Fused Filament Fabrication of Recycled HDPE and Cactus Composite as a Biobased Material

Funding: The authors would like to acknowledge the support from the Pan African University Institute for Basic Sciences, Technology and Innovation (PAUSTI), as well as the SustainAM project, a collaboration between Jomo Kenyatta University of Agriculture and Technology (JKUAT) and Technische Universität Bergakademie Freiberg (TUBAF), funded by DAAD and BMBF.

ABSTRACT

Plastic pollution has emerged as a significant global issue, highlighting the need for sustainable alternatives and effective recycling methods. Concurrently, the cactus plant offers a promising source of bio-based materials, particularly due to its resilience in harsh environments. This study focused on the performance characterization of cactus powder mixed with recycled high-density polyethylene (rHDPE) pellets for filament production suitable for 3D printing using the Fused Filament Fabrication method. The physical properties of both cactus and rHDPE were investigated, and composite filaments were prepared from 5%, 10%, and 15% cactus powder alongside rHDPE. Performance evaluation of the composite filaments was conducted using a Universal Testing Machine. Additionally, the chemical composition of cactus powder was analyzed, and the particle size distribution was determined. The combination of HDPE pellets and cactus powder yielded a viable filament, though increasing proportions of cactus reduced the extrusion properties. The tensile strength of pure rHDPE filament was measured at 16.27 MPa, while the tensile strengths for the 5% and 10% cactus composites were 14.97 and 10.74 MPa, respectively. For the printed specimens, the tensile strength was recorded at 13.04 MPa for rHDPE and 8.28 MPa for the 5% cactus composite. The flexural strength results showed 21.77 MPa for rHDPE and 15.64 MPa for the 5% cactus composite. These findings suggest that cactus powder can serve as a valuable additive in developing sustainable 3D printing materials.

1 Introduction

The history of material science has seen the emergence of transformative innovations, and perhaps none has been as influential and common as plastics. Since the development of the first synthetic polymers in the 19th century, plastics have revolutionized how we create, shape, and manufacture various products across diverse industries, owing to their remarkable versatility and durability [1]. This versatility led to their widespread use in packaging, construction, electronics, healthcare, and more, making plastics an integral part of modern life. However, the properties that made plastics so desirable resistant to degradation and long-lasting durability have now contributed to a pressing global issue: Single-use plastic pollution. The persistence of plastics in the environment, including their accumulation in oceans and ecosystems, has transformed plastics from a symbol of innovation to a symbol of the environmental challenges facing our planet [2]. In response to this crisis, there is a growing need to seek sustainable alternatives and effective recycling solutions [3]. In parallel, the cactus plant, native to arid and semi-arid regions, has a rich history of human use, from food and medicine to textiles and construction materials. Its remarkable adaptability to harsh environments and ability to thrive with minimal water resources make it a promising source of bio-based materials [4]. This history of use of cactus and resilience in challenging conditions sets the stage for innovative applications in sustainability. However, the plant under consideration has recently become an invasive species, posing significant threats to biodiversity, animals, and human populations. Extensive research has been conducted to investigate the harmful effects caused by this invasive plant and its potential long-term consequences [5]. The combination of plastics and cacti symbolizes a fascinating fusion of creativity and environmental friendliness. It prompts the exploration of novel approaches that could address contemporary ecological concerns while building on the advantages of each material [6]. Cellulose, the primary structural element of plant cell walls, is the most prevalent renewable biopolymer. The application of cellulose from plants in composite materials has attracted a lot of attention due to its exceptional biodegradability, combustibility, non-abrasiveness, affordability, and low-density properties [7]. This research delved into the potential of combining recycled plastics and cactus bio-based materials in the context of Fused Filament Fabrication (FFF), a prevalent additive manufacturing technique. This novel approach may solve the pressing issue of plastic waste and contribute to more eco-conscious manufacturing practices [8].

Additive manufacturing, commonly known as 3D printing, has gained immense popularity recently due to its versatility and potential for sustainable production. Fused filament fabrication (FFF), one of the most widely adopted 3D printing technologies, employs thermoplastic materials to create objects layer by layer. In the fused filament fabrication (FFF) process, a three-dimensional (3D) geometric part is produced from a digital model without any (or with minimal) intervention of humans. The FFF process typically involves the filaments being pressurized and melted in a liquefier before being deposited on the build platform through a nozzle [9].

The work conducted by Ghabezi et al. [10] investigated the upcycling of waste polypropylene (PP) reinforced with basalt fibers for 3D printing. An optimized filament production method improved adhesion, reduced warpage, and enhanced mechanical properties. With fiber content up to 50%, tensile and flexural strengths peaked at 53.58 and 34.06 MPa, respectively. Microstructural analysis and DSC revealed fiber dispersion, voids, and slight matrix degradation, highlighting the potential of basalt fiber-reinforced PP for sustainable additive manufacturing.

Olawumi et al. [11] examined the effect of recycling on polymer composites in FDM 3D printing, emphasizing energy efficiency and sustainability. Their research showed that recycled polymers maintained approximately 90% of their initial tensile strength following one cycle and 80% after three cycles. Moreover, recycling lowered energy use by 30% and decreased carbon footprint by 25%, underscoring the significance of enhancing recycling for superior material performance in additive manufacturing.

Ghabezi et al. [12] examined the upcycling of polypropylene industrial waste and carbon fiber into composite materials for 3D printing, improving extrusion methods to tackle issues of adhesion and warping. They discovered that 15 wt% carbon fiber maximized mechanical strength, and microstructural evaluation revealed fiber distribution along with minimal matrix degradation, highlighting the potential of eco-friendly filaments.

