Dynamic Mechanical Analysis of Borassus Husk Fiber Reinforced Epoxy: Evaluating Suitability for Advanced Aerospace and Automotive Applications

ABSTRACT

This study investigates the effect of elevated temperatures on the mechanical properties of Borassus husk fiber-reinforced epoxy composites, focusing on their potential for aerospace internal structural components. Composites were fabricated using Borassus husk fibers incorporated with epoxy resin, including 5% alkali-treated fibers (treated for varying durations) to improve adhesion. Dynamic Mechanical Analysis (DMA) was performed according to ASTM D5418-01 standards. Results revealed that both untreated and alkali-treated fibers enhanced the storage modulus of the composites. The highest loss modulus was observed for the composite with 1-h treated fibers. The glass transition temperature (Tg), determined from the peak loss modulus, was significantly higher (84°C–89°C) for treated Borassus husk fiber/epoxy composites compared to neat epoxy and composites reinforced with other natural fibers, such as flax, jute, palm sprout, date palm, sisal, and kenaf. Alkali treatment also notably increased the tan δ (damping factor), with the highest value (1.2) for the 0.75-h treated fiber composite, outperforming several other natural fiber-epoxy composites. Cole–Cole plots indicated improved resin-fiber adhesion for composites containing 0.75- and 1-h treated husk fibers. Phase angle data confirmed enhanced energy dissipation and viscoelastic behavior. Thermo-mechanical stability improved, with the 0.75-h treated fiber composite showing the lowest total mass loss (0.4%). Overall, alkali-treated Borassus husk fiber composites exhibited superior mechanical stiffness, damping capacity, and thermal stability, making them ideal for aerospace and automotive applications requiring strength, impact resistance, and sustainability. It will also contribute to achieving the “net-zero” target established in the 2015 Paris Agreement.

1 Introduction

Composites are widely used in spacecraft, military planes, commercial aircraft, and unmanned aerial vehicles (UAVs), and their applications include engine parts, aeroplane coverings, and interior coatings [1]. Composites are suitable for their high specific strength, impact resistance, fatigue resistance, corrosion resistance, and ability to control mechanical characteristics in high-stress locations. They are also frequently used to reduce weight in aeroplanes to boost fuel economy [2-6]. Balakrishnan et al. [7] reported that the aircraft sector alone has a huge need for lightweight materials due to rising oil and gas prices since fuel expenses make up around half of operating costs, even in general aviation, and the average cost to launch a heavy lift system into low Earth orbits is around €5000–15,000/kg. Bhadra and Dhar [8, 9] state that reducing the weight of a Boeing 747 by 1 kg results in a 0.94 kg cut in carbon emissions and a 0.3 kg reduction in aviation fuel consumption.

Aircraft cabin components must be designed with resistance to moisture absorption while being lightweight to reduce fuel consumption and carbon emissions without compromising performance [1]. Sustainability should be prioritized by incorporating end-of-life strategies such as recyclability, biodegradability, and ease of reuse or refurbishment, supporting a circular economy and reducing material waste [10-12]. Thermal comfort is essential, requiring materials that maintain a stable temperature to prevent internal components from becoming too hot or too cold. Additionally, panels should enhance passenger comfort by effectively reducing cabin noise levels [8, 9, 13]. Hexion L-285 epoxy resin (hardenerH-285) is used extensively in aeronautics, including gliders and light aircraft since it has excellent mechanical and thermal characteristics as well as a broad temperature range of operation [14]. The fuselage of the Boeing 787 Dreamliner, for example, is made of hardened epoxy resin [3].

Flexible and versatile materials play a crucial role in numerous light spacecraft applications, such as solar sails, sun shields, radar systems, rovers, reflect arrays, solar concentrators, and antennas. Vidal et al. [15] reported that one square meter of the novel panels could save up to 6000 kg of carbon dioxide equivalents. An example of their importance in aerospace is seen in the Sikorsky S92 rotorcraft, where over 80% of the structure is made from composite materials for fuel efficiency purposes [14]. The wing box made up of Ramie fiber saved up to 14% weight compared to 7000-series aluminum alloy due to its low density without compromising structural integrity [10]. The reduced density of the composite compared to conventional aluminum alloy helps aircraft to be lightweight, resulting in less fuel consumption and reduced CO2 emissions that promote carbon neutrality as per the Paris Agreement, 2015 [16].

Natural fibers derived from renewable resources present a promising, biodegradable alternative to conventional synthetic reinforcements. These fibers offer numerous benefits, including low density, cost-effectiveness, biodegradability, and favorable specific properties. Additionally, they provide superior thermal and insulating performance while requiring minimal energy for processing [3, 5].

A range of polymer composite materials reinforced with natural fibers has been developed using modified synthetic strategies, enabling applications that extend from automotive to biomedical fields [17-19]. Commonly used natural fibers include coconut, sisal, jute, ramie, banana, hemp, kenaf, flax, pineapple leaf, abaca leaf, bamboo, date palm, sugarcane fiber, and cotton. These fibers are integrated into polymer systems to enhance specific properties in the final products [20-22]. Among conventional natural fibers, Borassus flabellifer (Palmyra palm) husk fiber remains relatively unexplored despite its high potential found in previous studies [23-25]. This fiber possesses similar chemical constituents, such as cellulose, hemicellulose, and lignin, along with comparable mechanical properties and thermal resistance to well-known fibers like jute, sisal, hemp, bamboo, and flax [26-29].

