Orthogonal Multi-Swarm Greedy Selection Based Sine Cosine Algorithm for Optimal FACTS Placement in Uncertain Wind Integrated Scenario Based Power Systems

Funding: The authors received no specific funding for this work.

ABSTRACT

Modern power systems encounter significant challenges in optimal power flow (OPF) management due to the unpredictable nature of wind energy integration. Flexible AC Transmission System (FACTS) devices, including Static VAR Compensator (SVC), Thyristor-Controlled Series Compensator (TCSC), and Thyristor-Controlled Phase Shifter (TCPS), enhance system stability, reduce losses, and lower operational costs when optimally placed. Conventional optimization techniques like Particle Swarm Optimization (PSO), Sine Cosine Algorithm (SCA), Moth Flame Optimization (MFO), Gray Wolf Optimizer (GWO), and Whale Optimization Algorithm (WOA) struggle to balance exploration and exploitation in complex OPF problems, leading to suboptimal solutions. This study proposes a novel hybrid metaheuristic approach, the Orthogonal Multi-swarm Greedy Selection Sine Cosine Algorithm (OMGSCA), integrating orthogonal learning, multi-swarm mechanisms, and greedy selection to enhance solution quality. Orthogonal learning explores new search spaces, while the multi-swarm strategy improves exploitation. The greedy selection mechanism prevents premature convergence. OMGSCA optimizes FACTS device placement and sizing in wind-integrated power systems under fixed and uncertain loading conditions. Performance evaluation on the IEEE 30-bus test system with wind energy and FACTS devices demonstrates OMGSCA's superiority over traditional algorithms. Case studies focus on minimizing generation costs, active power losses, and gross costs. Results show OMGSCA achieves a power loss of 5.6209 MW in Case 1, comparable to WOA (5.6121 MW) and outperforming PSO, SCA, and MFO by 0.90%, 0.06%, and 0.57%, respectively. OMGSCA's gross generation cost (1369.3961 $/h) surpasses PSO, SCA, MFO, and GWO by 0.39%, 0.28%, 3.48%, and 0.20%, respectively. The algorithm proves effective in OPF problems, delivering cost-efficient operations, reduced losses, and enhanced stability across varying load conditions.

1 Introduction

Rapid integration of renewable energy sources (RES) such as wind and solar into modern power systems is leading to substantial changes in the energy landscape across the world. To reduce the use of greenhouse gases and slow down the pace of climate change, the move toward greener energy is necessary. However, the intermittent nature of RES presents significant challenges to power grid operators in the optimization of the power flow across the grid, while ensuring reliability and minimizing operational costs. Moreover, if RES are taken into account, the Optimal Power Flow (OPF) problem becomes tougher because the OPF problem should consider how to generate, transmit, and consume power in order to stabilize the grid and keep it efficient.

The placement and sizing of Flexible AC Transmission Systems (FACTS) devices such as Static VAR Compensators (SVC), Thyristor Controlled Series Compensators (TCSC) and Thyristor Controlled Phase Shifters (TCPS) is one of the most critical issues in this context. These devices are used to control voltage levels, control power flow, and improve the stability of the power grid under dynamic events. The integration of FACTS devices into the OPF problem has been shown to minimize costs of generation, reduce active power losses, and enhance overall grid performance under both fixed and uncertain loading conditions. However, the OPF problem is non-linear and non-convex, and the inclusion of RES and FACTS devices complicates the problem even further, rendering it intractable with conventional optimization methods.

This study focuses on solving the problem in power systems that integrate wind energy and FACTS devices. Beyond determining the optimal placement and sizing of these devices, the objective is to develop an algorithm capable of effectively exploring and exploiting the solution space. While various optimization algorithms have been utilized to solve the OPF problem, many suffer from drawbacks such as premature convergence, slow convergence rates, and suboptimal performance in high-dimensional and nonlinear scenarios. Consequently, these limitations highlight the necessity for an enhanced approach to achieve improved optimization outcomes in contemporary power systems.

1.1 Previous Research: Evolution of Algorithms and OPF Problem Solutions

1.1.1 Evolution of Metaheuristic Algorithms

In the last few decades, metaheuristic algorithms (MAs) have become popular because of their robustness in solving complex optimization problems in different domains, including power systems [1]. Often, these types of algorithms are inspired by natural processes or biological phenomena. One of such MAs is Genetic Algorithms (GA), based on the biological process of evolution, which emphasizes selection, crossover, and mutation [2]. As a second example, the differential evolution (DE) algorithm by Storn and Price [3], while widely used due to its simplicity and effectiveness, is another. Because of its fast convergence, Particle Swarm Optimization (PSO), introduced by Kennedy and Eberhart [4], which mimics the social behavior of birds, has been extensively used on the OPF problem.

Swarm intelligence based algorithms, Gray Wolf Optimizer (GWO) and Whale Optimization Algorithm (WOA) have shown great potential to solve non-linear optimization problems [5, 6]. However, their performances are quite different in the complexity of the problem, and usually need to be hybridized with other methods in exploration and avoiding local optimum. Recently proposed by Mirjalili, Sine Cosine Algorithm (SCA) [7] has been shown to provide competitive results in solving multi-modal problems, but it also suffers from the same problems as other algorithms, such as stagnation and suboptimal local exploration [8]. Accordingly, several modifications to SCA, such as hybridization with orthogonal learning and greedy selection strategies, have been suggested in order to improve its exploration– exploitation balance [9]. The Moth Flame Optimization algorithm is introduced by Mirjalili in [10] as a bio-inspired heuristic paradigm to solve complex optimization problems. Results show that this algorithm performs better in global optimization tasks and is particularly well-suited for solving power system optimization problems. Sulaiman et al. [11] developed a new bio-inspired algorithm for solving engineering optimization problems called the Barnacles Mating Optimizer. This algorithm had high efficiency when solving complex optimization problems in different fields of study (power systems included). In addition, Sulaiman et al. [12] used the Barnacles Mating Optimizer in software engineering and found that it performed well in solving complex optimization problems. This approach was promising in improving the performance of many engineering systems. Sulaiman et al. [13] applied the Barnacles Mating Optimizer for evolutionary optimization tasks. In power systems optimization and other complex engineering problems, the algorithm they developed showed significant improvement in system performance.

1.1.2 Application of Algorithms to FACTS Integrated Power System

Mahmoud et al. [14] introduced a Wild Horse Optimizer to improve the current control loops of wind-side converters in PMSG-based wind generation systems. This technique improved the dynamic performance of the system and ensured stable operation at different wind speeds and load conditions. Mahmoud et al. [15] applied the Harris Hawks Algorithm to optimize DVR controllers in low voltage smart distribution systems. Voltage quality and system stability were improved by the robust controllers, particularly in distributed generation networks with fluctuating power demands. A parallel capacitor control strategy for DC link voltage stabilization in PMSG-based wind turbines was proposed in [16]. The operation of the wind turbine under grid disturbances was stable with this method and mitigated the effects of various fault conditions. In [17], Junior and Freitas reviewed power electronics applications in sustainable power systems, particularly in distributed generation, microgrids, and smart grids. In their comprehensive review, they highlighted the increasing use of power electronics to increase system reliability and efficiency. Advanced load frequency control in microgrids using a Bat Algorithm supported by a balloon effect identifier for photovoltaic power sources was studied by Mahmoud et al. [18]. The method enhanced frequency control and stability in microgrids with RES. Kamel et al. [15] used electric vehicle integration and STATCOM systems to improve the performance of islanded microgrids. These technologies were integrated to enhance voltage stability and power balancing in isolated microgrids. Awad et al. [19] provided a comprehensive review of water electrolysis for green hydrogen generation considering different renewable energy systems including PV, wind, hybrid, and geothermal energy sources. Economic analysis and applications of hydrogen generation were also reviewed. Ewais et al. [20] applied adaptive frequency control in smart microgrids with controlled loads with real-time implementation. This control strategy improved frequency stability and system reliability under varying load conditions. Hussein et al. [21] proposed a load frequency regulation system for multi-area power systems incorporating Vehicle-to-Grid (V2G) technology. The V2G system improved and stabilized the dynamic response of interconnected power networks. Montoya et al. [22] used a recursive quadratic approximation to solve the OPF problem for bipolar DC networks. The method was shown to be an efficient way to optimize power distribution in bipolar DC networks, which increased operational stability.

Extensive study has been made on FACTS devices such as SVC and TCSC in OPF problems. Researchers have demonstrated that proper placement and sizing of these devices can significantly enhance power system performance, including voltage stability and power loss reduction. However, the placement and sizing of FACTS devices in a system with integrated RES is a challenging task due to the stochastic nature of renewable generation. Mallala and Dwivedi [23] used the Salp Swarm Algorithm to solve the OPF problem with a Thyristor Controlled Series Capacitor (TCSC). This approach was applied to power systems with reactive power management problems and improved voltage stability and reduced power losses. To solve the challenges of stochastic wind and solar power generation, Sulaiman et al. [24] solved the OPF problem using the Teaching Learning Based Optimization algorithm. The method they developed increased the stability and efficiency of power systems with renewable energy integration. Sulaiman and Mustaffa [25] utilized metaheuristic optimization techniques to identify the optimal sizing and placement of FACTS devices, aiming to enhance the efficiency and voltage stability of power systems integrated with RES. Nayak et al. [26] used the Grasshopper Optimization Algorithm to optimize multistage controllers for automatic generation control in systems with FACTS devices. The optimization resulted in reduced response times and increased voltage stability in large power grids. Ahmad and Sirjani [27] reviewed metaheuristic optimization techniques for optimal placement and sizing of FACTS devices in power systems. According to their updated review, the main improvements in the optimization techniques for enhancing system performance are highlighted. Khan et al. [28] apply the modified Salp Swarm Algorithm for optimal placement of Static Synchronous Series Compensators (SSSC) in power systems. This approach yielded improved voltage stability and optimized reactive power flow, and reduced system losses. Khan et al. [29] propose a novel technique for allocation of FACTS devices using a modified Lightning Attachment Procedure Optimization. Their method reduced congestion and improved the voltage profiles, and hence, power system stability. Biswas et al. [30] use MAs for optimal placement of FACTS devices in wind power integrated electrical networks. They show that their approach enhances system stability by enhancing voltage regulation and reducing power losses in wind integrated systems. Wang et al. [31] develop a hybrid metaheuristic algorithm based on butterfly and flower pollination mechanisms for solving global optimization problems. Results of this approach indicate that it is highly efficient in improving system optimization for many engineering problems. Shehata et al. [32] used a hybrid methodology for optimal FACTS device allocation to improve power system operations. Optimizing reactive power management greatly improved system stability and efficiency with their method. Mahadevan et al. [33] apply a multi-objective hybrid Artificial Bee Colony and Differential Evolution algorithm for optimal placement of microprocessor-based FACTS controllers. We found that this approach increased system efficiency by optimizing power flow in large interconnected networks. Inkollu and Kota [34] solved the voltage stability problem using a hybrid PSO and Adaptive Gravitational Search Algorithm (GSA). The hybrid approach improved voltage profiles and stability in large power systems with integrated FACTS devices. A hybrid Bacterial Foraging and Nelder–Mead algorithm for congestion management by optimally placing series FACTS devices was used by Hooshmand et al. [35]. They found their method reduced system congestion and improved overall voltage stability in large-scale power networks. An artificial neural network and heuristic probability distribution method were used by Siddiqui and Prashant [36] to find optimal location and sizing of DG-FACTS devices. They made their approach to stability improvement and efficiency in modern power systems.

