Visualization Analysis of Research Hotspots and Trends in Electrochemical Machining Based on Literature Big Data

ABSTRACT

Based on the big data of literature in the field of Electroforming processing, knowledge mapping and bibliometric methods are used in this article to conduct a visual analysis of the research hotspots, development trends, and research networks in this field. The results indicate that: (1) Research in the field of Electroforming processing has been shown to have a significant upward trend, reflecting the high attention and investment devoted to Electroforming technology by both academia and industry. Outstanding research performance in this field has been demonstrated by China, South Korea, and the United States, while core research forces in this domain are institutions such as the Chinese Academy of Sciences, Nanjing University of Aeronautics and Astronautics, Dalian University of Technology, and Seoul National University. (2) The co-occurrence analysis of keywords has revealed the close connection between Electroforming processing technology and hot technologies like resistance and memory, showcasing the broad application prospects of Electroforming processing technology across numerous fields, including electronics, materials, and biomedicine. (3) International cooperation in the field of Electroforming has been characterized by diversification and deepening, resulting in the formation of multiple cooperation networks encompassing Asia and Western Europe, North America and Asia, European scientific research powers, and emerging market countries. (4) Attention has continued to be paid to Electroforming technology in terms of precision and multidisciplinary integration. Driven by the increasing demand in aerospace, automobile manufacturing, and electronic circuits, innovations in Electroforming processing technology are constantly being made, thereby promoting the advancement of science and technology as well as the development of new materials.

1 Introduction

Electroforming technology, as an advanced manufacturing technology based on Electrochemical deposition principles, plays an important role in modern manufacturing [1, 2]. It has continuously attracted attention from academia and industry due to its excellent shape replication capability, high precision, and outstanding processing performance for complex structural components [3, 4]. In high-tech fields such as mold manufacturing, aerospace, and precision instruments, Electroforming has become an indispensable technology [5, 6], especially for microstructures or complex-shaped components that are difficult to achieve through traditional mechanical processing, highlighting its application value [7]. With the deepening of micro-fabrication, significant progress has been made in material selection, Electroforming solution formulation optimization, process control, and post-processing techniques for Electroforming technology [8-10].

Institute of Advanced Manufacturing Technology at Tsinghua University has made progress in microstructure control. They have successfully prepared metal parts with specific microstructures by regulating current density, temperature, and additive concentration during Electroforming [11], which show broad application prospects in micro-electromechanical systems, biomedical, and other fields. Nishimura et al. [12] and others from the Institute of Precision Engineering at Tokyo Institute of Technology have made progress in the manufacturing of three-dimensional complex structures. They have successfully achieved the direct manufacturing of high-precision, high-complexity three-dimensional metal structures using Electroforming technology combined with computer-aided manufacturing technology. This achievement is of great significance in the fields of aerospace, automotive manufacturing, and other fields. Nanyang Technological University in Singapore has conducted in-depth research on the preparation of functional surfaces. Chen et al. [13] and others successfully prepared functional surfaces with special physical and chemical properties on metal surfaces by introducing functional nanoparticles or coatings during Electroforming. These functionalized surfaces have shown excellent performance in catalysis, sensing, and corrosion prevention. Meng et al. [14, 15] mentioned that significant achievements have been made in the automation and digitization of electroplating production, which can achieve full automation and digital control from design to manufacturing, achieving the goal of reducing costs and improving efficiency. Tang and Septe [16, 17] focus on the application of electroplating technology in flexible electronic devices. By adjusting the current density and temperature, they successfully prepared metal mesh films with excellent flexibility and conductivity, providing a new method for the manufacturing of wearable devices and flexible displays. Zhu Di's [18] team at Nanjing University of Aeronautics and Astronautics focuses on the research of electrochemical micro-nano manufacturing technology, exploring the application of micro electroplating in high-precision machining, and improving machining accuracy and efficiency. Pan [19] and his team from Shanghai Jiao Tong University have made progress in surface treatment technology for electroplating. They have developed a novel surface modified electroplating process, which successfully forms a nano composite layer with excellent wear resistance and corrosion resistance on the metal surface, improving the service life of electroplated parts in extreme environments.

Significant improvements in the precision and performance of electroformed parts have been achieved by these breakthrough researches, leading to a substantial expansion of the application scope of Electroforming technology, particularly in the realms of microelectronics manufacturing, biomedical engineering, and nanotechnology. Electroforming technology is gradually being recognized as one of the key technologies driving technological progress. In recent years, bibliometrics, being a quantitative method for academic research, has been widely employed across various fields. Through bibliometric analysis, research hotspots, development trends, and the contributions made by important research teams and scholars in the field can be revealed.

Bibliometric research has garnered significant attention across disciplines, offering researchers deep insights into various fields. For example, Chen et al. [20] performed a comprehensive bibliometric analysis on the research output in environmental science over the past decade. Their study uncovered key trends, emerging topics, and influential authors, providing valuable guidance for future research directions in this critical field. Meanwhile, in the context of public health, Wang et al. [21] conducted a bibliometric analysis to assess the global research efforts on climate change and its impact on human health. Their analysis illuminated the publication patterns, major research institutions, and collaborative networks within this multifaceted research area. Diniz Oliveira et al. [22] evaluates USP's climate change publications from 1989 to 2022 using bibliometric analysis. It found increased output since 2010, with most collaborations national or with North American/European researchers. Three thematic groups emerged, highlighting USP's role in climate change research and potential for advancing the agenda with the Global South. Le et al. [23] uses bibliometric and text-mining analysis to explore AI advancements in surgical procedures. It assesses over 6000 scientific articles since 1990 to evaluate trends and inform managerial decisions on AI adoption. The study focuses on publications from influential publishers across North America, Northern Asia, and Europe, highlighting key markets for AI in surgery. Zhang et al. [24] explores trends in applying inorganic nanomaterials to autoimmune diseases from 1985 to 2024. Results show a 764% increase in annual publications, with China and the Chinese Academy of Sciences leading in productivity and influence. Emerging trends include combination therapy, microvesicles, and photothermal therapy, marking new frontiers in the field.

The research status, hot issues, and development trends in the field of Electroforming are comprehensively explored through systematic bibliometric analysis and content mining in this article. By analyzing high-frequency keywords, core research teams, research fields, and research frontiers in detail, a multi-dimensional and visual research framework has been constructed to uncover the evolution path and future direction of Electroforming technology. Through this comprehensive research, scientific decision support is provided for researchers and engineers in the field of Electroforming, further promoting theoretical research and application innovation in Electroforming technology.

2 Data Processing

2.1 Data Source

This study selected the original data of papers related to Electroforming processing from the WOS core collection database. The subject search formula used during the search was: TS = (“Electroforming” or “Electrodeposition”), with the type of paper limited to Article, and the search term set to “subject.” In order to obtain recent research results, the date range of the search was set from January 1, 2010 to March 31, 2024. After screening and eliminating the literature that was clearly unrelated to Electroforming, 1324 relevant articles were finally obtained as samples for this study. The extracted data information mainly includes the key information of the paper such as “keywords,” “title” “author,” “institution,” “country,” “journal,” “publication year,” “citation times,” and “funding institution,” in order to facilitate subsequent in-depth analysis and research.