B. flabellifer, or the Asian Palmyra palm, is an important crop in South and Southeast Asia, valued for its fruit and palm sugar. While it is believed to have originated in Africa, archaeological evidence indicates it has been present in Southeast Asia for over 1500 years, likely spreading through economic and cultural exchanges [30, 31]. Fibers are mainly obtained from the fruit of the B. flabellifer palm, though they can also be extracted from the leaves and bark using mechanical or water-retting methods. While various parts of the tree, including the fruit, leaves, trunk, and bark, are used for household applications, the fruit husk is often considered agricultural waste in Bangladesh [25, 32]. Unlike other natural fibers such as jute, sisal, flax, and ramie, acquiring the raw material from Borassus husk requires planting and/or preserving the B. flabellifer trees, rather than cutting them down. To do so, we are contributing towards the net-zero carbon emission aim set by the Paris Agreement, 2015 [33, 34]. On top of that, it would also help to keep locals safe from major natural calamities, such as floods [35], thunder, lightning [36], cyclones [37], river bank erosion [38], and keeping biodiversity [39] in Bangladesh.

Nevertheless, like other lignocellulosic fibers, B. flabellifer fibers are hydrophilic, meaning they absorb moisture easily, which reduces their compatibility with hydrophobic polymers and complicates composite formation [40-42]. Additionally, the fibers contain impurities like waxes and pectin, making them unfavorable for engineering applications directly [43-45]. To improve compatibility and reduce hydrophilicity by eliminating impurities, such as wax and hemicellulose, various chemical treatments can be adhered to, including alkali, saline, potassium permanganate, benzoylation, and acetic acid treatments. Among these, alkali treatment is the most widely used due to its cost-effectiveness, convenience, and efficiency [43, 44].

The mechanical properties of Borassus fine and coarse fiber were found to be improved from previous studies remarkably [46-48]. Marathe et al. [49] investigated composites made of raw as well as alkali-treated Borassus fiber with polylactic acid (PLA) and reported that the enhanced mechanical and thermal properties of composites made of alkali-treated Borassus fiber with PLA were due to the removal of hemicellulose, resulting in improved adhesion property. Sudhakara et al. [50] carried out mechanical experiments on alkali-treated Borassus fine fiber-reinforced polypropylene (PP) and found that the tensile strength improved by 31% and flexural strength improved by 30%, compared to its raw fiber-reinforced PP composite. Balakrishna et al. [51] carried out experiments on alkali-treated randomly oriented Borassus fine fiber reinforced epoxy and revealed that alkali treatment enhanced the tensile strength of composites remarkably. Debnath et al. [52] investigated the mechanical properties of alkali-treated Borassus fiber-reinforced epoxy and found that tensile, flexural, and impact properties were enhanced for 15% (wt) alkali-treated Borassus fiber-reinforced epoxy remarkably because of the reduction in hemicellulose content and water absorption; similar findings were also reported by [53] for Borassus fruit fiber/PP composites. Reddy et al. [54] reported that after alkali treatment, the mechanical properties, such as tensile strength, modulus, and so on, were enhanced for Borassus fiber-reinforced epoxy composite. Nevertheless, alkali-treated banana fiber composites exhibit enhanced fiber–matrix interactions, leading to improved mechanical properties [55]. Researchers have examined the impact behavior of natural fiber-reinforced polymer composites. Jute fibers are found to be very effective in improving the fiber matrix adhesion and, consequently, mechanical properties in jute fiber-reinforced PP composites [56].

So far, commercial success has been attained by natural fiber-reinforced polymer matrix composites in semi-structural and structural applications, including electronics, sports technology, cars, aircraft, and plastics. Using natural fibers and organically generated resins, bio-based composites with higher mechanical characteristics may be designed and utilized for more structural purposes [57]. Automotive companies like Mazda, Mitsubishi, Toyota, Fiat, Mercedes-Benz, BMW, and Volkswagen have adopted bio-composites to help reduce carbon footprints and lower fuel costs [17, 58, 59]. In aerospace, the recent invention of the nano-satellite LignoSat, made from the wood of the Japanese magnolia tree (honoki), has opened up future opportunities for bio-fiber-based materials [24, 60, 61]. This innovation has received widespread attention due to its sustainability potential.

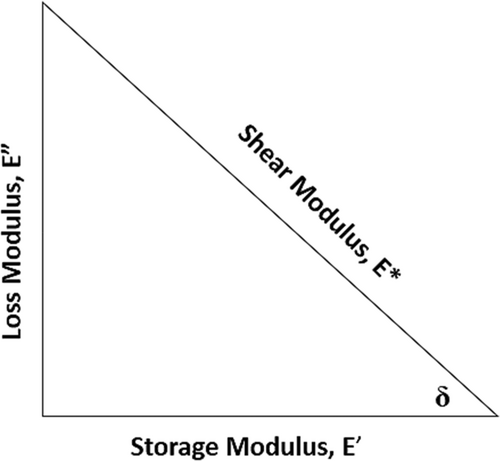

- The storage modulus, or dynamic modulus (E′), is closely linked to Young's modulus and reflects the material's “stiffness,” indicating how rigid or flexible a sample is. The storage modulus (E′) represents the material's ability to store energy applied to it for future use.

