Palmyra Palm Shell (Borassus flabellifer) Properties Part 1: Insights Into Its Physical and Chemical Properties

ABSTRACT

Bio-based materials are gaining importance in engineering due to their availability, recyclability, and eco-friendliness. Among them, Borassus flabellifer (Palmyra palm) fruit shell (husk) is an underutilized biofiber in Bangladesh, currently limited to disposal or waste-to-energy applications despite its potential for high-value uses. This study explores the physical, chemical, and microstructural properties of untreated Borassus flabellifer husk to evaluate its suitability as a sustainable material for engineering applications. The physical properties, including density, water absorption, moisture regain, and porosity, were assessed according to BS EN ISO 1183-1:2019, ASTM D750, ASTM D2654-22, and ISO 2738 standards. The husk was found to be significantly lighter than its fine as well as coarse fibers and conventional natural fibers like jute, flax, and sisal, making it ideal for lightweight engineering designs. FTIR analysis (qualitatively) revealed the presence of cellulose, hemicellulose, and lignin, which contribute to its mechanical strength, water absorption, and thermal insulation properties, respectively. SEM analysis further demonstrated a cross-linked, porous, and tubular fiber structure, enhancing its thermal and sound insulation features. The findings suggest untreated Borassus flabellifer husk can be a promising alternative for applications requiring lightweight, thermally, and acoustically insulating materials. While its moisture and water resistance outperform some biofibers, chemical treatments could enhance these properties further. To maximize its potential, efficient collection and supply chain systems are essential for industrial-scale production. Harnessing this abundant resource could support sustainable development while encouraging the cultivation and preservation of Borassus flabellifer trees.

1 Introduction

Global environmental concerns have driven the scientific community to explore eco-friendly and renewable natural fibers as alternatives to synthetic ones, due to their superior properties. Prolonged use of synthetic fibers has been linked to serious health risks, including cancer and skin disorders. Additionally, synthetic fibers are non-biodegradable and have limited recyclability, which worsens environmental challenges [1, 2]. Furthermore, Siciliano and co-researchers [3] stated that adopting bio-based low-carbon goods might reduce CO2 emissions from the materials' production process by more than 80%. It has been discovered that the disposal of synthetic fiber-based composite materials is a serious problem at the conclusion of the life cycle process, and during incineration, roughly 50% of the entire volume remains as a residue (unburned) [4].

As global temperatures and greenhouse gas emissions continue to rise, the United Nations Environment Programme's (UNEP) latest Emissions Gap Report finds that current Paris Agreement pledges put the world on track for a 2.5°C–2.9°C temperature rise above pre-industrial levels this century, highlighting the urgent need for increased climate action [5]. In accordance with this agreement, European Union (EU) members have vowed to put the EU on track to become the first climate-neutral economy and society by 2050, and the EU submitted its long-term carbon emission reduction strategy and vowed to cut emissions by at least 55% by 2030 compared to 1990 levels [6, 7]. Furthermore, the EU agreed to keep global average temperature rise to well below 2°C above pre-industrial levels, with efforts to limit it to 1.5°C [8].

To encounter the aforementioned context, natural fibers can play a crucial role in manufacturing green materials. The non-biodegradable qualities of synthetic fibers are causing global problems in reducing consumption. Hence, the industrial and academic sectors are increasingly showing an increased interest in natural fiber-based products. Natural fibers and bio-waste could be ideal alternatives to petroleum-based plastics since they are readily available, recyclable, and eco-friendly, Mohanty, Misra et al. [9], Mohanty, Amar et al. [10], Kumar et al. [4] reported that in 2010, the global natural fiber polymer composite material market had the highest value of USD289.3 million in 2010 and is expected to be increased by USD531.3 million in the next 10 to 12 years. Whereas Siciliano et al. [3] suggested that the global market for bio-based insulation is expected to reach USD 229 million by 2027, with a compound annual growth rate of 23.1% from 2022 to 2027.