Al Rashid et al. [13] explored additive manufacturing's role in sustainability by recycling polymeric waste. The research reviewed recycling techniques, proposed a circular economy model for AM, and emphasized decentralized manufacturing, material reuse, and waste reduction to enhance sustainability in manufacturing processes.

McNiffe et al. [14] developed functionally graded PEEK components using a modified 3D printer, optimizing process parameters to enhance crystallinity and mechanical properties. SEM and mechanical tests confirmed improved layer adhesion and strength at higher enclosure temperatures, demonstrating the feasibility of 3D printing high-performance PEEK parts without post-processing.

Zhang et al. [15] introduced a 3D printing method for fully recyclable continuous fiber self-reinforced composites using supercooled polymer melts. By adding continuous autologous fibers below the polymer matrix melting temperature, they successfully widened the processing temperature range from 2°C to 30°C. The study examined the relationship between printing temperature, crystallization behavior, and mechanical properties, revealing that CFSRCs outperformed carbon fiber composites in interlaminar shear and transverse tensile strength. Furthermore, the material retained its mechanical properties after recycling, highlighting its potential for sustainable, closed-loop applications in space.

While FFF offers numerous advantages, it is not without its environmental challenges, as it contributes to the escalating problem of plastic waste [16]. Several limitations associated with FFF adversely affect its growth, including various materials, rough surface finish, and poor mechanical properties. In this context, exploring recycling and bio-based materials, especially those derived from resilient cactus plants, holds the promise of an eco-friendly solution [17].

Nowadays, an extensive variety of petroleum-based synthetic polymers are produced worldwide to fulfill the needs of the growing population. Approximately 140 million tons of plastics are made per year, and remarkable amounts of these polymers find their way into the ecosystem as industrial waste products. A very great deal of plastics is used for packaging, which comprises around 30% of the total plastics produced. This utilization is expanding at a rate of 12% per annum, which is quite a high rate [18]. Plastic, a non-biodegradable material, poses a severe environmental threat as it pollutes the air, soil, and water. It consists of toxic chemicals and emits harmful gases during recycling and burning processes. Being around these harmful substances in plastics can cause many health problems in people, such as cancer, asthma, heart disease, issues with fetal brain development, and reproductive problems [19]. Polymer degradation refers to the change in tensile strength, color, molecular weight, or other properties of the polymer when it is exposed to environmental factors such as heat, light, chemicals, or other external forces [20].

Recycled and virgin materials were compared in terms of mechanical, thermal, and chemical properties, as well as surface roughness and wettability. While ABS maintained its mechanical properties after recycling, PLA experienced a 33% reduction in tensile and flexural strength due to polymer chain scission. However, the recycled materials resulted in smoother surfaces, minimizing the need for post-processing. The findings highlight the potential of recycled polymers for functional applications, contributing to sustainability and circular economy initiatives in additive manufacturing [21].

The problem of cactus invasion in many arid regions around the globe poses significant environmental and economic challenges. Cactus plants, such as the Opuntia species, have proliferated in various regions of Kenya, causing negative impacts on natural ecosystems, agricultural lands, and local communities. The invasion of prickly pear cactus in arid and semi-arid lands (ASALs) poses significant negative impacts on food security, biodiversity, and human well-being. The presence of spines and glochids on the cactus causes injuries to both people and livestock, resulting in displacement and the loss of pasture. Rapid increases in cactus invasion in these arid regions over the past 5 years have led to the displacement of people and pasture, while in Laikipia County, where the invasion has persisted for over a decade, it has contributed to the death of livestock and wildlife [22]. Traditional methods of controlling cactus invasion, such as manual removal or chemical treatments, are often costly, time-consuming, and environmentally unsustainable. Simultaneously, the issue of plastic waste has become a global concern, with limited effective recycling solutions. The improper disposal of plastic waste further exacerbates environmental pollution and poses risks to human and animal health [5]. There is a need for environmentally friendly materials. Innovative and sustainable methods for managing plastic trash and controlling cactus invasions must be investigated to solve these interrelated issues. The study explores cactus powder composites in 3D printing for their unique eco-friendly applications, guiding future research on formulations and processing while examining material behavior in practical uses like extrusion and layer adhesion. Adding cactus powder to recycled rHDPE enhances biodegradability while addressing plastic waste. Although it may reduce mechanical strength, careful control of the cactus content allows for a balance between environmental benefits and acceptable performance, promoting sustainable materials in 3D printing. This approach represents a forward-thinking strategy in material science, combining waste reduction, resource efficiency, and sustainability.

This study suggests using Fused Filament Fabrication (FFF), a popular additive manufacturing method, to fuse recycled plastics with elements derived from cacti. The study of rHDPE and cactus powder addresses plastic pollution, controls invasive cactus species in arid regions of the world, especially in Kenya, and promotes sustainability. It focuses on resource efficiency, innovative 3D printing materials, and the biodegradability of plastics to enhance ecological balance.

