The Effects of Waste-Based and Thermal Energy-Storing Building Materials on Sustainable Architecture: A Review

ABSTRACT

The utilization of waste-based thermal energy-storing building materials in construction is a significant advancement in the reduction of the environmental impact of human activities. Such materials provide thermal comfort, reduce energy consumption, and promote the use of renewable resources. Phase change materials (PCM) have been the subject of these achievements in recent years regarding their heat storage potentials. On the other hand, the utilization of waste is of significant consequence with regard to the sustenance of a circular economy and the alleviation of waste-related environmental concerns. However, the majority of studies on PCM in the literature tend to concentrate on the thermal, physical, chemical, and mechanical properties of the materials, and thus fails to provide a comprehensive perspective on the sustainability of these materials. In this study, 11 articles selected from a total of 178 studies aiming to produce building materials with waste-PCM combinations are analyzed according to five categories related to sustainable built environment, which are resource use, environmental impact, health, comfort, and cost. As a result, it is proved that composite building materials that contain waste and store thermal energy have the potential to contribute significantly to sustainable architecture.

Abbreviations

-

- DSC

-

- Differential Scanning Calorimetry

-

- EAFD

-

- Electrical Arc Furnace Dust

-

- EDS

-

- Energy-Dispersive Spectroscopy

-

- EIA

-

- Energy Information Administration

-

- EPS

-

- Expanded Polystyrene

-

- EU

-

- European Union

-

- FTIR

-

- Fourier Transform Infrared Spectroscopy

-

- Gt

-

- Gigatonne

-

- IAQ

-

- Indoor Air Quality

-

- IRT

-

- Infrared Thermography

-

- LA

-

- Lauryl Alcohol

-

- LCA

-

- Life Cycle Assessment

-

- MDF

-

- Medium-Density Fibreboard

-

- n.a.

-

- Not Available

-

- nZEB

-

- Nearly Zero-Energy Buildings

-

- PCM

-

- Phase Change Material

-

- SEM

-

- Scanning Electron Microscopy

-

- SSPCM

-

- Shape-Stabilized PCM

-

- TGA

-

- Thermogravimetric Analysis

-

- XRD

-

- X-ray Diffraction

1 Introduction

The construction of buildings necessitates the utilization of a plethora of building materials throughout the entirety of their life cycle and the construction sector is responsible for 25% to 45% of the total energy during extraction of raw materials and transporting processes [1]. Moreover, around 12% of global emissions are caused by building materials such as cement and steel [2]. As indicated by the Energy Information Administration (EIA), the projected increase in carbon emissions from energy consumption by 2023 is 37.2 Gt [3]. Consequently, the objective of the European Union (EU) countries is to reduce greenhouse gas emissions by 40% between 1990 and 2030 [4]. Furthermore, the EU aims to decarbonize the building stock by 2050 [5]. The twin challenges of resource depletion and climate change require a fundamental rethink of the built environment [6]. In order to address this situation, it is necessary to implement measures that will ensure the efficient use of resources, facilitate a shift towards renewable energy sources [7]. It is of the utmost importance that such decisions are made in order to construct a sustainable built environment.

One of the reasons for the observed increase in energy consumption for space cooling in buildings is the transition from the use of traditional materials with thermal mass properties, such as stone and brick, to the adoption of lightweight structural materials, including wood and composites [8]. The utilization of thermal mass is of significance in the context of space cooling, as it serves to retain heat and enhance thermal comfort [9]. The advantages of thermal energy storage have been acknowledged and incorporated into environmental policies at the international level. In accordance with Directive 2023/2413 of the European Parliament and of the Council, the integration of thermal energy storage is to be made mandatory in order to achieve greater energy efficiency and cost-effectiveness. In this context, it is of paramount importance that EU Member States promote interoperability for heating and cooling systems and thermal energy storage units [10]. It is imperative that all EU policies on energy efficiency in buildings address the potential of thermal mass in conjunction with other solutions, including insulation, heating and cooling systems, and renewable energy. Moreover, sustainability policies in the construction sector should encompass social aspects such as well-being and comfort [11].