Natural lignocellulosic fibers, like jute, flax, sisal, coir, palm, and so on, contain cellulose, hemicellulose, and lignin [11]. Cellulose is a primary structure of the cell wall. Cellulose has a crystalline structure that gives high strength to the plant. It has a long polymer chain with a high degree of polymerization and high molecular weight. Hemicellulose has a random unshaped structure that gives low strength and a low degree of polymerization. Lignin is a complex branched polymer of phenyl propane and is an important part of the plant's secondary cell walls. Lignin acts as a bonding agent for cellulose fibers that hold neighbor cells together, and its thermal durability is better than that of cellulose and hemicellulose [4, 12-15]. Nevertheless, the variation in the properties of any natural fibers is primarily attributed to their origin, climatic conditions, and growth period, leading to non-uniformity in physical properties along their length [16-18].

Palmyra Palm is a species of Borassus flabellifer, which belongs to the palm (Arecaceae) family. It contains over seven kinds, depending on the tree structure and tropical zone where it is planted. This is often known as the Asian palm, is the most significant of these species and has a wide range of commercial applications [17, 19]. For example, the leaf has long been used for fuel and thatching material and for weaving baskets, mats, boxes, caps, fans, toys, country umbrellas, etc. [20-22]. Fruits are being used in the production of jelly, cordials, ice cream, pastries, jams, drinks, and toffee, and the apple pulp can help treat skin inflammations. It treats nausea, vomiting, and worm infestation [16, 21, 23]. The trunk has been used as wood for construction and furniture and is also considered raw material for making wharf pilings into pillars, beams, and rafters [21, 22]. The tree root has been used to treat some respiratory illnesses since it is diuretic and anthelmintic. Nevertheless, the husk has been considered agricultural waste and used as fuel for cooking food in rural Bangladesh [24], which adversely affects the environment.

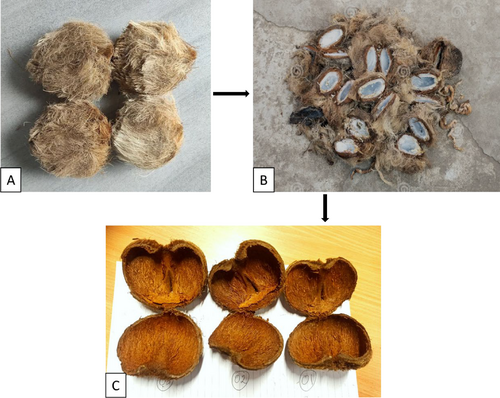

Borassus fibers are primarily harvested from the fruit of the Borassus flabellifer palm tree. However, they can also be extracted from the leaf and bark through mechanical and water retting methods. The properties of these fibers vary depending on the part of the plant from which they are sourced—whether from the fruit, sprouts, or leafstalks. This variation affects the fiber aspect ratio, a key factor influencing the performance of composite materials [25, 26]. Therefore, many researchers investigated the physical and chemical properties of Borassus fine and coarse fibers to evaluate their feasibility as an alternative material to existing conventional biofiber, such as jute, flax, sisal, coir, and hemp, to promote sustainable development. Saravanya and co-workers [27] extracted fiber from Borassus sprouts using manual and water retting techniques, and the densities were found to be 1.47 and 1.36 g/cm3, respectively, while Boopathi and co-workers [28] extracted fiber from Borassus fruit and found the density to be 1.26 g/cm3. Balakrishna and co-researchers [29] found that the density of the Borassus leafstalks was 0.7 g/cm3. The reported composition of Borassus flabellifer lignocellulosic fibers includes cellulose (45%–70%), hemicellulose (14%–32%), lignin (5%–30%) and extractives that may offer distinct mechanical and thermal properties [19]. Table 1 summarizes the properties and composition of Borassus fiber as reported in the literature, and Figure 1 shows the Borassus fruit shells (husks).

| Composition | |||||

|---|---|---|---|---|---|

| Parts of the plant | Density (g/cm3) | Cellulose (%) | Hemicellulose (%) | Lignin (%) | Reference |

| Fruit | — | 50 | — | — | [30] |

| Fruit | — |

45.67 [Coarse] 53.40 [Fine] |

32.76 [Coarse] 29.60 [Fine] |

21.53 [Coarse] 17 [Fine] |

[31] |

| Sprouts |

1.47 [Manual] 1.36 [Water retting] |

61.72 [Manual] 55.63 [Water retting] |

— |

23.25 [Manual] 30.66 [Water retting] |

[27] |

| Fruit | — | 70 | 14 | 11 | [32] |

| Fruit | — |

53.40 [Fine] 45.67 [Coarse] |

— | — | [33] |

| Fruit | — | 53.40 | 29.60 | 17 | ([34]; [35]; [36]) |

While from the engineering material perspective, low density and porous properties are desirable for manufacturing lightweight insulators, yet low moisture as well as water absorption is also required because a higher sorption value deteriorates material mechanical properties.