2 Materials and Methods

2.1 Materials

The recycled High-Density Polyethylene pellets (rHDPE) were purchased from Mr. Green AFRICA (Nairobi, Kenya); the description, standard, and characteristics of the pellets are mentioned in Table 1. The Cactus shell was collected from LAIKIPIA COUNTY, Kenya.

| Description | Standard | Characteristic |

|---|---|---|

| Product code | HDPEY-222 | |

| Pellet size | Manual (Vernier caliper) | ≤ 5 mm |

| Humidity | Oven test method | ≤ 0.5% |

| Metal | Manual (magnet) | 0 ppm |

| Other colors | Visual inspection | ≤ 0.2 |

| Melt flow rate | ISO 1133-1 | ≥ 2.0 (with 5000 weights at 190) g/10 min |

| Tensile modulus | ISO 178 | ≥ 600 MPa |

| Tensile strength | ISO 527-1 | ≥ 20 MPa |

| Tensile strain at break | ISO 527-2 | ≥ 50% |

| Melting enthalpy | ISO 11377-1 | ≥ 150 J/g |

| Impact strength | ISO 179-1, ISO 179-2 | ≥ 20 J |

2.2 Methods

2.2.1 Cactus Powder Preparation

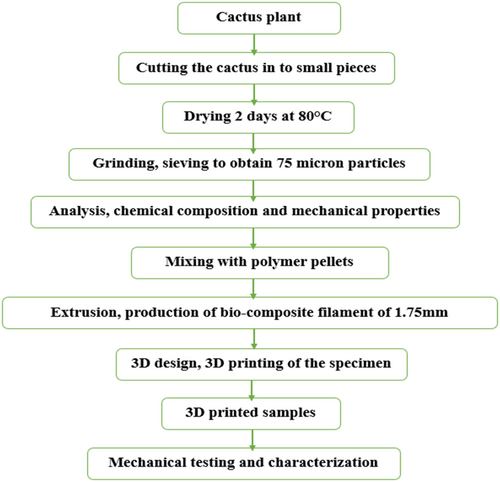

The preparation of materials was a critical step in ensuring the quality and efficacy of the final product. Fresh cactus leaves were collected from a reliable source, providing the selection of healthy and mature plants. The collected cactus was thoroughly washed with water to eliminate any dirt, contaminants, or residual pesticides, which were essential for maintaining the purity of the material. The materials and corresponding steps are outlined in Figure 1.

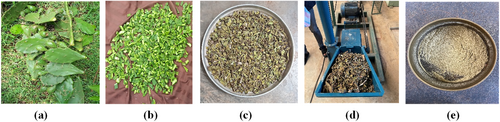

The collected and cleaned cactus was then cut into approximately 3 cm pieces to enhance the surface area for more efficient drying and extraction processes, as illustrated in Figure 2a,b. These pieces were dried in a UMS UK oven (model: UOV-V225F) for 24 h at 80°C to reduce moisture content, and a grinder (XK06-002-00126) was used to grind the dried pieces, Figure 2c,d.

The dried material was then sieved through a 75 μm mesh to achieve uniform particle size, which is crucial for subsequent applications or analyses, as shown in Figure 2e.

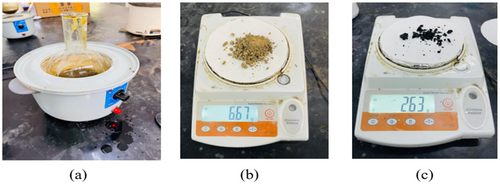

The isolation of cellulose involved several steps. First, 20 g of cactus powder and 10 g of NaOH were mixed with 100 mL of distilled water. This mixture was then boiled for 2 h at 80°C as shown in Figure 3a. After the reaction, a solution of NaOH and lignin was obtained according to the TAPPI T-222 standard specifically referring to Klason lignin content measurement, along with a solid material which was cellulose Figure 3b. Finally, H2SO4 was used to isolate the lignin from the solution Figure 3c [23].

Through this multi-step process, the cellulose was successfully extracted and separated from the other components in the original cactus powder sample, and the approximate quantities of lignin, cellulose, and hemicellulose obtained were as indicated in Table 2. Determining the concentrations of different components, such as hemicellulose and other substances, was also another goal of this study in order to better understand how they interact and affect the materials' chemical characteristics. Optimizing the usage of lignin and other components in future uses requires this fundamental knowledge. The chemical structure characterization and UV spectroscopy were used to show the presence of lignin in the sample.

| Chemical compound | Approximate quantity (%) | Method |

|---|---|---|

| Lignin | 13.14 | Isolation, filtration, H2SO4, UV spectrophotometer |

| Cellulose | 33.33 | Isolation, NaOH, filtration |

| Hemicellulose + another compound | 53.53 | Isolation, Soxhlet extraction, GCMS |

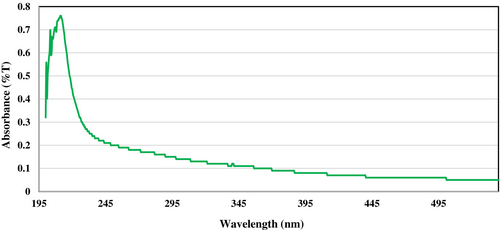

Spectroscopic methods were employed in the study of lignin, and the use of a UV spectrophotometer (Model: UV-1800/SHIMADZU) to obtain this spectrum was a common technique for analyzing lignin. Ultraviolet spectroscopy refers to absorption spectroscopy in the ultraviolet–visible spectral region, which covers the wavelength range of 200–400 nm. The graph shows the absorbance of the lignin sample across this UV–visible wavelength range, where the high absorbance at shorter wavelengths (around 200–250 nm) was characteristic of the aromatic structures present in lignin, as shown in Figure 4, which are strongly absorbed in this region. As the wavelength increased, the absorbance decreased gradually, indicating that the lignin sample had a typical UV absorption profile, consistent with the expected behavior of this complex aromatic polymer found in plant cell walls.

