Performance of Alkali Treated and Untreated Ronier Fiber (Borassus aethiopum) on Mechanical and Durability Properties of Reinforced Concrete

Funding: This work was supported by the African Union.

ABSTRACT

This study investigates the effect of 1% sodium hydroxide (NaOH)-treated and untreated Ronier fibers (Borassus aethiopum) on concrete's mechanical and durability properties. Ronier fibers were incorporated into concrete at proportions of 0.5%, 1%, and 1.5% by volume. The fibers treated with 1% NaOH underwent chemical modification to enhance their bonding with the cement matrix and improve their durability in aggressive environments. The performance of the concrete was assessed through tests for compressive strength, tensile strength, flexural strength, durability properties such as water absorption, and resistance to sulfuric acid attacks. The results indicated that treatment with 1% NaOH significantly improved the performance of the fibers. Among the variations studied, concrete reinforced with 1% treated fibers demonstrated the best combination of mechanical and durability properties. The treated fibers increased the concrete's tensile and flexural strength while maintaining adequate compressive strength. Durability assessments showed that 1% treated fibers effectively reduced water absorption and enhanced resistance to sulfuric acid, improving the concrete's performance in aggressive environments. Although higher dosages of fibers (1.5%) provided better crack control, they slightly reduced workability and compressive strength.

1 Introduction

Concrete is a basic building material because of its durability, strength, and adaptability. Nevertheless, reinforcing is required to improve its performance due to its intrinsic brittleness and fracture vulnerability [1]. Future construction materials are envisioned to possess qualities like lightweight, high strength, user-friendliness, cost-effectiveness, and enhanced environmental sustainability [2]. Nontraditional building materials, including agricultural wastes, are being explored. An innovative sustainable approach taking into account environmental benefits such as carbon dioxide sequestration and oxygen release [3, 4] involves integrating natural fibers (NFs) into concrete. The properties of concrete are influenced by the types, shapes, and surface textures of the incorporated fibers [5].

Research has been conducted on Banana, Coir, Sisal, Jute, Flax, Palm, Pine needle fibers, and rice straw. Nambiar and Haridharan [6], Tiwari et al. [7], and Hasan et al. [8] conducted a study on the effect of jute fibers in a reinforced concrete mix after 28 days. From their findings, the inclusion of jute fibers up to 1% significantly enhances tensile strength.

Kore [9], Ali et al. [10], Al-Masoodi et al. [11], Naamandadin et al. [12], and Nadgouda [13] focused their study on the efficacy of coir fibers in enhancing tensile strength. It was observed that the addition of coir fiber had a peak influence on tensile strength in the ER.

Asim et al. [14] and El-Nadoury [15] conducted research on sugarcane fibers. Their findings showed an increase in the ER of compressive strength in tandem with a rising fiber percentage. From their study, a peak enhancement ratio (ER) of 6.67% was recorded when a 1.5% fiber concentration was used. However, a sharp decrease to an ER of −66.4% was noted with the introduction of 10% sugarcane fibers. The performance of alkali-treated Ronier fibers (RFs) on the mechanical and durability properties of concrete has not been studied.

The NF known as RF, which comes from the African fan palm (Borassus aethiopum), has a lot of promise for use as reinforcement in concrete, particularly in areas where it is widely accessible [16].

However, untreated NFs frequently have problems like poor cement matrix adherence, high water absorption (WA), and vulnerability to deterioration in hostile environments. To overcome these restrictions, RFs are treated with 1% NaOH to increase their compatibility with the cement matrix [17]. Through the removal of lignin, hemicellulose, and other contaminants from the fiber surface, this treatment improves the fibers' ability to link and decreases their absorption of water. In comparison to their untreated counterparts, treated fibers should have better mechanical and durability performance [18].

- WA test: To assess the fiber-reinforced concrete's porosity and moisture resistance.

- Sulfuric acid resistance test: This test evaluates the concrete's resistance to acid exposure-induced degradation by simulating a hostile chemical environment with a 3% sulfuric acid (H2SO4) solution.

The findings show that 1% treated RF is the ideal dosage, resulting in a balance between better mechanical qualities and increased resistance to acid attack and WA. Concrete's overall durability is enhanced by the NaOH treatment, which also dramatically lowers WA and boosts fiber acid resistance.

