The Preparation of a Modifier for Recycled Aggregate and Its Effect on Properties of Recycled Aggregate

ABSTRACT

In this study, silicon-based hybrid material modifiers were synthesized using organic–inorganic hybridization methods from polyvinyl alcohol and nano-SiO2 as principal raw materials. The effects of the hybridization ratio and various factors on the workability and mechanical properties of cement mortar were systematically studied. Subsequently, the hybrid material modifiers were optimized to improve cement performance to enhance recycled aggregate. The experimental results show that the hybrid enhancement with the developed silicon-based modifiers improved mortar workability, increased its water retention, and reduced the water absorption rate of recycled aggregate by 35%, in addition to a 30% decrease in the crushing value.

1 Introduction

The rapid expansion of China's construction industry has inevitably led to the depletion of natural resources such as natural sand and gravel, as well as the constantly increasing accumulation of considerable urban construction waste. From 2020 to 2023, the production of concrete in China has shown a trend of decline year by year. Specifically, data indicates that the concrete output was 2.944 billion cubic meters in 2020, slightly increasing to 3.293 billion cubic meters in 2021, but significantly dropping to 2.397 billion cubic meters by 2023. At the same time, the demand for sand and gravel aggregates across the country has also shown an overall downward trend during this period. The consumption of sand and gravel aggregates was 17.826 billion tons in 2020, increasing to 18.691 billion tons in 2021, but falling to 15.172 billion tons by 2023. This series of data reflects the market changes and fluctuations in resource demand within the Chinese construction industry during this period. The annual amount of construction waste in China is approximately 2.0 billion tons [1]. Failing to effectively and timely manage and process construction waste results in safety hazards, air quality deterioration, water pollution, land occupation, and soil quality degradation. A resource-based approach to waste utilization, involving processes such as crushing, purification, and sieving to convert construction waste into recycled aggregates (RA) as a substitute for natural aggregates, has emerged as a sustainable solution. The formation of construction waste not only mitigates the scarcity of natural sand and gravel resources but also effectively addresses the challenges related to construction waste management. However, the complex composition of construction waste and substantial variations in its origin result in inferior quality of RA compared to natural counterparts, for example, rough surface, poor uniformity, higher impurity level, greater porosity, and increased water absorption. Recycled aggregate concretes (RAC) with such deficiencies do not satisfy engineering requirements, which limits their widespread practical applications. Hence, research on the modification and enhancement of the materials is critical to overcome the inherent disadvantages of RA and enable the utilization of RA-based products.

The current RA modification methods can be primarily divided into two categories [2-4]. The first category comprises the removal of defects from RA via microwave treatment, mechanical grinding, and acid immersion, aiming to directly eliminate adhered mortar from the surface of RA. The second category of modification methods focuses on enhancing the performance of surface cracks and adhered mortar on RA by employing various reinforcement methods, including polymer immersion, carbonation, bio-deposition, and improved mixing processes. It should be noted that these methods consume significant energy, incur high costs, and may potentially damage RA [4]. Moreover, some modification approaches are limited to laboratory research and may not be suitable for large-scale applications.

Inherent characteristics of nanomaterials, that is, small particle size and high reactivity, are frequently used to mitigate microstructural defects in RAC [5-7]. Nano-SiO2 and nano-CaCO3 demonstrated their effectiveness in enhancing the microstructure of the interfacial transition zone (ITZ) and sealing microcracks within RA, thereby enhancing the fundamental mechanical properties and durability of RAC [8-13]. Yuan et al. [14] modified RA by immersing it in a nano-SiO2 sol for 2 days, and the compressive strength, flexural strength, splitting tensile strength, and axial compressive strength of the nano-SiO2 sol-modified RAC were increased by 13.3%, 2.1%, 4.3%, and 19.4%, respectively, compared to the control group. Nevertheless, soaking or spraying typically results in the physical adsorption of nanomaterials on the surface of RA, leading to their relatively weak bonding to RA. An effective approach to further enhance the performance of RA involves in situ grafting or direct growth of nanomaterials on RA.