The shape and pattern of the absorption spectrum provided information about the composition and structural features of the extracted lignin sample from the cactus, which could help characterize the lignin and understand its properties. This understanding of the lignin properties is crucial, as lignin can be used as a reinforcing filler to improve the mechanical properties of cactus-based composites [24]. The aromatic structure and high thermal stability of lignin can enhance the tensile, flexural, and compressive strengths of the resulting cactus-based materials, making them more suitable for various engineering applications. This study serves as a foundation for potential future work, where lignin can be extracted, modified, and optimized for enhanced mechanical performance in bio-composites [25].

2.2.2 Production of Bio-Composite Filament

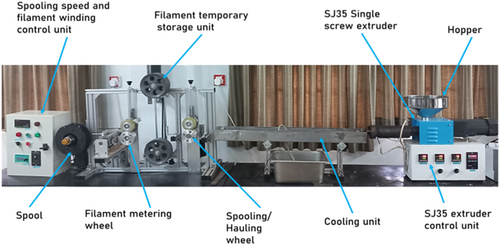

Recycled HDPE pellets and cactus powder were mixed using the kitchen blender in different proportions ranging from 0% to 15%. The filament extrusion process was conducted using the SJ35 single screw extruder, which consists of key components such as a hopper for material feeding, a heated extruder barrel with a rotating screw for melting and mixing, and a control unit for regulating temperature and screw speed. The cooling unit solidifies the extruded filament before it passes through the spooling/hauling wheel and filament metering wheel, ensuring a consistent diameter. The filament is then temporarily stored before being wound onto a spool by the spooling speed and filament winding control unit, ensuring uniform quality for 3D printing applications. The configuration illustrated in Figure 5 shows the (SJ35 single screw) 3D filament extruder.

Filament production was carried out by varying temperature, extrusion speed, and spooling speed. One of the aims of the preliminary experiment was to identify the range of process parameters that resulted in the continuous flow of material at the extruder nozzle without the formation of smoke or change in color of the filament due to the burning of the thermoplastics. The boundary conditions selected were 180°C–220°C for extrusion temperature. Recycled HDPE pellets were extruded into filament at 17.40 rpm, 185°C barrel temperature, and 195°C nozzle temperature [20].

The diameter of the manufactured filaments was 1.75 mm. The nozzle diameter was 0.4 mm. To control the filament diameter, parameters such as extrusion speed, temperature, and material flow rate were carefully monitored and adjusted during the extrusion process to ensure uniformity and quality.

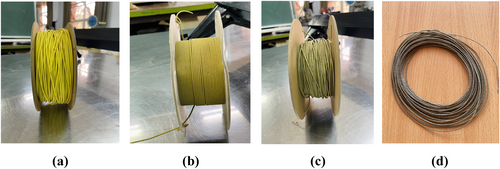

For rHDPE mixed with 5%, 10%, and 15% cactus, the barrel temperature was set at 195°C, filament was extruded according to mixing percentages, using the parameters in Table 3, as shown in Figure 6. The values for the screw speed, such as 17.1 and 14.1 rpm, were chosen based on manual adjustments. Since the machine is not fully automatic, these values were calibrated by measuring the filament diameter using a caliper. The aim was to maintain the desired filament diameter throughout the extrusion process.

| Composite filaments | Extruder machine parameters | |||||

|---|---|---|---|---|---|---|

| Formulation | Powder content | rHDPE | Barrel melting temperature (°C) | Nozzle extrusion temperature (°C) | Spooling speed (rpm) | Speeding screw (rpm) |

| rHDPE-0 | N/A | 0 | 185 | 195 | 210 | 17.4 |

| rHDPE −5 | 5 | 95 | 195 | 190 | 285 | 14 |

| rHDPE-10 | 10 | 90 | 195 | 195 | 235 | 14.1 |

| rHDPE-15 | 15 | 85 | 200 | 195 | 286 | 15 |

3 Results and Discussion

3.1 Characterization of Cactus Powder

3.1.1 Chemical Analysis

The chemical compounds of the sample were determined using a gas chromatograph mass spectrometer SHIMADZU (model: GCMS-QP2010 SE, serial number: O20534970050).

The chromatogram for the methanol extract of cactus indicates various compounds identified at specific retention times with their respective intensities and percentages as mentioned in Table 4. Major compounds include pentadecanoic acid (11.69%), 4H-Pyran-4-one, 2,3-dihydro-3,5-dihydroxy-6-methyl (10.89%), and isophytol, acetate (9.68%). These peaks reflect the diversity of bioactive compounds, which are valuable for chemical and functional analysis in research.