This study emphasizes how treated NFs can be used to make long-lasting and sustainable concrete composites. Underlined with global sustainability goals, this research helps produce eco-friendly construction solutions by decreasing the use of synthetic materials and improving the material's performance under challenging conditions.

2 Experimental Program

2.1 Material

One of the materials utilized in this investigation was Portland pozzolanic cement (CEM I/B-P 42.5 N), as shown in Table 1, which was purchased from a nearby manufacturer and met EN 197 standards. The coarse aggregate (CA) came from Kasarani in Nairobi, Kenya, and consisted of crushed stone up to 12.5 mm in size. The fine aggregate (FA) was obtained from Mlolongo quarries in Nairobi, Kenya, and consisted of river sand with a maximum particle size of 5 mm. Sika Chemicals in Nairobi provided the Sika ViscoCrete 20HE KE superplasticizer (SP), which was utilized to improve the concrete's workability. Ninety-eight percent of pure sodium hydroxide (NaOH) pellets were bought locally in Nairobi. The water pump system at Jomo Kenyatta University of Agriculture and Technology (JKUAT) provided drinkable water for mixing and curing.

| Materials | Properties |

|---|---|

| Cement (CEM I/B-P 42.5N) | Specific gravity of 3.11 |

| Fine aggregate (river sand) | Maximum size of 5 mm |

| Coarse aggregate (crushed stone) | Maximum size of 12.5 mm |

| Water (potable water) | Specific gravity of 1.00 |

| Superplasticizer (Sika Viscoflow 20HE KE) | Specific gravity of 1.06 kg/m3 |

| Sodium hydroxide pellets (NaOH) | 98% extra pure |

| Untreated Ronier fiber (UT RF) | Specific gravity of 1.15 |

| Boil-treated Ronier fiber (BT RF) | Specific gravity of 1.18 |

| BT combined with NaOH-treated Ronier fiber (NT RF) | Specific gravity of 1.23 |

2.2 Methods

2.2.1 Characterization of CA and FA

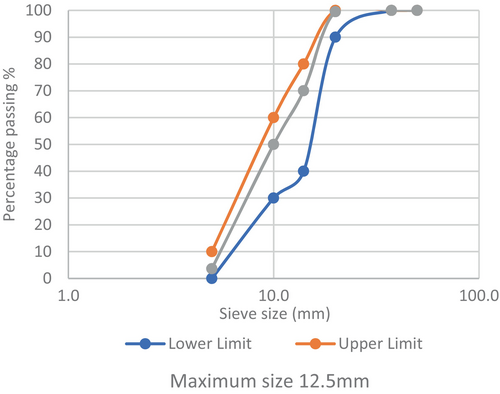

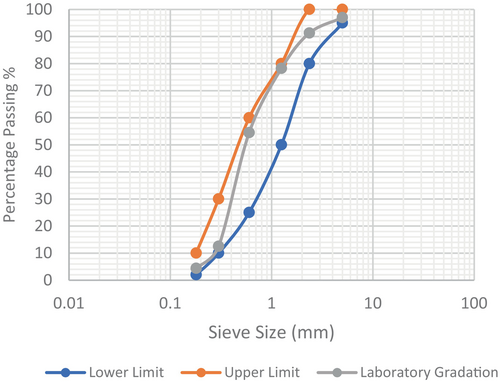

The particle size distribution of FA and CA was analyzed to assess their suitability for use in concrete, as illustrated in Figures 1 and 2. Before utilization, both FA and CA were prepared at a density of 2.00 kg/m3. The specific gravity of FA and CA, measured on an oven-dry basis, was found to be 3.05 and 3.57, respectively. To ensure the removal of impurities, the aggregates were thoroughly cleaned and sun-dried to eliminate all moisture. Sieving and grading were performed in accordance with ASTM C33 standards, maintaining compliance with prescribed upper and lower limits. The analysis confirmed the suitability of both materials for concrete production, as specified by BS EN 196-6:2018. The FA exhibited a maximum particle size of 5 mm, while the CA particles ranged from 12.5 to 2.36 mm, passing through a 12.5 mm sieve but retained on a 2.36 mm sieve. The fineness modulus was determined to be 2.50 for FA and 2.41 for CA, both falling within the acceptable range of 2.3 to 3.1, as outlined in BS EN 196-6:2018 for aggregate fineness in concrete mixtures (Figures 1 and 2).