Density and porosity are fundamental physical properties of any materials. While evaluating the mechanical performance of any dynamic designs, such as automobiles and aircraft, density is arguably the most important factor that defines the potential application of the fiber as a lightweight engineering material [37, 38], and porosity content is significant for the thermal insulation property [39-42]. The density of homogeneous solid materials is relatively easy to determine, as it only requires measurements of weight (or mass) and volume. However, measuring the density of natural fibers is more complex due to their porous structure and diverse geometry. Currently, there is no standardized testing method for determining the density of natural fibers in the industry [43]. They carried out density measurement tests on oilseed flax fiber and found the density in the range of 1.4–1.6 g/cm3. Nevertheless, they recommended selecting any fluid with low viscosity and surface tension, because it coats the fiber well, and it allows the fiber to sink into the fluid and be easily immersed. Amiri et al. [44] carried out density measurement experiments on flax fiber and found the density within the common range of 1.28–1.5 g/cm3, whereas Huo and co-workers [45] used the Archimedes method with distilled water as the immersion liquid and found the density of linen flax fiber to be 1.42 g/cm3. They finally recommended two methods: Archimedes (with the use of canola oil as immersion fluid) and helium pycnometry for their accuracy and reliability.

De Kerariou and co-researchers [46] investigated the impact of the porosity of flax fiber using scanning electron microscopy (SEM), ultrasonic C-scans, and gravimetric analysis. They reported that gravimetric adherence to Archimedean law using ethanol provides consistent and reliable results compared to the other two methods mentioned earlier. They revealed that the hygroexpansion is not substantially affected by changes in porosity—the lower the porosity, the slower the moisture ingress, and the tensile strength and stiffness decrease with the increase of void content. Researchers [47] investigated porosity using the toluene displacement method (using pycnometry) of pea (Pisum sativum) seed and found the porosity to be 40.32%.

Water absorption is an important ground for the degradation in the mechanical performance of the natural fiber and composites made of this, which resists them from being used in outdoor applications. Nevertheless, water absorbency is a key quality in textile fibers as it determines comfort properties in textile materials due to its influence on textile characteristics such as stiffness, frictional-mechanical properties, and electrical properties [11]. Additionally, the water absorption of fibers helps regulate humidity and improve the thermal and hygroscopic characteristics of buildings [48]. Sahu and Gupta [49] reviewed the effect of water absorption impact on material properties made of bio-fibers. They reported that the hydrophilic nature of cellulosic fibers is due to the hydroxyl groups in hemicellulose, cellulose, and lignin, which attract water through hydrogen bonding. Hemicellulose is the primary contributor to water absorption, followed by amorphous cellulose, lignin, and crystalline cellulose. Water absorption in biofiber-based composites follows a Fickian diffusion process at room temperature, but a non-Fickian process occurs at higher temperatures. The water absorption behavior is typically measured using ASTM D570, based on Archimedes' fluid displacement principle. Adebayo et al. [50] carried out a water absorption test on wood plastic composite as per ASTM D570, and they discovered that the tendency of cellulose at the filler-matrix interface to expand in the presence of water or moisture causes a shear stress at the interface, promoting ultimate debonding of the fillers and resulting in a loss in tensile strength. Hussain et al. [48] analyzed the effect of water absorption on tropical fibers, such as palm oil flower fibers, palm oil fruit fibers, sugarcane bagasse, coconut coir, and banana spine, and found that the water absorption was about 1–2 times their mass since natural fibers are hydrophilic in the presence of hemicellulose. Swelling and shrinkage of fibers occur during the interaction of fibers with water and drying, which induces voids in composites and affects their strength and performance.