2.2 Data Preprocessing

Deletion and merging of keywords. In order to standardize the sample keywords, the following selection rules were applied to the keywords: (1) deleting words unrelated to Electrochemical machining; (2) Merging words that are essentially synonyms or belong to the same category reduces the synonym rate of concepts, improves the accuracy of word frequency statistics, and prevents concepts with the same meaning from appearing in the keyword set. See Table 1 for some merged words.

| Merge type | Keywords before merging | Keywords after merging |

|---|---|---|

| Synonyms | Batteries, battery | Battery |

| Electrolytes, electrolyte | Electrolyte | |

| Hardness | Microhardness | |

| Biosensor, biosensors | Sensors |

3 Methods

In this article, co-occurrence network analysis [25] is used to quantify the co-occurrence information of domain keywords, and based on co-occurrence clustering and clustering visual analysis, the information association and the co-occurrence relationship implied by feature items are analyzed. A keyword analysis of the literature is conducted to analyze the hot topics and development trends in the field of Electrochemical machining.

An analysis of the co-occurrence network was performed on the countries, journals, and funding support mentioned in the published articles to examine the shifts and primary foci within Electroforming research. The co-occurrence matrix serves as a valuable tool for dissecting the relationships among words within texts and finds widespread application in bibliometrics and information science. Typically, the creation of a co-word matrix relies on a collection of keywords extracted from a corpus of documents. When two keywords concurrently appear in multiple documents, it suggests a correlation between them.

In the study of key words in electroplating processing in the article, based on the above method, the word frequency and co-occurrence matrix of domain keywords were calculated, and the co-occurrence matrix was imported into visualization software to obtain a visualization map through settings. The keyword frequency calculated in the article is shown in Table 8, and the co-occurrence matrix calculated is shown in Table 9. Due to space constraints, only a portion of the table data is presented in the article.

This article uses VOSviewer, CiteSpace, and cooc tools to visualize the authors, publishing institutions, publishing countries, research fields, and keywords in the literature. It uses scientific knowledge mapping and bibliometric visualization techniques to quantify the development context and research frontiers of Electroforming processing research and to mine, analyze, construct, draw, and display the research trends and their interrelationships in this field.

4 Results and Discussion

4.1 Field Overview

4.1.1 Evolution Characteristics of Document Volume

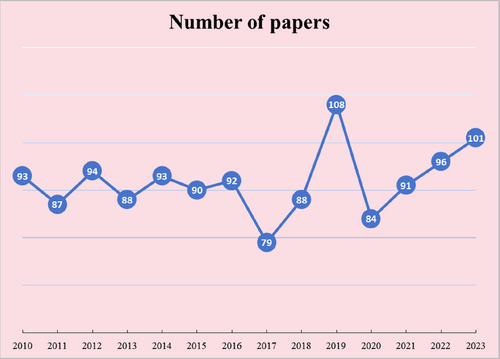

Through the quantitative analysis of the number of articles in the field of Electroforming research, we have initially grasped the development trends and hot topics in this field. Figure 1 shows the number of publications in the field of Electroforming research over the years, showing the trend of research papers in the field of Electroforming from 2010 to 2023 in the Web of Science (WOS) core collection. The literature data was collected up to March 2024, and the trend analysis here is up to 2023. This can better reflect the differences between years. Overall, the research field of Electroforming has shown significant development and hot trends through changes in the number of research papers published in the past 13 years (2010–2023). The blue curve in the figure represents the number of research papers in the field of Electroforming processing within the WOS core collection over the years, highlighting the research activity and development trend of this field during this period.

The trend of the blue curve indicates that the number of research papers in the field of Electroforming processing remained relatively stable from 2010 to 2013. This may suggest that the field was in a relatively mature and stable stage during this period, with researchers continuously exploring and accumulating knowledge. However, by 2014, a brief decline was observed in the number of papers. This decline may reflect some challenges or technical bottlenecks that the field was facing at that time, leading to a slowdown in research activities. It is noteworthy that since 2015, the blue curve has shown a clear upward trend, indicating that research activities in the field of Electroforming have been revitalized and have entered a stage of rapid development. This growth trend is expected to continue until 2023, demonstrating the optimism and continuous investment of researchers and academia in this field. This growth results from technology advances and improved manufacturing in Electroforming, enhancing accuracy, efficiency, and cost, broadening its applications. Additionally, new materials and technologies drive research in this field.

Based on the data in Table 2, an in-depth analysis of the number of publications, total citations, and average citations per article in the field of Electroforming processing can be conducted for each country (or region) to evaluate their scientific research activity and influence in this field.

| ID | State | Number of articles | Total cites | Citation frequency per article |

|---|---|---|---|---|

| 1 | China | 375 | 5011 | 13.36 |

| 2 | South of Korea | 210 | 4151 | 19.77 |

| 3 | USA | 206 | 5292 | 25.69 |

| 4 | Germany | 134 | 2905 | 21.68 |

| 5 | Japan | 76 | 777 | 10.22 |

| 6 | India | 60 | 906 | 15.10 |

Firstly, in terms of the number of publications, 375 publications are led by China, indicating that a high level of research investment and activity in the field of Electroforming processing is attributed to China. 210 and 206 papers are closely followed by South Korea and the United States, respectively, which are also recognized as global scientific research powers, making significant contributions across numerous fields. 134 and 76 papers are ranked fourth and fifth by Germany and Japan, respectively. Although their numbers are not as high as those of the top three, their performance cannot be underestimated, considering their strong capabilities in other technological fields. 60 papers are contributed by India, ranking sixth, showing that investments have also been made in Electroforming processing, and certain research capabilities are possessed by India.

Next, the total cited frequency is analyzed. The total citation frequency is considered an important indicator for measuring the recognition of research results by peers. 5292 citations are attributed to the United States, ranking first and far exceeding other countries, which reflects the high influence and academic value of its research achievements in Electroforming processing. 4151 citations are closely followed by South Korea, indicating that its research results have also received widespread attention and citations. Although the largest number of publications is contributed by China, its total citation frequency stands at 5011, which is slightly lower than that of the United States, potentially due to the diversity and quality distribution of its research results. 2905 and 777 citations are attributed to Germany and Japan, respectively, indicating that their research results have also gained a certain degree of recognition from their peers. 906 citations are attributed to India, which is relatively low; however, considering the relatively small number of publications, this figure falls within a reasonable range.

Finally, we analyze the average citation frequency per article. The average citation frequency per article is calculated as the ratio of the total citation frequency to the number of articles published, reflecting the average influence of each paper. The United States leads the list, with an average of 25.69 citations per paper, indicating that each paper is of extremely high academic value and influence. South Korea ranks second, with an average of 19.77 citations per article, also performing well. Germany and Japan are ranked third and fifth, respectively, with averages of 21.68 and 10.22 citations per article, suggesting that their research achievements in the field of Electroforming are also of high quality and influence. The average citation frequency for the People's Republic of China is 13.36, which, while not as high as the top three countries, still demonstrates that its research results possess certain academic value. India's average number of citations per article is 15.10, higher than Japan's but lower than that of other major countries, indicating an improvement in the quality of its research results.

Overall, the field of Electroforming processing is most outstandingly researched by the United States, South Korea, and China, in terms of both the number of publications, total citations, and average citations per article. Germany, Japan, and India have also made certain contributions in this field. In the future, it is expected that these countries may continue to increase their research investment in Electroforming processing to promote further development and innovation in this area.