2.2.2 Physical and Mechanical Properties of Aggregates

The characteristics and properties of the FA and CA used in this study are summarized in Table 2. The compacted dry bulk density of FA and CA intended for the concrete mix was measured as 1170 and 1103 kg/m3, respectively, meeting the requirements for dry rodded bulk density of aggregates used in concrete, which typically falls within the standard range of 1400 kg/m3. The aggregate impact value (AIV) for CA was determined to be 3.76%, while the aggregate crushing value (ACV) was 12.91%, both well within the permissible limits of 10% and 30%, respectively, as specified in BS 812-112 and BS 812-110. These results confirm that the aggregates satisfy the required standards and are suitable for use in concrete mixtures, as detailed in Table 2.

| Properties | Fine aggregates | Coarse aggregates |

|---|---|---|

| Specific gravity on an oven-dry basis | 3.02 | 3.62 |

| Specific gravity on an oven-dry basis | 2.71 | 2.69 |

| Water absorption (%) | 2.92 | 3.21 |

| Bulk density-dry rodded (kg/m3) | 1.170 | 1.103 |

| AIV (%) | / | 5.5 |

| ACV (%) | / | 12.91 |

2.2.3 Characterization of RFs

2.2.3.1 Fourier Transform Infrared (FTIR)

To determine which chemical functional groups were present in the sample, FTIR spectroscopy was utilized. The potassium bromide (KBr) pellet method was used to create the sample powder, which involved finely grinding 10 mg of the sample with 1000 mg of analytical-grade KBr [21]. After forming the pellets for 1 min at a pressure of 75 kN/cm2, they were put in a sample holder for examination. After that, the processed sample was examined with a Shimadzu FTIR spectrophotometer, which averaged 32 scans per measurement and acquired spectrum data across a wavelength range of 400–4000 cm−1 at a resolution of 4 cm−1 [21, 22].

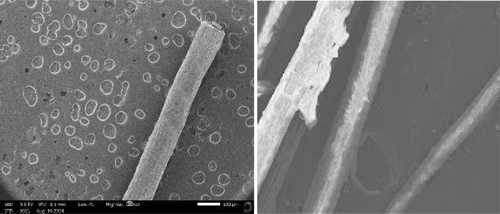

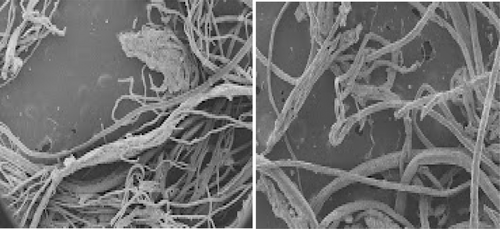

2.2.3.2 Examining Scanning Electron Microscopy (SEM) Test

The surface morphology of RFs was examined using EM. An electron detector, which is designed to detect secondary electrons, was used to look for any changes in the fibers' surface structure after treatment. The detector operated at a voltage of 5.0 kV. SEM examination was performed in the food fortification lab at Jomo Kenyatta University of Agriculture and Technology (JKUAT). TESCAN provided the VEGA3 scanning electron microscope for the investigation.

2.2.3.3 Chemical Treatment of RFs

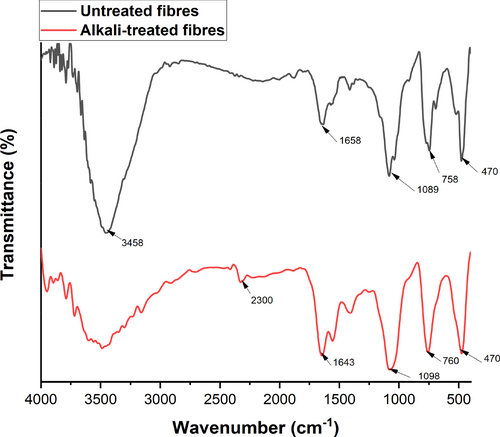

Applying a 1% NaOH solution to the fibers greatly increased their hydrophilicity and surface roughness. The fiber surface became cleaner and more reactive as a result of the efficient removal of lignin, hemicellulose, and other contaminants by this chemical process. A smoother surface and improved bonding with the cementitious matrix were produced by the 1% NaOH treatment, which altered the fibers' porosity structure. Previous research has found similar outcomes [23]. Alkali treatment of rice husk ash with NaOH, for instance, decreased hydrophilicity and increased compatibility with cement composites, according to [24], while Mehta et al. [25] showed that alkali treatment altered the porous structure of rice husk ash, leading to improved fiber–matrix interactions and decreased WA. These results support the study's determination that 1% NaOH is the ideal concentration for treating RFs (Figure 3).