While there are no specific measures for thermal energy storage in Turkey's national energy policies, various strategies have been proposed to reduce energy consumption. The 2017–2023 National Energy Efficiency Action Plan aims to reduce Turkey's primary energy consumption by 14%. In accordance with the EU Energy Efficiency Directive, the report anticipates a 50% surge in residential heating demand by 2040 and mandates that all edifices exceeding 2000 m2 must attain the status of nearly zero-energy buildings (nZEB) by 1 January 2025 [12]. The action plan, which covers the period from 2024 to 2030, aims to reduce total emissions by 100 million tons [13].

In light of the prevailing patterns of energy consumption, the significance of renewable resources is further underscored. In light of the aforementioned considerations, the capacity of building materials to store thermal energy and provide passive heating and cooling functions within buildings has constituted a significant research focus in recent years. Phase change materials (PCM), which offer the potential for the utilization of solar energy, can also be employed in the creation of highly effective composites in the field of thermal energy storage.

The utilization of PCM and heavy thermal masses has the potential to reduce the intensity of mechanical air conditioning systems, as they are capable of storing excess heat [14]. PCM constitutes a subgroup of thermal energy storage systems, functioning on the principles of latent heat storage and sensible heat. They are capable of storing considerable quantities of heat energy within narrow temperature ranges. In order to utilize PCM in a building, it is necessary for the materials in question to possess a number of different physical, chemical, environmental and economic properties. Nevertheless, no PCM product currently available on the market exhibits all of these properties simultaneously. The greater the number of these properties that a PCM exhibits, the more significant its contribution to the building users, the environment, the budget and the lifetime of the structure [15].

PCMs are classified into three categories: organic, inorganic, and eutectic [16-18]. The organic group comprises paraffins, alcohols and fatty acids, whereas the inorganic group includes salt hydrates and metallic species. The eutectic group comprises combinations of at least two distinct organic and/or inorganic species [19-22]. Each type of PCM has inherent advantages and disadvantages; therefore, it is essential to implement appropriate measures to mitigate the disadvantages. It is recommended that paraffins, fatty acids, salt hydrates and their eutectic mixtures be employed in order to achieve optimal energy efficiency and thermal comfort in buildings [23-25]. A variety of techniques have been developed to apply thermal energy storage in building materials, including direct mixing, impregnation, encapsulation, and shape and form stabilization [26, 27].

A substantial body of research on PCM has been published in recent years. Jouhara et al. [28] investigated the active and passive applications of PCM types with latent heat storage in a variety of sectors, including food, automotive and construction. Some papers concentrated on a single type of PCM. For instance, Purohit and Sistla [29] underscored the attributes of salt hydrates, including their high thermal heat storage capacity, cost-effectiveness, and non-flammability. Furthermore, a number of methods have been put forth with the aim of addressing the negative properties of PCMs, including corrosiveness, supercooling and phase separation. Other research on PCM has concentrated on their behavior in accordance with climatic conditions [30], cooling-only [31] or heating-only applications. A limited number of comprehensive review articles have been published that examine the materials used in waste-derived PCM production [32]. Additionally, studies have addressed the economic and environmental properties of waste-based PCM composites [33]. The aforementioned study provides a comprehensive examination of active and passive systems and applications according to waste types.

Furthermore, numerous studies in the literature examine PCM products derived from waste materials within the context of laboratory analyzes and experimental studies [34-36]. Nevertheless, the number of articles that synthesize these studies in a comprehensive framework is relatively limited. The development of an approach, particularly within the context of the architectural field, is of significant importance with regard to the integration of waste into the circular economy and the provision of sustainable architectural solutions through the utilization of innovative building materials. It is therefore essential that the evaluation of studies be conducted with a multidisciplinary approach.

The novel aspect of this study is the evaluation of the waste-based thermal energy storage systems in buildings within the context of sustainable architectural principles. The study investigates examples from the last decade. In addition to technical features, this study considers the holistic implications for the human being, the social subject of architectural design, the natural environment in which architecture comes to life, and the economic investments that make architecture feasible. This study focuses exclusively on the waste-based, thermal energy-storing building materials for passive applications in buildings. The target audience includes architects, building material manufacturers, environmental, civil and material engineers, and academics engaged in research in this field.

