ductility but higher strength [28].

More substantial solid solution strengthening is produced by a larger ϵ, which is ideal for improving the mechanical characteristics of lightweight HEAs.

Lastly, it leverages advanced simulation techniques, data-driven approaches, and high-throughput screening to predict alloy compositions and properties efficiently [10]. Researchers may find and optimize lightweight HEAs for high-performance applications more quickly by combining computational techniques with experimental validation [36, 37]. This will ultimately save time and money in the material development process. This diverse approach creates new opportunities for the development of novel materials with specialized qualities for sectors including energy, automotive, and aerospace [7, 38].

3 Fabrication Techniques

3.1 Arc Melting

Arc melting is a prominent technique for creating lightweight HEAs, since it can withstand high temperatures and produce uniform alloy compositions [39]. Arc melting creates uniform molten mixes of components with varying melting points by using an electric arc, which is a heat source that melts metallic elements in a controlled setting [39, 40]. The first of several crucial processes in the process is the processing of the raw materials, which are cleaned to get rid of surface impurities and weighed in precise ratios [40]. Reactive metals like Mg and Al are kept from oxidizing by the melting process, which occurs in an inert atmosphere or vacuum [1, 10]. The materials are melted at temperatures as high as 3500°C by passing a high current via a tungsten electrode, which produces an arc [10]. The materials are then stirred to guarantee homogeneity. After the alloy has melted, it is quickly cooled to maintain its microstructure and prevent element segregation [41]. Additional post-melting processing, such as heat treatment, rolling, or annealing, may be performed to further improve the alloy [1, 41]. However, the high volatility of metals like Mg and Li, which can result in composition loss, and their reactive character, which necessitates stringent control to prevent oxidation, are problems in arc melting lightweight HEAs [42]. Despite these difficulties, the arc melting process offers HEAs uniformity, adaptability, and efficiency in the production of high-purity alloys [43, 44]. Arc-melted lightweight HEAs are used in a variety of industries, such as the automotive and aerospace sectors, where weight reduction is essential, and the marine and defense sectors because of their resistance to corrosion [45]. When producing lightweight HEAs on an experimental or small-scale basis, where compositional accuracy and consistency are crucial, arc melting is especially well-suited.

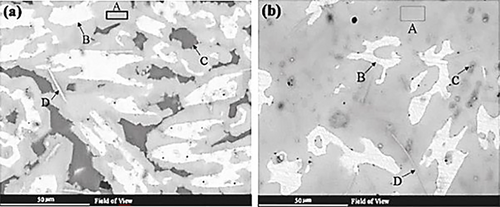

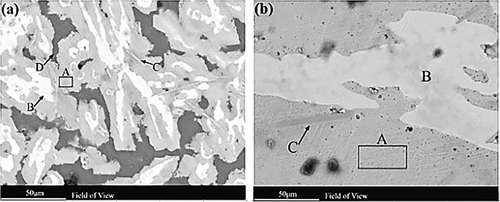

Sadeghi and Niraumand [40] gave an overview of the initial findings of a study, which aimed to design and develop a novel low melting point lightweight HEA based on the AlMgZnCuMn alloy system without appreciably boosting the production of intermetallic compounds. The alloy in this study was melted in a resistive electric furnace after its basic chemical composition was created using thermodynamic parameters. Density, compressive strength, and hardness were < 3.4 g/cm3, 95 MPa, 110–120 HV respectively. The die cast (DC) and sand cast (SC) samples were characterized using the scanning electron microscope (SEM); spherical and needle-like phases were produced. DC samples appeared finer and less complex than SC samples, as shown in Figure 1. There was an increase in grain size after the samples had gone under heat treatment from 28 to 40 μm in SC samples and from 24 to 26 μm in DC samples, as indicated in Figure 2.

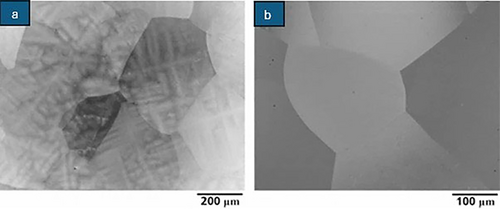

Stepanov et al. [46] also looked into the microstructure, mechanical properties, density, microhardness and crystal structure of AlNbTiV lightweight HEA. Coarse-grained single BCC phase structure was observed as shown in Figure 3. The density of an alloy was 5.59 g cm3 and its hardness ranged from 4315 to 4394 MPa. At room temperature, the compressive yield strength of an alloy was 1020 MPa; at 800°C, it dropped to 685 MPa; and at 1000°C, it fell to 158 MPa.