The studies mentioned above have a wide range of approaches to optimize power systems with FACTS devices and various MAs such as Wild Horse Optimizer, Harris Hawks Algorithm, Salp Swarm Algorithm, etc. Although these techniques show promise for increasing voltage stability, increasing the system resiliency, and optimizing power flow, they still have some limitations. However, many existing algorithms have poor convergence speed, particularly when applied to large-scale, complex power systems. However, some approaches, including the Salp Swarm and Grasshopper Optimization Algorithms, have been found to have difficulty escaping local optima, resulting in suboptimal placements of FACTS devices. Additionally, the stochastic behavior of RES, such as wind and solar power, adds complexity to the problem, as most existing algorithms struggle to maintain high efficiency under fluctuating conditions.

Nevertheless, these limitations necessitate the creation of new MAs that can more effectively cope with the multiobjective and nonlinear nature of FACTS placement optimization problems. The new algorithms should be designed to enhance exploration–exploitation balance, convergence speed, and to handle the uncertainty and variability of RES. An innovative approach that integrates hybrid strategies or adaptive mechanisms can overcome the current drawbacks of FACTS placement optimization and obtain more efficient and robust solutions.

Recent studies have explored advanced optimization techniques for power system management. Kar et al. [37] proposed a modified DE algorithm for reactive power management, demonstrating improved efficiency in control applications. In another study, Kar et al. [38] utilized a modified whale optimization algorithm to optimize FACTS device placement, effectively reducing transmission losses. Additionally, Kar et al. [39] developed an enhanced sine cosine algorithm with ensemble search agent updating schemes, which showed promising results in small signal stability analysis. These studies highlight the effectiveness of MAs in addressing complex power system challenges.

Modern power systems require critical attention for renewable energy source (RES) integration, especially wind energy, because the world aims to reduce greenhouse gas emissions and combat climate change. The random nature of wind power generation creates operational difficulties for power system optimization procedures. The OPFOPF problem faces growing complexity when RES enter the system because it needs to optimize power generation and transmission, and distribution with cost reduction and loss minimization. High-dimensional non-convex nonlinear problems with traditional optimization algorithms result in suboptimal solutions, along with premature convergence and operation inefficiencies in power systems.

FACTS devices deployed in strategic positions and selected correctly for their size, including SVC and TCSC and TCPS improve power system stability and simultaneously minimize active power losses while optimizing power flow patterns. The incorporation of FACTS devices into power systems that include RES creates additional complexity for the OPF problem, so it requires optimization techniques that can manage this enhanced complexity and uncertainty. The Orthogonal Multi-swarm Greedy Selection Sine Cosine Algorithm (OMGSCA) represents an advanced optimization method because it addresses critical problems that exist in current power systems.

Rising wind and solar energy penetration into power grids causes operational challenges because it creates unpredictable patterns in power systems. The stochastic characteristics of RES remain beyond the ability of standard OPF methods, so operations become costly and inefficient. The rising expenses for power generation and distribution, and transmission continue to increase because of the need to build new infrastructure for RES integration and the complexity of modern power system operations. Power system operators need efficient optimization methods that will decrease generation expenses and power losses, as well as operational costs. The irregular nature of RES causes difficulties with voltage stability and produces frequency instabilities, as well as power quality problems. The implementation of FACTS devices solves power system problems through their ability to dynamically control both voltage levels and power distribution. Advanced optimization approaches must be used to determine the best placement points for these devices alongside their correct size limits because this maximizes their effectiveness. The worldwide effort to decrease carbon pollution, alongside renewable energy transition requirements, forces power systems to improve their RES utilization capabilities. The implementation of efficient OPF solutions both decreases power system fuel usage and diminishes power dissipation, which together create a sustainable energy environment. PSO, alongside SCA and GWO, experiences limited performance and slow convergence speed when operating with both high-dimensional and nonlinear data, and faces premature convergence problems. The current optimization techniques need improvement to tackle the complex nature of present-day power systems effectively.

The current power system operation and optimization problems require advanced optimization algorithms such as OMGSCA to find effective solutions. OMGSCA solves power system problems with integrated wind energy and FACTS devices through its implementation of orthogonal learning and multi-swarm mechanisms, and greedy selection strategies, which optimize exploration and exploitation phases. OMGSCA provides a complete answer to present-day power system problems through its ability to minimize generation expenses while simultaneously decreasing power losses and enhancing system stability.

The algorithm used to solve the OPF problem with integrated renewable energy and FACTS devices is the development of the algorithm, Orthogonal Multi-swarm Greedy selection Sine Cosine Algorithm (OMGSCA) [40]. Orthogonal learning and multi–swarm strategies are used in OMGSCA to improve the exploration–exploitation balance, overcoming the shortcomings of the traditional algorithms and offering a more robust solution for modern power systems. Scaling OMGSCA for larger systems and investigating its use in real-time, dynamic conditions in different grid scenarios is the future work. In the next section, we will discuss the OPF problem formulation and placement and sizing of FACTS devices.

The world pauses attention on renewable energy source (RES) integration into modern power frameworks because it remains vital to reduce emissions while fighting climate change. The irregular nature of RES creates substantial operational difficulties for power system control because it affects both grid stability and operational expenses. The OPF problem faces increased complexity when it includes RES and FACTS devices in power generation and transmission operations, and consumption management. The grid stability enhancement and power flow optimization, alongside voltage level control, depend heavily on FACTS devices, which include Static VAR Compensators (SVC) and Thyristor-Controlled Series Compensators (TCSC) and Thyristor-Controlled Phase Shifters (TCPS). The random behavior of renewable energy generation makes it difficult to determine the best locations and sizes for FACTS devices in power systems.

California demonstrates the foremost position when adopting clean energy yet struggles with large-scale integration efforts involving wind and solar power to its power system. The California Independent System Operator (CAISO) detected grid instability followed by renewable energy curtailment because supply exceeded demand in 2020. Wind and solar power intermittency produced unstable voltage conditions while increasing power transmission losses, which required FACTS controllers to stabilize the power grid. The real-world situation demonstrates that systems with elevated RES integration must optimize their FACTS systems to sustain grid stability by minimizing operational expenses.

The state of Texas operates one of the world's biggest wind energy facilities yet faces difficulties in maintaining its power grid operations. The grid became unstable during the extreme weather event of February 2021 because wind power generation showed high variability. The power system faced widespread blackouts because inadequate reactive power support combined with absent voltage control mechanisms made the situation worse. The recent power grid failure demonstrates the necessity for efficient optimization approaches, which this research proposes to strengthen power delivery reliability in wind-heavy power systems.

The European countries Denmark and Germany have managed to incorporate significant amounts of wind energy into their power grid systems. The process of integrating wind energy into power systems has faced multiple obstacles despite its implementation. The German power grid suffered from congestion and power loss spikes because wind energy distribution was not balanced throughout the transmission system during 2019. Through deployments of SVCs and TCSCs as FACTS devices, utilities successfully control power flow characteristics and provide vital dynamic voltage support to solve these issues. The practical implementation of solving the OPF problem with RES and FACTS integration proves essential for maintaining stable and efficient power system operations.

The country of India aims to reach ambitious renewable energy targets but struggles to unite wind and solar power grids. The power grid in India endured frequency fluctuations and voltage instability problems because of renewable energy generation variability during 2021. The power industry uses FACTS devices including TCPS and SVCs to resolve these operational issues. The correct deployment and dimensioning of these devices prove difficult especially when systems contain substantial amounts of RES. The important role of the proposed Orthogonal Multi-swarm Greedy Selection Sine Cosine Algorithm (OMGSCA) becomes more evident for improving power grid stability while minimizing operational expenses.

The worldwide power systems require solutions for renewable energy source integration and stable grid operation, due to which the current study's problem requirements have become essential. Systems that combine RES with complex power networks need improved optimization approaches to guarantee efficient and reliable performance because of the intermittent source behavior. The implementation of FACTS devices presents a promising solution to power system difficulties, although their optimal deployment needs sophisticated algorithms that can address the non-convex and nonlinear characteristics of the OPF problem. OMGSCA presents a dependable computational method to address this vital challenge by maintaining exploration-exploitation harmony while managing background conditions, which produces superior results in cost minimization for generation units and power network losses, together with operational costs throughout multiple application studies.

The research addresses real power sector issues which lead to more stable and efficient electric system operations resulting in a sustainable energy future. Analysis of practical cases demonstrates the critical importance of the studied problem which warrants the application of OMGSCA to integrate renewable systems and FACTS devices into contemporary power networks efficiently.