Silane-based modifiers can increase the bond strength in the ITZ of RAC, but they may also reduce the mechanical properties and durability of concrete [15, 16]. Kou and Poon [17] demonstrated that treatment with polyvinyl alcohol (PVA) solution improved the physical properties of RA. Speth and Tegguer [18] immersed RA in siloxanes and silane polymer solutions and found no significant change in the compressive strength of RAC, while its water absorption rate was notably reduced.

Organic–inorganic hybrid materials represent a novel class of materials formed via molecular interactions between organic and inorganic substances [19]. Hybrid materials with exceptional performance can be synthesized by optimizing and complementing the properties of two or more organic materials in conjunction with inorganic materials.

In this study, we have independently developed a silicon-based hybrid material for the modification and enhancement of RA. The hybrid materials form a hydrophobic film on the surface of RA via immersion and spraying, enveloping the RA surface and preventing water molecules from entering and accumulating on it. During its hydration, cement reacts with inorganic components within the hybrid material. Cement, water, and cement hydration products penetrate into the pores on the RA surface, thereby increasing the bond strength in the ITZ between RA and cement mortar, consequently enhancing the overall mechanical properties of RAC.

2 Experimental Procedure

2.1 Materials

2.1.1 Binder Materials

Portland cement P.O 42.5, commercially available grade-II fly ash, and slag powder (Ground Granulated Blast Furnace Slag [GGBFS]), grade S95 were used in the experiments. The chemical composition of the binder materials is shown in Table 1.

| Composition | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 |

|---|---|---|---|---|---|---|

| Cement | 20.12 | 6.63 | 4.72 | 61.78 | 1.21 | 3.43 |

| Slag powder | 31.08 | 16.01 | 0.389 | 40.63 | 7.63 | 1.35 |

| Fly ash | 47.97 | 32.85 | 5.73 | 7.20 | 1.15 | 1.02 |

| Nano-SiO2 | 67.02 | 19.79 | 4.02 | 2.04 | 1.71 | 0 |

2.1.2 Aggregate

Recycled coarse aggregates (hereinafter referred to as RA): RA was sourced from a demolition site of a construction project in Shenzhen. Following crushing and sieving, RA with a size between 10 and 30 mm was selected, with a minor inclusion of red bricks. Performance indicators are given in Table 2.

| Coarse aggregate type | Gradation/mm | Water absorption/% | Crushing index/% | Apparent density/(kg m−3) | Bulk density/(kg m−3) |

|---|---|---|---|---|---|

| RA | 10–30 | 9.53 | 12.3 | 2550 | 1160 |

Washed sand: we used commercially available washed sand from Shenzhen. Particles larger than 4.75 mm and smaller than 0.15 mm were sieved out in the laboratory, and the fineness modulus of the washed sand was adjusted to 2.7 (Figure 1).

2.1.3 Chemical Reagents

PVA: Transparent white flakes with a 99% hydrolysis degree and a polymerization degree of 1700 were used.

Nano-SiO2: SiO2 nanoparticles with a diameter of 10–20 nm in the form of white powder were employed in this study.

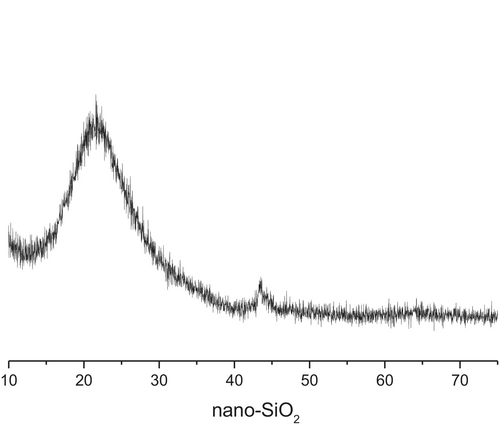

Surface active agent: Commercially available silane coupling agent KH550 was used (Figure 2).

2.2 Preparation of Silicon-Based Hybrid Material Modifiers

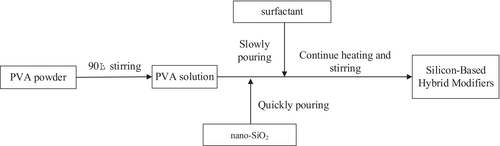

Silicon-based organic–inorganic hybrid materials were synthesized using a blending method. PVA solutions were combined with the nano-SiO2 to form hybrid composites. Hybrid solutions were prepared with various proportions of PVA, nano-SiO2, and SiO2 sol. The preparation process, as illustrated in Figure 3, was carried out under continuous stirring at 90°C in a water bath environment.