- The loss modulus (E″), also known as the dynamic loss modulus, measures the material's viscous response and its tendency to dissipate applied energy. This parameter is often associated with “internal friction” and is highly sensitive to molecular motions, transitions, relaxation processes, morphology, and structural heterogeneities [66-68].

- Tan δ, expressed as a dimensionless quantity, represents the mechanical damping factor and is defined as the ratio of the loss modulus to the storage modulus (tan δ = E″/E′). A high tan δ value indicates a material with a significant nonelastic strain component, whereas a low value signifies greater elasticity [64, 69]. Enhanced bonding at the fiber/matrix interface reduces the damping factor, as the mobility of molecular chains at the interface decreases.

- The component derived from E′ and E″ in the plot is referred to as the complex modulus (or shear modulus), denoted as E*, and it indicates the material's resistance to deformation [56, 67]. A high E* value indicates strong intermolecular forces within the material, while a low value suggests weaker intermolecular strength.

- The glass transition temperature (Tg) is the temperature range at which a thermosetting polymer transition from a rigid, “glassy” state to a more flexible, “rubbery” state [70, 71]. This is distinct from the melting temperature (Tm), where the material transitions to a liquid state. At Tg, the polymer softens, but it does not melt. Above Tg, the polymer exists in the rubbery state, while below Tg, it remains in a glassy or brittle state. Tg can be measured by several methods stated in literature along the ASTM D7028-07 standard, but the peak of the loss modulus, E″, has been suggested by many researchers as the most reliable one, whereas peak tan δ has been considered for comparable aspect state [62, 64, 68, 70, 71]. A higher glass transition temperature (Tg) signifies a denser cross-link structure, resulting in higher storage and loss moduli, which reflect increased stiffness. Conversely, lightly cross-linked polymers have lower moduli, indicating a looser network and reduced stiffness.

- A Cole–Cole plot is a powerful tool for analyzing the relationship between the dynamic modulus (E′) and the dynamic loss modulus (E″). Homogeneous polymer composites are characterized by smooth, semi-circular arcs on the plot, while irregularly shaped curves suggest nonuniform dispersion and heterogeneity within the polymer composite phases [56, 68, 69].

Gupta and Srivastava [72] carried out DMA analysis on jute fiber reinforced epoxy at different fiber loadings and revealed that with 25% (wt) jute fiber incorporated, epoxy was found to be improved in storage modulus as well as loss modulus along with a reduced damping factor (tan δ), compared with neat epoxy and other composites. Manral et al. [73] found that 10% sodium bicarbonate-treated jute fiber reinforced PLA composite showed better impact properties (tan δ), while the composite with 20% treated jute fiber achieved maximum storage and loss modulus values. Kumar et al. [74] carried out DMA at different frequencies on alkali-treated flax fiber reinforced composites and found that with increasing frequency, the storage and loss modulus as well as glass transition temperatures, Tg, increased, whereas the damping factor (tan δ) found to be decreased compared to neat epoxy. Ram et al. [75] carried out DMA on alkali-treated Asian Palmyra sprouts fiber-reinforced epoxy composites at different fiber loadings. They found that the effectiveness of fiber is highest at 40% fiber loading with epoxy, and the loss modulus and damping peaks decreased with the increase of fiber loading, whereas the storage modulus decreased with an increase in fiber loading. Gheith et al. [76] carried out dynamic mechanical experiments on date palm fiber (DPF) reinforced epoxy at different fiber loadings and found that incorporation of DPF into epoxy also improves the storage modulus (E′) and loss modulus (E″), whereas the damping factor decreases considerably by the reinforcement of DPF and is found to be lowest for 50% DPF/epoxy composites among all composites. VarunKumar et al. [77] found that the storage modulus (E′) values for 30% (wt) ramie root reinforced unsaturated polyester composites are at their highest, while the damping factor was found to be the lowest among all composites with different fiber loadings. Researchers [78] reported that hybrid composite, alkali-treated sisal (50%) incorporated with jute, banana, and palm-reinforced epoxy showed promising thermo-mechanical properties, such as storage modulus, loss modulus, and tan δ, compared to neat epoxy. Interestingly, glass transition, Tg, found from peak loss modulus was found to be higher than Tg achieved from peak tan δ.