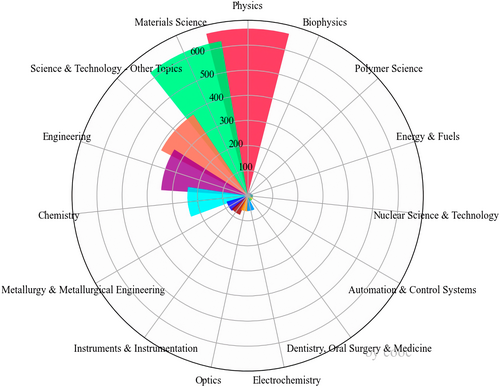

4.1.2 Evolution Characteristics of Research Fields

Based on the number of publications since 2010, it is observed that Electroforming processing encompasses 60 disciplines, with a threshold set at more than 12 publications. The research field ranking is presented in Table 3. The article analyzes the proportion and significance of each research field category within the overall research landscape. First, the number of records is dominated by Physics and Materials Science, which constitute 50.3% and 47.2% of the total, respectively. Together, these two fields account for nearly the entire research domain, reaching 97.5%. This indicates that the current Electroforming research environment is predominantly shaped by Physics and Materials Science, marking them as the most focused areas of scientific investigation.

| ID | Category of research field | Number of records | Percentage (%) |

|---|---|---|---|

| 1 | Physics | 666 | 50.3% |

| 2 | Materials Science | 625 | 47.20% |

| 3 | Science & Technology—Other Topics | 389 | 29.38% |

| 4 | Engineering | 345 | 26.05% |

| 5 | Chemistry | 240 | 18.12% |

| 6 | Metallurgy & Metallurgical Engineering | 87 | 6.57% |

| 7 | Instruments & Instrumentation | 82 | 6.19% |

| 8 | Optics | 62 | 4.68% |

| 9 | Electrochemistry | 61 | 4.6% |

| 10 | Dentistry, Oral Surgery & Medicine | 23 | 1.73% |

| 11 | Automation & Control Systems | 23 | 1.73% |

| 12 | Nuclear Science & Technology | 21 | 1.58% |

| 13 | Energy & Fuels | 17 | 1.28% |

| 14 | Polymer Science | 15 | 1.13% |

| 15 | Biophysics | 12 | 0.9% |

Next, a significant proportion is accounted for by Science & Technology—Other Topics and Engineering, at 29.38% and 26.05%, respectively. Although the number of research papers in these two fields is not as high as that in physics and materials science, a high level of research activity is still shown by them, potentially covering a broader range of research directions and interdisciplinary applications.

The field of Chemistry is ranked fifth with a percentage of 18.12%, indicating the importance of chemistry in scientific research activities being recognized. The fields of Metallurgy & Metallurgical Engineering, Instruments & Instrumentation, Optics, and Electrochemistry are each occupied by a certain proportion, but these are relatively small, reflecting the specific position and contribution of these fields being acknowledged in overall research.

It is worth noting that the number of records in the fields of Dentistry, Oral Surgery & Medicine, Automation & Control Systems, Nuclear Science & Technology, Energy & Fuels, Polymer Science, and Biophysics is relatively small, and the percentage is also relatively low. This does not mean that research in these fields is not important, but rather that the number of research papers is relatively small due to factors such as the specificity of research directions, differences in research difficulty, or allocation of research resources. It may also be a new research trend.

4.1.3 Distribution of Journals

Table 4 shows the main journals in the field of Electroforming research. From the journal distribution data provided in Table 4, we can see the publication of research papers in different journals in Electroforming or related fields. The following is an analysis based on this data. Applied Physics Letters ranks first with 74 publications, accounting for 5.58% of the total, showing the importance and influence of this journal in related fields. 《ACS Applied Materials& Interfaces》and《Journal of Applied Physics》 followed closely, with 46 and 37 papers published respectively, indicating that these two journals are also important platforms for publishing research results in this field.

| ID | Journal | Number of articles | Percentage (%) |

|---|---|---|---|

| 1 | Applied Physics Letters | 74 | 5.58% |

| 2 | ACS Applied Materials & Interfaces | 46 | 3.47% |

| 3 | Journal of Applied Physics | 37 | 2.79% |

| 4 | Microsystem Technologies-Micro-And Nanosystems-Information Storage And Processing Systems | 35 | 2.64% |

| 5 | Scientific Reports | 26 | 1.96% |

| 6 | Microelectronic Engineering | 26 | 1.96% |

| 7 | Journal of Micromechanics And Microengineering | 25 | 1.88% |

| 8 | Nanotechnology | 23 | 1.73% |

| 9 | International Journal of Advanced Manufacturing Technology | 21 | 1.58% |

| 10 | Japanese Journal of Applied Physics | 21 | 1.58% |

| 11 | Micromachines | 20 | 1.51% |

| 12 | Advanced Electronic Materials | 19 | 1.43% |

| 13 | IEEE Electron Device Letters | 16 | 1.20% |

| 14 | IEEE Transactions on Electron Devices | 16 | 1.20% |

| 15 | Journal of Vacuum Science & Technology B | 14 | 1.05% |

| 16 | Applied Surface Science | 14 | 1.05% |

| 17 | Nanoscale | 12 | 0.90% |

| 18 | Journal of Physics D-Applied Physics | 12 | 0.90% |

| 19 | Journal of Alloys And Compounds | 12 | 0.90% |

| 20 | Journal of Materials Chemistry C | 11 | 0.83% |

Table 4 displays the primary journals within the realm of Electroforming research. Based on the journal distribution data presented in Table 4, the publication of research papers across various journals in Electroforming or related domains can be observed. The following analysis is derived from this data. 《Applied Physics Letters》 is ranked first, with 74 publications, accounting for 5.58% of the total, highlighting the significance and influence of this journal in the related fields. 《ACS Applied Materials& Interfaces》 and 《Journal of Applied Physics》 are closely followed, with 46 and 37 papers published respectively, indicating that these two journals are also essential platforms for the publication of research findings in this field.

From the distribution of the top-ranked journals, a wide array of research achievements in the fields of micro-nano technology and materials science is covered by articles published in 《Applied Physics Letters》, 《Acs Applied Materials & Interfaces》, 《Journal of Applied Physics》, and other journals mentioned. 《Applied Physics Letters》 serves as an important platform where research results in the field of micro and nanotechnology are published. Hot topics include electroforming processing, the exploration of new materials, and related micro-nano scale manufacturing and performance research. Closely following is the journal 《ACS Applied Materials & Interfaces》, which is focused on the development of new materials, interface properties, and their practical application performance. In this journal, an important position is occupied by breakthrough research on electroforming in the field of new materials, particularly those concerning the optimization of material interface properties, performance improvement, and the development of new functional materials. The 《Journal of Applied Physics》ranks third, being focused on the practical application of physics principles. It encompasses research on the physical mechanisms, process optimization, and performance evaluation of electroplating technology in the preparation and assessment of new materials.

Based on the publication status of these journals, it can be inferred that the application of advanced manufacturing technologies, such as electroplating, is being actively explored by researchers in the development of new materials within the fields of micro-nano technology and materials science. 《Microsystem Technologies-Micro-And Nanosystems-Information Storage And Processing Systems》is ranked fourth, with 35 articles published, indicating that electroplating remains a hot research topic in microfabrication and nanosystems. With the continuous development of information technology and the integration of electroplating processes, there is an increasing demand for smaller, faster, and more energy-efficient storage materials and processing technologies. Therefore, research in this field holds significant practical importance. 《Scientific Reports》and 《Microelectronics Engineering》are tied for fifth place, with 26 articles published in each, indicating the application research of electroplating processes in the field of microelectronics engineering, primarily focusing on materials used in microelectronic devices. In lower-ranked journals such as 《Advanced Electronic Materials》, 《IEEE Electron Device Letters》, and 《IEEE Transactions on Electron Devices》, although the number of articles is relatively small, more focus may be placed on cutting-edge research in specific fields such as advanced electronic materials, electronic devices, and their manufacturing processes. Research conducted in these fields is of great significance for advancing the development of micro-nano technology and electronic engineering.