- PVA solid is accurately weighed and placed in water, then heated in a water bath at 90°C and continuously stirred for 150 min to prepare the PVA solution;

- Nano-inorganic materials are rapidly added to the PVA solution and stirred at 90°C for 20 min.

- The surfactant is slowly added to the mixed solution, which is then stirred in a water bath at 90°C for 60 min to prepare a silicon-based hybrid modifier.

-

Temperature

Temperature influences the uniformity and stability of the modifier. PVA solid dissolves at temperatures of 90°C and above. Stirring at high temperatures helps improve the uniformity and stability of the PVA solution. A uniform PVA solution can effectively disperse the subsequently added nano-inorganic materials, affecting the final physical and chemical properties of the modifier.

-

Dispersion of inorganic nano materials

Rapidly adding nano-inorganic materials and ultrasonically stirring at high temperatures help enhance the dispersion of the nano materials and avoid agglomeration. Good dispersion can improve the mechanical properties and thermal stability of the modifier.

-

Addition of surfactants

Slowly adding surfactants can control their distribution in the solution, promoting the interaction between nano materials and PVA, and improving interfacial adhesion. This has a positive impact on the performance of the modifier (such as wettability and adhesion).

-

Reaction time and temperature

The duration of stirring at an appropriate temperature (e.g., 150, 20, and 60 min) can affect the completeness and uniformity of the reaction, thereby influencing the final performance of the modifier. Longer stirring times can help improve the mixing uniformity and reaction extent of the materials, but excessively long stirring times can affect production efficiency.

2.3 Testing Methods

The performance of aggregates is tested according to the national standards GB/T 25177-2010 “Recycled Coarse Aggregate for Concrete” and GB/T 14685-2022 “Pebble and Crushed Stone for Construction.”

The water requirement and setting time of cement are determined following the testing methods specified in GB/T 1346-2011 “Test Methods for Water Requirement of Normal Consistency, Setting Time, and Soundness of Portland Cement.”

The workability of cement mortar is evaluated according to the testing methods outlined in GB/T 2419-2005 “Test Method for Fluidity of Cement Mortar” and JGJ/T 70-2009 “Standard for Test Method of Basic of Construction Mortar.”

The mechanical properties of cement mortar are tested in accordance with the standard GB/T 17671-2021 “Test Method of Cement Mortar Strength.”

3 Results and Analysis

3.1 Impact of Raw Materials on the Cement Mortar Performance

3.1.1 Impact of PVA on Cement Performance

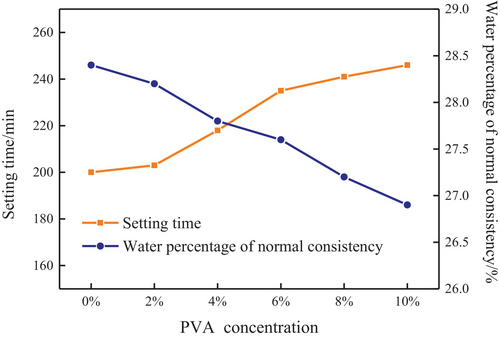

PVA solids were dissolved in a water bath at 90°C to prepare solutions of various concentrations. These solutions were added to cement mortar at a dosage of 5 wt% of the cement content to test the influence of PVA on the workability and mechanical properties of mortar.

Figure 4 shows that the water requirement for achieving the standard consistency of cement in the control group is 28.4%, that is, for 500 g of cement, 142 g of water is required to achieve standard consistency, with an initial setting time of 200 min. As the PVA concentration increases, the initial setting time of the cement paste extends, and the required water percentage for achieving standard consistency exhibits a linearly decreasing trend. With an increase in the PVA concentration dosage from 2% to 10%, the initial setting time of the cement paste increased from 203 min to 246 min, while the water requirement for standard consistency decreased from 28.2% to 26.9%. This phenomenon is attributed to the foam generated by the PVA solution during mixing, which, on one hand, acts as a lubricant in the cement, increasing its porosity and thereby reducing the water requirement; on the other hand, the foam envelops cement particles, preventing cement from contacting water, which decelerates the hydration reaction and consequently prolongs the cement's setting time.