2.2.4 SP

Sika ViscoCrete-20 HE KE, an SP, was utilized in this study to enhance the workability and flowability of freshly mixed concrete. Through a 30% reduction in water content and a significant improvement in flow, this additive is specifically designed to increase the strength of concrete. Precast and ready-mix concrete applications can both benefit from its ability to reduce bleeding and segregation. Sika ViscoCrete-20 HE KE fits the SP requirements outlined in ASTM C494 Type G and EN 934-2, having a specific gravity of 1.09 and a pH of 1.09.

2.2.5 Mix Proportion

2.2.5.1 Mix Design

The study used the Design of Experiments (DOE) approach for mix proportioning to achieve a Grade 60 concrete strength. Compressive strength tests were conducted using 100 mm × 100 mm × 100 mm cubes, tensile strength tests were conducted using 200 mm tall cylinders with a 100 mm diameter, and flexural strength tests were conducted using 100 mm × 100 mm × 350 mm rectangular beams. Table 3 lists the precise mix ratios for the prepared concrete samples.

| Mix | Fiber content (%) | Cement (kg/m3) | Water | SP | Fine aggregate | Coarse aggregate | W/C ratio |

|---|---|---|---|---|---|---|---|

| Mix 0 | 0% | 4.70 | 1.64 | 0.4 | 5.4 | 8.17 | 0.35 |

| Mix 1 | 0.5% Untreated | 4.70 | 1.64 | 0.4 | 5.4 | 8.17 | 0.35 |

| Mix 2 | 1% Untreated | 4.70 | 1.64 | 0.4 | 5.4 | 8.17 | 0.35 |

| Mix 3 | 1.5% Untreated | 4.70 | 1.64 | 0.4 | 5.4 | 8.17 | 0.35 |

| Mix 4 | 0.5% Treated | 4.70 | 1.64 | 0.4 | 5.4 | 8.17 | 0.35 |

| Mix 5 | 1% Treated | 4.70 | 1.64 | 0.4 | 5.4 | 8.17 | 0.35 |

| Mix 6 | 1.5% Treated | 4.70 | 1.64 | 0.4 | 5.4 | 8.17 | 0.35 |

2.2.5.2 Concrete Mixing, Pouring, and Curing Procedure

The components were combined using a rotary drum mixer, including RF, cement, water, SP, fine, CA, and FA. First, a lubricant solution was made by mixing the SP with water to prepare the new concrete. For even dispersion, this solution was then added gradually to the mixer with the dry ingredients. After the freshly mixed concrete was put into molds that had been previously lubricated, tests for slump and compaction factors were used to determine its workability and density. To guarantee homogeneity and remove air pockets, compaction was accomplished with an electric vibrator.

Following a 24-h period, the concrete samples were meticulously demolded and cured in water until testing at 3-, 7-, 14-, and 28-day intervals. Particle bonding, hardening, and strength development were all ensured by the water-curing process, which supplied enough moisture to enable cement hydration. Additionally, by avoiding early drying and inadequate hydration, this technique preserved the concrete's structural integrity. By minimizing shrinkage and lowering the chance of cracking, maintaining a moist atmosphere during curing improved the concrete structures' lifetime and durability.

As shown in Figure 4, test containers were cylindrical for split tensile strength, prismatic for flexural strength, and cubic for compressive strength, WA, and resistance to sulfuric acid.

2.2.5.3 Concrete's Fresh Density and Air Void Content

For each batch in this study, the density and air content of freshly mixed concrete were tested in accordance with ASTM C138.

2.2.6 Mechanical and Physical Properties

2.2.6.1 Compressive Strength Test

The RF-reinforced concrete (RFRC) cubes' compressive strength was evaluated at 3, 7, 14, and 28 days. For every percentage of fiber, three cube specimens with dimensions of 100 mm × 100 mm × 100 mm were made. In accordance with ASTM C39, the cubes were compressed until failure to ascertain the maximum load they could sustain following the curing interval.

2.2.6.2 Tensile Strength Test

In accordance with ASTM C39, split tensile strength tests were conducted on cylindrical specimens measuring 100 mm in diameter and 200 mm in height. Both samples of RFRC and plain concrete were used in the experiments. Fibers treated and untreated with NaOH were added in different percentages of 0.5%, 1%, and 1.5%. The tensile strength was measured at 7, 14, and 28 days using a compression testing equipment. The strength was determined by averaging three specimens for each fiber percentage.