Most previous studies have focused primarily on DMA of the Borassus fine and coarse fibers reinforced polymer composites, with no research conducted on Borassus husk fiber-based epoxy composites. Preliminary investigations into the properties of Borassus husk fibers have already been reported by the authors [23-25]. Hence, this paper aims to investigate the potential of B. flabellifer husk fiber-reinforced epoxy composites by comparing them with neat epoxy and conventional natural fiber-based composites, using DMA in accordance with ASTM D5418-01 standards. The fibers were incorporated into the epoxy both untreated and after treatment with sodium hydroxide (NaOH) for varying durations (0.75, 1, and 2 h). Key properties analyzed include storage modulus (E′), loss modulus (E″), and damping factor (tan δ). Furthermore, other influencing properties, such as shear modulus (E*), phase angle (δ), glass transition temperature (Tg), and total mass loss (TML), were also evaluated.

2 Materials and Methods

2.1 Raw Materials

The primary raw material used in this study was B. flabellifer husk fiber, sourced from rural areas in Bogura, Bangladesh. The collected fruit shells were thoroughly cleaned using a water-retting process to remove dust, dirt, and impurities. Once cleaned, the shells were sun-dried for several days to ensure minimal moisture content before being chopped and ground into fine powder using an electric blender. The resulting powder was subjected to sieve analysis to achieve a uniform particle size distribution, ensuring consistency across composite samples.

Epoxy laminating resin (EL2) with a compatible slow hardener was obtained from Easy Composites, UK. For the alkali treatment, hydrochloric acid (HCl), litmus paper, and NaOH were obtained from Sigma-Aldrich, UK.

2.2 Alkali Treatment

The B. flabellifer husk fibers were treated with a 5% (wt) NaOH (alkali) solution for 0.75, 1, and 2 h. The ratio of the distilled water to NaOH to fiber used was 19:1:1 [23]. Then, the solution with samples was neutralized with 37% concentrated HCl using litmus paper and rinsed with tap water to eliminate any remaining chemical residue. The optimum mechanical properties of the composite were observed at a concentration of 5% NaOH [46, 47, 79]. The fibers were thoroughly washed and then conditioned at 80°C for 24 h in a hot air oven before being stored in desiccator containers.

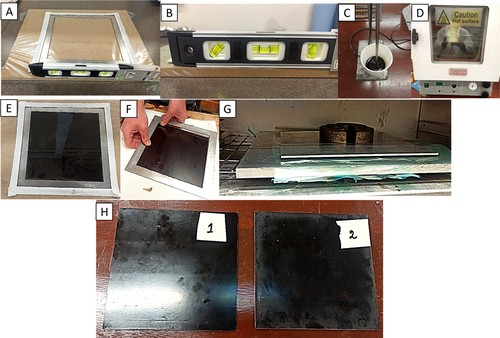

2.3 Composite Preparation

The preparation of the composite samples followed the hand layup method, a widely used technique for natural fiber-reinforced composites due to its simplicity and efficiency. Initially, 10% by weight Borassus husk powder (both treated and untreated) was mixed with epoxy resin (EL2) and stirred mechanically for 10 min to ensure homogeneous dispersion of the fibers within the resin matrix.

The prepared mixture was then placed inside a vacuum chamber at a gauge pressure of 20 bar for 20 min to eliminate trapped air bubbles and moisture, which have the potential to degrade the composite's structural integrity. After degassing, the mixture was poured into a 160 × 160 mm2 mold with a thickness of 3 mm, which had been pre-coated with a release agent to prevent adhesion to the mold surface. The mold was left to cure at room temperature for 24 h, followed by post-curing in an oven at 60°C for 6 h to ensure complete polymerization of the epoxy resin (following the guidance provided in the technical datasheet by the supplier). Once cured, the composite sheets were carefully removed from the mold and cut into rectangular specimens for experiments. Figure 1 demonstrates the entire process of composite fabrication.

2.4 DMA

DMA was performed to evaluate the viscoelastic behavior of Borassus/epoxy composites along with neat epoxy, adhering to the ASTM D5418-01 standard. The experiments used a TA Instruments DMA Q800 in dual-cantilever mode. Samples were cut into rectangular shapes having 55 mm × 13 mm × 2.5 mm dimensions. Experiments were conducted at a frequency of 5 Hz with a regulated amplitude of 20 μm, and the temperature was incrementally increased from room temperature to 150°C using controlled sinusoidal strain, with a heating rate of 3°C/min, under a compressed air atmosphere at 4.6 bar.

3 Results and Discussion

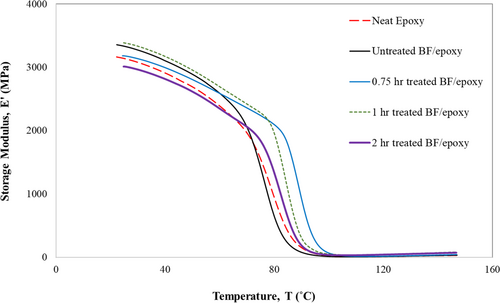

3.1 Storage Modulus (E′)

The storage modulus (E′) measures the energy (potential) stored in a material during a single oscillation cycle. It also demonstrates temperature-dependent stiffness behavior and load-bearing capabilities of the composite material. Figure 3 depicts the storage modulus-temperature curve, where neat epoxy along with untreated and alkali-treated Borassus husk fiber-reinforced epoxy composites are presented. It has been evident that E′ was found to decrease with rising temperature for all samples. Nevertheless, only untreated Borassus husk fiber-reinforced epoxy shows higher storage modulus loss than neat epoxy. The rest of the alkali-treated husk fiber reinforced epoxies show higher storage modulus retention capability during the test, and the 0.75-h treated one shows the highest value. These outcomes agree with previous studies [68, 69, 81]. Figure 3 shows that in the glassy zone, the E′ broadens due to closely packed and frozen components, resulting in a large storage modulus value below the glass transition temperature, Tg.