1.1.3 Research Gap and Key Contributions

The implementation of RES and FACTS devices creates substantial difficulties when solving the OPF problem in modern power systems. The widespread research about implementing MAs for these challenges includes unexplored opportunities that are absent from current studies. Power systems face substantial unpredictability because renewable power sources present a stochastic behavior with solar and wind energy. The performance of current algorithms deteriorates when operating under changing conditions, which results in inferior solution outcomes. The optimization methods need improvement to properly address the unpredictable behavior of renewable energy generation systems. The weakness of traditional metaheuristic optimization methods, which include PSO and Sine Cosine Algorithm, and Gray Wolf Optimizer, appears when they confront high-dimensional nonlinear problems and show fast convergence together with weak exploration-exploitation management abilities. The suboptimal placement and sizing of FACTS devices become a result of this limitation since these devices play a critical role in system stability and efficiency enhancement. The extensive research on FACTS device placement and sizing has not resulted in effective optimization of their integration within power systems that contain high levels of renewable energy. A sophisticated optimization framework needs to handle the dynamic FACTS device and RES interaction for the simultaneous achievement of power loss reduction and cost minimization, and voltage stability improvement. The majority of current optimization algorithms work with a single optimization goal that targets either cost reduction or power loss reduction. Multidimensional system optimization becomes vital for actual power grids because operators need to achieve excellence in both cost reduction and operational reliability together with sustainable environmental outcomes. Advanced optimization algorithms need development to process multiple objectives efficiently when solving power system problems. The success rate of optimization algorithms on the IEEE 30-bus system diminishes for larger and complex power grids. System scalability represents an ongoing technical challenge specifically for operation systems that consist of high renewable energy participation and many operational control parameters. Modern power systems operated in real-time need optimization capabilities because they handle uncertain loads combined with sporadic renewable energy inputs. The current algorithms were developed mainly for offline optimization, yet they do not meet the real-time system requirements. Research about achieving optimal economic performance along with environmental impact optimization remains scant despite making generation costs and power loss reduction primary targets. To achieve sustainable power system operation, it is necessary to develop algorithms that effectively minimize costs together with greenhouse gas emissions reduction. The proposed algorithms receive validation through limited operating conditions that include fixed load conditions. The proposed solutions require further testing under conditions representing diverse circumstances involving unpredictable load patterns and fluctuating renewable power supply together with different network setups for ensuring dependable system solutions. Standard metaheuristic optimization algorithms employ fixed parameters together with set strategies because these approaches restrict their suitability for various solution contexts. To achieve better performance, hybrid and adaptive optimization strategies must leverage several algorithms by allowing their parameters to automatically adjust according to the problem conditions. The implementation of advanced learning techniques, including orthogonal methods and multi-swarm systems, proves effective for improving MAs' exploration-exploitation equilibrium. The utilization of these methods for power system optimization, especially regarding RES and FACTS devices, needs further investigation. Research gaps need immediate attention because they are essential for developing superior optimization algorithms that enhance power system reliability. The proposed Orthogonal Multi-swarm Greedy Selection Sine Cosine Algorithm (OMGSCA) aims to solve the identified gaps in power system optimization through advanced learning mechanisms and multi-swarm strategies, and greedy selection techniques for better exploration-exploitation balance and scalability, and robustness during unpredictable events.

Overcome the deficiencies of existing algorithms in solving the OPF problem with integrated wind energy and FACTS devices, a novel metaheuristic algorithm, Orthogonal Multi swarm Greedy selection Sine Cosine Algorithm (OMGSCA) is proposed in this work. To enhance the exploration and exploitation phases of the optimization process, we include orthogonal learning, multi swarm mechanisms, and a greedy selection strategy. These modifications enable OMGSCA to better explore the complex, non-linear search space of the OPF problem and reduce the probability of premature convergence and improve solution accuracy.

- A novel variant of the Sine Cosine Algorithm (SCA) is introduced in this study, incorporating orthogonal learning, multi-swarm strategies, and greedy selection to enhance optimization efficiency.

- The algorithm is employed to resolve the OPF problem in the power systems featuring wind energy and FACTS devices, focusing on optimizing placement and sizing under both stable and variable loading scenarios.

- OMGSCA is evaluated on the IEEE 30-bus system, a widely used test system in power systems research, and compared with traditional algorithms, including PSO, SCA, MFO, GWO, and WOA.

- The comparative analysis reveals that OMGSCA excels in reducing costs of generation, active power losses, and overall gross costs, outperforming other algorithms across both stable and uncertain loading conditions.

- This article presents an in-depth examination of OMGSCA's convergence patterns, highlighting its enhanced capability to balance exploration and exploitation, especially in solving complex, high-dimensional, and non-linear problems.

2 Mathematical Modeling and Problem Definition

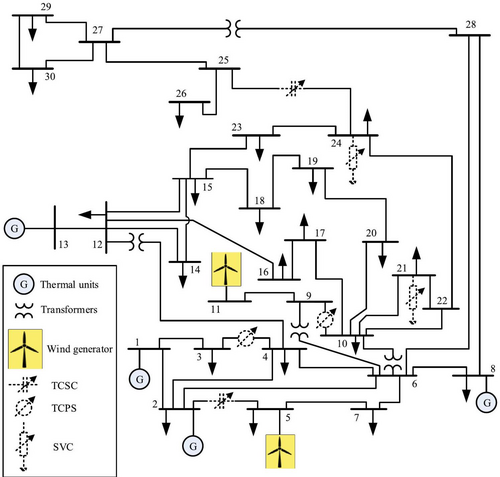

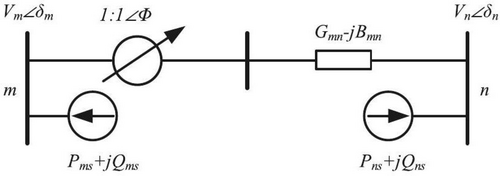

The IEEE 30-bus test system [41] is utilized in this study, modified to include wind generators and Flexible AC Transmission System (FACTS) devices. The system configuration, depicted in Figure 1, focuses on determining the optimal sizing and placement of FACTS devices, which are represented by dotted lines.

2.1 Mathematical Framework for Cost Evaluation

2.1.1 Fuel Costs or Generation Expenses of Thermal Units

The calculations utilize the cost coefficients of each thermal unit, as outlined in Table 1 [42].

| Generator | Bus | |||||

|---|---|---|---|---|---|---|

| 1 | 0 | 2 | 0.00375 | 18 | 0.037 | |

| 2 | 0 | 1.75 | 0.0175 | 16 | 0.038 | |

| 8 | 0 | 3.25 | 0.00834 | 12 | 0.045 | |

| 13 | 0 | 3 | 0.025 | 13.5 | 0.041 |

2.1.2 Calculation of Wind Power Probabilities

Here, and denote the scale and shape parameters of the Weibull distribution, which define the variability and spread of wind speeds at the given site.

- Cut-out regions ( or ): The turbine remains non-operational due to insufficient or excessive wind speeds.

- Partial load region (): The turbine generates power proportionate to the wind speed, increasing linearly until reaching rated power.

- Rated power region (): The turbine maintains constant output at its rated capacity.

Equation (5) calculates the probability that the turbine is either non-operational or generating zero power, while Equation (6) evaluates the likelihood of the turbine running at its rated capacity.

This equation provides a detailed representation of the turbine's power generation likelihood in the partial load region, reflecting the continuous nature of wind speed variability.

By combining these equations, a complete statistical understanding of wind turbine power output across all operational states can be achieved. This approach ensures an accurate assessment of wind energy's potential contribution to the grid.

2.1.3 Direct Costs Associated With Wind Power

In this equation, represents the scheduled power output of the wind generator, while denotes the cost coefficient per unit of power generated by the wind farm. This formulation provides a straightforward representation of the operational cost for scheduled wind energy production.

2.1.4 Assessing Costs of Uncertain Wind Power

Uncertainty in wind power generation introduces additional costs, such as reserve costs and penalty costs, due to deviations from scheduled output.

2.1.4.1 Reserve Cost

This expanded form incorporates the Weibull parameters ( and ) to account for the statistical variation of wind power output.

2.1.4.2 Penalty Cost

Equation (12) incorporates the same statistical parameters and wind turbine characteristics to evaluate penalties for deviations in actual power output.

The coefficients required for these cost calculations are presented in Table 2.

| Scenario | Loading level | Probability |

|---|---|---|

| 54.749 | 0.15866 | |

| 65.401 | 0.34134 | |

| 74.599 | 0.34134 | |

| 85.251 | 0.15866 |

2.2 FACTS Device Modeling

The Flexible AC Transmission System (FACTS) devices modeled in this study include the Thyristor-Controlled Series Capacitor (TCSC), Thyristor-Controlled Phase Shifter (TCPS), and Static Var Compensator (SVC). Each device enhances power system flexibility by improving power flow control and reactive power compensation [48].

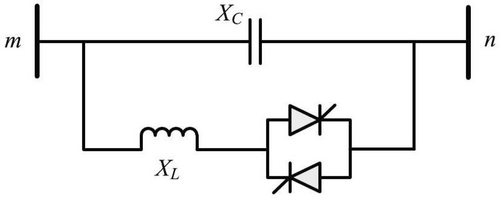

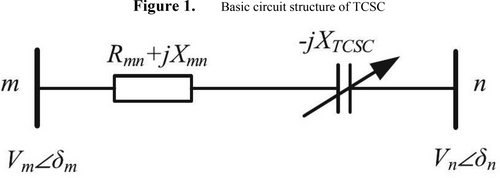

2.2.1 TCSC Model

Here, refers to the inductive reactance of the line, and denotes the line resistance.

When a TCSC is installed in a transmission line, the power flow equations are modified to reflect its effect on the line's impedance. The active and reactive power flows between buses and are calculated using the following equations:

- and denote the voltages at buses and , respectively.

- and represent the phase angles at these buses.

- and are the conductance and susceptance of line connecting buses and .

By incorporating the TCSC into the transmission line, the system's power flow and stability are significantly improved, making it a vital component in modern power systems (Figure 2).

Basic circuit structure of TCSC (Figure 3).

2.2.2 TCPS Model

The Thyristor-Controlled Phase Shifter (TCPS) serves as a series compensation device embedded within the transmission line connecting buses and , as depicted in Figure 4. Through the application of a controllable phase shift angle (), the TCPS adjusts the line's power flow, contributing to improved load distribution and enhanced system stability. The corresponding power flow equations for line with TCPS integration are outlined in Equations (20-27) and elaborated in References [49, 50].