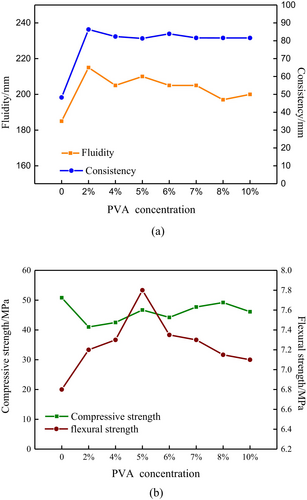

The addition of the PVA solution can improve the workability of cement mortar by increasing its flowability and consistency. Figure 5a shows that a PVA concentration of only 2% can significantly enhance the mortar's workability. Moreover, as the PVA content increases from 2% to 10%, the flowability and consistency of mortar remain essentially unchanged, independent of further PVA addition. However, the inclusion of PVA reduces the compressive strength of mortar, and it decreases to different degrees with the various PVA content. With a 2% PVA concentration, the compressive strength is 80% of that of the control group. However, as the dosage increases, the decrease extent lessens, and with an 8% PVA content, the compressive strength is 96% of that of the control group. The flexural strength of mortar initially increases, followed by a decrease in the PVA content. Without PVA, the mortar's flexural strength is 6.8 MPa. The addition of PVA increases the flexural strength of the mortar; when a 5% PVA concentration is added, the flexural strength peaks at 7.8 MPa (Figure 5b). As the PVA content increases further, the flexural strength decreases, reaching 7.10 MPa at a 10% PVA concentration, yet it remains higher than that of the control group. The PVA solution forms a film upon drying and, when uniformly mixed with the mortar, acts as a binder between RA and the hardened cement paste, increasing the bond strength and thus the flexural strength of the mortar. However, the introduction of PVA creates bubbles during mixing, which evolve into pores in the hardened mortar, resulting in a higher porosity compared to the control group. Additionally, some bubbles encapsulate cement particles, forming a film on the surface upon hardening, which prevents contact between cement and water, reducing the amount of cement available for hydration reactions and thereby decreasing the compressive strength of the mortar.

3.1.2 Impact of Nano-SiO2 on Mortar Performance

The hydration of cement yields calcium silicate hydrate (CSH), along with a significant amount of Ca(OH)2, tending to accumulate at the interface between concrete and aggregate and forming a weak bond in the ITZ, which affects the mechanical properties and durability of concrete. The pozzolanic activity of nano-SiO2 can be ascribed, on one hand, to dispersed nano-SiO2 particles in the cement paste, serving as nucleation sites for the growth of CSH and accelerating the hydration reactions of cement minerals, such as C3S and C2S [20]. On the other hand, nano-SiO2 can react with the hydration product, Ca(OH)2, in a pozzolanic reaction, reducing the concentration of Ca(OH)2 particles in the cement ITZ, and thus improving the overall performance of the ITZ.

The X-ray fluorescence (XRF) analysis of nano-SiO2 (Table 1) shows that SiO2 is the main component. The XRD analysis (Figure 2) reveals that nano-SiO2 exhibits a broad diffuse diffraction peak, indicative of an amorphous structure, representing a form of reactive SiO2. This further demonstrates, from a microscopic perspective, that nano-SiO2 used in this experiment possesses pozzolanic activity.