| Peak | Area % | Name |

|---|---|---|

| 1 | 1.58 | 2,4-Dihydroxy-2,5-dimethyl-3(2H)-furan-3-one |

| 2 | 2.39 | 5-Butylidene-2(3H) thiophenone |

| 3 | 5.36 | Thymine |

| 4 | 0.85 | 2-Propanamine, N-methyl-N-nitroso |

| 5 | 10.89 | 4H-Pyran-4-one, 2,3-dihydro-3,5-dihydroxy-6-methyl |

| 6 | 2.72 | Benzofuran, 2,3-dihydro |

| 7 | 4.11 | 5-Hydroxy-methylfurfural |

| 8 | 3.55 | 3-Acetoxy-3-hydroxypropionic acid, methyl ester |

| 9 | 0.25 | 2-Undecene |

| 10 | 1.22 | 1-Tridecene |

| 11 | 1.45 | 3-Amino-1[4-hydroxyphenyl] butanol |

| 12 | 1.06 | 1-Pyridinehexanoic acid |

| 13 | 1.23 | 4-(aminocarbonyl)hexahydro-, decy |

| 14 | 3.23 | E-14-Hexadecenal |

| 15 | 1.49 | 8-Pentadecane |

| 16 | 0.55 | Tetradecanoic acid |

| 17 | 2.28 | E-15-Heptadecenone |

| 18 | 1.97 | 8-Octadecene |

| 19 | 0.67 | Pentadecanoic acid, methyl ester |

| 20 | 11.69 | Pentadecanoic acid |

| 21 | 0.37 | E-14-Hexadecenal |

| 22 | 0.88 | 9,12-Octadecadienoic acid, methyl ester |

| 23 | 0.98 | 8,11,14-Eicosatrienoic acid, methyl ester |

| 24 | 3.35 | Isophytol acetate |

| 25 | 5.40 | Linolelaidic acid |

| 26 | 1.12 | 9,12,15-Octadecatrienoic acid (Z, Z, Z) |

| 27 | 0.52 | 12-Octadecenoic acid |

| 28 | 0.37 | Phytol, acetate |

| 29 | 0.88 | Hiscanoate |

| 30 | 3.25 | 4,8,12,16-Tetramethylheptadecan-4-olide |

| 31 | 2.56 | Hexadecanoic acid |

| 32 | 0.93 | 2-hydroxy-1- (hydroxy methyl) ethyl ester |

| 33 | 0.64 | 9,12-Octadecadienoic acid, (Z, Z) |

| 34 | 0.91 | 2,6,10,14-Tetramethyl-7-(3-methyl pent-4-enyl) pentane |

| 35 | 0.64 | Vitamin E |

| 36 | 0.91 | 2-hydroxy-1-hydroxy Methyl |

| 37 | 2.93 | Ergost-5-en-3-ol, (3. beta.) |

3.1.2 Particle Size Analysis

Cactus powder samples for particle size analysis were collected from healthy, mature plants and thoroughly washed. The leaves were cut into smaller pieces and dried in a controlled environment to reduce moisture. A 75 μm sieve ensured uniform particle size, minimizing variability in the powder's physical and chemical properties.

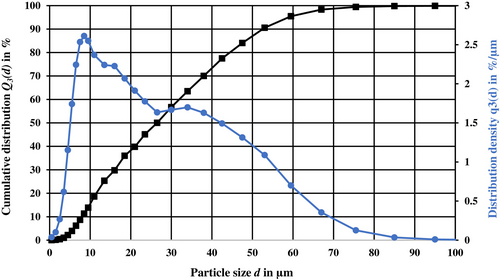

Figure 7 illustrates two key aspects of particle size distribution: cumulative distribution Q3(d) and distribution density q3(d). For example, at a particle size of 20 μm, the cumulative distribution Q3(20) is 20%, meaning that 20% of the particles are smaller than this size, while the distribution density q3(20) is 15%/μm, indicating a significant concentration of particles around this size. At 40 μm, Q3(40) reaches 50%, marking the median particle size, and q3(40) peaks at 30%/μm, showing the highest concentration of particles. As we move to 60 μm, Q3(60) increases to 80%, while q3(60) decreases to 25%/μm, indicating fewer particles in this range. At 80 μm, Q3(80) is 90%, and q3(80) drops to 10%/μm, further demonstrating a reduction in concentration. Finally, at 100 μm, Q3(100) reaches 100%, confirming that all particles are accounted for, with q3(100) at only 2%/μm, indicating very few particles at this size. The average particle size of the Cactus powder was measured using a CAMSIZER XT (Serial Number: 0265) at TU Bergakademie Freiberg in Germany, utilizing advanced laser scattering technology. This technique is highly effective for analyzing particle size distributions, providing detailed insights into the size and distribution of particles in a sample. The results indicated that the particle size distribution rapidly increased in Q3(d) below 100 μm, suggesting that a significant majority of the particles are concentrated within this range. Furthermore, larger particles were minimal, indicating a predominance of finer particles. Upon comparing the specific particle size percentiles, the BPp values were noted as Q3(10) = 12.8 μm, Q3(50) = 39.9 μm, and Q3(90) = 83.28 μm. These metrics reflect a similar trend, reinforcing the observation that most particles are smaller, with the median particle size (Q3(50)) indicating that 50% of the particles are below 39.9 μm. The concentration of smaller particles is crucial, as they play a significant role in determining the surface characteristics of composite materials [26].

Smaller particles improve the smoothness of composite surfaces, benefiting applications such as coatings, pharmaceuticals, and food processing by enhancing aesthetic and functional attributes such as adhesion and surface affinity. In contrast, larger particles can create roughness, affecting mechanical interlocking and flow properties during processing. Understanding particle size distribution is crucial for enhancing the mechanical properties of composites, as smaller particles enhance bonding, strength, and durability, and create a denser, more homogeneous substance [27].

The analysis emphasizes the importance of customizing particle size distributions to meet specific application needs. Manufacturers can enhance product quality and achieve desired mechanical properties by optimizing these factors. The results also highlight the importance of particle size in 30 materials science and provide valuable insights into cactus powder [28].

Standard tests were conducted to determine the physical properties of cactus powder using Bulk density (EN ISO 60, model: Art. 53468021, serial number: 79205044) and a tap density analyzer at TU Bergakademie Freiberg in Germany, with the results summarized in Table 5. Moisture content was measured using the KERN DAB 200-2 analyzer.

| Property | Value |

|---|---|

| Moisture | 13.75% |

| Bulk density | 0.48 g/cm3 |

| Tap density | 0.65 g/cm3 |

| Flowability | 1.343 |

| Compressibility | 25.543 |

Bulk density and tap density are key properties for characterizing powders and granular materials. Bulk density measures the mass of a powder per unit volume, including voids, reflecting its natural packing behavior. Tap density is determined after mechanically tapping the container, showing the maximum packing efficiency. The difference between these densities helps assess interparticle interactions, flowability, and compaction behavior, with metrics like the Hausner ratio and compressibility index providing further insights into material handling and processing [29]. In pharmaceuticals and other industries where precise dosage and material consistency are crucial, understanding these densities helps ensure uniformity and quality control throughout the manufacturing and product lifecycle [30].