Huang et al. [47] looked at how the microstructure and attributes of TixZrVNb alloys were affected by increased Ti content. The observed yield strengths of the TiZrVNb, Ti1.5ZrVNb, and Ti2ZrVNb alloys were 1229, 1119, and 1086 MPa, respectively, indicating a slight decreasing trend. However, the alloys' fracture strain clearly increased from 35.2% to > 50% as the additional Ti concentration rose from 1 to 1.5. Furthermore, when the Ti content was raised to 2, such good ductility was maintained. Different authors have fabricated different lightweight HEAs using arc melting, and the mechanical properties are shown in Table 1 below.

| References | Alloy | Treatment condition | Yield strength (Mpa) | Elongation (%) | Hardness (HV) |

|---|---|---|---|---|---|

| [48] | Ti3V2NbAl0.5 | As-cast | 760 | 50 | 293.7 |

| [48] | Ti3V2NbNi0.5 | As-cast | 1130 | 20 | 389.7 |

| [49] | AlNbTiZr | As-cast | 1509 | 8.6 | 422 |

| [49] | AlNbTiZr | As-cast + annealed | 1579 | 17.8 | 418 |

| [51] | Ti1.5ZrNbAl0.3 | As-cast + annealed | 876 | 23.9 | — |

| [50] | AlNbTiVZr | As-cast + annealed | 1080 | 2.3 | 550 |

| [52] | Al0.4NbTiV | As-cast | 1298 | 9.29 | — |

| [53] | AlNbTiV | As-cast | 1379 | 20.9 | — |

| [46] | AlNbTiV | As-cast + annealed | 1020 | 5 | — |

| [52] | Al0.5NbTiZr | As-cast | 1264 | 6.15 | — |

3.2 Vacuum Induction Melting (VIM)

VIM is a popular method for creating high-purity metals and alloys, such as lightweight HEAs. A vacuum atmosphere in this process ensures high-quality materials by preventing contamination from gases including oxygen, nitrogen, and hydrogen [44, 54]. The metallic elements, or raw materials, are properly weighed according to the composition of an alloy and carefully selected based on the desired qualities [54]. The raw ingredients are put into a crucible composed of a refractory substance (often zirconia or alumina) that can tolerate the high temperatures needed for melting in the VIM furnace [55].

To get rid of air pollution and lessen oxidation, a vacuum is created in the melting chamber [12]. To accomplish this, air is pumped out, lowering the pressure to very low levels (~10−5 Torr or less) [12]. An induction coil encircling the crucible receives a high-frequency alternating current. This produces an electromagnetic field that causes the metal charge to experience eddy currents, which causes internal heat generation [1]. When the materials encounter the electromagnetic heating, they melt. While the induction heating guarantees uniform mixing of the components, the vacuum stops oxidation [56, 57]. The electromagnetic field itself (via electromagnetic stirring) or mechanical techniques are used to stir the molten metal during the melting process. To make sure the metals are completely liquefied and combined, the melt is closely watched for temperature consistency. With the appropriate composition and characteristics determined by the components selected, the high entropy alloy is now completely created in its molten state [57]. The furnace is filled with a preheated mold, usually composed of ceramic or steel [56]. The alloy is put into the heated mold while still under vacuum or a controlled inert environment (such as argon) after it has melted and thoroughly mixed to avoid contamination during solidification [12, 43]. As it cools, the alloy inside the mold hardens, creating the ingot or part.

The alloy's microstructure can be influenced by adjusting the cooling rate. Larger grains may be possible with slow cooling, although fine-grained or amorphous structures may result with rapid cooling [58]. To prevent contamination or oxidation, the vacuum is kept constant during the cooling process. The ingot or casting is taken out of the mold once the metal has completely solidified. The alloy's mechanical characteristics and microstructure can be further improved by using post-melting heat treatments such as annealing, quenching, or aging [59]. To enhance its surface qualities and dimensional accuracy, the finished product may be subjected to surface treatments including coating, polishing, or grinding [40]. To make sure it matches the target composition, the composition of the generated HEA is examined using characterization techniques such as X-ray fluorescence (XRF) and optical emission spectroscopy (OES) [40, 60]. The microstructure and distribution of elements are examined using microscopic methods including energy dispersive X-ray spectroscopy (EDS) and scanning electron microscopy (SEM) [7]. To make sure the alloy has the necessary mechanical qualities, measurements are made of its toughness, tensile strength, and hardness [7]. Table 2 summarizes the mechanical properties of lightweight HEAs which were prepared using induction melting. Before being utilized in industrial or research applications, the alloy may need to go through additional remelting, alloying, or processing to modify its composition or qualities [65]. High-purity materials with improved performance characteristics appropriate for high-performance applications such as automotive and aerospace are produced by this vacuum induction melting process for lightweight high entropy alloys [66, 67].

| References | HEA preparation method | HEA composition | Strength (Mpa) | Hardness (HV) |

|---|---|---|---|---|

| [61] | Furnace induction melting under argon atmosphere | Al25Ti25Ga25Be25 | 1620 | 490 |

| [62] | Induction melting and casting in air | Al0.3CoCrFeMnx | 119 | 141 |

| [63] |

Induction melting of pure metals, and the samples went through three cycles of remelting |

Al0.3CoCrFeNi | — | 568 |

| [6] |

Induction melting under a high purity Argon atmosphere |

Al2CrFeMnTi | — | 198 |

| [64] | Powder melting and electromagnetic stirring of molten powder under low vacuum in a medium induction furnace | Al0.5CoCrCuFeNi | 693 | — |