In addition, it is worth noting that a certain number of articles have also been published in journals such as 《Nanoscale》 and 《Journal of Physics D-Applied Physics》, indicating that the study of nanoscale and the exploration of physical principles in practical applications remain important topics in the field of electroplating microfabrication.

Overall, various fields such as micro-nano technology, materials science, and electronic engineering in the domain of electroplating are covered by these journals, demonstrating that extensive exploration and in-depth research are being conducted by researchers in these areas. From microfabrication to advanced electronic materials and nanotechnology, progress in the field of microfabrication has been driven by these studies.

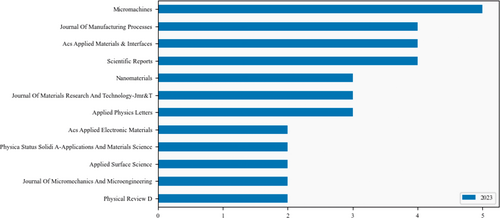

With the development of technology and in-depth research, it is foreseeable that more high-quality research papers will be published in these journals in the future. At the same time, with the emergence of new research fields and the strengthening of interdisciplinary cooperation, new journals may also be added to this list. These journals play an important role in the research of Electroforming or related fields, not only providing a platform for researchers to publish their research results, but also promoting academic exchanges and knowledge sharing. As shown in Figure 2, the top 12 journals in terms of the number of published articles in 2023.

With the development of technology and in-depth research, it is foreseeable that more high-quality research papers will be published in these journals in the future. At the same time, as new research fields emerge and interdisciplinary cooperation strengthens, new journals may also be added to this list. An important role is played by these journals in the research of Electroforming or related fields, where not only a platform is provided for researchers to have their research results published, but also academic exchanges and knowledge sharing are promoted. As shown in Figure 2, the top 12 journals in terms of the number of articles published in 2023 are presented. According to the data of journals with published articles in 2023, 《Micromachines》 ranks first in terms of the number of articles published, with a lot of overlap between the research content and microstructure manufacturing. In the field of chip and other new material processing, research on new materials is receiving increasing attention. Another factor may be that the review cycle of 《Micromachines》 is relatively short, and research authors need to present their latest research results faster. The 《Journal of Manufacturing Processes》 has always been closely watched, and the latest research results on new processes in the field of electroplating are still published in this journal.

4.1.4 Fund Investment

By analyzing the investment in the field of electroforming research, we can discern the extent of support provided by various countries in this field. Out of all articles published in the field of Electroforming between 2010 and 2023, 1054, or approximately 79.6%, were funded by various types of funds. A high level of investment in the field of electroforming is maintained by countries. Table 5 presents a summary of the funded projects' situation in China, South Korea, Japan, and India, and also ranks the countries with the largest number of funding types, indicating the support provided for electroforming processing in these countries.

| ID | State | Funding agencies |

|---|---|---|

| 1 | China |

National Natural Science Foundation Of China National Natural Science Foundation Of China (Nsfc) For Excellent Young Scholars, Specialized Research Fund For The Doctoral Program Of Higher Education Of China, Science Fund For Creative Research Groups Of Nsfc, Priority Academic Program Development Of Jiangsu Higher Education Institutions, National Key Research And Development Program Of China, Natural Science Foundation Of Jiangsu Province, Program For New Century Excellent Talents In University Of China, Natural Science Foundation Of Shanghai, Doctoral Program Of Higher Education Of China. |

| 2 | South of Korea | National Research Foundation Of Korea, Creative Materials Discovery Program Through The National Research Foundation Of Korea, Nano Material Technology Development Program Through The National Research Foundation Of Korea. |

| 3 | Japan | Japan Society For The Promotion Of Science, Japan Science And Technology Agency, Japanese Ministry Of Education, Culture, Sports, Science And Technology |

| 4 | India | Department Of Science And Technology, India, Ministry Of Human Resource Development (Mhrd), Government Of India, Science And Engineering Research Board, India |

4.1.5 Number of Documents Issued and Main Issuing Institutions

Table 6 shows the top 15 institutions that have issued documents. Based on the data in Table 6, a more detailed and specific analysis of the data on “the volume of documents issued and the main issuing institutions” is conducted to provide a comprehensive understanding of the research trends and institutional research performance in this field.

| ID | Institution | Number of papers |

|---|---|---|

| 1 | Chinese Acad Sci | 45 |

| 2 | Dalian Univ Technol | 40 |

| 3 | Seoul Natl Univ | 40 |

| 4 | Nanjing Univ Aeronaut & Astronaut | 25 |

| 5 | Hanyang Univ | 23 |

| 6 | Forschungszentrum Julich | 22 |

| 7 | Pohang Univ Sci & Technol Postech | 18 |

| 8 | Yonsei Univ | 18 |

| 9 | Natl Chung Hsing Univ | 17 |

| 10 | Rhein Westfal Th Aachen | 17 |

| 11 | Korea Univ | 15 |

| 12 | Tsinghua Univ | 14 |

| 13 | Dongguk Univ | 14 |

| 14 | Univ Autonoma Barcelona | 13 |

| 15 | Natl Univ Singapore | 13 |

Chinese Acad Sci (Chinese Academy of Sciences) leads the list with 45 papers, which indicates that a profound accumulation and strong research strength in this field are possessed by the Chinese Academy of Sciences. The high number of publications may be attributed to the large research team, advanced experimental facilities, and rich scientific research resources that are available to it. Not only are the papers of the Chinese Academy of Sciences numerous, but they also often carry high academic standards and influence, positioning it as an important leader in the research field.

Strong strength in this field has been demonstrated by Dalian Univ Technol (Dalian University of Technology) and Seoul Natl Univ (Seoul National University). As a well-known engineering university in China, a focus on applied technology and engineering practice in its research may be emphasized by Dalian University of Technology; As a top university in South Korea, the integration of basic theory and practical application in its research has been achieved by Seoul National University, forming a unique research characteristic that showcases South Korea's investment and output in the field of Electroforming processing.

Among the leading research institutions, numerous universities from China, including Nanjing University of Aeronautics and Astronautics, Nanjing University, and Tsinghua University, as well as renowned universities and research institutions from South Korea, Germany, Spain, Singapore, and other countries, are represented. This demonstrates that research in the field of Electroforming is characterized by extensive international participation and cooperation, with scholars from various nations collectively driving the advancement of this field. It is noteworthy that Nanjing University of Aeronautics and Astronautics, which ranked fourth with 25 papers, indicates a significant research focus on the field of aerospace at this institution.

Institutions with more than 20 publications are the core strength in this field, and their research results have an important role in promoting the development of the field. These institutions may have relatively complete research systems and mature research teams, which can continuously produce high-quality research results. There are many institutions with a publication volume of 10–19 articles. Although these institutions publish relatively few articles, they also play an important role in research in this field. They focus on a specific direction or issue and develop their own research characteristics and advantages.

Institutions that have published more than 20 papers are considered the core strength in this field, and their research results play an important role in driving the field's development. These institutions may be endowed with relatively complete research systems and mature research teams, which enable the continuous production of high-quality research results. There are numerous institutions with a publication volume ranging from 10 to 19 articles. Although relatively few articles are published by these institutions, they still play a crucial role in research within this field. A specific direction or issue is focused on by these institutions, allowing them to develop their unique research characteristics and advantages.