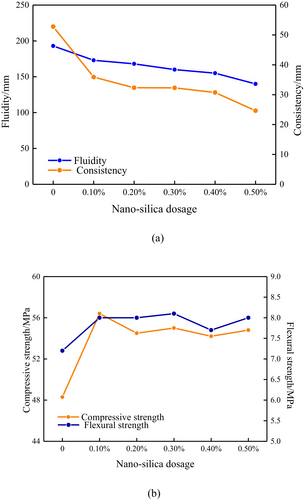

Incorporating nano-SiO2 can enhance the mechanical properties of mortar. As shown in Figure 6b, when the nano-SiO2 dosage is 0.1% of the cement mass, the compressive and flexural strengths of mortar increase by 16.8% and 10.4%, respectively, compared to the control group. However, a further increase in the nano-SiO2 dosage does not further improve the mortar's flexural and compressive strengths. Instead, these mechanical parameters show little difference or even a slight decrease compared to those determined at a lower dosage of nano-SiO2, which is because the addition of nano-SiO2 significantly reduces the workability of mortar. At a low dosage of 0.1%, the mortar flowability decreases by 10.4%, and the consistency increases by 32.0% in relation to the control group, as depicted in Figure 6a. By further increasing the nano-SiO2 dosage, the mortar workability continues to decline to the point where it completely loses workability, which affects molding, resulting in less dense cast specimens, with larger voids and more apparent defects, ultimately reducing the mortar strength (Figure 6a).

3.2 Impact of Silicon-Based Hybrid Modifiers on Mortar Performance

3.2.1 Impact of Silicon-Based Hybrid Materials on the Mortar Performance

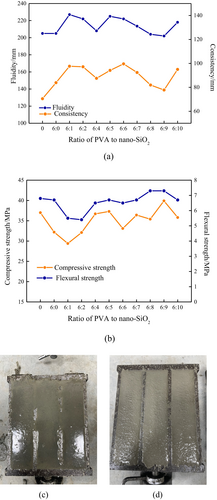

Silicon-based hybrid modifiers, containing PVA, enhance the workability of mortar. The incorporation of silicon-based hybrid modifiers increases flowability and reduces consistency compared to the control group and samples with only PVA added. Additionally, it mitigates bleeding and sticking to the bottom observed for the control group (Figure 7c,d) and improves the water retention of mortar.

Hybrid modifiers combine the characteristics of organic and inorganic materials. When PVA alone is added to mortar, the mortar workability is improved, but its mechanical properties decrease compared to the control group. Conversely, the addition of nano-SiO2 alone reduces workability and enhances mechanical properties. The incorporation of silicon-based hybrid modifiers prepared from the hybridization of both PVA and nano-SiO2 into the mortar improves its workability without compromising its mechanical properties. The workability of mortar is enhanced by adding silicon-based hybrid modifiers with varying organic–inorganic ratios. As shown in Figure 7a, the flowability of mortar with added modifiers slightly decreases with an increase in the inorganic component but remains higher than that of the control group (the dosage of different types of modifiers is 5 wt% of cement). Meanwhile, as the inorganic content in the silicon-based hybrid modifiers increases, the consistency of the mortar increases, but still remains lower than that of the control group. Comparing the mechanical properties of the mortar from the control group, that is, the group only with PVA, and the group only with silicon-based hybrid modifiers (Figure 7b), the compressive and flexural strengths of mortar increase with the inorganic component amount in the hybrid modifier. When a PVA-to-nano-SiO2 ratio of 6:5 is used, the compressive and flexural strengths of mortar are comparable to those of the control group. By further increasing the nano-SiO2 content, the mechanical properties of mortar slightly improve, although the extent of the improvement is not obvious.

The modifier is a silicon-based composite material formed by the chemical hybridization of PVA and nano-silica (nano-SiO2), possessing the physicochemical properties of PVA as well as the superior characteristics of nano-silica. On one hand, the organic molecules in the modifier create a slip layer between particles during the mixing process of cement mortar, utilizing the shear force generated by stirring, which significantly reduces the inter-particle friction resistance. On the other hand, the polymer chain structure of the modifier forms a three-dimensional network within the cement mortar, effectively counteracting the van der Waals forces and electrostatic attractions between cement particles. Additionally, the modifier exhibits certain surface activity and lubricating properties, facilitating interactions with the particles in the cement mortar, thereby improving their dispersion in the aqueous phase and enhancing the segregation resistance of the cement mortar. Consequently, the modifier can significantly enhance the workability of the cement mortar.

In the modifier, hydroxyl groups (OH) can form hydrogen bonds with calcium ions (Ca2+) and hydration products in the cement, thereby increasing the bonding strength between the cement and sand, which enhances the flexural strength of the cement mortar. The modifier possesses the pozzolanic activity of nano-silica, where the active silica (SiO2) reacts with calcium hydroxide (Ca(OH)2), a hydration product of cement, to generate calcium silicate hydrate (CSH) gel. This gel effectively fills the pores within the cement mortar matrix, resulting in a denser microstructure and significantly improving the mechanical strength of the cement mortar.