Sanchez et al. [68] created low-density and multiphase three new HEAs Al40Cu15Cr15Fe15Si15, Al65Cu5Cr5Si15Mn5Ti5, and Al60Cu10Fe10Cr5Mn5Ni5Mg5 by large-scale vacuum die casting under the guidance of CALPHAD modeling. The microhardness ranged from 743 to 916 Hv, while the observed densities ranged from 3.7 to 4.6 g/cm3. Xia et al. [69, 70] investigated AlxCoCrFeNi made by induction-levitation-melting (ILM). AlxCoCrFeNi HEAs made using the ILM process were identical to those made using arc-melting. When exposed to heavy ion radiation at normal temperature, the HEAs demonstrated exceptional phase stability. After being exposed to 3 MeV Au ions, these HEAs showed no sign of amorphization, ordering, or phase separation, with the highest fluence being 1 × 10−16 cm2.

Huang et al. [71] investigated a notable order–disorder transition in a lightweight AlCrTiV high entropy alloy system using CALculation of Phase Diagram (CALPHAD) modeling, transmission electron microscopy (TEM) characterization, differential scanning calorimetry (DSC) measurement, and mechanical testing. Ti has been found to reduce ordering, lower the order–disorder transition temperature, and provide ductility to AlCrTiV alloys. The new Al10Cr10Ti70V10 alloy had a noticeable tensile elongation of 1.1% and remarkable strengths of 877 MPa yield strength and 889 MPa ultimate tensile strength.

Qiu et al. [72] used VIM to study the impact of Fe concentration in FexCoNiCu HEAs. As the Fe concentration increased, they observed a phase transition from a single FCC phase to a mixture of FCC and BCC phases. The Vickers hardness increased to 6.72 GPa, and the ultimate tensile strength (UTS) reached 639 MPa.

In a related investigation, Kim et al. [56] used VIM in an argon environment to create a Co10Cu20Mn30Ni40 HEA. The alloy was rolled into a 1.5 mm thick sheet, reduced by 75%, and homogenized for 6 h at 1373 K. The sample underwent heat treatment at five varied temperatures, ranging from 873 to 1173 K, and the samples heat treated at 873 K showed the most superior tensile strength of 996 MPa.

3.3 PM

Lightweight high-entropy alloys (HEAs) with specific qualities can be produced using the popular PM process. Lightweight HEAs are perfect for demanding applications in the automotive, aerospace, and other industries because of their high strength-to-weight ratios, wear resistance, and exceptional mechanical qualities [73, 74]. These alloys usually contain elements like Al, Mg, Ti, and Li. Depending on the HEA composition, pure metallic powders of the desired alloying elements (such as Al, Ti, and Mg) are chosen. Particles are blended in a high-energy ball mill to create a composite powder and encourage homogeneity [73]. This stage is essential for HEA processing to achieve uniform distribution. Mechanical alloying is used to introduce lattice strain and produce fine-grained structures for further refining [75, 76]. The combined powders are compressed into a compact shape at room temperature, while pressure (typically 300–700 MPa) is applied to accomplish an initial a process called densification [76-78]. A binder can be added to the compacted powder to improve shape retention before sintering [78]. This green compact, which has already been sintered, needs to be strong enough to handle. The green compact is heated to just below its melting point, often from 80% to 90% of the melting point of the alloy [76, 77]. HEAs typically operate at temperatures from 800°C to 1200°C [73]. To avoid oxidation, sintering is frequently carried out in a vacuum or an inert gas (such as argon) [73]. This is particularly important for lightweight HEAs that are prone to oxidation.

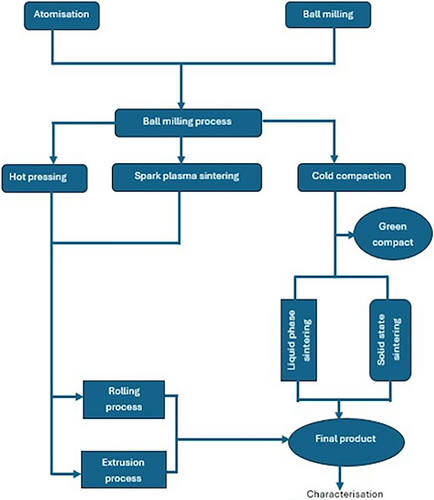

Atomic diffusion between particles is made possible by sintering, which densifies the material, enhances phase homogeneity, and improves mechanical characteristics [79, 80]. Hot isostatic pressing (HIP) can be used to improve mechanical qualities and further decrease porosity [81]. HIP achieves near-full density by simultaneously applying high pressure and heating to the component. Grain refinement, phase stability, and desirable mechanical properties can all be enhanced by customized heat treatments [75, 78]. Table 3 shows some of the mechanical properties of different lightweight HEAs prepared by mechanical alloying and spark plasma sintering. To improve surface qualities, methods like coating or shot peening might be used. Grain structure, phase composition, and uniformity are examined using methods such as X-ray diffraction (XRD) and SEM [75]. The toughness, tensile strength, and hardness of a material are examined to make sure it satisfies design specifications [83]. PM contributes to the creation of fine microstructures, which increase ductility and strength. Lightweight HEAs with superior strength-to-weight ratios, fatigue resistance, and durability may be designed using PM, which is particularly useful in cutting-edge industries like automotive and aerospace engineering [78, 83, 84]. Figure 4 below represents the PM process route.