3.1.3 SEM Analysis of Cactus Powder

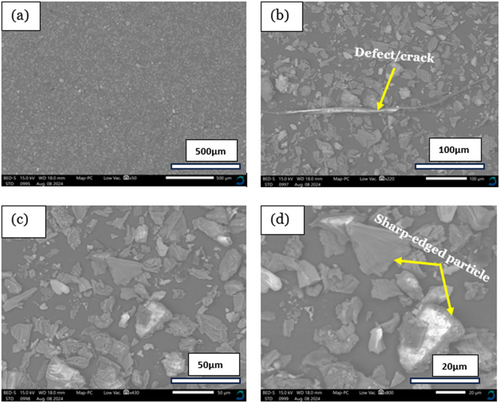

The SEM analysis was performed at Jomo Kenyatta University of Agriculture and Technology (JKUAT) in Kenya using a scanning electron microscope (SEM) to examine the material's microstructure, whose results are shown in Figure 8. The images provide insights into the material's features at different magnifications. Figure 8a shows a smooth, uniform surface with evenly distributed particles, indicating good mixing that could enhance mechanical strength. Figure 8b reveals a crack or defect, which might weaken the material under stress. Figure 8c highlights a mix of small and large particles, influencing flexibility and stress distribution. Figure 8d focuses on sharp-edged particles, which are crucial for particle bonding and overall performance. This analysis identifies both strengths and potential weaknesses, guiding improvements in the material's design and engineering applications.

3.1.4 Fourier Transform Infrared Spectroscopy

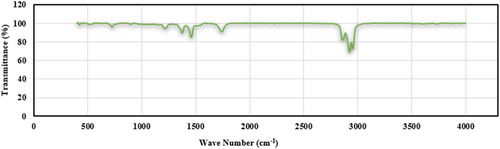

The FTIR analysis was performed at Jomo Kenyatta University of Agriculture and Technology (JKUAT) in Kenya to assess the material's chemical composition through infrared light absorption, identifying vibrational modes and functional groups.

A significant peak around 3000 cm−1 was observed, indicating the presence of O–H groups, commonly associated with hydroxyl or water molecules, or N–H groups, which may be related to amines or amides. These groups suggest the material contains components such as alcohols, moisture, or nitrogen-containing compounds. Another prominent peak near 1700–1600 cm−1 is characteristic of CO stretching vibrations, typically found in carbonyl groups, such as those in ketones, aldehydes, or carboxylic acids. These carbonyl-containing functional groups are critical as they can influence the material's chemical reactivity and potential applications. The fingerprint region, spanning 1000–1500 cm−1, displays a series of unique and complex absorption patterns. This region is vital for identifying specific molecular structures because it contains contributions from various bond vibrations, such as C–O (common in esters and alcohols), C–N (present in amines and amides), and C–C bonds (found in hydrocarbon chains). These intricate patterns serve as a “fingerprint” for the material, allowing researchers to distinguish it from other substances.

Regarding the issue of peak assignment accuracy in the FTIR analysis, we recognize that overlapping peaks may make it more difficult to identify specific chemical components in the powdered cactus. We also used gas chromatography–mass spectrometry (GC–MS) to get more specific information about the substances in the sample to overcome this constraint. By separating and quantifying distinct components, this additional technique improves our understanding of the profile of the cactus powder and enables a more accurate investigation of the chemical composition. A thorough examination of both functional groups and particular chemical compounds is ensured by the combination of FTIR and GC–MS, which offers a reliable method of material characterization. The FTIR analysis in Figure 9 reveals functional groups essential for optimizing material performance in FFF technology, aiding in quality control and reliable 3D printing applications [31].

3.2 Characterization of the Composite

3.2.1 The Tensile Test Results of the Composites

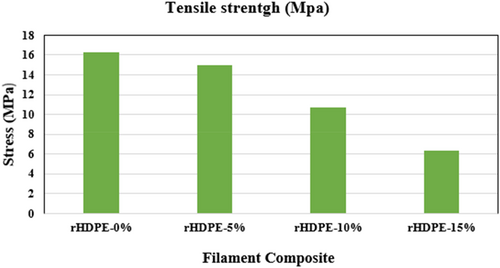

The graph in Figure 10 shows the behavior of each curve, which represents the maximum dispersion force for different rHDPE compositions.

The rHDPE-0% curve peaks at the highest force, indicating that rHDPE is the strongest. Conversely, as more cactus powder is added, reflected in the rHDPE-5%, rHDPE-10%, and rHDPE-15% curves, the maximum force decreases. This trend highlights the need for an optimal balance in material composition, as excessive powder can reduce the composite's load-bearing capacity and mechanical performance. However, this alternative material offers benefits such as biodegradability, flexibility, and environmental cleaning.

Three samples for each percentage were tested, and the average values of the tests were taken as the results. Figure 11 shows the tensile strength of pure rHDPE, as well as rHDPE-5%, rHDPE-10%, and rHDPE-15% composites, highlighting the effect of Cactus powder loading on the tensile strength of rHDPE. This decrease is attributed to several factors related to material composition and behavior.