The international level of research in the field of electroforming is enhanced, and academic exchanges and cooperation between different countries and regions are promoted, by the participation of internationally renowned universities and research institutions, including the Autonomous University of Barcelona, the National University of Singapore, and the University of Texas at Austin. Global wisdom is pooled, and the challenges and problems faced in this field are jointly addressed through this cooperation. It is noteworthy that outstanding research in this field is also conducted by institutions such as Forschungszentrum Julich and Oak Ridge Natl Lab. These institutions may possess unique experimental equipment and technical means, which provide new methods for research in this field.

4.2 Analysis of Partnership

Based on multi-angle analysis of network cooperation among countries, institutions, and teams, it is possible to study the social relationships and academic influence among different countries, research institutions, and research teams, which are beneficial for developing institutions, countries, and research teams worthy of attention in the field of electroforming processing.

4.2.1 Collaborative Analysis of Authors

Table 7 shows the top 10 authors of the study, four of whom are from China, indicating China's leading position and advantages in the field of Electroforming processing. Based on the author's publication information and frequency, 14 clusters were obtained, and the authors belonging to the same cluster had a relatively close cooperative relationship.

| ID | Author | Number of articles | ID | Author | Number of articles |

|---|---|---|---|---|---|

| 1 | Du, Lq | 34 | 6 | Zhang, L | 18 |

| 2 | Hwang, Cs | 25 | 7 | Li, Y | 17 |

| 3 | Kim, J | 24 | 8 | Waser, R | 17 |

| 4 | Kim, S | 21 | 9 | Lee, J | 16 |

| 5 | Zhu, Zw | 20 | 10 | Lee, S | 15 |

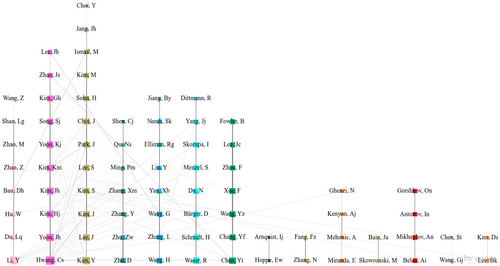

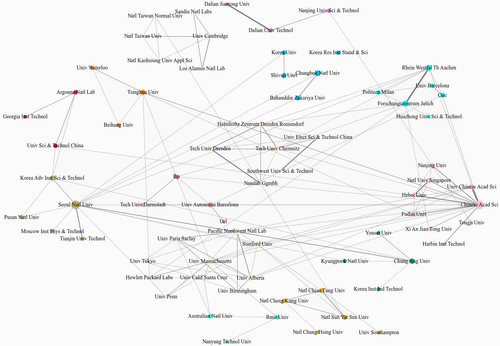

Figure 3 is a network map that analyzes the collaboration between authors in the field of Electroforming, by examining the frequency and contribution of authors to determine their collaborations. The thickness of the lines in the map is indicative of the degree of collaboration between the authors. Each column in the map belongs to a cluster, with the bottom author of each column serving as the central node of that cluster. The network is centered around authors such as Li Y., Hwang C.S., Kim Y., Zhu D., Wang H., Waser R., Chen Y. T., and others.

Cluster 1: It encompasses Li Y., Du L. Q., Hu W., Bao D. H., Zhao Z., Zhao M., Sao L. G., and Wang Z., forming a multidisciplinary research cluster.

Cluster 2: Centered on “Hwang C. S.,” this cooperation network has an author cooperation rate of 3.22 and a cooperation degree of 6.7, indicating close collaboration among the authors. Cluster 2 includes Yoon J. H., Kim H. J., Kim J. H., Kim K. M., Yoon K. J., Song S. J., Kim G. H., Zhao J. S., Lee J. H., and Kim Y. Du L. Q. leads with 34 papers, followed by Hwang C. S. and Kim J. with 25 and 24 articles, respectively, highlighting their active research output within this cluster.

Cluster 3: It comprises Kim Y., Lee J., Kim J., Kim S., Lee S., Park J., Choi J., Sohn H., Kim M., Ismail M., Jan J. H., Choi Y., and Kim S. leads the cluster with 21 papers, followed by Lee J. and Lee S. with 16 and 15 papers respectively, showing their significant contributions in this cluster.

Cluster 4: It includes Zhu D., Zhu Z. W., Zhang Y., Zhang X. M., Min P. M., Qu N. S., Shen C. J., and Wang H. Zhu Z. W. leads in the distribution with 20 papers, and Zhu D. has published 14 papers, indicating a deep research focus in the field of Electroforming.

Cluster 5: It consists of Wang H., Zhang L., Wang G., Yan X. B., Liu Y., Elliman R. G., Nandi S. K., Jiang B. Y., and Waser R. Zhang L. leads this cluster with 18 papers, while Wang H. and Wang G. also have a high frequency of texts, indicating their technical leadership in this research area.

During the analysis of author clustering, the characteristics of different clusters in terms of publication frequency and author composition were observed. Clusters 1–6 showed a high degree of publication activity, and the cooperative relationship between clusters 2 and 3 was more prominent. The “Du L. Q.” in cluster 1 was the first with 34 papers, while the “Kim S.” in cluster 3 was the first with 21 papers. These clusters may represent research teams with close cooperation, focus on specific research fields, and have a high influence in academia.

Although the publication frequency of clusters 4–5 is lower than that of the first two clusters, they still show stable research output. Notably, “Zhu Z. W.” in Cluster 4 is the first with 20 papers, and “Zhang L” in cluster 5 is the first with 18 papers. These “clusters” are composed of authors who have expertise in specific subject fields, and their research achievements play a crucial role in the development of Electroforming.

The frequency of papers published from cluster 7 to 12 is relatively low. Some authors, such as “Chen Y. T.” in cluster 7 and “Hopper E. W.” in cluster 8, are more dispersed in research output. Perhaps their research fields may be more specialized and subdivided. These clusters may represent emerging research fields and interdisciplinary research teams.

4.2.2 Institutional Partnership Analysis

In the visual relationship analysis of mechanism cooperation clustering, set the threshold of the number of documents to 12 and get 48 institutions. Select “institution” as the node type and get the cooperation network relationship map of the main institutions in the field of Electroforming processing research, as shown in Figure 4.

On the whole, Chinese Acad SCI is ranked top in intermediary centrality, Dalian Univ Technol, Seoul Natl Univ, Natl Sun Yat Sen Univ, Tsinghua Univ, Argonne Natl Lab. The above-mentioned research institutions are at the center of the cooperation network and have a high degree of cooperation with other institutions. This article mainly discusses the prominent clusters, where the institutions within each cluster exhibit a high degree of cooperation in academic endeavors.

Cluster 1: Centered on Chinese Acad SCI (Chinese Academy of Sciences), this cluster encompasses a number of top academic institutions in China, including Univ Chinese Acad SCI (University of Chinese Academy of Sciences), Nanjing Univ (Nanjing University), Fudan Univ (Fudan University), and Xi'an Jiao Tong Univ (Xi'an Jiaotong University). These institutions are endowed with strong research capabilities across various disciplines. They are closely cooperating with in the field of Electroforming and have jointly contributed 45 papers to numerous research projects. Wang et al. [25] from the Institute of Metals of the Chinese Academy of Sciences have made progress in the Electroforming of high-performance materials. By optimizing the Electroforming process, they have successfully prepared new metal matrix composites that possess high hardness, high toughness, and excellent corrosion resistance. These materials are anticipated to have broad application prospects in aerospace, marine engineering, and other fields, and can significantly enhance the performance and reliability of materials.

Cluster 2: Centered on Dalian Univ technol (Dalian University of Technology), including Nanjing Univ Sci & Technol (Nanjing University of science and Technology) and Dalian Jiaotong Univ (Dalian Jiaotong University). These institutions have significant cooperation in the field of engineering technology.