The E′ curves show a significant drop at around 65°C–110°C, indicating a glass/rubbery state transition, depending on the samples. As the temperature rises, the composites lose their tight packing structure losing inter-molecular bond strength, resulting in decreased E′ values in the rubbery zone. The dramatic fall in E′ value near the Tg suggests the material is transitioning from glass to rubber. Above Tg, the untreated fiber/epoxy composite has a lower storage modulus than other composites, indicating increased molecular mobility that supports the phenomenon resulting from increased molecular mobility of polymer chains above Tg.

The storage modulus curves show that adding untreated fiber decreases, but incorporating treated fiber into epoxy significantly raises the E′ values. The inclusion of treated fiber enhanced the adhesion property between stiff husk fiber and epoxy matrix, improving interfacial bonding, which has been found in previous studies [45, 82]. This can be attributed to the clear as well as rough surface found from the scanning electron microscopy (SEM) images revealed in previous studies [23, 47, 49, 54, 83, 84], and hemicellulose, moisture-absorbing composition found to be eliminated from Fourier transform infrared (FTIR) analysis [23, 48, 83, 85].

The untreated fiber/epoxy composite shows a greater decrease in storage modulus compared to all treated/epoxy samples. This is because impurities and hemicellulose (as identified in the FTIR analysis) act as barriers, preventing proper bonding with the matrix. This observation is further supported by the SEM results [25, 48, 86], where the raw fiber surface was found to be covered with impurities. It is noticeable that the 0.75-h treated fiber/epoxy composite shows a higher E′ than that of the 1-h treated and 2-h treated epoxy composites. This can be attributed to the prolonged time of alkali treatment that removes cellulose [23, 45, 87], which deteriorates mechanical properties. At higher temperatures in the rubbery region, above 120°C, all the samples exhibit more flexibility and have enhanced molecular mobility; therefore, the influence of alkali treatment is less pronounced. The findings are in good agreement with previous works, where sisal, jute, palm, and banana-reinforced epoxy [78], banana fiber-reinforced epoxy [55], flax fiber-reinforced epoxy [88], and sisal fibril-reinforced epoxy [89] are used.

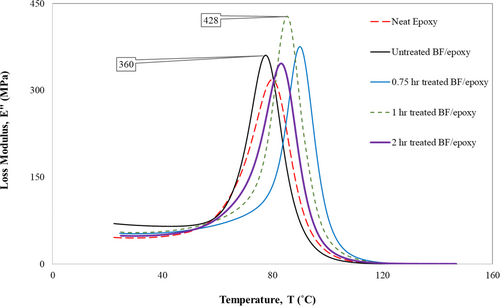

3.2 Loss Modulus (E″)

Loss modulus refers to the amount of energy released as heat during the deformation or viscous reaction of materials. This property assesses the viscous behavior of a material under stress. Figure 4 represents the loss modulus-temperature curve, where neat epoxy shows the least energy dissipation, followed by all Borassus husk fiber/epoxy composites. Adding Borassus husk to composites improves loss modulus, which follows a similar pattern as storage modulus. Nevertheless, 1-h treated husk fiber/epoxy composite shows the highest loss modulus, followed by 0.75-h and 2-h treated/epoxy composites. The loss modulus curves demonstrated the highest mechanical energy dissipation, which decreased at higher temperatures due to the increased mobility of polymer chains.

As the temperature rose, the polymer chains exhibited greater freedom of movement, leading to reduced energy dissipation. The E″ value peak height was much larger for husk fiber/epoxy composites compared to neat epoxy, indicating increased internal friction and energy dissipation. The loss modulus of composites increased with the inclusion of Borassus husk fiber content but decreased significantly during the rubbery stage.

The glass transition temperature (Tg) calculated from the E″ curve is provided in Table 1. The study found that Tg values derived from the loss modulus were more accurate than those obtained from the damping factor [56, 62]. Thus, this is a crucial point for any materials to be suitable for engineering designs. The outcomes show good agreement with previous research works [77, 78, 90-92]. However, Shinoj et al. [66] found that alkali treatment did not influence transition temperatures for oil palm fiber-based composites from the loss modulus.