2 Materials and Methods

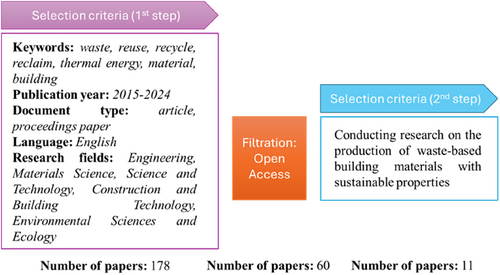

A search of the Web of Science database was conducted using the following keywords: “waste*,” “reuse*,” “recycl*,” “reclaim*,” “thermal energy,” “material*,” and “building*.” The language was set to English, and the search was limited to articles and proceedings papers published between 2015 and 2024. The studies identified were confined to the disciplines of engineering, materials science, science and technology, construction and building technology, and environmental sciences and ecology. In accordance with the aforementioned criteria, 60 of the 178 documents retrieved were identified as being available via open access (Figure 1).

All 11 studies exhibit common characteristics, including the utilization of waste materials, the development of PCMs that can be integrated into the composition of building materials, and the utilization of thermal storage systems that can operate within temperature ranges aligned with thermal comfort standards for indoor environments. Furthermore, the studies were selected on the basis of their presentation of data pertaining to at least one of the following categories: resource use including energy, raw material and water, environmental impact analysis, cost analysis, occupant comfort and health.

3 Research Status

3.1 Waste Utilization

The requisite characteristics of a PCM for utilization in a structural context are elucidated in Chapter 1. In the event that these properties are not satisfied, a number of issues may arise within the structure. Such issues may manifest as insufficient thermal and chemical stability, elevated supercooling temperatures, reduced thermal conductivity, leakage problems, and low viscosity. The utilization of various waste materials serves to prevent such problems.

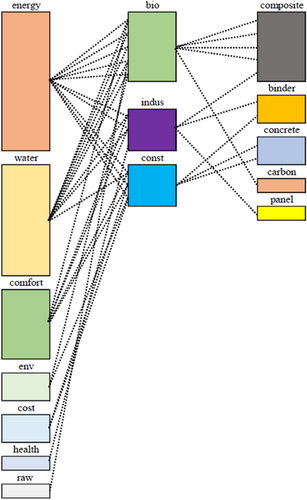

A review of the literature reveals that a considerable number of waste materials derived from biological, agricultural, industrial and construction sources are employed in the manufacture of thermal energy storage building materials. The principal reasons for the preference of these wastes are their low environmental impact, accessibility, cost advantages and biodegradability. However, it is also observed that wastes that are not biodegradable (such as tire rubber) or that may contain harmful components (such as electrical arc furnace dust) are also employed in the production of PCM (Figure 2).

In selecting waste materials for use in PCM, it is essential to consider their porosity and water absorbency, as these properties can prevent potential leaks that may occur during the phase change of the material. In addition to enhancing thermal performance, some wastes are also employed to improve acoustic performance, augment structural strength and regulate viscosity. For instance, the high porosity and absorbency characteristics of waste materials permit their effective utilization in form stabilization applications. Furthermore, waste cooking oils have been identified as a viable thermal energy storage agent in direct applications.

The utilization of waste materials in the construction industry plays a pivotal role in advancing environmental sustainability. Furthermore, the incorporation of waste into the circular economy and the production of energy-efficient materials derived from it also influences the embodied and operational energy consumption of buildings. It has been demonstrated that the incorporation of appropriately selected waste materials can enhance not only the energy performance but also the overall strength, fluidity, water absorbency and acoustic properties of materials.