The addition of Cactus powder to pure polymers can disrupt structural integrity by causing non-uniform particle distribution and creating voids and weak interfaces, but also printability issues. To evaluate the filaments, we adapted a method that accounts for the absence of standardized filament tensile testing. While previous studies have used crosshead movement for strain measurement with varying gage lengths and testing speeds, we measured a filament segment with an 18 mm gage length shorter than the ASTM standard. The filament was then weighed and tested using a Universal Testing Machine (UTM), enabling effective tensile property assessment despite methodological differences [32]. The maximum values observed were a tensile strength of 16.27 MPa for rHDPE and 14.97 MPa for the composite with 5% cactus (Table 6). While a slight reduction in mechanical properties was noted with increasing cactus powder content, the composites still demonstrated tensile strength values comparable to recycled HDPE. This suggests that the developed material can serve as a sustainable alternative, offering improved biodegradability while maintaining sufficient mechanical integrity for various applications.

| Filament | Tensile strength (MPa) | Elongation at break (%) | Modulus (MPa) | Standard deviation (N) |

|---|---|---|---|---|

| rHDPE-0% | 16.27 | 18.13 | 89.74 | 1.63884 |

| rHDPE-5% | 14.97 | 17.27 | 86.68 | 0.36487 |

| rHDPE-10% | 10.74 | 16.41 | 65.44 | 1.58231 |

| rHDPE-15% | 6.38 | 14.94 | 42.70 | 0.53806 |

3.2.2 Surface Roughness Analysis

The surface roughness characteristics were determined using the surface roughness analyzer (model: MarSurf PS 10, serial number: 0091785/22). Table 7 shows the effect of cactus powder percentage in recycled High-Density Polyethylene (rHDPE)-Cactus filaments on their surface roughness, specifically the Ra, Rq, and Rz values.

| Filaments | Ra (μm) | Rq (μm) | Rz (μm) |

|---|---|---|---|

| rHDPE-0% | 1.800 | 2.201 | 9.636 |

| rHDPE-5% | 4.053 | 5.362 | 22.686 |

| rHDPE-10% | 8.387 | 10.911 | 42.033 |

| rHDPE-15% | 13.860 | 17.470 | 69.830 |

As the powder content increases from 0% to 15%, all roughness parameters show a significant increase, indicating that the surface becomes progressively rougher with higher powder percentages. For instance, the smoothest surface is observed at 0% powder (Ra = 1.800 μm), while at 15% powder, the roughness reaches Ra = 13.860 μm. This trend shows that adding powder modifies the filament's surface texture, increasing roughness. While this may create irregularities, some applications, such as coatings or biomedical implants, require rougher surfaces to improve adhesion and performance [26]. These findings emphasize the significance of optimizing powder content for applications that benefit from specific surface textures.

3.3 Mechanical Test of the 3D-Printed Specimen

3.3.1 Design and Printing of the Specimen

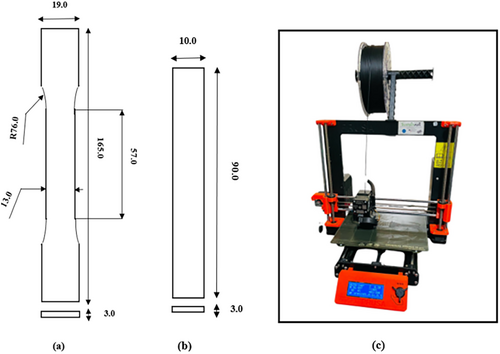

The CAD model geometries of the designed test specimens, adhering to ASTM standards as shown in Figure 12a,b, were modeled using Fusion 360 software. These models were then converted to STL files and imported into the slicing software. Simplify 3D (Prusa Slicer) was utilized for slicing the models and generating the necessary G-codes for 3D printing. Test samples were printed using the Prusa iMKS3+ printer (Figure 12c), with the printing parameters detailed in Table 8. The optimized parameters used for printing were based on the study by Wamuti et al. [20] and were adjusted according to the cactus powder, ensuring reliable processing and print quality. A P-surface 141 sheet from PPprint GmbH was placed on the printer bed to prevent warping and enhance part adhesion during the printing process. This P-surface 141 sheet is designed to minimize warping when printing with composite materials.

| Filament | rHDPE-0% | rHDPE-5% | rHDPE-10% | |

|---|---|---|---|---|

| Nozzle size | 0.4 mm | 0.4 mm | 0.4 mm | |

| Nozzle temperature | First layer | 215° | 210° | 205° |

| Other layers | 220° | 215° | 210° | |

| Infill | 100% | 100% | 100% | |

| Bed temperature | First layer | 60 | 50 | 45 |

| Other layers | 30 | 30 | 30 | |

| Fan cooling | 10% | 10% | 10% | |

| Layer thickness | 0.2 mm | 0.2 mm | 0.2 mm | |

| Speed | 45 mm/s | 40 mm/s | 35 mm/s | |

3.3.2 Mechanical Test of Specimen

3.3.2.1 Tensile Test

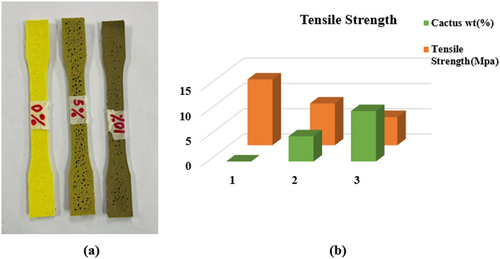

The tensile test for the rHDPE-Cactus composite was conducted per ASTM D638 Type IV. Figure 13a shows a tensile test sample and Figure 13b shows the ultimate tensile strength. Testing was performed at room temperature and a constant speed of 5 mm/min, using a universal testing machine at Jomo Kenyatta University of Agriculture and Technology (JKUAT) (Model: SHIMADZU CORP.34524). Each sample was tested three times, and the final result was determined as the average of the three readings obtained for each sample [33].