2.2.6.3 Flexural Strength Test

RFRC beams underwent flexural strength tests at 7, 14, and 28 days. Following the guidelines in ASTM C348, three beam specimens measuring 100 mm × 100 mm × 350 mm were examined for each fiber %. To test the beams' flexural strength, loads were applied uniformly in the middle and on either side of the support points.

2.2.7 Durability Properties

2.2.7.1 WA

2.2.7.2 Sulfuric Acid

3 Result and Discussions

3.1 Characterization

3.1.1 Treatment of RF With NaOH

The study's findings support the idea that treating RFs with 1% NaOH can increase their performance and durability. Superior hydrophilicity and bonding with the cementitious matrix were demonstrated by the treated fibers, which decreased WA and increased durability. These results are consistent with earlier studies that demonstrated that treating rice husk ash with NaOH decreased its hydrophilicity and enhanced its compatibility with cement composites [24]. Likewise, alkali treatment with NaOH changed the fibers' porosity structure, resulting in a smoother surface and improved cement-fiber interactions [25]. Because larger concentrations may cause fiber deterioration or decreased workability, the choice of 1% NaOH in this study achieves a balance between practical application and successful chemical alteration.

3.1.2 FTIR

The FTIR (Figure 6) spectra indicate prominent C=H and N-H (alkyne and amino) absorption bands at 3450 cm−1 for untreated cellulose, while the treated cellulose exhibits multiple peaks in the range of 3300–3800 cm−1. Additionally, the stretching vibrations of the alkyne (C-H) at 2337 cm−1 suggest the inclusion of a tertiary amine in the product's chemical composition. These absorptions are attributed to the abundance of amino and C-H bonds in the biomass. A strong absorption band above 1646 cm−1 corresponds to the carbonyl stretching (C=O) of carboxyl and ester groups in hemicellulose. Peaks at 1394, 1078, and 766 cm−1 are associated with the vibrations of the aromatic skeleton, including C-O stretching and C-H movements in and out of the plane of the syringyl ring in lignin. The pronounced band at 1074 cm−1 represents C-O and C-O-C stretching vibrations in hemicellulose, lignin, and cellulose. The small absorption at 911 cm−1, linked to β-1,4-glycosidic linkages in the monosaccharides of hemicellulose, is completely eliminated in alkali-treated fibers. This disappearance confirms a significant reduction in hemicellulose content due to the alkaline treatment. FTIR analysis thus validates the removal of hemicellulose during the treatment process.

3.1.3 Examining SEM Test

The SEM images of the untreated samples reveal smooth, compact fibers with intact surfaces and minimal structural disruption. The fibers are well preserved, with no visible roughness, cracks, or fibril exposure, indicating that the lignin and hemicellulose matrix remain intact, providing protection to the cellulose. The circular features visible in the background may represent impurities or particulate matter, but the overall structure reflects the natural, unaltered morphology of the biomass in Figure 7.

In contrast, the 1% NaOH-treated samples show significant structural changes, including surface roughness, peeling, and the exposure of cellulose fibrils. Detached, thread-like structures and delaminated layers indicate the removal of hemicellulose and partial degradation of lignin due to the alkaline treatment. Cracks, grooves, and irregularities on the fiber surface highlight the disruption of the biomass matrix, confirming the effectiveness of NaOH in breaking down the protective components and increasing the accessibility of the cellulose (Figure 8).

3.1.4 Properties of RFs (Borassus aethiopum Fruit)

The table outlines the properties of RFs derived from the fruit of B. aethiopum, highlighting their suitability for concrete reinforcement. With a fiber length of 30 mm, the fibers are long enough to enhance load transfer and improve tensile strength without causing clumping in the concrete matrix. Their tensile strength of 105 MPa ensures the fibers can withstand significant tension, improving stress distribution and reducing the likelihood of cracks in the concrete. Additionally, the small diameter of 1 mm provides a high surface area-to-volume ratio, promoting strong bonding with the cement matrix and enhancing mechanical performance, as shown in Table 4.

| Characteristics | RF |

|---|---|

| Fiber length (mm) | 30 |

| Tensile strength (MPa) | 105 |

| Diameter (mm) | 1 |

These properties demonstrate that RFs are not only effective as reinforcements but also sustainable. Derived from a natural and renewable source, they reduce reliance on synthetic fibers and energy-intensive materials like steel, supporting eco-friendly construction practices. The combination of high tensile strength, optimal length, and small diameter makes RFs an excellent choice for improving the durability and toughness of concrete composites while contributing to more sustainable building materials. The mechanical properties of the cementitious composite are influenced directly by fiber–matrix interactions since the interphase is the region of the material that conditions the ability of fibers to transfer loads to the matrix and stabilizes crack propagation.