The natural fibers are long-lasting, but when extracted by different mediums and different methods, they show different characteristics in the presence of moisture. Different natural fibers have different moisture absorption rates and different behaviors after moisture absorption [51]. Yalcin and co-workers [47] investigated the moisture absorption of pea (Pisum sativum) seeds with pycnometry using toluene and found the moisture content to be 35.08%. Sudhakara et al. [52] carried out an experiment on Borassus fine fiber-based composites and compared them with jute, sisal, and coir-based composites in terms of moisture and water absorption properties. They discovered that moisture uptake increases for Borassus fiber-based composites as fiber loading increases due to an increase in voids and cellulose content in the fiber, whereas water absorption in Borassus fiber-based composites is slightly higher than that of coir-based composites but lower than for jute and sisal-based composites. Boopathi and co-researchers [28] carried out an experiment on untreated (raw) Borassus fruit fiber and found the moisture content to be 8.04% in accordance with ASTM D2654-22 standards.

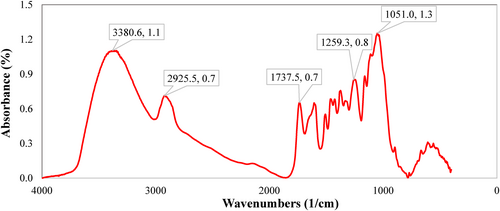

Fourier-transform infrared spectroscopy (FTIR) has been used in many studies to qualitatively confirm chemical changes caused by chemical reactions [13]. Previous studies [31, 33, 53] of FTIR on untreated Borassus fine fibers were carried out by dispersing the powdered fiber samples on KBr pellets at room temperature to analyze chemical compositions qualitatively and found the presence of three significant compositions, such as cellulose, hemicellulose, and lignin corresponding to hydroxyl (OH), alkyl (CH), carbonyl (CO), carboxyl (COOH) ether (COC) etc. at different wavenumbers, which arguably influence the fiber properties.

Most previous studies have focused primarily on the fine and coarse fibers of Borassus, with limited research conducted on Borassus husk fibers. Preliminary investigations into the thermal and mechanical properties of Borassus husk fibers have already been reported by the authors [54]. This paper presents an experimental study on the physical properties of untreated Borassus flabellifer husk fiber, including density (BS EN ISO 1183-1:2019), porosity (ISO 2738), water absorption (ASTM D 750) and moisture regain (ASTM D2654-22). It also examines its chemical properties using FTIR (ASTM E168-06 and ASTM E1252-98) and morphological characteristics through scanning electron microscopy (SEM). The study evaluates the potential of this fiber as an innovative bio-material for next-generation engineering applications.

2 Materials and Methods

Fruit shells of the Palmyra Palm (Borassus flabellifer) were collected from rural areas in Bogura, Bangladesh. The shells were cut and then thoroughly cleaned using a water-retting process, which is arguably the most widely used method [55]. Afterwards, the shells (Figure 2A) were sun-dried for several days and chopped into small pieces (Figure 2B,C) and prepared for physical and morphological experiments. Furthermore, they were crushed into powder (Figure 2E) using an electric blender (Figure 2D) to carry out chemical analysis. Figure 2 briefly represents the Borassus husk fiber preparation procedure.

2.1 Scanning Electron Microscopy (SEM)

A Hitachi S-3400N SEM was used to visualize the surface morphology of the shell. All the samples were mounted on aluminum posts using carbon conductive adhesive tape. Samples were sputter-coated before SEM analysis with a conductive gold layer using a Quorum Technologies SC7620 coater since biofibers are non-conductive. A low electron beam energy of 2–10 keV was used.

2.2 Fourier Transform Infrared Spectroscopy (FTIR)

Pellets were made with dried fibers, using potassium bromide (KBr) at a 2% concentration. The FTIR spectra of the untreated samples were acquired in the 4000–400 cm−1 range, with 36 scans at a resolution of 4 cm−1 using a Thermo Scientific Nicolet iS10 FTIR spectrometer and using ASTM E168-06 and ASTM E1252-98 standards in previous studies [35, 53, 56] to analyze chemical compositions of untreated Borassus husk fiber qualitatively.