2.2.2.1 Power Flow Equations for TCPS

The active and reactive power flows from bus to bus are calculated using the following equations:

2.2.2.2 Power Injected by TCPS

The TCPS impacts both real and reactive power injections at buses mmm and nnn, which are characterized by the equations provided below:

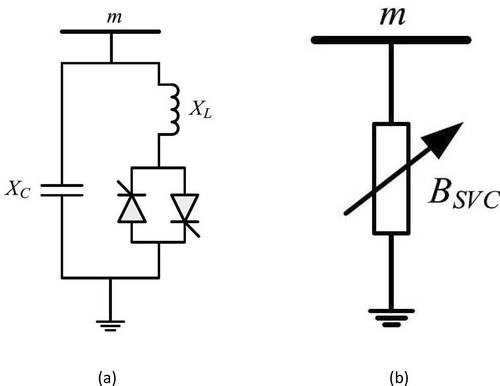

2.2.3 SVC Model

The static var compensator (SVC) operates as a shunt compensation device, enabling dynamic reactive power control. Figure 5a,b illustrate the fundamental circuit design and operational model of the SVC, respectively. It comprises a capacitor () and a thyristor-controlled reactor (), with the reactance regulated by varying the firing angle () of the thyristor.

- represents the capacitive susceptance.

- accounts for the variable inductive susceptance controlled by the firing angle .

- is the angular frequency, is the capacitance, and is the inductance.

- is the voltage at the bus where the SVC is connected.

- determines whether the SVC operates in capacitive or inductive compensation mode.

The SVC provides versatile compensation by dynamically injecting or absorbing reactive power to maintain voltage stability at the connected bus. In capacitive mode, the SVC injects reactive power into the system, improving voltage levels. Conversely, in inductive mode, it absorbs reactive power, mitigating voltage surges. This dual functionality makes the SVC an essential device for maintaining power system stability and efficiency.

2.3 Objectives and Constraints of Optimal Power Flow

In the adapted IEEE 30-bus test system, two thermal generators are substituted with wind power generators. FACTS devices such as TCSC, TCPS, and SVC are strategically placed to improve overall system performance. The optimization objectives are outlined as follows:

Minimization

Here, and represent the number of thermal and wind power generators, respectively.

Minimization

In this equation, is the line conductance, and represents the phase angle difference between buses and .

Minimization

2.3.1 Voltage Deviation

In this context, represents the voltage magnitude at the bus.

2.4 Equality Constraints

The system's power balance equations define the equality constraints. For the default configuration, which excludes FACTS devices, these equations are represented as [51]:

With the integration of FACTS devices, the equations are adjusted as follows:

- and are the active and reactive power injected by the TCPS at bus .

- denotes the reactive power contribution from the SVC.

2.5 Inequality Constraints

The OPF problem incorporates several inequality constraints, defined as follows:

2.6 Problem Formulation

The OMGCA algorithm is utilized to solve the OPF problem, targeting the reduction of generation costs, power losses, and overall gross expenses across different operating conditions. The optimization focuses on determining generator outputs, bus voltage levels, transformer tap settings, and the placement of FACTS devices to improve system performance.

2.6.1 Scenarios With Fixed Load Conditions

Under fixed loading scenarios, the network functions at its full load capacity (100%). Optimization is carried out to achieve three distinct objectives:

Case I: Reducing generation cost

Case II: Reducing real power losses

Case III: Minimizing both generation cost and real power losses simultaneously

2.6.2 Scenarios Involving Uncertain Load Demand

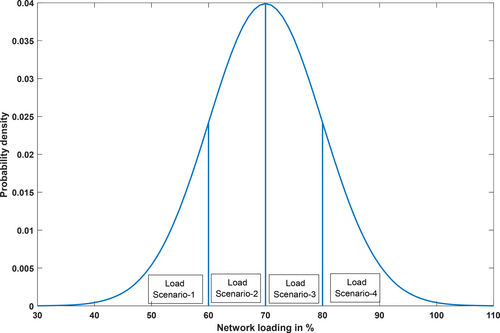

Table 3 outlines the calculated means and corresponding probabilities for all loading scenarios. In each case, generator schedules are optimized based on the given conditions. The algorithm determines the optimal placement of FACTS devices using the most probable scenario (load level 3), and these placements are maintained consistently across all scenarios. However, the FACTS device ratings are adjusted individually to suit the requirements of each specific scenario.

Here, is the total number of scenarios, and represents the probability of each scenario as outlined in Table 3.

Summary of cases and load uncertainty.

Table 3 provides a summary of the various cases considered in this analysis, highlighting the optimization objectives and constraints under different loading conditions. The impact of load uncertainty on the system is visualized in Figure 6, illustrating the variability in load levels across scenarios.

By incorporating the probabilities of different scenarios, the algorithm ensures robust and adaptive optimization of generation costs, power losses, and FACTS device ratings, maintaining system efficiency.

The algorithm manages wind integration uncertainties by using a detailed probabilistic modeling system which represents wind power generation randomness. Wind power output uncertainty gets modeled through the Weibull probability density function that shows site-based wind speed variability. Through this statistical format, the algorithm determines the probability distribution of wind power output between the three operational zones: cut-out, partial load, and rated power regions. The wind power probabilities follow the calculation method described in Equations. The probability calculations for turbine non-operation and zero power generation and rated capacity operation are defined through Equations (5) and (6). Additionally, the power generation likelihood of the turbine in the partial load region is shown in detail through Equation (7) because wind speed variations follow a continuous pattern. The probabilistic model delivers precise wind energy forecasting that can evaluate contributions to the power grid effectively at different operation levels. The algorithm includes penalty terms and reserve costs which evaluate the differences between planned and realized wind power outputs. The reserve cost calculation from Equation (9) determines the expenses when scheduled wind power surpasses actual generation, while Equation (11) calculates the penalty cost from exceeding scheduled output with actual generation. The optimization process includes these costs to guarantee dependable system operation under unpredictable wind conditions. The algorithm assesses various load conditions with specified probability distributions according to Table 2 to handle unpredictable load requirements. The calculations for expected generation cost (EGC) and expected power loss (EPL) and expected gross cost (EGRC) occur across all scenarios through Equations (50-52). The optimization process adopts this approach to handle the probabilistic characteristics of wind power generation and load demand, which produces more resilient and cost-effective solutions. The integrated probabilistic models alongside cost mechanisms in the algorithm resolve wind integration uncertainty while achieving optimal FACTS device installation locations alongside their sizes for fewer power costs and reduced losses, and stable operating conditions.

3 Proposed OMGSCA

3.1 Sine Cosine Algorithm (SCA) and Evolution of OMGSCA

where is the total number of iterations, and is the current iteration number. Despite its simplicity, SCA has limitations, such as a tendency to stagnate in local optima, particularly in high-dimensional or complex problems. To address these issues, the OMGSCA incorporates enhancements, including orthogonal learning, multi-swarm mechanisms, and greedy selection strategies. The pseudocode of the SCA algorithm is illustrated in Algorithm 1.

ALGORITHM 1. Pseudo-code of SCA.

1. Initialize a set of search agents (solutions) (X)

2. While (t < maximum number of iterations)

3. Evaluate each of the search agents by the objective function

4. Update the best solution obtained so far (P = X*)

5. Update r1, r2, r3 and r4

6. Update the position of search agents using Equation (56)

8. Return the best solution obtained so far as the global optimum

The random variable is drawn from a uniform distribution in . Despite its simplicity and effectiveness, SCA can be prone to getting trapped in local optima, particularly in complex or high-dimensional optimization problems. To address these shortcomings, three enhancements have been integrated into the SCA: orthogonal learning, multi-swarm, and greedy selection. The multi-swarm strategy, in particular, comprises three components: the dynamic sub-swarm number strategy (DNS), the sub-swarm regrouping strategy (SRS), and the purposeful detecting strategy (PDS). It is proposed that these improvements will enable the enhanced SCA variant to search the solution space more effectively, especially when applied to complex optimization problems.

3.2 Orthogonal Learning

3.2.1 Orthogonal Design

This systematic approach improves solution quality while reducing computational complexity, and the remaining columns are the non-basic columns in Algorithm 2.

ALGORITHM 2. Construction of orthogonal array LM(QK).

1 for {i = 1: J} do

2

3 for [k = 1: QJ] do

4

5 end for

6 end for

7 for {i = 2: J} do

8

9 for {m = 1: j − 1} do

10 for {n = 1: Q − 1} do

11 aj + (m−1) (Q−1)+n = (am × n) + aj modQ

12 end for

13 end for

14 end for

15 ai,j = ai,j + 1 1 ≤ i ≤ M and 1 ≤ j ≤ K

3.3 Multi-Swarm Mechanism

By directing the swarm to promising regions, PDS improves the algorithm's ability to escape local optima and explore effectively pseudo-code given as Algorithm 5.

ALGORITHM 3. DNS.

Input: fes, t, Cgen, N, Nsub, Ssub, m, N, Xij (1 ≤ i ≤ Nsub, 1 ≤ j ≤ Ssub), GBEST;

1 If mod(t, Cgen) == 0 and

2 m = m + 1

3 Nsub = {nm|nm ∈ N}; Ssub = N/Nsub

4 Randomly divide the whole swarm into Nsub sub-swarms, including Xij, Vij, and ;

5 Assign [0.1 * fes] fitness evaluations to GBEST to carry out the BFGS Quasi-Newton method;

6 fes = fes + 0.1 * fes;

7 End If

Output: fes, Nsub, Ssub, m, Xij (1 ≤ i ≤ Nsub, 1 ≤ j ≤ Ssub), GBEST.

ALGORITHM 4. SRS.

Input: Stagbest, Nsub, Ssub, Xij (1 ≤ i ≤ Nsub, 1 ≤ j ≤ Ssub)

1 If Stagbest ≥ Ssub/2

2 Randomly regroup the whole swarm into Nsub sub-swarms;

3 Stagbest = 0;

4 End If

Output: Stagbest, Xij (1 ≤ i ≤ Nsub, 1 ≤ j ≤ Ssub)

ALGORITHM 5. PDS.

Input: fes, GBEST, Mij, tabuij (1 ≤ i ≤ D, 1 ≤ j < Rn)

1 TmpGB = GBEST;

2 For i = 1 to D

3 If tmpgbi ∈ {Sij|Mij is greater or equal to other Mik (1 ≤ k ≤ Rn)} /* tmpgbi is the i-th value of TmpGB */

4 tmpgbi will be replaced by a random value within an inferior segment Sik where tabuik = 0;

5 Evaluate TmpGB; fes = fes + 1;

6 If TmpGB is better than GBEST

7 GBEST = TmpGB;

8 End If

9 tabuik = 1;

10 If all tabuik(1 ≤ k < Rn) are equal to 1, 11. Set each tabuik to 0;

11 End If

12 End If

13 End For

Output: fes, GBEST, tabuij (1 ≤ i ≤ D, 1 ≤ j ≤ Rn)

3.4 Greedy Selection

OMGSCA represents a new hybrid metaheuristic algorithm that targets the OPF challenges in power systems that incorporate wind energy and FACTS devices. The algorithm integrates Sine Cosine Algorithm (SCA) with orthogonal learning and multi-swarm mechanisms, and greedy selection strategies to achieve better exploration and exploitation capabilities. Orthogonal learning integration with multi-swarm strategies allows OMGSCA to achieve optimal exploration-exploitation behavior that helps it avoid suboptimal solutions while finding superior results. The OPF problem solution provided by OMGSCA effectively handles both the non-convex and nonlinear characteristics that exist in power systems with renewable energy integration and FACTS devices. OMGSCA delivers stable performance results in different operational scenarios with fixed and uncertain loading conditions, which enables its use in practical power system applications.