4 Mechanical Properties

4.1 Compressive Strength

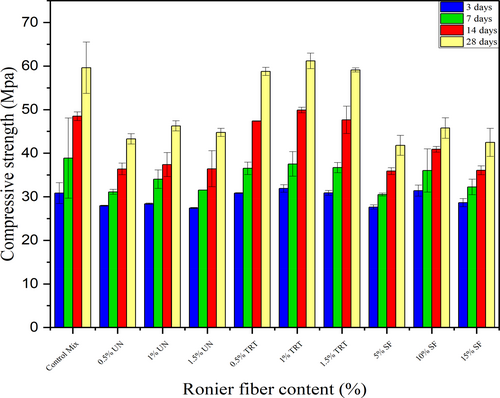

Figure 9 demonstrates the positive impact of RFs on concrete performance, particularly compressive strength, with 1% treated fibers (TRT) achieving optimal results (62.117 MPa at 28 days). Treated fibers significantly enhance fiber–matrix bonding, improving load transfer, crack resistance, and overall strength. Untreated fibers (UN) also improve compressive strength, though to a lesser degree, while short fibers (SFs) show benefits at lower content (5%) but lead to performance declines at higher dosages (1% and 1.5%) due to poor distribution and bonding.

The optimal performance at 1% treated fibers with NaOH highlights the balance between mechanical enhancement and sustainable usage. Treated fibers provide superior bonding and durability while maintaining minimal environmental impact compared to synthetic reinforcements. Using RFs, a renewable and biodegradable resource, improves concrete's strength and toughness, reduces cracking, and enhances sustainability. This approach delivers better concrete performance and supports eco-friendly construction practices by reducing carbon emissions and reliance on energy-intensive materials like steel.

Figure 9 demonstrates the positive impact of RFs on concrete performance, particularly compressive strength, with 1% treated fibers (TRT) achieving optimal results of 62.11 MPa and 1.34 MPa standard deviation (SD) at 28 days. The inclusion of standard deviation confirms the consistency of the results across tested specimens.

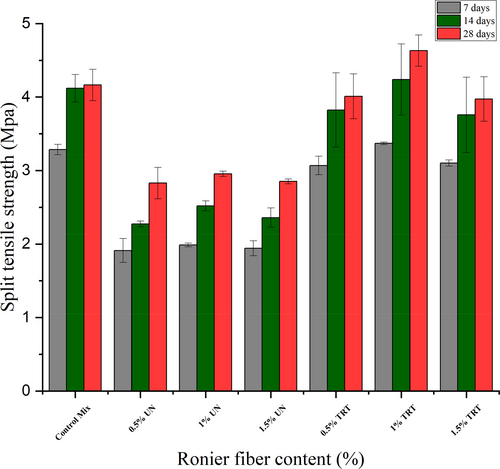

4.2 Split Tensile Strength

Figure 10 demonstrates that the addition of RFs significantly influences the tensile performance of concrete, with 1% treated fibers (1% NaOH) achieving the optimal split tensile strength of 4.631 MPa at 28 days, comparable to the control mix. Treated fibers (TRT) enhance concrete performance by improving fiber–matrix bonding, which allows for better crack-bridging and stress redistribution under tensile loads. This results in higher durability and toughness of the concrete. Untreated fibers (UN) also improve tensile strength to some extent, particularly at higher contents (1%), but their performance remains inferior to that of treated fibers due to weaker bonding with the cementitious matrix.

The incorporation of RFs improves concrete's resistance to cracking and tensile stresses, contributing to better long-term durability. Treated fibers, especially at the optimal 1% dosage, offer an efficient reinforcement strategy by enhancing the mechanical properties of the concrete. Additionally, their renewable and biodegradable nature supports sustainable construction practices by reducing dependence on synthetic and energy-intensive materials like steel, while maintaining or even improving the mechanical performance of concrete. This makes RFs a practical and environmentally friendly solution for enhancing concrete performance.