Cluster 3: Centered on Seoul National University, including Korea Adv Inst Sci & Technol and Pusan Natl Univ. Seoul National University in South Korea [26] has made significant progress in the versatility of electroforming technology. By regulating the Electrochemical parameters in the Electroforming process, they have achieved the simultaneous deposition of multiple metals or metal alloys on the same Electroforming casting to prepare composite materials with complex compositions and functions. This achievement has opened up a new way for the application of Electroforming technology in the fields of electronic packaging, thermal management, and so on. These Korean research institutions have in-depth cooperation in the field of Electroforming processing and jointly published high-quality academic papers.

Cluster 4: Natl Sun Yat Sen Univ (National Sun Yat sen University) as the center, including Natl Chiao Tung Univ (National Chung Hsing University) and Natl Cheng Kung Univ (National Chenggong University). The higher education institutions in Taiwan have a close cooperative relationship in academic research and jointly promote regional academic development.

Cluster 5: Centered on Tsinghua Univ (Tsinghua University), including Univ Waterloo (University of Waterloo) and Beihang Univ (Beijing University of Aeronautics and Astronautics). They have close academic exchanges and cooperation in the field of engineering technology. Tsinghua University shows its important position in the scientific research cooperation network in the whole Electroforming field. Wu et al. [27] from Tsinghua University have made remarkable achievements in the high-precision control of Electroforming processing. By optimizing the formula of the Electroforming solution, the three-dimensional microstructure manufacturing with sub-micron precision has been successfully realized. They developed a new type of composite Electroforming solution, which effectively reduced the internal stress of the deposited layer and improved the surface quality and flatness of the structural parts. The research results are of great significance for improving the manufacturing accuracy of microelectronic devices and optical components.

Cluster 6: Argonne Natl Lab (Argonne National Laboratory) is the center, including Univ Sci & Technol China (University of science and technology of China) and Georgia Inst technol (Georgia Institute of Technology). They have in-depth cooperation in the fields of materials science, physics, and energy research. Through close cooperation, the research institutions in these clusters have achieved remarkable research results in their respective academic fields and jointly promoted the innovation of Electroforming processing.

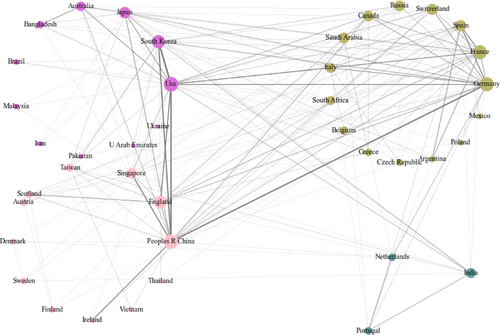

4.2.3 Analysis of Cooperation Between Countries

From the perspective of cooperation between countries, the international cooperation of Electroforming research is analyzed. The international cooperation pattern of Electroforming research is clearly revealed through the cluster analysis depicted in Figure 5. Figure 5 shows three major cooperation clusters. Each cluster demonstrates the cooperation mode and tightness among different countries in the research and development of Electroforming processing technology. The analysis of the four clusters' national cooperation in the field of Electroforming processing is presented as follows:

Cluster 1: It forms a diversified cooperation cluster between Asia and Western Europe, bringing together scientific research forces from many countries in both regions, including China, the United Kingdom, Singapore, Scotland, Austria, Denmark, Sweden, Finland, Ireland, Vietnam, Thailand, and others. This cluster shows how countries with different geographical and cultural backgrounds in the field can be jointly promoted in Electroforming technology through international cooperation. In cluster 1, Asian countries are dominant. As the largest economy and technology power in Asia, China plays an important role in cluster 1. The cooperation between China and Singapore as well as Southeast Asian countries not only promotes technological exchanges and resource sharing within the region but also provides these countries with opportunities to be exposed to and learn advanced Electroforming processing technology. In terms of the contributions made by Western European countries, although Cluster 1 is dominated by Asian countries, the involvement of Western European nations such as Britain, Austria, Denmark, Sweden, Finland, and so forth adds a diversified perspective and a profound scientific research heritage to Cluster 1. These countries possess unique advantages in areas such as basic research, material science, precision manufacturing, and other facets of Electroforming processing. Their cooperation with Asian countries results in complementary effects and fosters the comprehensive development of the technology.

Cluster 2: It forms a high-tech cooperation group between North America and Asia. Cluster 2 focuses on high-tech and developed countries in the field of Electroforming processing technology, including the United States, Japan, South Korea, Australia, Canada, Singapore, and emerging technology countries in the southern hemisphere such as Malaysia, Pakistan, and Iran, etc. Among them, the United States, as the core of the cluster, has particularly significant cooperation with Japan and South Korea, and the technical exchanges and resource sharing among the three are very frequent. Singapore also plays an important role in this cluster with its strong scientific research strength and advanced manufacturing foundation. Although the countries in this cluster are geographically dispersed, their cooperation in the field of Electroforming processing is closely linked and jointly promotes technological innovation and progress.

Cluster 3: This cluster is the alliance of European scientific research powers, which is composed of major European scientific research powers, including Germany, France, Italy, Spain, Switzerland, Russia, Canada (also included in this cluster due to its deep historical ties and scientific research cooperation with Europe), South Africa, Belgium, Greece, Czech Republic, and so on. These companies maintain close cooperation in the R&D and application of electroforming technology. They jointly solve the key problems in Electroforming technology and promote the commercialization of technology through scientific research projects within the framework of the European Union and bilateral or multilateral cooperation agreements.

Cluster 4: This cluster is an emerging market and regional cooperation cluster. Cluster 4 covers India, Poland, Portugal, the Netherlands, and some emerging market countries in Asia and Africa. Although these countries started late in the research and development of Electroforming processing technology, they are actively absorbing and introducing advanced technologies through strengthening international cooperation to improve their scientific research strength and industrial level. Their cooperation is more focused on technical exchanges.

From the overall trend, the international cooperation in the field of Electroforming processing shows the characteristics of diversification and deepening. Although different countries have different priorities and advantages in cooperation, they have jointly promoted the continuous innovation and development of Electroforming processing technology by strengthening international technical exchanges and cooperation. The close cooperation between China and the United States in many fields is also reflected in the field of Electroforming processing. With the application of Electroforming technology in aerospace, automotive manufacturing, electronic communications, and other fields, countries within the cluster have more opportunities for cooperation. Through joint research and development of new technologies, these countries are expected to achieve the development goal of mutual benefit and win-win results.

4.3 Research Hotspots and Evolution Trends

4.3.1 Hot Word Analysis

After data de-duplication, de-noising, and other processing, 301 keywords with a word frequency greater than 2 are obtained. A total of 122 keywords with a word frequency greater than 3 are selected. Table 8 shows the frequency of some keywords. The first one is “Electroforming,” with a frequency of 213. The second is “Resistant switching,” with a frequency of 111. “Microelectroforming” ranks sixth with a frequency of 18, while “Nickel” ranks seventh with a frequency of 16. In the ninth place is “Neuromorphic computing.”

| ID | Keywords | Frequency | ID | Keywords | Frequency |

|---|---|---|---|---|---|

| 1 | Electroforming | 213 | 10 | Current density | 14 |

| 2 | Resistive switching | 111 | 11 | Oxygen vacancies | 13 |

| 3 | Memristor | 64 | 12 | Electroforming process | 12 |

| 4 | Rram | 31 | 13 | Surface roughness | 11 |

| 5 | Microstructure | 18 | 14 | TiO2 | 11 |

| 6 | Microelectroforming | 18 | 15 | Copper | 11 |

| 7 | Nickel | 16 | 16 | Oxygen vacancy | 10 |

| 8 | Mechanical properties | 14 | 17 | Threshold switching | 10 |

| 9 | Neuromorphic computing | 14 | 18 | Electroplating | 10 |

Combined with the high-frequency vocabulary, the current research hotspots and related technologies in the field of Electroforming and related technologies can be described more deeply. The following is a comprehensive analysis of the keywords in the research field in the list.