Xu et al. [85] used vacuum sintering at 5 × 103 Pa, uniaxial compaction, and high energy ball milling to create FeMn28Six (x = 0–4 wt%) ternary alloys. Following an hour of heating to 800°C at a rate of 10°C per minute, the green compacts were then heated to 1200°C, held for 3 h, and cooled in a furnace. The alloy containing 4 wt% Si demonstrated the viability of producing HEAs using traditional sintering by achieving an ultimate tensile strength of roughly 350 MPa.

Fu et al. [86] used the vacuum hot pressing (VHP) method to consolidate the Al0.6NiFeCr and Al0.6NiFeCrCo HEA powders. During the consolidation process, a uniaxial pressure of 30 MPa and 1.2 × 102 Pa was applied for 1 h at 1000°C. In a similar investigation, Sun et al. [87] used the HP approach to consolidate the Fe18Ni23Co25Cr21Mo8WNb3C2 HEA powders at various temperatures for 2 h while under vacuum and 30 MPa of pressure. At a temperature of 650°C, the ultimate tensile strength and ductility of the HEA were approximately 0.8 GPa and 13.3%, respectively, whereas at ambient temperature, they were approximately 4% and 1.45 GPa.

Francis [88] compared the as-cast state and HIP to examine the tensile characteristics of AlCoCrFeNi HEA. The as-cast HEA had a UTS of 400 MPa but only 1% ductility at room temperature, whereas the HIP-processed HEA had a UTS of 393 MPa and 12% ductility. The microstructural change brought on by homogeneous heat treatment was responsible for the increased ductility in the HIP-fabricated HEA.

Sharma et al. [88] used high-energy ball milling and spark plasma sintering (SPS) for densification to create AlCuSiZnFe HEA. The 45-h-milled powders mainly showed an FCC phase with a little BCC phase that further developed during SPS. At 600°C, alloying was inadequate; however, beyond 650°C, the Cu–Zn FCC phase split from the Fe–Si-rich BCC phase, indicating an improvement. Al stabilized the BCC phase at 700°C while Cu–Zn maintained a soft FCC phase. The formation of Cu–Al intermetallic compounds at 800°C melted the HEA compacts completely. With SPS temperature, microhardness rose from 690 to 974 HV. At 650°C, the HEA demonstrated its best compressive qualities, with an elastic modulus of around 27,945 MPa and a compressive strength of about 1987 MPa. Densities ranging from 4.98 to 5.24 g/cm3 were measured.

3.4 Additive Manufacturing (AM)

The production of lightweight HEAs, which are renowned for their distinctive microstructures and remarkable mechanical properties, has greatly benefited from AM [89, 90]. To make a HEA, a powder blend of five or more primary elements in almost equimolar ratios is generated [89, 91]. Elements including Mg, Ti, and Al can be found in lightweight HEAs. To produce spherical powder particles, which are necessary for seamless AM processing, methods such as gas atomisation are frequently employed [1]. Typical AM methods for HEAs include Binder Jetting, directed energy deposition (DED), and laser powder bed fusion (LPBF) [92, 93]. In LPBF, a laser creates a dense and accurate structure by selectively melting powder layers to construct the object layer by layer [93]. DED, on the other hand, is perfect for larger structures since it directly distributes metal powder into the melt pool produced by a laser or electron beam [94]. Manufacturers can adjust the fast heating and cooling rates to customize microstructures and improve mechanical qualities by adjusting controlled AM parameters (such as laser power, scan speed, and layer thickness) [92, 95]. The formation of a fine-grained microstructure, which enhances the alloy's strength-to-weight ratio, is particularly influenced by the cooling rate [12].

Post-processing processes such as heat treatment, surface finishing, and HIP are employed on the material produced. Heat treatments are employed to improve ductility, smooth out grain structure, and release residual stresses [94, 96]. HIP improves mechanical integrity and density by decreasing internal porosity [59]. Surface finishing, which includes coating or polishing the component to enhance wear and corrosion resistance [59]. The produced alloy is tested for mechanical attributes such as corrosion resistance, hardness, and tensile strength [95]. Microstructural homogeneity and phase formation are evaluated by sophisticated characterization techniques like XRD and electron microscopy [7, 97]. Complex geometries are made possible by AM, which is crucial for structural effectiveness and weight reduction [97]. Control over local material properties and microstructures is possible through layer-by-layer fabrication. This process shows promise for applications in aerospace, automotive, and energy sectors, where lightweight yet strong materials are critical [96, 98, 99].