| Glass transition temperature, Tg (°C) | |||

|---|---|---|---|

| Samples | Tg (°C) (from E″) | Tg (°C) (from tan δ) | tan δ (Damping factor) |

| Neat epoxy | 82 | 106 | 0.9 |

| Untreated BF/epoxy | 79 | 94 | 0.9 |

| 0.75-h Alkali-treated BF/epoxy | 89 | 101 | 1.2 |

| 1-h Alkali-treated BF/epoxy | 85 | 95 | 1.2 |

| 2-h Alkali-treated BF/epoxy | 84 | 94 | 1.1 |

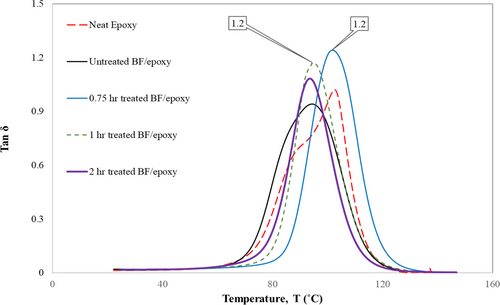

3.3 Damping Factor (tan δ)

The damping factor (tan δ) is the ratio of the loss modulus to the storage modulus (E′/E″). The damping factor may be used to assess the interlocking bonding of the fiber matrix as well as the curing behavior of composites [63, 72]. This property is incredibly crucial for engineering applications, especially in aerospace and automotive, where materials need to sustain their integrity under the simultaneous effect of heat and mechanical load [5, 55, 62, 93].

Figure 5 illustrates the tan δ for all composites, where the untreated husk fiber/epoxy composite shows the lowest value, followed by neat epoxy. Nonetheless, all of the husk fiber/epoxy composites display a single peak, indicating good interaction between fiber and matrix due to lower heterogeneity in the composite [66]. For all the samples, up to the peak of the tan δ, the damping factor increased with rising temperature, and after that, it dropped gradually with increasing temperature. Table 1 summarizes the damping factors for all the samples along with corresponding temperatures. The corresponding temperature with the peak of tan δ is also considered as the glass transition temperature, Tg, but this one is suggested for comparison purposes [70]. After this, the material becomes soft and rubbery, suggesting inter-molecular bond strength drops drastically, and the material loses its load-bearing capability.

It is noticeable that all the alkali-treated fiber/epoxy composites showed higher enhancement in tan δ value than neat epoxy, and particularly, 0.75-h and 1-h treated Borassus husk fiber reinforced epoxy composites exhibit the maximum value, 1.2, which is higher than tan δ found in the literature for other biofibers-based composites, such as 0.46 for jute reinforced epoxy [72], 0.42 for woven flax reinforced epoxy [74], 0.86 for Borassus sprout reinforced epoxy [75], 0.43 for kenaf reinforced epoxy [68], 0.62 for date palm reinforced epoxy [76], 0.17 for ramie root reinforced polyester [77], and 0.58 for banana reinforced epoxy [55]. It is interesting to find that after the treatment, the adhesion property of Borassus husk fiber enhanced, resulting in better interlocking characteristics between husk fiber and epoxy matrix. This improves heat dissipation and load absorbing capacity of the treated sample, which can also be attributed to their impact and toughness, whereas it has been found in the literature that after incorporating fibers, such as ramie, flax, jute, sisal, banana, and so on, into polymeric resin reduced the damping factor is reduced [63, 74, 75, 77, 78, 88, 90, 94-97]. Untreated fiber/epoxy composite results in decreased damping factor can be attributed to less matrix volume in composites and poor adhesion between resin and fiber, which reduces vibration energy and fiber agglomeration [68, 98].

A larger peak indicates slower polymeric chain movement, resulting in increased cross-linking density for treated fiber/epoxy composites with improved interfacial interaction and energy dissipation ability [64, 65]. In contrast, neat epoxy and untreated husk fiber/epoxy composites exhibit a lower damping factor. This can be attributed to the heterogeneity of the mixture, the limited ability to convert mechanical energy into heat, and the thermal instability of the material [67]. This work shows good agreement with previous studies [81, 90, 99, 100], although some found a decreased value after the alkali treatment [63].

3.4 Glass Transition Temperature, Tg

Tg may be calculated using numerous approaches, including the peaks of loss modulus (E″) and tan δ from Figures 4 and 5. Nonetheless, Tg determined by the peak E″ has been deemed more convincing and realistic than damping factor-derived ones [56, 62, 68], since after this point, molecules become agitated and lose their inter-molecular bond strength, resulting in reduced storage modulus, which impacts the material's load-bearing capability adversely. Table 1 presents the data of Tg of all the samples, where Tg derived by E″ was determined to be lower than that of tan δ curves, as evaluated by previous studies [63, 101, 102]. The data clearly indicate that incorporating untreated Borassus husk fiber into epoxy resin introduces heterogeneity. Additionally, the presence of hemicellulose and other impurities in the fiber may compromise the composite's integrity during DMA experiments. As a result, the composite exhibits a lower glass transition temperature (Tg), corresponding to the peak E″, compared to neat epoxy. On the other hand, all the alkali-treated fiber/epoxy composites show higher values than neat epoxy because of improved adhesion properties between resin and fiber.