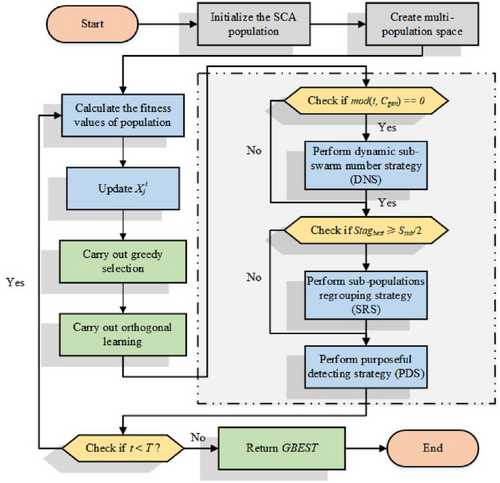

3.5 Framework and Computational Complexity of OMGSCA

Despite the added complexity, the algorithm's efficiency is significantly improved due to better exploration and convergence capabilities. The pseudo-code for the entire framework is provided in Algorithm 6, while the overall flowchart of the OMGSCA process is depicted in Figure 7.

ALGORITHM 6. OMGSCA.

1 Initialization: D, N, MaxIter, MaxGens, fes = 0, t = 0, Rn = 10, Stagbest = 0;

2 {n1, n2, …, np}, m = 1, ;

3 Divide each dimension search space into Rn same-sized subregions;

4 Nsub = nm, Ssub = N/Nsub, Mij, tabuij (1 ≤ i ≤ D, 1 ≤ j ≤ Rn);

5 Randomly initialize xij (1 ≤ s ≤ Ssub, 1 ≤ m ≤ Nsub);

6 Initialize the swarm at the first generation;

7 Evaluate the initial swarm by computing the function values for each individual;

8 Update the best solution obtained so far;

9 While not meeting stop conditions

10 t = t + 1;

11 Update r1 and r2;

12 For i = 1 to ns in parallel /* ns denotes the number of sub-swarms

13 For j = 1 to ss in parallel / ss denotes the size of each sub-swarm

14 For l = 1 to D / D denotes the number of dimensions

15 Update r3 and r4;

16 Update Xij according to Equation (56);

17 Carry out greedy selection;

18 End For

19 End For

20 For j = 1 to ss

21 Carry out orthogonal learning strategy;

22 End For

23 Evaluate the swarm by computing the function values for each individual;

24 Update the best solution obtained so far;

25 End For

26 Update A according to Equation (63);

27 Update GBEST and Stagbest;

28 Execute SRS();

29 Execute DNS();

30 Execute PDS();

31 End While

4 Result Analysis

The IEEE 30-bus system, which includes wind energy integration and FACTS devices, underwent testing using the OMGSCA approach. This approach was utilized to reduce generation costs, active power losses, and total expenditures under both stable and dynamic load conditions examined in multiple case studies. Comparative analysis was carried out with the outcomes of PSO, SCA, MFO, GWO, and WOA algorithms. The findings demonstrated that OMGSCA outperformed the baseline scenario by achieving reduced generation and operational costs while ensuring the stability of the system. The parameter settings utilized for all algorithms addressing the OPF problem are outlined in Table 4. In result analysis cases, power loss will be written as gross generation cost will be written as voltage deviation as minimum generation cost , run time as and Friedman Rank Test as

| Method | Other parameters |

|---|---|

| OMGSCA | Limit |

| PSO | vMax |

| SCA | |

| GWO | |

| MFO | |

| WOA |

The power system configuration needs definition through its bus count and transmission lines and generator types (thermal and wind) together with FACTS devices (SVC, TCSC, and TCPS). The researchers employ the IEEE 30-bus system as their experimental test case. Set the initial parameters for OMGSCA through population size determination and maximum iteration count together with orthogonal learning factor adjustment and multi-swarm mechanism implementation and greedy selection threshold selection. Input the load demand, generation capacities, and cost coefficients for thermal and wind generators. The Weibull distribution serves as the probabilistic model to describe wind power generation in the system. The optimization model should include both equality and inequality constraints which include power balance equations together with generator limits and voltage limits and operational constraints for FACTS devices

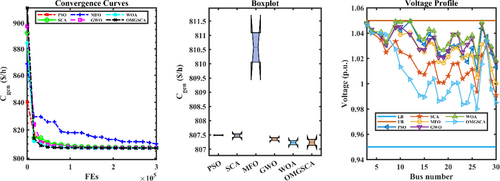

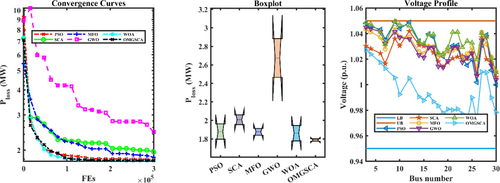

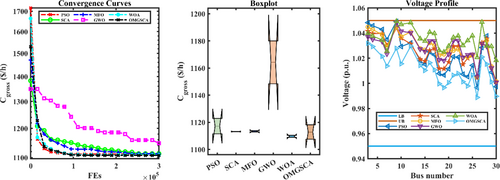

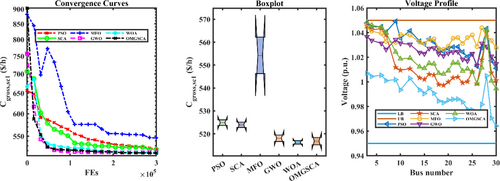

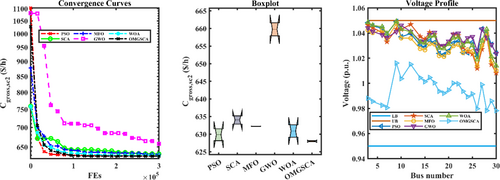

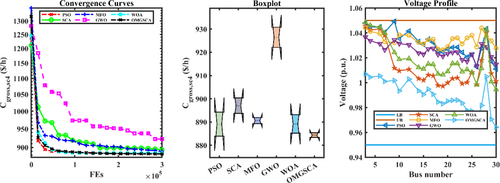

The convergence curves show how the objective function (generation cost or power loss or gross cost) changes with each iteration. The solution improvement rate shows an initial steep descent until the algorithm reaches its optimal point, where the rate becomes progressively flatter. Multiple runs of objective function values are displayed through box plot distribution. A box in the plot contains the interquartile range (IQR) and displays the median value as a line within this range. The minimum and maximum values extend from the whiskers, and outliers appear as individual points. The power system's voltage magnitudes appear in voltage profiles at various system buses. The optimal system operation requires flat profiles where voltages remain close to 1.0 per unit (p.u.).

4.1 Case 1: Minimizing Generation Cost

An evaluation of the OMGSCA algorithm reveals its superior performance compared to other methods like PSO, SCA, MFO, GWO, and WOA in optimizing power system parameters. Simulation results for reveal that OMGSCA achieves a value of 5.6209 MW. Although this is slightly higher than WOA's value of 5.6121 MW, OMGSCA demonstrates reductions in power loss by 0.90%, 0.06%, and 0.57% when compared to PSO, SCA, and MFO, respectively. These findings highlight OMGSCA's ability to effectively minimize power losses, which is crucial for enhancing efficiency and lowering operational costs.

For , OMGSCA achieves 1369.3961 $/h, surpassing PSO, SCA, MFO, and GWO by 0.39%, 0.28%, 3.48%, and 0.20%, respectively. While WOA produces a marginally lower value, OMGSCA demonstrates substantial cost-effectiveness, making it a competitive option for economic optimization within power systems.

Regarding VD, the algorithm recorded a value of 0.8418 per unit. Although this result is higher compared to MFO's best outcome of 0.3891 per unit, it surpasses GWO and WOA by 5.34% and 16.67%, respectively. This reflects OMGSCA's ability to balance voltage stability with other optimization goals.

The minimum generation cost, , achieved by OMGSCA is 807.1371 $/h, which aligns closely with the best outcomes from GWO and WOA. Additionally, the mean generation cost, , for OMGSCA is 807.2392 $/h, indicating greater cost consistency compared to PSO, SCA, and MFO.

In terms of runtime, OMGSCA exhibits remarkable efficiency with a runtime of 174.1932 s, making the algorithm the fastest among the algorithms tested. This represents improvements over PSO, SCA, MFO, GWO, and WOA by 2.68%, 3.65%, 5.56%, 7.91%, and 6.59%, respectively, rendering OMGSCA well suited for large-scale applications requiring swift optimization.

The Friedman Rank Test (FRT) results further reinforce OMGSCA's outstanding performance. With an FRT value of 2, OMGSCA is ranked equally with WOA but surpasses PSO, SCA, MFO, and GWO, which exhibit higher FRT values. This underscores OMGSCA's reliable and consistent optimization capabilities.