3.4.1 Binder Jetting

Binder jetting is an indirect additive manufacturing technique that creates pieces without melting metal powder [100]. Rather, a liquid binder is applied to a powder bed in a selective manner, binding the particles together layer by layer [101]. After printing, the green part is subjected to post-processing procedures like sintering, curing, and de-powdering to attain the required mechanical qualities [101, 102]. This procedure is beneficial for creating lightweight HEAs since it avoids residual stresses and thermal distortions, which are frequent in laser-based methods [103]. Binder jetting is appropriate for large-scale production because it is affordable and enables high production rates [104]. Due to the intrinsic porosity processes, the density of a material is reduced (85%–95%), necessitating sintering or infiltration to improve its performance [104, 105]. Al–Co–Cr–Fe–Ni and other lightweight HEAs are especially well-suited for Binder Jetting because of their strong oxidation resistance and lower density, which make them perfect for aerospace applications [105].

3.4.2 DED

DED involves feeding wire or metal powder into a melt pool that is produced by a high-power energy source, such as a laser, electron beam, or plasma arc [100]. This method is a great option for creating and fixing high-performance HEAs because it allows the production of fully dense components with high deposition rates [100, 103]. DED enables in situ alloying, which allows the addition of various elements throughout the process to fine-tune the material composition, which is beneficial for creating lightweight HEAs with ideal qualities [102]. The fast heating and cooling cycles of DED, however, make it susceptible to residual stresses and coarse microstructures, which makes post-processing procedures like heat treatment and HIP necessary [106]. DED is frequently used to treat lightweight HEAs with an exceptional strength-to-weight ratio, such as Ti–Zr–Nb for applications in the aerospace and energy sectors where high strength and wear resistance are necessary alloys [106, 107].

3.4.3 LPBF

LPBF is an extremely accurate additive manufacturing technique that builds objects with near-full density (> 99%) layer by layer, by selectively melting thin layers of metal powder with a focused laser [100, 108]. The capacity of the method to create fine microstructures that improve mechanical performance makes it popular for creating intricate and lightweight HEA components [109]. Lightweight HEAs benefit greatly from LPBF since it makes it possible to produce complex geometries with ideal weight distribution, which is crucial for applications in biomedicine and aerospace [110]. The procedure necessitates careful adjustment of laser parameters and powder properties, but it is comparatively slow, expensive, and susceptible to flaws like porosity and cracking. Al-containing HEAs (e.g., AlCoCrFeNi) and Ti–Zr-based HEAs are examples of lightweight HEAs that are frequently made using LPBF for high-performance applications where strength, corrosion resistance, and weight reduction are crucial [100, 108, 110]. Table 4 shows a comparison between the different additive manufacturing processes.

| Parameters | Binder jetting | Direct energy deposition | Laser power bed fusion |

|---|---|---|---|

| Form of material | Powder | Powder or wire | Powder |

| Source of energy | Binder and furnace | Laser or plasma | Laser |

| Density | 85%–95% | 90%–98% | > 99% |

| Rate of deposition | High | Very high | Low–moderate |

| Microstructure | Coarse | Coarse | Fine |

| Residual stress | Low | High | Moderate |

| Cost | Low | Medium | High |

| Post processing | Sintering | Heat treatment, machining | HIP, heat treatment |

| Best for LWHEAs? | Al-rich HEAs for low cost applications | In situ alloying and repairs | High precision components |

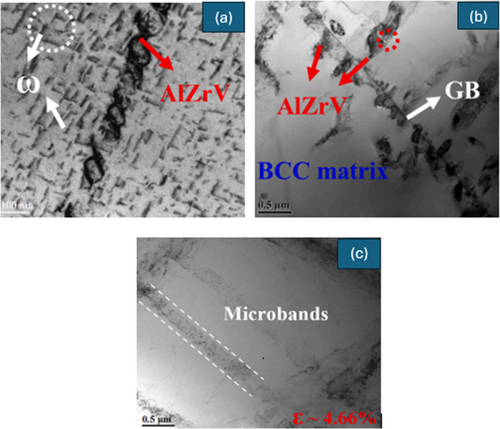

Zhang et al. [89] investigated Al0.3NbTi3VZr1.5 using laser directed energy deposition (LDED). As deposited, the material exhibited low strength and ductility and brittle behavior. After solid solution treatment (SST), a two-phase combination increased fracture strain to around 25% and yield strength to 1032 MPa with a decrease in laves phases and ω particles. Solid-solution strengthening was responsible for the increased strength, and a deformation mechanism involving multi-stage microbands and kinking as shown in Figure 5c was linked to the extraordinary ductility, which decreased localized stress and postponed breakage. Plastic deformation performance was further enhanced by fine-tuning microband spacing.