2.3 Density Measurement

2.4 Water Absorption

2.5 Porosity

2.6 Moisture Regain

3 Results and Discussion

3.1 Scanning Electron Microscopy (SEM)

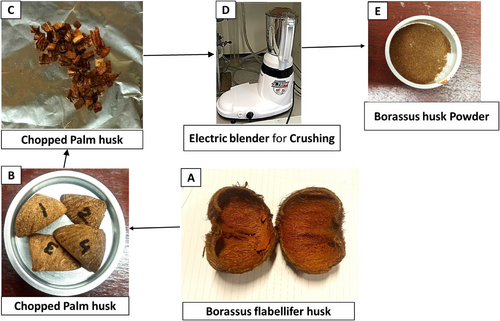

Figure 3 depicts the outcomes from the SEM experiment: the fibers appear to be elongated and have an uneven and rough surface, which is also found by Boopathi et al. [28] and Sarasini et al. [30]. However, other studies [27, 53] also found that the untreated fiber and Palmyra sprout fiber surfaces were smooth and compact. The arrangement seems relatively parallel (Figure 3A), suggesting that the fibers lie somewhat aligned, which is also found for wood apple shell material [64]. Furthermore, the fiber diameter is non-uniform, ranging from 150 to 300 μm (Figure 3B), and it is cylindrically hollow (Figure 3C). Researchers [3, 40, 42] suggested that porous structures can successfully reduce sound energy by increasing air-pore wall friction while also decreasing thermal transmission by reducing the material's cross-sectional solid area and increasing the tortuosity of heat transfer channels. Mawardi et al. [65] suggested that voids or pores have a direct connection with density and thermal conductivity properties, and they revealed that the density and heat conductivity were found to be less with increasing pores (voids) in the natural fibers. Figure 3 D reveals the cross-section of the fiber that is covered with impurities and wax content, which can be removed through chemical treatment [30, 55, 66-69]. Nevertheless, the average fiber diameter was reported to be 241.18 μm [28] and 140 μm [19] for Borassus fine fiber. Whereas the diameters of relevant plant-based bio-fibers, such as jute, sisal, and ramie have been reported as 5–30 mm, 7–47 mm, and 7–80 mm, respectively, in the previous works [70, 71].

3.2 Fourier Transform Infrared Spectroscopy (FTIR)

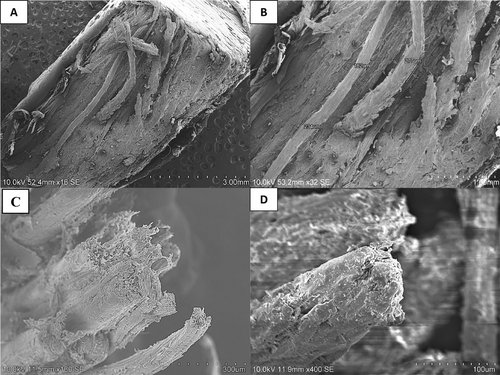

The spectra of the untreated fibers in Figure 4 revealed a significant absorption band for inter-molecularly linked hydroxyl (OH) groups at around 3413 cm−1. This observation provided evidence that the hydroxyl groups were engaged in hydrogen bonding. The CH stretching vibrations of the methylene/methylene units of all three ingredients were detected as a shoulder peak at 2920 cm,−1 owing to aliphatic saturated molecules, such as cellulose and hemicellulose.