It has been found from previous studies that after the alkali treatment, Borassus fiber shows enhanced thermal stability [23, 84] and better mechanical properties [46-48]. 0.75-h treated Borassus husk fiber/epoxy shows the highest Tg value, 89°C, corresponding to E″, which should be attributed to the fiber's intrinsic thermal stability found in the author's previous work [23], compared to other samples [23, 103], where prolonged duration can be associated with the deterioration of cellulose. The glass transition temperature, Tg (from peak loss modulus), in this study for 0.75-h alkali-treated Borassus husk fiber reinforced epoxy is found to be higher than those found in the literature, such as 70°C for banana-reinforced epoxy [55], 70°C for kenaf reinforced epoxy [68], 72.5°C for sisal, jute, banana, palm reinforced epoxy [78], 79°C for date palm reinforced epoxy [76] 79°C for palm sprouts reinforced epoxy [75], 74.7°C for woven flax reinforced epoxy [74], and 74.5°C for jute reinforced epoxy [72].

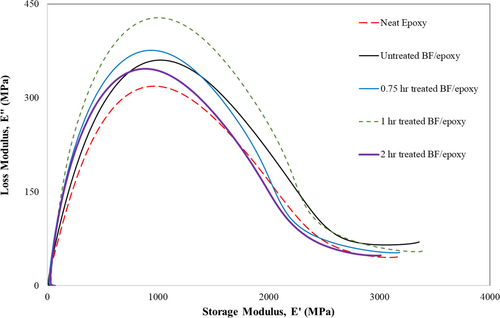

3.5 Cole–Cole Plot

The Cole–Cole or Wicket plot provides useful insight into the connection between loss modulus (E″) and storage modulus (E′). In principle, a perfect semi-circle curve means a homogeneous mixture between fiber and matrix, an imperfect semi-circle refers to a heterogeneous mixture between fiber and matrix, and an irregularly shaped curve represents a nonhomogeneous mixture between fiber and matrix [69, 77, 92, 104].

Figure 6 shows plot for all the samples, where all the samples exhibit imperfect semi-circular shape compared to kenaf/epoxy composite [68], where it was found that with the perfect semi-circle, the damping factor increased (0.43) so as Tg (70°C) corresponding to loss modulus, E″. In this study, all alkali-treated Borassus fiber/epoxy show imperfect semi-circular shapes that refer to heterogeneity in adhesion resulting in higher damping factor and energy-absorbing properties. Interestingly, the 0.75-h and 1-h treated husk fiber/epoxy composites have greater Cole–Cole curves than the other composites, the similar result reported by previous studies on flax fiber/epoxy [74] as well as date palm/epoxy [76] and they suggested that a widen curve indicates that strong interaction between fiber and matrix exists, resulting enhanced strength of the composites. In this study, alkali treatments significantly increased fiber–matrix bonding, providing strong evidence.

3.6 Phase Angle, Shear Modulus, and TML

Materials exposed to temperature fluctuations and cyclic loading, such as vibrations, gradually dissipate internal energy, resulting in a loss of strength over time. This process can also lead to mass loss. With each vibration, intermolecular bonds weaken, causing molecules to shift from their original state to new configurations at a specific angle, known as the phase angle (δ).

Under cyclic loading, polymers typically display viscous behavior, with molecules shifting between positions [92, 105]. If a molecule does not undergo dislocation under applied mechanical or thermal load (loss modulus, E″ = 0), and only temporarily changes its shape, the phase (change) angle is 0°, indicating the material is fully elastic. In contrast, if the deformation is permanent (storage modulus, E′ = 0), the phase angle is 90°, signifying the material is fully plastic [67]. Materials that exhibit a combination of elastic and plastic behavior are termed viscoelastic. For these materials, the phase angle lies between 1° and 89°, reflecting their ability to recover from plastic (permanent) deformation. This can influence the damping factor and Cole–Cole plot of any sample.

Table 2 summarizes all the data, including phase (change) angle (δ), shear modulus (E*), and TML for all samples at initial and peak loss modulus (E″) conditions indicate that alkali-treated fiber/epoxy composites exhibit higher phase angles at peak E″. The neat epoxy shows the least phase angle change, 17.6°, followed by untreated Borassus husk fiber/epoxy composite, indicating its elastic nature compared to other alkali-treated fiber/epoxy composites. The 1-h treated Borassus husk fiber/epoxy showed the highest phase angle, 23.3°, followed by 0.75-h and 2-h treated fiber/epoxy composites, 21.6°. This suggests that treated fiber/epoxy composites possess superior viscoelastic properties compared to neat epoxy and untreated Borassus husk fiber-reinforced epoxy. Similarly, in the shear modulus, 1-h treated fiber/epoxy shows the highest drop in shear value (modulus) compared to other composite samples. This behavior can be attributed to the high damping factors, Cole–Cole plot, and loss modulus (E″) found earlier from the DMA experiments.