3.2.2 Film-Forming Ability of Silicon-Based Hybrid Modifiers

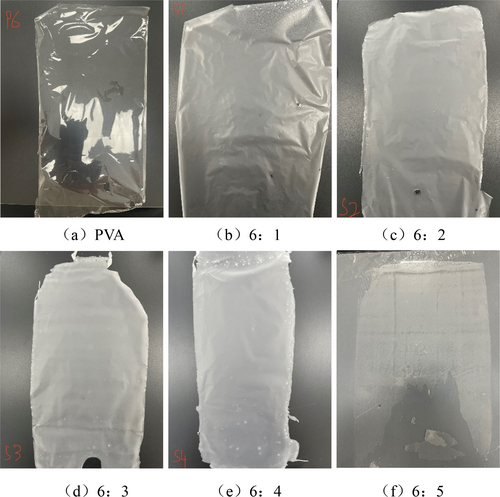

According to the initial design in this study, the silicon-based hybrid modifiers should exhibit the film-forming ability of PVA. The method for testing the film-forming ability of silicon-based hybrid modifiers involves precisely pouring the prepared solution onto an acrylic plate, then evenly spreading the solution across the plate using a wire-wound rod coater, ensuring that the modifier solution is uniformly and smoothly applied. After drying, a film of the modifier is obtained (Figure 8).

As the content of the nano-SiO2 material in the silicon-based hybrid modifiers increases, the viscosity also increases, leading to thicker films available from the same mass of solution but a decreased volume. The films produced from PVA solutions exhibit a thinner profile compared to hybrid modifier films, and the surfaces of PVA films tend to adhere to each other, despite PVA films having superior toughness. With an increase in the inorganic content, the thickness of the films increases, but their toughness decreases, so they become more brittle. A complete film can still be formed when the organic-to-inorganic ratio is 6:4. However, as the mineral content further increases, the film gradually adopts powder-like characteristics. When the organic-to-inorganic ratio reaches 6:6, the silicon-based hybrid modifier completely turns to powder.

The modifier forms a film layer on the surface of the recycled aggregate, primarily relying on the PVA molecules dissolved in the modifier. These PVA molecules interact through hydrogen bonding to create a network structure. When the modifier envelops the aggregate surface, the gradual evaporation of water molecules facilitates the aggregation and close packing of PVA molecules at the surface, resulting in the formation of a uniform film.

Upon immersing the modified film in an alkaline solution (to simulate the internal environment of concrete), it was observed that the film exhibited low solubility in the alkaline medium. After 6 months of immersion, the film material remained intact in the alkaline solution, although the solution became turbid. This indicates that the dissolution rate of the modifier film in an alkaline environment is extremely slow.

3.3 Performance of RA After Modification and Enhancement With Silicon-Based Hybrid Modifiers

3.3.1 Physical Properties of Silicon-Based Hybrid Modifiers-Enhanced RA

The water absorption rate of unmodified RA increases with the soaking time but grows more slowly in the first 8 h, reaching 64% of the absorption rate upon 24 h. Afterward, the water absorption rate of RA accelerates, reaching 99.5% of the 24-h absorption rate after 12 h. This indicates that RA can almost achieve the 24-h water absorption level after soaking for 12 h. Based on the water absorption evolution with time, the optimal modification time for RA is predicted to be 12 h.

RA was soaked in a silicon-based hybrid modifier solution for 1, 2, 3, 5, 8, 12, 24, 36, and 48 h. According to the physical properties of RA treated with the silicon-based hybrid modifier for various times (Table 3), the soaking duration improves the quality of RA. With an increase in the modification time, the water absorption rate and crushing value of RA decrease, without affecting the apparent density of RA. Table 4 shows that the 2-h water absorption rate of RA modified for different durations drops to about 85% of that of unmodified RA, and its 24-h water absorption rate decreases with the modification time. When the modification time is 8 h, the water absorption rate of the modified RA is 5.89%, reducing to 62% of that of unmodified RA. At a modification time of 12 h, the water absorption rate of modified RA is 5.45%, only 57% of that of unmodified RA. Further increasing the modification time does not significantly reduce the water absorption rate of the modified RA, so 12 h is the optimal modification time from the perspective of water absorption performance.