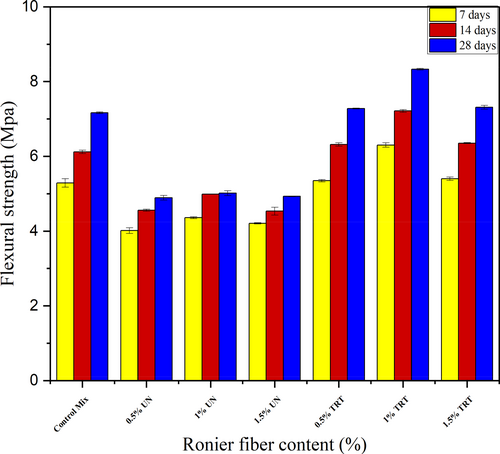

The treated fibers achieved optimal flexural strength of 8.33 ± 0.19 MPa SD at 28 days. Similarly, the split tensile strength peaked at 4.63 ± 0.16 MPa SD with 1% treated fibers, indicating a consistent enhancement in mechanical properties across multiple specimens.

4.3 Flexural Strength

Figure 11 shows how RFs significantly affect concrete's flexural performance, especially when 1% NaOH is added. The fiber-reinforced samples that match the control mix in terms of flexural strength (8.329 MPa at 28 days) are 1% treated fibers (TRT). By strengthening fiber–matrix bonding, treated fibers improve load transfer, stress redistribution, and crack-bridging in concrete. This results in increased toughness and durability, which improves the concrete's capacity to withstand bending pressures. Untreated fibers (UN), on the other hand, exhibit little improvement; at 1.5% UN, the flexural strength reaches a maximum of about 6 MPa, indicating a weaker interfacial bond.

In addition to enhancing concrete's mechanical qualities, RFs help make it more sustainable. Utilizing renewable and biodegradable ingredients obtained from B. aethiopum fruit, treated fibers ensure economical resource usage while delivering excellent flexural strength with a low dosage of 1%. By reducing the need for artificial and energy-intensive reinforcements such as steel, these NFs help to reduce the carbon footprint of buildings. RFs offer an efficient, environmentally friendly way to reinforce concrete while encouraging resilient and sustainable building methods by fusing improved performance with environmental advantages.

5 Durability Test

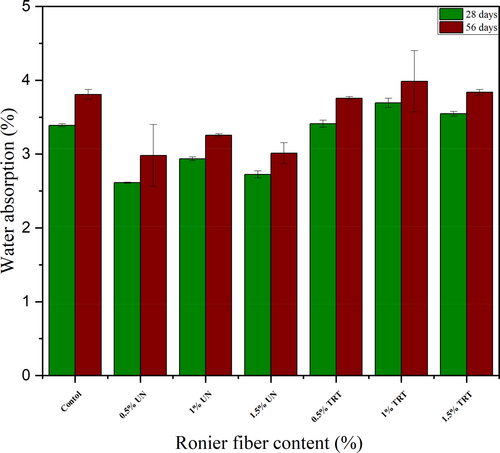

5.1 WA

The WA test, as shown in Figure 12, demonstrates that alkali-treated RFs significantly enhance the durability of concrete by reducing moisture infiltration. At 56 days, the WA rate for concrete reinforced with 1% treated fibers was 3.986%, compared to 5.312% for untreated fibers. This reduction is attributed to the alkali treatment, which decreases the hydrophilicity of the fibers and strengthens their interaction with the cement matrix by removing lignin and hemicellulose. Similar reductions in WA have been reported for rice husk and jute fibers following chemical treatment [28], supporting these findings. Additionally, studies on coconut fibers [29], as well as flax and hemp fibers [30], have shown that alkali treatment enhances moisture resistance by decreasing porosity and creating a denser cementitious matrix. However, higher fiber dosages can lead to the formation of voids that increase WA. The optimal 1% dosage of treated fibers in this study strikes a balance between reducing WA and maintaining workability. These findings highlight the effectiveness of alkali-treated RFs in producing durable, sustainable concrete suitable for environments with high moisture exposure.

1% treated fibers (TRT) strike the best balance, maintaining manageable WA levels of 3.99, with 0.12% SD at 56 days. This low variation demonstrates the reliability of the WA results for treated fiber-reinforced concrete.