The keyword “Electroforming” is most frequently used in the table, with a frequency of 213. Electroforming is recognized as an important precision manufacturing technology, where metal or alloy layers are formed on the conductive substrate through the Electrochemical deposition process. It is widely utilized in the manufacture of microstructures, complex-shaped parts, and high-precision molds. The keywords “resistive switching” and “memristor” are closely associated with Electroforming, particularly in the realm of electronic communication materials like nonvolatile memory. Precision electrodes or structures of memory are manufactured using Electroforming technology.

The performance of “RRAM” is closely related to its microstructure, including surface roughness and oxygen vacancy. These microscopic characteristics are achieved by precise control in the Electroforming process. The two key words “microstructure” and “TiO2” reflect the concern of the field of new materials on the microstructure of Electroforming products. Titanium dioxide is a commonly used Electroforming material, and its microstructure has an important impact on the performance of the electroforming layer. By optimizing the Electroforming process parameters, the microstructure of the electroformed layer can be controlled, and then its mechanical properties and corrosion resistance can be improved. In the two key words of “Microelectroforming” and “copper,” the micro Electroforming of copper structure is the application of Electroforming processing on the micro scale, and copper is one of the commonly used materials in micro Electroforming. Micro-Electroforming technology can produce high-precision copper micro structure to meet the needs of microelectronics and micro-machinery.

“Nickel” is another metal material commonly used in Electroforming. The Nickel Electroforming layer has excellent corrosion resistance, weldability, and mechanical properties, and is widely used in the manufacture of corrosion-resistant parts and electronic components. The two keywords “mechanical property” and “threshold switching” are related to the physical and mechanical properties of Electroforming products, including matrix materials and subsequent treatment processes. Electroforming technology plays a role in the manufacture of electronic devices. The two key words “Neuromorphic computing” and “Electroplating” show that with the increasing research and application of neural computing in high-precision and high-performance electronic components, the development of Electroforming technology in this field is promoted.

Table 9 shows the co-occurrence matrix of six high-frequency words Electroforming, the frequency of the common occurrence of Resistive Switching, Memristor, Electrodeposition, and Rram. Microstructure in the same dataset is only given in this section, but in actual research, the relationships between all keywords are presented. The values in the matrix represent the number of times two words appear together. For example, “Electroforming” appears 0 times with itself, 5 times with “Resistive Switching,” 8 times with “Memristor,” 10 times with “Electrodeposition,” 2 times with “Rram,” and 9 times with “Microstructure.” “Resistive Switching” appeared 5 times with “Electroforming,” 0 times with itself, 19 times with “Memristor,” 1 time with “Electrodeposition,” 8 times with “Rram.” “Memristor” has appeared 8 times with “Electroforming,” 19 times with “Resistive Switching,” no co-occurrence with “Electrodeposition,” 3 times with “Rram,” and no co-occurrence with “Microstructure.” “Electrodeposition” appeared 10 times with “Electroforming,” 1 time with “Resistive Switching,” no co-occurrence with “Memristor,” no co-occurrence with “Rram.” “Rram” has appeared twice with “Electroforming,” 8 times with “Resistive Switching,” no co-occurrence with “Electrodeposition,” and no co-occurrence with “Microstructure”. “Microstructure” appeared 9 times with “Electroforming,” not with “Resistive Switching,” and appeared 0 times with itself. This matrix can help us understand the degree of association of these high-frequency words in the dataset. For example, the co-occurrence of “Memristor” and “Resistive Switching” is 19 times, indicating that these two words are often mentioned together in literature because they are in the same or related research fields. The co-occurrence frequency between “Electrodeposition” and “Microstructure” is once, indicating a low correlation between these two words in the literature.

| 0 | Electroforming | Resistive Switching | Memristor | Electrodeposition | Rram | Microstructure |

|---|---|---|---|---|---|---|

| Electroforming | 0 | 5 | 8 | 10 | 2 | 9 |

| Resistive Switching | 5 | 0 | 19 | 1 | 8 | 0 |

| Memristor | 8 | 19 | 0 | 0 | 3 | 0 |

| Electrodeposition | 10 | 1 | 0 | 0 | 0 | 1 |

| Rram | 2 | 8 | 3 | 0 | 0 | 0 |

| Microstructure | 9 | 0 | 0 | 1 | 0 | 0 |

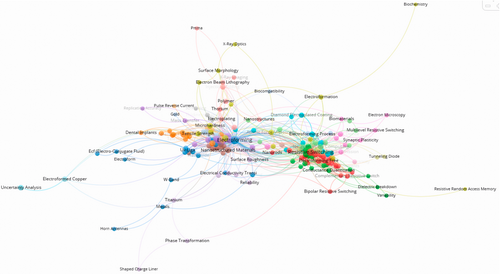

In this paper, the co-occurrence matrix of high-frequency keywords is imported into UCINET, and the Netdraw component is used to draw the network map of keywords to obtain the clustering network map of keywords, as shown in Figure 7, which is the clustering map of some keywords displayed in vosviewer.

Figure 6 shows the status of technology research in the field of Electroforming and its cross integration with other disciplines and technologies. In terms of core technology and process, “Electroforming processing,” as the central node of the entire network, connects several closely related sub-technologies and application fields. “Surface engineering” is one of the sub-technologies closely connected with Electroforming processing. It focuses on the surface quality, roughness, corrosion resistance, and other aspects of Electroforming layer. By optimizing Electroforming process parameters and subsequent treatment processes, the surface properties of the Electroformed product can be significantly enhanced to meet specific application requirements. As a secondary node in the network, “Electrochemical analysis” is used to monitor and control the composition, pH value, current density and other key parameters of the electroforming solution. This ensures the stability and consistency of the Electroforming process and provides a theoretical foundation for process optimization. “Mold Design” is connected with the node of “Electroforming processing,” which is an indispensable component of the whole process. A reasonable mold design ensures that Electroformed parts possess accurate dimensions and shapes, while also minimizing material waste and processing costs.

In terms of key technologies and methods, there are nodes such as “Spectroscopy” and “x-ray diffraction.” “Spectroscopy,” as an analytical technology, is primarily utilized in analyzing the composition, structure, and performance of the Electroforming layer within the field of Electroforming processing. Detailed information about the Electroforming layer can be obtained through spectroscopic methods, providing data support for process optimization and quality control.

“x-ray diffraction” is used to study the crystal structure and phase composition of Electroforming layers. Through the analysis of x-ray diffraction patterns, we can understand the microstructure characteristics of Electroforming layers and subsequently evaluate their mechanical properties and corrosion resistance. In terms of interdisciplinary applications, the “Biomedical” node indicates that with the development of Biomedical Engineering, Electroforming technology is increasingly widely used in the biomedical field. Electroforming technology can be employed to manufacture precision medical equipment, implants, or tissue engineering scaffolds. The “Biomedicine” and “Electroforming” nodes in the atlas are connected, demonstrating the cross-integration between the two fields. The appearance of the “Superconductor” node showcases the potential of Electroforming technology in the preparation of materials with special structures or properties. For example, components such as memory. Electroforming technology can be used to produce superconducting materials with complex shapes and microstructures to meet specific application requirements. Figure 7 illustrates the research status of technology in the field of electroforming and its cross-integration with other disciplines and technologies through a complex network diagram.