Overall, OMGSCA demonstrates impressive performance across multiple metrics, such as power loss, generation cost, and runtime. Although its voltage deviation is marginally higher, this trade-off is acceptable due to its exceptional performance in other critical aspects. Detailed findings are presented in Table 5, with convergence trends and performance metrics visualized in Figure 8.

| Parameters | PSO | SCA | MFO | GWO | WOA | OMGSCA |

|---|---|---|---|---|---|---|

| 40.5369 | 40.4255 | 40.0765 | 40.2718 | 40.4705 | 40.5436 | |

| 49.4332 | 50.3354 | 47.6647 | 50.0225 | 49.8439 | 49.5901 | |

| 10.1222 | 10.0728 | 14.2059 | 10 | 10.0001 | 10.0023 | |

| 41.9729 | 41.154 | 40.4666 | 41.8044 | 41.7529 | 41.9296 | |

| 12.1099 | 12.1003 | 12 | 12 | 12 | 12.0001 | |

| 1.0769 | 1.0694 | 1.0746 | 1.0773 | 1.0712 | 1.0756 | |

| 1.0593 | 1.0548 | 1.0608 | 1.0626 | 1.0569 | 1.0605 | |

| 1.0416 | 1.0409 | 1.0574 | 1.0407 | 1.0362 | 1.0387 | |

| 1.0367 | 1.0383 | 1.0448 | 1.0407 | 1.0359 | 1.0373 | |

| 1.0892 | 1.0758 | 1.0672 | 1.0932 | 1.0749 | 1.0877 | |

| 1.0468 | 1.0664 | 1.0025 | 1.0519 | 1.0817 | 1.0577 | |

| 1.04 | 1.02 | 1.02 | 1.06 | 1 | 1.04 | |

| 0.92 | 0.92 | 0.94 | 0.9 | 0.92 | 0.92 | |

| 0.98 | 1.02 | 1 | 0.96 | 1.02 | 0.98 | |

| 0.98 | 0.96 | 0.98 | 0.96 | 0.98 | 0.96 | |

| 12 | 24 | 22 | 24 | 7 | 15 | |

| 24 | 21 | 19 | 27 | 24 | 21 | |

| 3.5956 | 7.8825 | 1.0019 | 9.9999 | 9.9884 | 7.7066 | |

| 8.8652 | 9.7657 | 1.2103 | −0.8152 | 9.9977 | 7.719 | |

| 27 | 18 | 38 | 19 | 40 | 13 | |

| 13 | 34 | 10 | 13 | 5 | 41 | |

| 0.0364 | 0.291 | 0.1142 | 0.3767 | 0.2964 | 0.3607 | |

| 0.2998 | 0.3383 | 0.1312 | 0.3958 | 0.2302 | 0.1544 | |

| 33 | 13 | 13 | 38 | 14 | 14 | |

| 8 | 9 | 37 | 39 | 13 | 8 | |

| 0.7963 | 0.4374 | 2.6481 | −0.9024 | 3.0365 | 2.6262 | |

| −0.4375 | 0.9014 | −2.6447 | −0.9049 | 3.5755 | −1.1655 | |

| 134.897 | 134.9683 | 135.0705 | 134.9552 | 134.9447 | 134.9552 | |

| 9.927 | −0.5116 | 1.9461 | 4.4098 | −0.2464 | 4.0256 | |

| 12.9233 | 10.2255 | 13.7323 | 22.054 | 16.7544 | 20.2192 | |

| 29.7188 | 31.1649 | 45.6368 | 25.3602 | 20.977 | 25.3815 | |

| 32.8078 | 38.6651 | 53.8853 | 36.4971 | 34.6595 | 32.351 | |

| 34.0949 | 17.7187 | 21.9589 | 39.0208 | 15.8753 | 32.4129 | |

| 4.8863 | 20.8886 | −0.667 | 1.9908 | 27.7619 | 6.3407 | |

| 5.6721 | 5.6563 | 6.0842 | 5.6539 | 5.6121 | 5.6209 | |

| 1374.795 | 1373.1898 | 1418.7303 | 1372.8674 | 1368.5049 | 1369.3961 | |

| 0.6568 | 0.7965 | 0.3891 | 0.8893 | 0.7215 | 0.8418 | |

| 807.4814 | 807.4133 | 810.0588 | 807.3045 | 807.1568 | 807.1371 | |

| 807.4910 | 807.4745 | 810.5757 | 807.3524 | 807.2303 | 807.2392 | |

| Run time | 178.9883 | 180.7888 | 184.4904 | 189.1504 | 186.4505 | 174.1932 |

| FRT | 5.5 | 5.5 | 9 | 3 | 2 | 2 |

4.2 : Minimizing Active Power Loss

In Case 2, the algorithm OMGSCA algorithm showcases outstanding performance in optimizing loss of active power within the OPF problem. A comparison of its efficiency against other algorithms is provided in Table 6. OMGSCA achieves the lowest active power loss () of 1.7753 MW, outperforming all evaluated methods. This equates to reductions of 0.13%, 9.17%, 3.53%, 27.98%, and 0.17% when compared to PSO, SCA, MFO, GWO, and WOA, respectively, underlining OMGSCA's remarkable capability to reduce power loss and improve energy efficiency.

| Parameters | PSO | SCA | MFO | GWO | WOA | OMGSCA |

|---|---|---|---|---|---|---|

| 25.257 | 26.4192 | 26.8021 | 46.54 | 25.1935 | 25.1925 | |

| 74.999 | 74.7568 | 74.7272 | 68.9463 | 75 | 74.9999 | |

| 34.9999 | 33.271 | 33.6913 | 33.0062 | 34.9999 | 34.9984 | |

| 60 | 59.8763 | 59.6841 | 57.125 | 60 | 60 | |

| 39.9567 | 39.3068 | 39.4587 | 27.4833 | 39.9999 | 39.9995 | |

| 1.0562 | 1.0529 | 1.0492 | 1.0411 | 1.0575 | 1.0527 | |

| 1.0504 | 1.0455 | 1.0459 | 1.0356 | 1.0517 | 1.0472 | |

| 1.0406 | 1.0345 | 1.0391 | 1.0267 | 1.0417 | 1.0374 | |

| 1.0456 | 1.0372 | 1.0451 | 1.0149 | 1.0472 | 1.0427 | |

| 1.0625 | 1.096 | 1.0767 | 1.0634 | 1.094 | 1.0608 | |

| 1.0813 | 1.0544 | 1.0626 | 1.0442 | 1.0736 | 1.0883 | |

| 0.98 | 1.02 | 1.02 | 1.04 | 1.02 | 1 | |

| 0.94 | 0.94 | 0.94 | 0.98 | 0.92 | 0.94 | |

| 7 | 19 | 24 | 18 | 4 | 24 | |

| 24 | 24 | 21 | 6 | 24 | 21 | |

| 9.651 | 5.0773 | 7.5323 | 4.9236 | −1.5086 | 9.6548 | |

| 9.9999 | 9.2539 | 6.8329 | −9.0724 | 10 | 9.9902 | |

| 34 | 16 | 13 | 9 | 39 | 13 | |

| 25 | 7 | 14 | 13 | 14 | 34 | |

| 0.4949 | 0.3265 | 0.1063 | 0.2361 | 0.067 | 0.4304 | |

| 0.4998 | 0.0878 | 0.3121 | 0.0464 | 0.4999 | 0.4998 | |

| 35 | 16 | 13 | 16 | 34 | 14 | |

| 41 | 23 | 35 | 33 | 35 | 35 | |

| 3.7261 | 1.0586 | −0.4864 | 2.8506 | −0.7861 | −2.3577 | |

| −0.002 | 0.6643 | 3.8025 | 2.5051 | 4.2309 | 4.5753 | |

| 50.0005 | 51.7362 | 50.8904 | 52.7839 | 50.005 | 49.9904 | |

| −2.3054 | 1.0561 | −9.078 | 0.0714 | −2.4234 | −4.9393 | |

| 11.5539 | 9.1339 | 10.7774 | 16.0116 | 10.7165 | 8.1568 | |

| 19.3493 | 22.4142 | 24.7518 | 31.7805 | 22.7115 | 22.2938 | |

| 40.1476 | 30.3552 | 40.3876 | 24.0515 | 36.9747 | 33.1032 | |

| 10.1359 | 30.1978 | 23.4933 | 34.0941 | 27.2538 | 12.0285 | |

| 27.6267 | 19.6553 | 21.3275 | 29.822 | 23.5457 | 33.755 | |

| 939.4183 | 936.4394 | 936.6383 | 912.3866 | 939.4571 | 939.4137 | |

| 1120.7299 | 1133.0666 | 1122.0185 | 1160.8575 | 1119.2855 | 1117.4843 | |

| 0.7782 | 0.6978 | 0.6456 | 0.3794 | 0.8095 | 0.8405 | |

| 1.7978 | 1.9547 | 1.8403 | 2.4652 | 1.7783 | 1.7753 | |

| 1.8801 | 2.0074 | 1.8772 | 2.6745 | 1.8621 | 1.7885 | |

| Run time | 193.3431 | 188.6912 | 187.1101 | 181.4410 | 184.5565 | 185.4699 |

| FRT | 4 | 6.5 | 3.5 | 8.5 | 2.5 | 2 |

For the generation cost (), OMGSCA records a value of 939.4137 $/h. Although slightly higher than GWO by 2.96% and marginally above SCA and MFO, it maintains a strong equilibrium between minimizing power loss and ensuring economic feasibility. In terms of gross operational cost (), OMGSCA achieves the lowest value of 1117.4843 $/h among all algorithms. This represents cost reductions of 0.29%, 1.38%, 0.41%, 3.88%, and 0.16% relative to PSO, SCA, MFO, GWO, and WOA, respectively, showcasing its efficiency in reducing overall operational expenses.

For voltage deviation (VD), OMGSCA recorded a value of 0.8405 per unit, which is marginally higher than the optimal value obtained by GWO (0.3794 per unit). However, it outperforms PSO and WOA by reducing voltage deviation by 5.09% and 0.06%, respectively. This balance between stability of voltage and other optimization goals establishes OMGSCA as a strong candidate for comprehensive system optimization.

The mean active power loss () achieved by OMGSCA is 1.7885 MW, ranking among the lowest values across all algorithms. OMGSCA demonstrates superior performance by reducing power losses by 4.87%, 10.91%, 4.72%, 33.13%, and 3.95% compared to PSO, SCA, MFO, GWO, and WOA, respectively, further emphasizing its efficiency in minimizing overall losses.

In computational efficiency, OMGSCA achieves a runtime of 185.4699 s. While slightly longer than GWO, OMGSCA outperforms PSO, SCA, and MFO with improvements of 4.08%, 1.71%, and 0.88%, respectively, making it suitable for reliable optimization within a reasonable timeframe. The algorithm achieves an FRT value of 2, ranking it as one of the best-performing methods. It outperforms PSO, SCA, MFO, and GWO in FRT by 50%, 69.23%, 42.86%, and 76.47%, respectively, demonstrating consistency and reliability in finding optimal solutions.

OMGSCA demonstrates exceptional efficiency by minimizing active power losses, delivering competitive outcomes in both generation and gross costs, and attaining a top reliability ranking as indicated by FRT values. Although its voltage deviation is slightly higher compared to the best-performing algorithm, the significant benefits in other metrics outweigh this drawback. Results are detailed in Table 6, and Figure 9 illustrates convergence trends and related performance metrics.