| Phase angle, δ (°) | Shear modulus, E* (MPa) | ||||

|---|---|---|---|---|---|

| Samples | Initial phase angle, δi (°) | Phase angle at E″, δg (°) | Initial shear modulus, Ei* (MPa) | Shear modulus, Eg* at E″ (MPa) | TML (%) |

| Neat epoxy | 0.9 | 17.6 | 3102 | 1010 | 0.6 |

| Untreated BF/epoxy | 1.2 | 19.5 | 3381 | 1090 | 0.6 |

| 0.75-h Alkali-treated BF/epoxy | 1.0 | 21.6 | 3001 | 949 | 0.4 |

| 1-h Alkali-treated BF/epoxy | 0.9 | 23.3 | 3336 | 1072 | 0.5 |

| 2-h Alkali-treated BF/epoxy | 1.0 | 21.6 | 2954 | 934 | 0.7 |

Additionally, under the specified conditions, alkali-treated fiber/epoxy composites show less TML, except 2-h treated fiber/epoxy, compared to neat epoxy and untreated fiber/epoxy composites. Nevertheless, 0.75-h treated fiber/epoxy composite shows the least mass loss, 0.4%. Hence, this sample should perform better in thermo-mechanical conditions than neat epoxy. 2-h treated Borassus husk fiber reinforced was found to have the highest TML of 0.7%, which can be attributed to the loss of higher thermal and mechanical load-bearing composition cellulose content because of prolonged treatment duration [41, 42, 106].

4 Conclusion

- The storage modulus increased with the incorporation of treated Borassus husk fiber in the epoxy composite, surpassing that of polymer composites reinforced with other biofibers such as sisal, flax, ramie root, jute, palm sprouts, and banana. Similarly, the loss modulus values also increased with alkali-treated fibers, reaching the highest value in the 1-h alkali-treated Borassus husk fiber/epoxy composite.

- The glass transition temperature (Tg), corresponding to E″, was 82°C for neat epoxy. This increased to 89°C in the composite containing 0.75-h alkali-treated Borassus husk fiber, which was higher than the composites reinforced with other biofibers, such as kenaf (70°C), flax (74.7°C), jute (74.5°C), and banana (70°C), indicating higher thermal stability. However, Tg decreased to 79°C in the composite with untreated husk fiber.

- Single tan δ (damping factor) peaks were observed for all composite samples except neat epoxy. The lowest tan δ value was recorded for the untreated husk fiber-reinforced epoxy composite. The addition of alkali-treated fibers significantly increased the tan δ peak values, with the highest value (1.2) observed for the 0.75-h and 1-h alkali-treated Borassus husk fiber/epoxy composites. This value exceeds those of neat epoxy (0.9) and other fiber-reinforced composites, including banana/epoxy (0.58), kenaf/epoxy (0.43), Borassus sprout/epoxy (0.86), date palm/epoxy (0.62), woven flax/epoxy (0.42), ramie root/polyester (0.17), and jute/epoxy (0.46), suggesting better impact properties.

- Cole–Cole plot revealed all the samples show heterogeneity, but 1-h and 0.75-h alkali-treated fiber/epoxy composites reveal comparatively high curves that are associated with better adhesion properties between epoxy resin and fiber.

- Phase angle (δ) data showed that all treated fiber/epoxy composites exhibited a greater change in phase angle from their initial state to the glass transition point, indicating their better viscoelastic nature. A similar trend was observed in the shear (complex) modulus, which can be attributed to the treated samples' enhanced toughness and impact properties.

- TML is higher for the 2-h treated and untreated Borassus husk fiber/epoxy composites, as well as neat epoxy. In contrast, the lowest TML value (0.4%) is observed in the 0.75-h alkali-treated Borassus husk fiber/epoxy composite, which is approximately 33% lower than that of neat epoxy. This reduction can be attributed to the enhanced intrinsic thermal stability of the treated Borassus husk fiber.

Alkali-treated Borassus fiber/epoxy composites revealed an exceptional combination of energy dissipation and mechanical stiffness compared to neat epoxy (base resin) and other biofiber-based composites. They exhibit less TML, high strength, and high tan δ because of their incredible intrinsic thermal stability. Notably, 0.75-h treated Borassus husk fiber/epoxy with both high damping factor (tan δ) and storage modulus (E′) reflects a well-engineered material that achieves an optimum balance between stiffness and damping. This makes it a promising candidate for manufacturing demanding engineering components, precisely in aircraft and automobiles, which require mechanical strength as well as impact properties. Nevertheless, the properties of biofibers can vary significantly due to factors such as environmental conditions, geographic origin, and maturity, so extensive investigations are required in the future. Consequently, while the B. flabellifer husk is locally abundant, establishing an efficient collection and supply chain system is essential for supporting industrial-scale production.

Nomenclature

-

- E*

-

- shear (complex) modulus (MPa)

-

- E′

-

- storage modulus (MPa)

-

- E″

-

- loss modulus (MPa)

-

- tan δ

-

- damping factor

-

- Tg

-

- glass transition temperature (°C)

-

- TML

-

- total mass loss (%)

-

- δ

-

- phase angle (°)

Author Contributions

Md Atiqur Rahman: conceptualization, methodology, investigation, funding acquisition, writing – review and editing, writing – original draft, formal analysis, software, resources, data curation, visualization. Mamadou Ndiaye: visualization, writing – review and editing, project administration, supervision. Bartosz Weclawski: validation, methodology, visualization, writing – review and editing, supervision, project administration. Peter Farrell: supervision, visualization, writing – review and editing, project administration.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to privacy or ethical restrictions.