A wide, medium-intensity ester carbonyl vibration at 1734 cm−1 was attributed to carbonyl (CO) stretching of acetyl groups in hemicellulose. The distinctive COC stretching vibration of hemicellulose ester groups was detected at 1252 cm−1. Peaks at 1618 and 1637 cm−1 are attributed to bending hydroxyl (OH) bonds that account for water absorption. The bands at 1509 and 1462 cm−1 corresponded to aromatic CC ring stretching and CH deformation in the methyl, methylene, and methoxyl groups of lignin. The bands at 1426, 1377, and 1320 cm−1 correspond to the CH2 scissoring, OH bending vibration, and CH asymmetric deformation of cellulose. The bands at 1162, 1109, and 1045 cm−1 correspond to the COC, CO, and CC stretching of cellulose. The analysis has been found to be consistent with previous research works [33, 34, 53]. Kabir et al. [14] reported that cellulose is considered the major framework component of the fiber structure, covered by hemicellulose and lignin constituents and provides strength, stiffness, and structural stability of the fiber. In lignocellulosic fiber, the hydroxyl groups present in the amorphous hemicellulose and lignin initially give access for water molecules to penetrate the fiber surface. Additionally, non-crystalline cellulose, with its nano-porous structure and exposed hydroxyl sites, affects the sorption process significantly [15]. Nevertheless, these compositions have also been found in conventional lignocellulosic fibers, such as jute, sisal, and flax, reported in previous works [71-74]. Moreover, the presence of hemicellulose, cellulose, and lignin contents has been suggested in the authors own work through TGA and DSC analysis [54].

3.3 Physical Properties and Moisture Interaction Characteristics

The density of the Borassus husk was found to be 0.74 ± 0.06 g/cm3, which is higher than its leafstalks' density, 0.70 g/cm3 [29] but less than its fine fiber (1.26 g/cm3) reported earlier. Dharmaratne et al. [12] found the density of brown coir fiber from Sri Lanka to be 1.02 g/cm3, using the pycnometry method. McNulty and co-researchers [75] used the pycnometry method to evaluate the density of grass. They used toluene and air as a reference fluids and found that the density of grass was 1.02 g/cm3 and 1.12 g/cm3, respectively. Hussain et al. [48] found that the density values of tropical fibers, such as palm oil flower fibers, palm oil fruit fibers, sugarcane bagasse, coconut coir, and banana spine, range from 0.79–1.36 g/cm3 and are influenced by lumen. Huo and co-workers [45] used the Archimedes method with distilled water as immersion liquid and found the density of linen flax fiber to be 1.42 g/cm3. The Borassus husk demonstrates a lower density, which can be linked to its higher porosity, as observed in the previous SEM analysis. This density is not only lower than that of synthetic fibers but also the lowest among common natural fibers, including jute (1.3–1.46 g/cm3), ramie (1.38–1.6 g/cm3), sisal (0.76–1.58 g/cm3), and hemp (1.47 g/cm3), as reported in the literature [71, 72, 76-78].

The water absorption of the samples was measured to be 46.58% ± 3.77%, and the moisture regain of the samples was found to be 4.41% ± 0.50%. The moisture regain of the raw Borassus fine fiber reported by Boopathi et al. [28] was 8.04%. While Kongdee et al. [11] found the water absorption of the cellulosic fibers, such as lyocell, viscose, and modal, to be 76%, 96%, and 71%, respectively, and the moisture regain found to be 11%, 12%, and 11%, respectively, the mean moisture content of the grass stem was found to be 83.4% [75]. Hill with co-researchers [79] carried out a comparative study on flax, jute, coir, cotton, and hemp on moisture and water absorption, and they found that jute (4.53%) and coir (4.14%) exhibited higher moisture contents compared to fibers having very low lignin levels, such as hemp (3.79%), flax (3.68%) and cotton (2.65%). They also suggested that cotton has the highest cellulose (94%), the lowest lignin (0%) and hemicellulose (6%), which can be the reason for the least moisture level.

The initial hypothesis of this study is that biomass with a higher proportion of hygroscopic components (such as hemicellulose and amorphous cellulose) compared to hydrophobic components (such as lignin and crystalline cellulose) will exhibit different equilibrium moisture content, primarily due to the accessibility of hydroxyl groups [15]. Hemicelluloses have a more open structure than cellulose and are thus more hydrophilic and soluble in water, but the sensitivity to water is drastically reduced when cellulose stacks to create crystalline areas [12, 14, 49, 51, 80]. Berthold with co-workers [81] reported that the higher values obtained for water absorption are attributed to the fact that water sorption in fibers is not limited to the pores alone; it can also occur on the surface of the fiber microstructures. Therefore, the observed water retention is the result of bound water, pore water, and surface water present within the fibers.