4.3 Case 3: Minimizing Gross Cost

As detailed in Table 7 for Case 3, the OMGSCA algorithm delivers remarkable results, attaining the lowest gross cost () of 1107.5111 $/h. This result highlights OMGSCA's ability to efficiently balance cost minimization with power loss reduction, surpassing the performance of other algorithms. The gross cost results for PSO, SCA, MFO, GWO, and WOA are 1111.4985 $/h, 1113.0317 $/h, 1112.8791 $/h, 1148.4546 $/h, and 1108.9023 $/h, respectively. Compared to these methods, OMGSCA achieves reductions of 0.36%, 0.50%, 0.48%, 3.56%, and 0.13%, respectively, highlighting its superior cost optimization performance.

| Parameters | PSO | SCA | MFO | GWO | WOA | OMGSCA |

|---|---|---|---|---|---|---|

| 40.1364 | 35.9111 | 42.6045 | 49.4742 | 38.5459 | 38.8761 | |

| 75 | 74.5096 | 74.976 | 75 | 75 | 74.9999 | |

| 35 | 34.7655 | 34.129 | 31.9872 | 34.9999 | 34.9999 | |

| 60 | 58.5513 | 58.8382 | 52.0931 | 60 | 59.9943 | |

| 25.2106 | 31.2469 | 24.3907 | 26.2542 | 26.7584 | 26.4247 | |

| 1.0586 | 1.0532 | 1.0453 | 1.0422 | 1.0498 | 1.0524 | |

| 1.0534 | 1.0485 | 1.0418 | 1.0402 | 1.0443 | 1.0469 | |

| 1.0426 | 1.0349 | 1.0297 | 1.0233 | 1.0329 | 1.0351 | |

| 1.0463 | 1.0389 | 1.037 | 1.0213 | 1.0362 | 1.0385 | |

| 1.0928 | 1.0946 | 1.0857 | 1.0437 | 1.0715 | 1.083 | |

| 1.0646 | 1.0724 | 1.0654 | 1.0803 | 1.0763 | 1.0784 | |

| 1.04 | 1.02 | 1 | 0.98 | 1 | 1 | |

| 0.9 | 0.94 | 0.94 | 0.98 | 0.9 | 0.94 | |

| 1 | 1.02 | 1 | 1.04 | 1 | 1.02 | |

| 1 | 0.98 | 0.98 | 0.96 | 0.96 | 0.96 | |

| 24 | 19 | 21 | 22 | 6 | 19 | |

| 19 | 24 | 24 | 24 | 24 | 24 | |

| 9.9616 | 4.3968 | 8.9859 | 5.3812 | 9.9999 | 5.6831 | |

| 5.1777 | 8.1751 | 6.1716 | 2.9382 | 9.6358 | 8.9055 | |

| 16 | 37 | 18 | 27 | 13 | 34 | |

| 24 | 33 | 29 | 26 | 14 | 22 | |

| 0.2816 | 0.3252 | 0.0225 | 0.1816 | 0.1973 | 0.2177 | |

| 0.4615 | 0.1903 | 0.2058 | 0.1658 | 0 | 0.4027 | |

| 26 | 35 | 33 | 19 | 33 | 25 | |

| 13 | 17 | 8 | 22 | 35 | 35 | |

| −0.13 | 2.1458 | 3.7454 | −1.4765 | 3.5654 | −0.2895 | |

| −5 | 0.4942 | −0.9538 | −0.3828 | −0.7967 | 2.6555 | |

| 50.0453 | 50.3305 | 50.4634 | 50.9713 | 50.0138 | 50.0117 | |

| −1.6721 | −3.866 | −6.1005 | −7.565 | −1.4539 | −2.0629 | |

| 11.3606 | 14.2584 | 14.0217 | 25.2023 | 11.4501 | 10.8041 | |

| 22.8601 | 20.4216 | 20.8881 | 21.4585 | 22.5892 | 22.2079 | |

| 35.3866 | 30.0287 | 40.3248 | 30.5606 | 34.5423 | 34.2192 | |

| 27.9953 | 29.2785 | 22.5916 | 10.6389 | 16.8561 | 20.8393 | |

| 16.8666 | 24.7611 | 19.5891 | 39.6442 | 21.9969 | 26.0641 | |

| 916.9298 | 922.5634 | 914.5 | 912.7377 | 918.5168 | 918.0647 | |

| 1.9923 | 1.9149 | 2.0018 | 2.38 | 1.918 | 1.9066 | |

| 0.8049 | 0.6698 | 0.6531 | 0.3088 | 0.8355 | 0.8302 | |

| 1111.4985 | 1113.0317 | 1112.8791 | 1148.4546 | 1108.9023 | 1107.5111 | |

| 1117.1996 | 1113.1755 | 1113.3838 | 1164.2458 | 1109.6625 | 1112.8210 | |

| Run time | 188.1377 | 186.0268 | 184.3027 | 180.6488 | 184.2959 | 183.2485 |

| FRT | 5 | 5 | 5 | 9 | 4 | 2 |

For generation cost (), OMGSCA achieves a value of 918.0647 $/h. Although this is marginally higher than GWO by 0.58% and MFO by 0.39%, OMGSCA demonstrates reductions of 0.12% and 0.49% compared to PSO and SCA, respectively, showcasing its strong competitiveness in maintaining low generation costs while meeting other optimization objectives.

When analyzing active power loss (), OMGSCA achieves a value of 1.9066 MW, which is lower than the values recorded by PSO, SCA, MFO, and WOA by 4.30%, 0.43%, 4.76%, and 0.60%, respectively. While GWO achieves a slightly better result in power loss reduction, OMGSCA excels in other critical performance areas, maintaining a robust balance between cost and loss minimization.

For the mean gross cost (), OMGSCA achieves a value of 1112.8210 $/h, which reflects reductions of 0.39%, 0.32%, 0.35%, 4.43%, and 0.83% compared to PSO, SCA, MFO, GWO, and WOA, respectively. This demonstrates OMGSCA's comprehensive efficiency in managing overall costs effectively.

In terms of computational efficiency, OMGSCA records a runtime (RT) of 183.2485 s. While slightly slower than GWO and WOA by 1.44% and 0.57%, respectively, OMGSCA is faster than PSO, SCA, and MFO by 2.60%, 1.49%, and 0.57%, respectively. These minor runtime differences do not overshadow OMGSCA's effectiveness, as its superior performance in minimizing both cost and power loss makes it an outstanding optimization solution.

The Friedman Rank Test (FRT) positions OMGSCA with a score of 2, tying it for the highest rank with WOA. Compared to other algorithms, OMGSCA's FRT performance is 60% better than GWO, 50% better than PSO, and 55.56% better than SCA, reflecting its reliability and robustness in delivering optimal solutions across multiple criteria.

OMGSCA demonstrates significant effectiveness in reducing gross cost, generation cost, and power loss, while maintaining competitive runtimes and achieving high FRT rankings. Although GWO slightly outperforms OMGSCA in power loss reduction, the overall trade-off favors OMGSCA due to its well-rounded optimization across essential objectives. Graphical analyses, including convergence curves, box plots, and voltage profiles, validate OMGSCA's exceptional performance and are illustrated in Figure 10.

4.4 Minimizing Gross Cost for Scenario—1

This analysis applied the OMGSCA algorithm to optimize the trade-off between generation cost and power loss, with a primary focus on minimizing gross cost. As presented in Table 8, OMGSCA attained the lowest gross cost () of 515.2232 $/h among all the algorithms evaluated. This represents cost reductions of 1.61%, 1.44%, 5.68%, 0.28%, and 0.06% when compared to PSO, SCA, MFO, GWO, and WOA, respectively, highlighting OMGSCA's exceptional efficiency in reducing system costs.