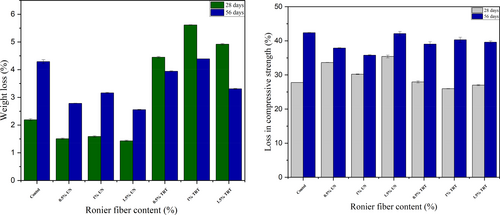

5.2 Sulfuric Acid

As illustrated in Figure 13, concrete reinforced with alkali-treated RFs showed noticeably more endurance in the sulfuric acid resistance test than untreated fibers. When exposed to a 3% sulfuric acid solution for 56 days, concrete with 1% alkali-treated fibers shed just 2.7% of its weight and retained 92% of its compressive strength. Concrete reinforced with untreated fibers, on the other hand, only kept 85% of its strength and lost 5.1% of its weight. The main reason for the treated fibers' increased acid resistance is the removal of hemicellulose and lignin during the alkali treatment procedure, which lessens the fibers' vulnerability to chemical deterioration. By strengthening the link between the fibers and the cement matrix, alkali treatment also makes the structure more impermeable, reducing acid penetration and the resulting damage.

These findings are consistent with earlier research by [26], which showed that NFs treated with alkali-enhanced acid resistance in high-strength concrete in a similar manner. Additional evidence supports the significance of chemical alteration in improving acid tolerance. Jute and flax fibers treated with alkali, for example, showed better structural stability and less weight loss in acidic environments [27]. Similarly, Rahim et al. [31] demonstrated how surface treatment might lessen microcracking and fiber damage in harsh chemical conditions.

The current investigation demonstrates that the best balance between workability and durability is achieved with a 1% dosage of treated RFs. Higher fiber dosages can lessen acid resistance by introducing microvoids and affecting workability, even though they may help manage cracks. For concrete constructions subjected to harsh chemical conditions, such as industrial floors, wastewater treatment plants, and maritime infrastructures, 1% treated RFs thus become a viable and sustainable option.

After 56 days of exposure to a 3% sulfuric acid solution, the concrete containing 1% treated fibers exhibited a 2.7% ± 0.21% SD weight loss and retained 92% ± 1.1% SD of its compressive strength. This statistical validation ensures that the performance improvements are consistently reproducible.

6 Conclusion

This study investigates the mechanical and durability properties of concrete reinforced with treated and untreated RFs (B. aethiopum). The fibers were incorporated into concrete at different proportions (0.5%, 1%, and 1.5%) by volume, with some treated using 1% NaOH to enhance bonding with the cement matrix. The chemical treatment improved fiber–matrix interaction by removing impurities such as lignin and hemicellulose, leading to superior performance in strength and durability tests compared to untreated fibers.

The findings showed that concrete reinforced with 1% treated fibers achieved the best overall performance. Treated fibers enhanced compressive strength (62.117 MPa), tensile strength (4.631 MPa), and flexural strength (8.329 MPa) at 28 days, while maintaining good workability. Although higher fiber contents improved crack resistance, they reduced workability and compressive strength slightly. Durability tests revealed that treated fibers reduced WA and improved resistance to sulfuric acid, making the concrete suitable for harsh environments.

From a sustainability perspective, the use of RFs derived from a natural and renewable source offers an eco-friendly alternative to synthetic reinforcements like steel. Treated fibers improve the mechanical and durability properties of concrete while promoting reduced carbon emissions and material sustainability. This aligns with global efforts to reduce the environmental impact of construction materials.

In conclusion, this study demonstrates that treated RFs can significantly enhance the mechanical properties and durability of concrete while supporting sustainability goals. The optimal 1% dosage of treated fibers offers a practical balance between strength and workability, making them a promising reinforcement material for sustainable construction.

Author Contributions

Mandelot-Matetelot Saint Jacques Le-Majeur: conceptualization, investigation, funding acquisition, writing – original draft, methodology, visualization, formal analysis, supervision, resources, validation. Philip Mogire: writing – review and editing, supervision, resources, formal analysis, visualization, validation. Brian Odero: writing – review and editing, formal analysis, supervision, resources, validation, visualization.

Acknowledgments

The authors thank the African Union and the Pan African University for Basic Sciences, Technology, and Innovation for funding and supporting this research. They also appreciate Jomo Kenyatta University of Agriculture and Technology for its laboratory facilities.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

The data presented in this study are available from the corresponding author upon request.