Peng et al. [111] examined the microstructure and tensile characteristics of Al0.3CoCrFeNi HEA LMD. Dislocation loops and a significant dislocation density were visible in the as-deposited samples. Heat stress-induced partial dislocation glide during LMD resulted in a disordered-to-ordered structural transformation. Annealing, on the other hand, reduced the critical shearing force necessary for plastic deformation by facilitating dislocation recovery. Consequently, after annealing, the yield stress dropped from 476.9 ± 6.4 to 373.5 ± 6.8 MPa. Despite this, annealing improved hardening, raising the samples' Vickers hardness and resistance to wear.

Lu et al. [112] examined the mechanical characteristics of CoCrFeNiAl0.3 HEA thin films that were formed at ambient temperature in a vacuum on a silicon substrate throughout a range of deposition times. The HEA thin films, which had a nano-hardness of 7.66 GPa and a Young's modulus of 150.35 GPa, showed better corrosion resistance than 316L stainless steel. Furthermore, Brif et al. [113] used SLM to manufacture FeCoCrNi HEA.

Thapliyal et al. [114] emphasized the high cooling rate of the laser-based powder bed fusion (PBF) technology in conjunction with the combined effect of transformation-induced plasticity (TRIP) by synthesizing Fe38.5Mn20Co20Cr15Si5Cu1.5 HEA. The alloy exhibited a tensile strength of 1235 MPa, effective strain hardening, and a deformation-induced FCC-to-HCP phase transition, despite the presence of microcracks. The demonstrated superior properties of HEAs produced through AM suggest that this method holds potential for developing lightweight HEAs in the future [115].

Sharma et al. [116] used additive manufacturing to fabricate AlCoCrFeNi lightweight and hard HEA. The alloy showed a BCC/FCC multiphase microstructure, a density of 4.3 g/cm3, and a hardness of 400 HV. Through microscopic analysis, passivating surface oxides were found on the powder particles, creating an alloy part that can withstand harsh conditions (Table 5).

3.5 Comparison of Fabrication Methods for Lightweight High/Medium Entropy Alloys

| References | Fabrication method | Key features | Merits | Limitations | Suitability for lightweight MEAs/HEAs |

|---|---|---|---|---|---|

| [117-119] | Arc melting |

Uses an electric arc and an inert gas (Ar) to melt elemental or pre-alloyed metals. |

|

|

Excellent for lightweight HEAs' lab-scale production and first property assessment |

| [1, 7, 55, 56, 120] | Vacuum induction melting (VIM) |

Enables fine composition control with the use of induction heating in a vacuum or inert atmosphere. |

|

|

Excellent for processing reactive and light elements more cleanly |

| [73-75, 77] | Powder metallurgy (PM) |

Combining powdered elements, then compacting and sintering (or hot pressing). |

|

|

Ideal for HEAs that are rich in magnesium and zinc, it aids in maintaining light components and producing homogeneous microstructures. |

| [7, 89, 121] | Additive manufacturing (AM) |

Layer-by-layer manufacturing with laser/electron beam melting of metal powders. |

|

|

New developments for lightweight HEAs that show promise for customizing structures and attributes |

4 Properties of Lightweight HEAs

The combination of strong strength and ductility, among other qualities, is one of the requirements for the attributes of next generation alloys [122, 123]. The intrinsic strength–ductility trade-off seen in traditional alloys is expected to be addressed by the development of lightweight HEAs [59]. The outstanding strength-to-weight ratio of lightweight HEAs is one of its primary characteristics. This makes them a desirable option for industries like aerospace, automotive, and defense where weight reduction is essential [55, 124]. The exceptional strength and hardness of these alloys can be ascribed to their multi-element composition-induced lattice distortion, solid solution strengthening, and grain boundary strengthening [28, 125, 126]. Lightweight components also aid in lowering the alloy's total density without sacrificing its strength [28]. The outstanding thermal stability and resistance to high-temperature deformation of lightweight HEAs is another crucial characteristic [122]. These alloys frequently have excellent oxidation, creep, and thermal fatigue resistance, which makes them perfect for use in harsh conditions like heat exchangers, turbine blades, and space exploration parts [1, 10, 46]. The capacity of HEAs to maintain mechanical qualities at high temperatures is a result of their slow diffusion effect [57]. Additionally, lightweight HEAs have outstanding corrosion resistance, which is essential for applications in challenging conditions [28, 125]. These alloys' resistance to oxidation and chemical assault can be increased by the presence of numerous elements, which can create a stable passive surface oxide layer [42]. Applications in the chemical and marine sectors, where exposure to harsh conditions is frequent, benefit greatly from this feature [124]. furthermore, even at low temperatures, these alloys exhibit good hardness and ductility [126]. Table 6 shows some of the properties of different lightweight HEAs at room temperature.