| Parameters | PSO | SCA | MFO | GWO | WOA | OMGSCA |

|---|---|---|---|---|---|---|

| 20.0344 | 20.2769 | 20 | 20 | 20.0012 | 20.053 | |

| 38.3454 | 36.3783 | 30.3422 | 36.5167 | 36.7001 | 37.9234 | |

| 11.6987 | 10.3058 | 17.1139 | 10 | 10.0025 | 10.0009 | |

| 23.3319 | 26.7401 | 24.7051 | 27.6415 | 27.4299 | 26.1464 | |

| 12.3752 | 12.1613 | 13.7205 | 12.0006 | 12.0106 | 12.0058 | |

| 1.0553 | 1.0479 | 1.0168 | 1.0575 | 1.0584 | 1.0594 | |

| 1.0457 | 1.0419 | 1.0117 | 1.0521 | 1.0525 | 1.0539 | |

| 1.0341 | 1.0302 | 1.0053 | 1.0438 | 1.0446 | 1.0457 | |

| 1.0397 | 1.0324 | 1.0025 | 1.0446 | 1.0448 | 1.0461 | |

| 1.0543 | 1.0647 | 1.0545 | 1.0321 | 1.0392 | 1.0449 | |

| 1.0454 | 1.0374 | 1.0097 | 1.0276 | 1.0455 | 1.0426 | |

| 1.04 | 1.02 | 1.04 | 1.02 | 1 | 0.96 | |

| 0.94 | 0.92 | 0.98 | 1.02 | 0.96 | 1.08 | |

| 1 | 1 | 0.98 | 1.02 | 1 | 1 | |

| 0.98 | 0.98 | 1.02 | 1.02 | 1 | 1 | |

| 24 | 18 | 28 | 21 | 24 | 21 | |

| 21 | 10 | 27 | 24 | 6 | 24 | |

| 7.3438 | 2.4495 | 3.1041 | 6.1058 | 5.982 | 7.4758 | |

| 3.9113 | −3.75 | 1.4881 | 5.2203 | 9.5095 | 4.9068 | |

| 17 | 26 | 23 | 7 | 7 | 5 | |

| 26 | 5 | 30 | 13 | 29 | 4 | |

| 0.3532 | 0.1649 | 0.3498 | 0.489 | 0.4454 | 0.0015 | |

| 0.2426 | 0.3589 | 0.2089 | 0.375 | 0.4246 | 0.4663 | |

| 13 | 14 | 24 | 24 | 14 | 34 | |

| 16 | 41 | 33 | 5 | 8 | 33 | |

| 0.3895 | 1.5256 | 0.1775 | 0.0572 | 1.1987 | −1.3263 | |

| −0.16 | 0.0847 | 2.1739 | −0.4847 | −0.4917 | 1.2724 | |

| 50.3896 | 50.3467 | 50.4539 | 49.9922 | 49.9971 | 50.0073 | |

| 6.6286 | −0.0395 | −2.7856 | −2.1337 | −0.6894 | −0.7051 | |

| −2.9304 | 9.5425 | 4.958 | 4.9402 | 4.4417 | 6.8462 | |

| 6.7493 | 8.3475 | 15.0598 | 11.2277 | 11.8306 | 12.1235 | |

| 18.409 | 21.4617 | 6.7315 | 17.9041 | 18.7243 | 23.2235 | |

| 11.7894 | 16.2614 | 27.3377 | 6.6673 | 0.9557 | −1.5467 | |

| 5.5171 | 5.2817 | 5.094 | 6.2095 | 5.4103 | 5.3519 | |

| 422.2319 | 418.9628 | 429.7054 | 418.0411 | 418.0869 | 418.6082 | |

| 1.0176 | 1.0514 | 1.178 | 0.9934 | 0.9837 | 0.9791 | |

| 0.8292 | 0.608 | 0.3176 | 0.437 | 0.7755 | 0.7469 | |

| 523.6419 | 522.7319 | 546.2683 | 516.6486 | 515.5210 | 515.2232 | |

| 524.8813 | 523.9176 | 554.2314 | 518.0795 | 516.2576 | 516.8129 | |

| Run time | 845.3898 | 844.2790 | 841.3661 | 830.6496 | 827.8053 | 1248.2433 |

| FRT | 6.5 | 5.5 | 9 | 2 | 2.5 | 2 |

For generation cost (), OMGSCA attained a value of 418.6082 $/h. Although slightly higher than GWO by 0.14%, OMGSCA outperformed PSO, SCA, and MFO by 0.86%, 0.82%, and 2.58%, respectively. These results demonstrate OMGSCA's ability to maintain low generation costs while achieving other optimization objectives.

In terms of active power loss (), OMGSCA achieved the lowest value of 0.9791 MW, demonstrating its exceptional capability to reduce energy losses. When compared to PSO, SCA, MFO, GWO, and WOA, OMGSCA reduced power loss by 3.78%, 6.87%, 16.93%, 1.44%, and 0.47%, respectively. These significant reductions highlight OMGSCA's effectiveness in minimizing energy losses within the system.

For voltage deviation (VD), OMGSCA recorded a value of 0.7469 per unit, which is higher than the optimal values obtained by MFO (0.3176 per unit) and GWO (0.437 per unit). However, OMGSCA surpassed PSO and WOA by achieving reductions of 10.12% and 3.68%, respectively. Despite its slightly higher VD, OMGSCA's overall optimization of cost, power loss, and voltage stability solidifies its position as a reliable solution.

The mean gross cost () achieved by OMGSCA was 516.8129 $/h, ranking as the second lowest among the compared algorithms and trailing GWO by only 0.11%. OMGSCA outperformed PSO, SCA, MFO, and WOA with reductions of 1.54%, 1.92%, 6.73%, and 0.11%, respectively. This showcases OMGSCA's consistency and effectiveness in managing system-wide expenses.

The runtime (RT) for OMGSCA was 1248.2433 s, which was significantly longer than other algorithms, with increases of 47.63%, 47.87%, 48.35%, 50.26%, and 50.77% compared to PSO, SCA, MFO, GWO, and WOA, respectively. Despite its extended runtime, OMGSCA's superior performance in minimizing costs and power loss justifies this trade-off, particularly for applications requiring optimal solutions.

The Friedman Rank Test (FRT) further validates OMGSCA's superior performance, ranking it first with an FRT value of 2. OMGSCA outperformed PSO, SCA, MFO, GWO, and WOA by 69.23%, 63.64%, 77.78%, 20%, and 20%, respectively, emphasizing its robustness and reliability in solving complex optimization challenges.

OMGSCA demonstrates significant effectiveness in reducing gross cost, generation cost, and power loss, while maintaining competitive runtimes and achieving high FRT rankings. Although GWO slightly outperforms OMGSCA in power loss reduction, the overall trade-off favors OMGSCA due to its well-rounded optimization across essential objectives. Graphical analyses, including convergence curves, box plots, and voltage profiles, validate OMGSCA's exceptional performance and are illustrated in Figure 11.

4.5 Case 5: Minimizing Gross Cost for Scenario-2

Table 9 summarizes the simulation results for Case 5, evaluated under dynamic loading conditions in Scenario 2, where the OMGSCA algorithm demonstrated exceptional performance. The gross cost () achieved by OMGSCA was 627.8541 $/h, the lowest among all compared methods. This represents reductions of 0.88%, 0.79%, 3.36%, 4.57%, and 0.20% when compared to PSO, SCA, MFO, GWO, and WOA, respectively, highlighting OMGSCA's superior efficiency in minimizing total system costs.

| Parameters | PSO | SCA | MFO | GWO | WOA | OMGSCA |

|---|---|---|---|---|---|---|

| 20.0001 | 20.9347 | 20.94 | 22.5145 | 20.0007 | 20 | |

| 52.5055 | 48.1333 | 53.4972 | 47.7366 | 48.5085 | 51.9351 | |

| 10.006 | 13.2124 | 11.6623 | 13.52 | 14.2297 | 10.2925 | |

| 41.9264 | 41.6989 | 37.5392 | 39.0836 | 41.6991 | 42.2082 | |

| 12.0002 | 12.4341 | 12.6336 | 12 | 12.0005 | 12 | |

| 1.0567 | 1.0501 | 1.0547 | 0.9976 | 1.0576 | 1.0576 | |

| 1.0512 | 1.0482 | 1.0491 | 0.9917 | 1.0522 | 1.0523 | |

| 1.0445 | 1.0381 | 1.0459 | 0.9913 | 1.0448 | 1.0455 | |

| 1.0435 | 1.042 | 1.0398 | 0.9785 | 1.0449 | 1.045 | |

| 1.0466 | 1.0931 | 1.051 | 1.0363 | 1.0902 | 1.072 | |

| 1.051 | 1.0368 | 1.0636 | 1.0439 | 1.052 | 1.0488 | |

| 1.02 | 1.02 | 1.02 | 0.96 | 1.02 | 1.04 | |

| 0.96 | 1 | 0.9 | 1.02 | 0.96 | 0.96 | |

| 24 | 22 | 24 | 16 | 24 | 15 | |

| 21 | 24 | 12 | 21 | 6 | 24 | |

| 6.2935 | 2.0937 | 6.6534 | −0.8981 | 7.4511 | 3.9844 | |

| 6.6936 | 6.7956 | −7.4284 | 10 | −3.1533 | 6.5654 | |

| 18 | 13 | 39 | 2 | 5 | 38 | |

| 30 | 37 | 13 | 23 | 4 | 13 | |

| 0.2301 | 0.1182 | 0.2232 | 0.1445 | 0.2159 | 0.0214 | |

| 0.4913 | 0.1393 | 0.3856 | 0.3773 | 0.4936 | 0.187 | |

| 26 | 16 | 14 | 38 | 35 | 14 | |

| 35 | 35 | 33 | 13 | 41 | 16 | |

| 0.3091 | −1.6589 | −0.049 | −0.6512 | 1.8135 | 2.7416 | |

| 1.8977 | 2.1329 | 1.1909 | −0.0486 | 0.0209 | −4.7074 | |

| 49.9929 | 50.0623 | 50.199 | 51.8798 | 49.9934 | 49.9949 | |

| −2.3698 | −9.2874 | −0.9002 | −1.8883 | −2.0294 | −2.4086 | |

| 4.9672 | 14.0416 | 5.983 | 2.6504 | 6.0036 | 4.9842 | |

| 14.0442 | 10.9789 | 18.8749 | 23.0474 | 14.162 | 13.34 | |

| 22.0822 | 20.3079 | 25.2061 | 10.8527 | 20.3585 | 18.8137 | |

| 8.1121 | 28.5179 | 8.9624 | 11.5961 | 23.013 | 22.6229 | |

| 13.4824 | 0.7783 | 17.09 | 21.5996 | 8.3762 | 6.1045 | |

| 520.5517 | 520.8485 | 521.3853 | 519.7933 | 521.4373 | 520.5394 | |

| 1.0836 | 1.1282 | 1.1238 | 1.387 | 1.0844 | 1.0832 | |

| 0.7034 | 0.713 | 0.8715 | 0.2332 | 0.837 | 0.7688 | |

| 628.1532 | 632.8572 | 632.2038 | 657.9286 | 629.1368 | 627.8541 | |

| 629.8489 | 634.0320 | 632.2298 | 659.7833 | 630.8910 | 627.9977 | |

| Run time | 868.1936 | 825.9443 | 823.0752 | 824.5183 | 825.6396 | 830.5950 |

| FRT | 3 | 6.5 | 4 | 9 | 3.5 | 1 |

In addition, OMGSCA attained the lowest generation cost () of 520.5394 $/h, outperforming PSO, SCA, MFO, and WOA with reductions of 0.02%, 0.06%, 0.16%, and 0.17%, respectively. While GWO achieved a slightly lower , OMGSCA maintained strong cost-effectiveness while excelling in other critical performance areas.

For active power loss (), OMGSCA recorded a value of 1.0832 MW, representing the best performance among all evaluated algorithms. It surpassed PSO, SCA, MFO, GWO, and WOA by achieving reductions of 0.04%, 3.99%, 3.60%, 21.91%, and 0.11%, respectively, showcasing its exceptional capability to minimize energy losses and improve overall system efficiency.

For voltage deviation (VD), OMGSCA achieved a value of 0.7688 per unit, which was marginally higher than the results obtained by GWO and MFO. However, it outperformed PSO and WOA by reducing VD by 4.87% and 8.25%, respectively. Despite being moderately higher than some algorithms, OMGSCA's excellent performance in cost and power loss minimization makes this trade-off acceptable.

OMGSCA achieved a mean gross cost () of 627.9977 $/h, the lowest among all tested algorithms. This corresponds to reductions of 0.29%, 0.95%, 0.67%, 4.82%, and 0.46% compared to PSO, SCA, MFO, GWO, and WOA, respectively, highlighting OMGSCA's consistent efficiency in optimizing total system costs.