One of the primary reasons for the degradation of the mechanical properties of polymeric composites is the absorption of water by the fibers. This issue is particularly significant when water-permeable resins are used without incorporating fiber hydrophobic surface treatments or resin additives, limiting the composites' applications primarily to indoor environments. When fibers absorb water, the capillaries swell and expand, which activates microcracks. Water molecules then infiltrate the bulk matrix and travel along the fiber-matrix interface through capillary action, effectively acting as a bonding removal agent [50, 51].

Porosity was calculated, followed by the results obtained from the dry sample density and water absorption. The average porosity of Borassus husk fiber was found to be 34.55% ± 2.8%. Sacilik with co-workers [82] found the porosity of the hemp seed to be 46.5% and the cotton seed to be 41.1%. Yalcin with co-researchers [47] found the porosity of pea to be 38.64%. Kongdee et al. [11] investigated the pore volume of cellulosic fibers, such as lyocell, viscose, and modal, and found the pore sizes to be 0.59, 0.71, and 0.49 mL/g, respectively. Nevertheless, the earlier SEM analysis (Figure 3) revealed the porosity in the Borassus husk fiber, which can be linked with its low density. Porous structures are required for thermal insulation and noise reduction, such as for construction and cold-chain transportation in modern engineering applications [40, 42].

The low density, water absorption, and moisture regain can be attributed to hollow cylindrical porous tubes found in this research and previous studies [19, 83, 84]. The mechanical and thermal properties of untreated Borassus husk fibers have been studied in a separate work by the authors [54]. The findings indicate that these fibers show significant potential as an alternative biofiber for modern engineering applications that require materials with a porous structure, lightweight, promising strength, and thermal insulation properties. Nevertheless, high water absorption is a concern for mechanical strength to be compromised, which can be improved through chemical treatments [25, 85-87]. Table 2 summarizes all the experimental outcomes of untreated Borassus fruit shell (husk) fiber.

| Physical properties | Standard | Mean value | Standard deviation, SD | Coefficient of variance, CV (%) |

|---|---|---|---|---|

| Density (g/cm3) | BS EN ISO 1183-1:2019 | 0.74 | 0.06 | 8.53 |

| Water absorption (wt. %) | ASTM D 750 | 46.58 | 3.77 | 8.10 |

| Porosity (wt. %) | ISO 2738 | 34.55 | 2.80 | 8.10 |

| Moisture regain (wt. %) | ASTM D2654-22 | 4.41 | 0.50 | 11.39 |

4 Conclusion

- The density was found to be 0.74 g/cm3, which is lighter than its fine fiber (1.26 g/cm3) and other natural fibers, such as jute, flax, sisal, and hemp. This point to a potential utilization in lightweight engineering designs.

- Water absorption (46.58%) and moisture regain (4.41%) values are also lower than comparable plant-based fibers, such as lyocell, viscose, and modal, which may improve the weathering resistance of processed materials.

- The porosity of Borassus flabellifer husk was measured at 34.55%, which is lower than that of hemp seed (46.5%), cotton seed (41.1%), and pea. This lower porosity is associated with the material's low density and improved thermal insulation properties. The voids within the material act as scattering centers for phonons, thereby disrupting heat transfer and reducing the effective heat conduction volume of the material.

- FTIR analysis confirms the presence of cellulose, hemicellulose, and lignin, as well as other lignocellulosic fibers, such as hemp, flax, sisal, ramie, and even Borassus fine as well as coarse fiber. Cellulose offers mechanical strength, lignin is for thermal insulation property, and hemicellulose is responsible for water absorption property.

- The microstructure analysis from SEM reveals that the fibers are cross-linked, porous, and tubular, with diameters ranging from 150 to 300 μm. This diameter is smaller compared to fibers, such as jute, ramie, and sisal. The lower density of the material can be attributed to the presence of voids, as an increase in voids typically results in a decrease in density.

Author Contributions

Md Atiqur Rahman: conceptualization, methodology, formal analysis, resources, writing – original draft, funding acquisition, investigation, software, data curation, visualization. Mamadou Ndiaye: supervision, project administration, writing – review and editing, validation. Bartosz Weclawski: writing – review and editing, investigation, supervision, visualization, validation, project administration, methodology.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to privacy or ethical restrictions.