| References | Alloy composition | Hardness (HV) | Elongation (%) | Yield strength (Mpa) | Fracture strength (Mpa) |

|---|---|---|---|---|---|

| [26] | Mg50 (MnAlZnCu)50 | 178 | 4.83 | 340 | 400 |

| [26] | Mg20 (MnAlZnCu)80 | 431 | 3.29 | 428 | 428 |

| [126] | Al2NbTi3V2 | 814 | 15.7 | 2397 | 2674 |

| [126] | Al2NbTi3V2Zr0.2 | 809 | 18.5 | 2322 | 2663 |

| [126] | Al2NbTi3V2Zr0.4 | 697 | 38.2 | 1742 | 2420 |

| [126] | Al2NbTi3V2Zr0.6 | 725 | 28.1 | 2004 | 2581 |

| [126] | Al2NbTi3V2Zr0.8 | 957 | 24.6 | 2098 | 2620 |

| [126] | Al2NbTi3V2Zr1 | 781 | 19.8 | 2153 | 2625 |

| [26] | Mg45.6 (MnAlZnCu)54.4 | — | 4.06 | 482 | 482 |

| [47] | Ti1.5ZrVNb | 383.1 | 50 | 1119 | — |

| [26] | Mg43 (MnAlZnCu)57 | — | 3.72 | 500 | 500 |

| [26] | Mg33 (MnAlZnCu)67 | — | 3.41 | 437 | 437 |

| [47] | TiZrVNb | 434.9 | 35.2 | 1229 | 2287 |

| [127] | AlCrMoTi | 606 | — | — | — |

| [128] | AlLiMgZnSn | — | 1.2 | — | 615 |

Corrosion resistance is essential for lightweight HEAs, especially in aircraft, biomedical, and marine applications where performance can be compromised by environmental deterioration. Al, Ti, and Nb-based lightweight HEAs show the formation of a protective oxide layer, improving corrosion resistance [5, 129]. For instance, Ti-containing HEAs create passive coatings of TiO2, which increase resilience in saline and acidic environments [129]. Lightweight HEAs may be more prone to pitting corrosion than conventional stainless steels and Ni-based alloys, particularly in situations with high chloride concentrations [130]. Cr and Mo additions, however, can improve localized corrosion resistance [131]. Research has indicated that Al-rich HEAs may have reduced electrochemical stability because Al-rich phases dissolve in alkaline or acidic conditions; nevertheless, their passivation behavior can be improved by optimizing composition and heat treatment [131, 132]. Heat treatment can alter residual stress and phase composition, which can affect corrosion performance [133]. While homogenization treatments can improve corrosion resistance and decrease segregation, aging can cause phases to precipitate, which, depending on how stable they are in the environment, can either improve or impair corrosion resistance [134, 135].

The mechanical and thermal properties of lightweight HEAs are largely determined by their microstructure. Lightweight HEAs have distinct microstructural characteristics in contrast to ordinary alloys because of their complicated composition and solid-solution strengthening [130]. The exceptional mechanical performance of lightweight HEAs is a result of the distinct elemental combinations that allow the production of several crystal structures, including FCC, BCC, and HCP phases [39, 93]. Al-rich HEAs frequently form BCC structures, which may impair ductility but also increase strength and density [132]. In contrast, FCC structures offer superior formability and durability. Rapid solidification in AM techniques like DED and Laser LPBF frequently produces nanostructured or ultrafine-grained microstructures that improve mechanical characteristics [131, 136]. Grain size and phase distribution can be further adjusted by heat treatment to increase toughness and ductility [137]. Certain lightweight HEAs, particularly those that contain Al and Ti, show secondary phase precipitation, such as intermetallic compounds (such the L12 or B2 phases), which enhance high-temperature strength and hardness [105]. These precipitates can be adjusted for better mechanical performance through controlled heat treatment [138]. The formation of stable oxides or nitrides by oxidation-resistant elements such as Al, Ti, and Nb can improve the high-temperature stability of lightweight HEAs [139].

5 Applications of Lightweight HEAs

Lightweight HEAs find extensive use in a variety of industries because of their special blend of low density and high strength, as well as superior resistance to corrosion and heat [37, 122]. Lightweight MEAs and HEAs, especially those that contain aluminium, magnesium, and zinc, are very desirable in the aerospace industry because of their high specific strength, superior thermal stability, and resistance to oxidation at high temperatures [12, 57]. These qualities are essential for aircraft structures, where weight reductions directly result in increased load capacity and fuel efficiency [93, 122]. They are also promising for engine parts, turbine blades, and spacecraft parts, where low mass and mechanical integrity are crucial due to their thermal and structural resilience under dynamic loading conditions [59]. These alloys are extremely appealing for creating complicated shapes needed in aircraft systems due to the quick development of processing methods like additive manufacturing [140]. The need to increase fuel efficiency and lower carbon emissions is driving the automobile industry's quest for materials that are both strong and lightweight [7, 55]. A great substitute for traditional aluminium or high-strength steel alloys is offered by MEAs and HEAs [141]. They are appropriate for engine blocks, gearbox gears, suspension parts, and structural frames due to their improved mechanical qualities, which include strength, ductility, and wear resistance [37]. Their excellent formability and resistance to corrosion also contribute to a long service life and lower maintenance needs [131]. In the development of structural elements for electric vehicles (EVs), where effective thermal and mechanical performance is crucial for battery enclosures and supporting structures, lightweight HEAs also exhibit potential [131].