| Water absorption at different times/% | Apparent density/kg/m3 | Crushing value/% | ||||||

|---|---|---|---|---|---|---|---|---|

| 1 h | 2 h | 3 h | 5 h | 8 h | 12 h | 24 h | ||

| 5.88 | 5.56 | 5.77 | 5.55 | 6.15 | 9.48 | 9.53 | 2450 | 12.3 |

| Modification time | 1 h | 2 h | 3 h | 5 h | 8 h | 12 h | 24 h | 36 h | 48 h |

|---|---|---|---|---|---|---|---|---|---|

| 2 h-water absorption/% | 4.97 | 5.27 | 4.71 | 4.62 | 4.51 | 4.55 | 5.01 | 4.60 | 4.76 |

| 24 h-water absorption/% | 7.68 | 7.21 | 6.92 | 6.58 | 5.89 | 5.45 | 5.02 | 5.00 | 5.08 |

| Crushing value/% | 10.9 | 10.3 | 10.55 | 9.8 | 9.0 | 8.9 | 8.6 | 9.1 | 9.3 |

| Apparent density/kg/m3 | 2470 | 2460 | 2490 | 2450 | 2470 | 2480 | 2450 | 2480 | 2460 |

As the modification time increases, the crushing value of RA decreases. After 24 h, the reduction in the crushing value of RA tends to level off and does not decrease further, indicating that the optimal modification state for the crushing value of RA is achieved after 24 h. At this point, the crushing value of the modified RA is 8.6%, that is, 30% lower compared to 12.3% of unmodified RA. For a modification time of 12 h, the crushing value of the modified RA is 8.9%, which is 27.6% lower compared to unmodified RA, showing little difference from the 24-h modification. Considering the crushing value, water absorption rate, and construction process, a modification time of 12 h is chosen as the optimal one.

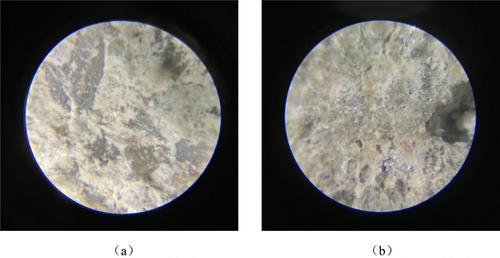

3.3.2 Surface Changes of RA Before and After Enhancement

Figure 9 shows the surface morphology of RA recorded under a 4× optical microscope. The surface of RA is rough, and the interface between old mortar and natural stone is a naturally weak area, more prone to cracking during mechanical crushing. After soaking RA in the silicon-based hybrid modifier designed in this experiment to enhance modification, as shown in Figure 9b, a film formed by the modifier on the surface of the aggregate can prevent water from entering the aggregate interior. Additionally, nano-SiO2 in the modifier reacts with Ca(OH)2 in RA to produce CSH, filling the voids within the aggregate and thus further densifying the surface of RA. Consequently, the water absorption rate and crushing value of the modified RA are reduced.

4 Conclusions

The silicon-based hybrid modifiers were developed in this experiment with favorable characteristics of both organic PVA and inorganic nano-SiO2, which addition improved the workability of mortar, increased its flowability, and reduced its consistency, while the mechanical properties of mortar were not adversely affected.

The enhancement duration affected the water absorption rate and crushing value of the modified RA, and slightly influenced the apparent density of RA. The optimal enhancement time in this experiment was 12 h, during which the water absorption rate of the modified RA was reduced to 57% of that of unmodified RA, and the crushing value was reduced to 72.3% of that of unmodified RA.

The possible reason is that the silicon-based hybrid modifier formed a hydrophobic film on the surface of RA, preventing water molecules from entering RA and thereby reducing its water absorption rate. Additionally, the reaction of the silicon-based hybrid modifier with Ca(OH)2 to produce C-S-H filled the voids within RA, further reducing the water absorption rate and crushing value of RA.

The experimental results shed a light on the resource utilization of construction wastes with high mechanical properties.

Author Contributions

Zhengsong Yang: data curation, validation, writing – original draft. Weibin Li: supervision, writing – review and editing.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.