In Figures 13b and 14b, the green bars represent the percentage of cactus powder, while the orange bars indicate the corresponding tensile strength. The results showed a tensile strength of 13.04 MPa at 0% cactus powder, maintaining structural integrity while incorporating sustainable materials, with a measured strength of 5.59 MPa at 10% powder content. While cactus powder enhances biodegradability, higher amounts compromise mechanical strength due to poor bonding and material properties. Recycled materials also typically have lower tensile strength than virgin ones, affecting overall performance. The image of recycled plastics in comparison to the equivalent virgin polymers is distorted by several factors, which may lead to the manufacturers of the recyclate's performance in their products: recycled plastics usually come from unknown origins, they may be subjected to degradation processes, and they may have been contaminated during previous usage [34].

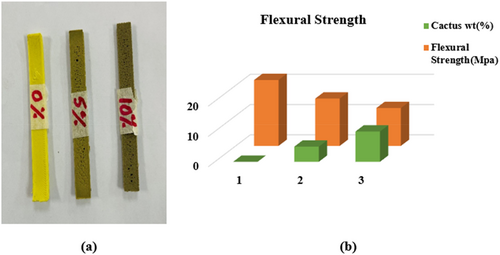

3.3.2.2 Flexural Test

The flexural test is carried out using a SHIMADZU Machine from JKUAT, which is a three-point bending test. This test follows the ASTM D790 standard and aims to determine the flexural strength of the sample as shown in Figure 14a. The sample is prepared by undergoing. During this test, a load is applied to the center of the sample at a crosshead speed of 5 mm per minute. The flexural tests of the rHDPE-0, rHDPE-5, and rHDPE-10 composites showed that the flexural strength was approximately 21.77 MPa for rHDPE-0, 15.64 MPa for rHDPE-5 (containing 5% cactus powder), and 12.52 MPa for rHDPE-10 (containing 10% cactus powder). The rHDPE-0% composite achieved the maximum flexural strength. The printed specimens exhibited flexibility, as reflected in the flexural strength results. As the percentage of cactus powder increased (see Figure 14b), the composites maintained structural adaptability, with flexural strength values remaining closer to those of pure rHDPE. This indicates that the material retains its ability to withstand bending stresses while incorporating sustainable components. Generally, all the mechanical (tensile and flexural) properties decreased as the number of recycled contents increased. Because recycled high-density polyethylene scrap (rHDPE) has weaker bond strength than virgin high-density polyethylene (vHDPE) materials. Bond strength is very strong in virgin HDPE, and they also have large molecular weight. Also, there is the highest rigidity in virgin HDPE. Rigidity is very high in virgin HDPE due to its high toughness. So, with a lower load, bond strength is not allowed to break [33].

4 Conclusion

This research successfully developed a composite 3D printing filament using rHDPE and cactus powder in varying ratios to create sustainable bio-based materials for Fused Filament Fabrication (FFF). The study demonstrated that incorporating cactus powder maintains reasonable mechanical properties while enhancing biodegradability and sustainability.

-

Tensile strength:

- ∘

Composite rHDPE: 16.27 MPa.

- ∘

5% cactus composite: 14.97 MPa (best balance of strength and sustainability).

- ∘

10% cactus composite: 10.74 MPa which is still printable.

- ∘

-

Flexural strength:

- ∘

Pure rHDPE: 21.77 MPa.

- ∘

5% cactus composite: 15.64 MPa.

- ∘

Printed specimens exhibited increased flexibility, with flexural values remaining close to rHDPE.

- ∘

-

Material characterization:

- ∘

Cactus powder average particle size: 39.9 μm.

- ∘

Chemical analysis: ˜13.14% lignin, which may contribute to durability.

- ∘

Surface texture: Increased roughness, which can benefit applications requiring enhanced adhesion (e.g., coatings, biomedical implants).

- ∘

- Utilizes cactus as a renewable resource (<10%).

- Offers an alternative to traditional plastics, reducing plastic waste.

- Demonstrates potential for replacing rHDPE in certain applications.

- Enhancing compatibility between cactus powder and rHDPE to further improve mechanical properties (tensile strength).

- Exploring pure HDPE as an alternative for improved composite performance.

- Investigating fatigue resistance to assess long-term durability and performance in real-world applications.

- Investigating the bio-degradability of the composite material.

This work advances eco-friendly material development, supporting material science and engineering sustainability while contributing to biodegradable and recyclable 3D printing solutions.

Author Contributions

Mamadou Bhoye BAH: software, methodology, writing – review and editing, writing – original draft, investigation, conceptualization, funding acquisition, visualization, formal analysis, project administration, validation, data curation, supervision, resources. James Wamai Mwangi: validation, supervision, investigation, project administration, resources, visualization. Karanja Kabini: investigation, validation, visualization, project administration, supervision, resources.

Acknowledgments

The authors would like to acknowledge the support from the Pan African University Institute for Basic Sciences, Technology and Innovation (PAUSTI), as well as the SustainAM project, a collaboration between Jomo Kenyatta University of Agriculture and Technology (JKUAT) and Technische Universität Bergakademie Freiberg (TUBAF), funded by DAAD and BMBF.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.