Military vehicles and equipment need materials that are both lightweight and resistant to harsh conditions for ease of mobility and transportation [132]. Toughness, impact resistance, and corrosion protection are all provided by HEAs and MEAs with aluminium and magnesium bases [102, 142]. These materials are being investigated for application in drones, next-generation light combat vehicles, portable equipment, and armor systems [137]. Their adjustable mechanical and ballistic qualities also give designers a tactical edge when creating components and protective gear that are more durable in field or combat situations [138]. Materials are prone to aggressive corrosion in marine environments because of the high humidity and salinity [137, 143]. Lightweight HEAs, particularly those containing Al and Cu, offer remarkable corrosion resistance because of their microstructural homogeneity and ability to form stable passive films [143]. These characteristics make them desirable for ship parts like fasteners, underwater housings, and propeller shafts. In the chemical sector, they can be used in reactors, pressure vessels, and pipelines where durability and weight reduction are crucial due to their resistance to acids, alkalis, and other reactive agents [144]. According to recent research, HEAs containing zinc and magnesium are biocompatible, which makes them attractive options for short-term biomedical implants [133]. These alloys provide a novel class of biodegradable orthopedic screws, plates, and fixation devices that safely break down inside the human body [103, 145]. They have a mechanical strength that is very similar to that of human bone, which lowers the possibility of stress shielding [145]. They are also perfect for applications that demand transient support and slow resorption without the need for further surgery since the corrosion behavior can be adjusted by composition or processing to manage the deterioration pace [146].

Energy and electronic applications benefit from lightweight HEAs' special electrical and thermal characteristics as well as their resistance to oxidation and corrosion [147]. These materials are being researched for application in electronics heat sinks or lightweight casings, battery components, and structural components of renewable energy systems (such as wind turbine parts) [100]. Furthermore, because of their microstructural tunability, alloys with customized thermal expansion coefficients may be created, making them appropriate for parts in high-performance computing devices or power systems that encounter temperature fluctuations [148]. The use of lightweight HEAs in nuclear contexts is a new field of study [101]. Alloys with high entropy compositions provide exceptional resistance to radiation damage because of their slow diffusion and lattice distortion effects, which reduce radiation-induced void swelling and embrittlement [149]. Lightweight systems with elements like Al and Mg are being investigated for structural materials in next-generation reactors [150]. This is because lowering component mass can enhance heat management and lower the need for shielding [151]. Furthermore, HEAs can be made to work as sophisticated radiation shielding materials in nuclear facilities, medical equipment, or space applications exposed to cosmic radiation by modifying the alloy composition (e.g., by adding neutron-absorbing elements like B, Gd, or Hf) [150].

6 Conclusions

Currently, lightweight HEAs are being explored as a potential substitute for conventional alloys in a variety of industries, including manufacturing, automotive, aerospace, and marine. This review discusses alloys that have superior properties and industry usability. The overall performance of the alloy, which includes properties like phase constitution, hardness, corrosion resistance, and wear resistance, is influenced by the composition of the alloy's constituent components as well as changes in the production routes' process parameters. Both conventional and unconventional manufacturing techniques have been thoroughly investigated and documented for the synthesis of HEA alloys. For the SSP approach, mechanical alloying in conjunction with SPS has resulted in HEAs with improved characteristics. In the meantime, electromagnetic stirring is frequently used in liquid processing techniques like VIM, VAM, and arc melting to improve the material's qualities. It was also noted that HEAs were manufactured using additive manufacturing techniques. It was found that techniques like DLF and SLM were better suited for creating these alloys. Additionally, a few of the most significant difficulties in processing and using HEAs were emphasized. When HEAs were compared to ordinary alloys, it was discovered that the alloys have unique mechanical properties, despite the difficulties involved in their design and manufacture.

The field of lightweight medium/high entropy alloys (MEAs/HEAs) has enormous potential in terms of future structural and functional materials. Future research should concentrate on expediting alloy design using integrated computational materials engineering (ICME) and machine learning-guided methodologies to forecast ideal compositions and phase stability. Advanced sintering processes, mechanical alloying, and additive manufacturing are examples of novel processing avenues that provide exact control over microstructure customization and property enhancement. Furthermore, increasing the use of these alloys in the nuclear, biomedical, and aerospace industries will require more research into their environmental performance, including resistance to radiation, oxidation, and corrosion under actual operating conditions. Finally, creating affordable, sustainable alloy systems with a wealth of elements and environmentally acceptable recycling techniques can close the gap between research and industrial-scale implementation, making lightweight MEAs/HEAs a practical option for applications that prioritize sustainability and performance.

Author Contributions

Fainah Madewu: writing – review and editing, writing – original draft, conceptualization. Nicholus Malatji: supervision, writing – review and editing. Mxolisi Brendon Shongwe: supervision, writing – review and editing. Tawanda Marazani: supervision, writing – review and editing. Lehlogonolo Rudolf Kanyane: supervision, writing – review and editing.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

The data will be made available by the corresponding author upon request.