4.3.2 Research Field and Evolution Trend Analysis

Figure 7 is the distribution chart of the top 15 research fields from 2010 to 2023, mainly distributed in the research of physics, materials science, science & technology-other topics, chemistry, metallurgy & metallic engineering, optics, chemistry, destiny, Oral surgery & medicine, nuclear science & technology, energy & fuels, polymer science, biology, and other fields. Physics and materials science occupy a dominant position. As can be seen from the pie chart, physics and materials science are the main fields of Electroforming research, accounting for a large number of papers. In 2019, Yan et al. [28] and others published a new memristor with 2D Ti3C2Tx mxene flakes as an artificial bio synapse in small, which studied the 2D mxene Ti3C2Tx slice as a memristor of artificial biological synapses with a citation frequency of 141. In 2018, Li et al. [29] and others published “analog and digital bipolar resistant switching in solution combustion processed NiO memristor” in ACS Applied Materials & Interfaces, and studied the simulation processing in NiO based memristor prepared by solution method, with a citation frequency of 114. In 2019, Ding et al. [30] and others published the article “2D metal organic framework nanosheets with time dependent and multilevel Memorial switching” on advanced functional materials, showing the application of electroforming in 2D metal, with a citation frequency of 109. In 2019, Hua et al. [31] Published a threshold switching selector based on highly ordered Ag nanodots for x-point memory applications in advanced science, and proposed an application of highly ordered Ag based memory in electroforming, with a citation frequency of 107.

In 2020, Cao et al. [32] Published the article nonvolatile multistates memories for high density data storage on ACS Applied Materials & Interfaces. In this paper, the latest progress and challenges of Electroforming technology in nonvolatile polymorphic memory were reviewed, and the citation frequency was 104. These articles are cited frequently, which shows that the theoretical basis and material research of Electroforming technology are the core driving force of its current development. The interdisciplinary integration shows that in addition to physics and materials science, there are also significant papers published in other fields such as biophysics, nuclear science and technology, metalology and metal engineering. In 2018, Hao et al. [33] and others published the article “improved unipolar resistant switching characteristics of Au doped nickel ferrite magnetic thin films for nonvolatile memory applications” in the Journal of alloys and compounds, which studied the application of Au doping in Electroforming in nickel ferrite with a citation frequency of 441. In 2022, Ilyas et al. [34] and others published the article “controllable resistant switching of sto:Ag/SiO2-based memristor synapse for neural computing” in the Journal of Materials Science & Technology, in which a sto:Ag/SiO2 double-layer memory for Electroforming processing based on neural computing was developed, with a reference frequency of 382.

The team of Nanjing University of Aeronautics and Astronautics [35] proposed a new TGV defect free copper plating and filling process based on cathode reciprocating motion. Research and experiments show that the new process can effectively ensure the uniform distribution of ion concentration in the TGV pore, improve the deposition rate, and achieve a higher average filling rate and a filling layer without pore defects in the additive free system. This provides a low-cost solution for the defect free Electroformed copper filling of TGV with high aspect ratio. The National University of Singapore advanced manufacturing technology research center [36] have made important progress in improving the efficiency of Electroforming. In 2022, they effectively improved the deposition rate and reduced the porosity by introducing ultrasonic assisted Electroforming technology, which significantly shortened the processing cycle and improved the performance of parts. This research is of great value for the large-scale production of high-precision complex structural parts. Zhang et al. [37] from the Institute of micro nano manufacturing and systems, School of mechanical engineering, Zhejiang University made progress in the intelligent control of Electroforming technology. In 2023, they issued a set of electroforming process optimization system based on machine learning, which can monitor and adjust electroforming parameters in real time to achieve high-precision and high-quality deposition. This research not only improves the automation level of Electroforming processing, but also provides a new solution for intelligent manufacturing. Schmidt et al. [38] of Aachen University of technology in Germany focused on the application of Electroforming technology in the manufacture of precision optical components. In 2023, they successfully prepared optical molds with complex micro nano structures by using high-precision Electroforming technology, which can be used for large-scale production of precision optical components such as microlens arrays and gratings. The research results are of great significance for improving the resolution and imaging quality of optical instruments. Green et al. [39] of the University of California, Berkeley, conducted research on the greening of Electroforming technology. In 2022, they developed an environmental friendly Electroforming solution, which produces less waste in the deposition process and is easy to recycle. At the same time, the Electroforming solution also has good deposition performance and high deposition rate, which provides a new solution for the sustainable development of Electroforming processing.

The above reflects the wide application and cross integration trend of Electroforming technology in various disciplines. Emerging fields are gradually emerging. Although the number of papers published in the fields of automation and control, instruments optics, and electrochemistry is relatively small, their existence indicates that Electroforming processing technology has gradually been paid attention to and applied in these emerging fields.

5 Conclusion

From 2010 to 2023, the field of Electroforming showed a vigorous development trend. From the perspective of the evolution of the number of papers published, it remained relatively stable between 2010 and 2013. After experiencing a brief decline in 2014, it witnessed a significant increase from 2015 until 2023. Multiple factors have contributed to this growth. Progress has been made in the precision, efficiency, and cost of Electroforming due to technological advancements. The continuous emergence of new materials and technologies has provided new directions for the field of Electroforming. Additionally, policy support and market demand have played crucial roles. In terms of research fields, Electroforming encompasses 60 disciplines, with physics and materials science occupying dominant positions, accounting for 50.3% and 47.2%, respectively. Furthermore, science and technology, engineering, chemistry, and other fields also have a high level of participation. Although there are fewer records in other fields, they still contribute to the development of this field, reflecting the interdisciplinary nature of Electroforming processing technology.

From the perspective of journal distribution 《Applied Physics Letters》 and other high-impact journals have been used as important publishing platforms for Electroforming research results, covering fields such as physics, materials science, micro-nano technology, and others, showing the broad scope and interdisciplinary nature of the research topics. Considerable efforts have been made by countries in fund investment. Approximately 79.6% of the articles are funded by various grants. China has the largest amount of funding in the field of Electroforming processing. In terms of the author collaboration network, 14 clusters have been formed, and four of the top ten papers originate from China. Institutional cooperation centers on the Chinese Academy of Sciences, Dalian University of Technology, Seoul National University, and others, forming multiple clusters. These institutions exhibit a high degree of cooperation in academic endeavors. Country cooperation is characterized by diversification and deepening, being divided into four clusters: the Asia and Western Europe diversified cooperation group, the North America and Asia high-tech cooperation group, the European research power alliance, and the emerging markets and regional cooperation group. Hot word analysis reveals that “Electroforming processing,” “Resistance,” and “Access memory” have become current research hotspots, reflecting the application and development direction of Electroforming processing technology in fields such as electronics, materials, biomedicine, and others. The trend of interdisciplinary integration is evident, with gradual applications in emerging fields like biomedicine.

Electroforming technology is expected to continue to advance in accuracy, efficiency, and cost control. Multidisciplinary integration will be further strengthened, opening up new application scenarios for Electroforming. International cooperation will become closer, with China playing a more significant role in it. With the increasing demand in aerospace, automotive manufacturing, and other fields, Electroforming technology has broad market prospects. At the same time, it also requires continuous innovation to address existing challenges and make greater contributions to scientific and technological progress and social development.

Author Contributions

Feng Ji: conceptualization, methodology, software, data curation, supervision, formal analysis, writing – original draft. Ye Kong: resources.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.