In this context, waste materials and PCM are employed in the production of building materials designed to enhance energy efficiency and thermal comfort in buildings. These building materials are typically in the form of composites, panels, concrete, and mortar (Table 1).

| Ref. | Waste | Waste properties | Waste as… | Building material |

|---|---|---|---|---|

| {1} [4] | Cuttlebone and pomelo peel | Porous, biodegradable, renewable, safe to use, cheap, abundant | Shape stabilizer | Composite material |

| {2} [37] | Coconut peat | Oil absorber, causing environmental pollution by dumping, abundant, cheap, biodegradable | Shape stabilizer | Composite material |

| {3} [38] | Hemp shives | Improves thermal properties, biodegradable, renewable | Shape stabilizer | Composite wall panel |

| {4} [39] | Apricot kernel shells | Abundant, cheap, low ash content, cellulosic | Shape stabilizer and thermal conductivity agent | Activated carbon |

| {5} [40] | Waste cooking oil (glycerine, fatty acid) | Low environmental impact | PCM | Cement-based composite panel |

| {6} [41] | Fly ash | Abundant, cheap, low environmental impact | Viscosity modifier | Geopolymer paste |

| {7} [42] | Electrical arc furnace dust | Acoustic insulation, hazardous | Shape stabilizer and insulation | PCM dense sheet |

| {8} [43] | Tire rubber | Non-biodegradable, abundant, hazardous when it burns | Shape stabilizer and thermal conductivity agent | Composite material |

| {9} [44] | Recycled expanded glass | Heat resistive, low embodied energy, rigid surface, recyclable, high absorption, good thermal and structural performance | Heat resistive shape stabilizer with low embodied energy and rigid surface | Concrete panel |

| {10} [45] | Recycled concrete powder | High porosity | Shape stabilizer | Foam concrete |

| {11} [46] | Recycled expanded glass aggregate | High porosity and adsorption | Shape stabilizer | Cement mortar |

3.2 Laboratory Analysis and Experiments

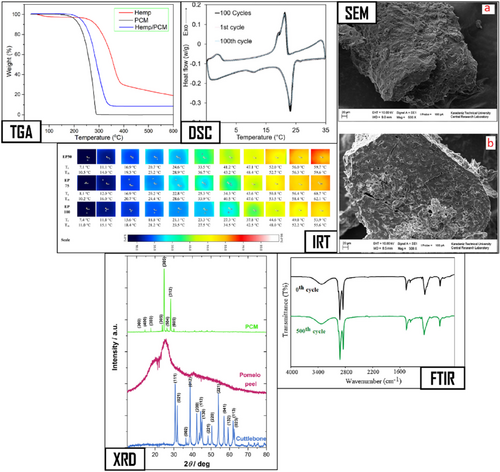

The tests and analyses employed during the production of building materials are typically conducted within a laboratory setting. The objective of these studies is to evaluate the chemical, thermal and physical characteristics of materials, as well as to ascertain their structural strength. Given that PCM-waste-based building materials are predominantly composite, it is of paramount importance that the components of these materials function in unison. The principal analytical techniques employed in the various studies, together with their intended applications, are set out below.

X-ray diffraction (XRD) is a technique used to analyze the crystal structure of a material. It generates pattern graphs that illustrate the chemical interactions and crystal structure of the components that constitute the material's structure. This analysis is employed for the identification of crystalline phases within the microstructure of the building material [4].

Scanning electron microscopy (SEM) and energy-dispersive spectroscopy (EDS) are further analytical techniques that can be employed in this context. SEM provides microscopic images that can be used to determine the pore structure, homogeneity and physical compatibility of the components. The EDS method is employed to ascertain the chemical distribution of elements on the surface of the material, with this analysis conducted on the basis of the aforementioned images [39].

Fourier transform infrared spectroscopy (FTIR) is a technique used to analyze the molecular structure of materials. This technique is employed to examine the chemical constitution of composite materials and the compatibility of chemical bonds between their constituent components. This method is particularly well-suited to the analysis of the chemical structure of PCM-based materials. This method is typically employed to assess the chemical stability of a material subjected to prolonged thermal cycling [43].

DSC (differential scanning calorimetry) is employed to ascertain the thermal properties and thermal strength of materials. This analysis provides insight into the phase change temperatures of materials and their thermal behavior, including melting and freezing. The analysis is typically repeated after more than 100 thermal cycles to ensure the reliability of the results [41].

Thermogravimetric analysis (TGA) is a technique used to determine the thermal stability of materials. The technique is employed to quantify the loss of material and assess thermal stability as a function of temperature. This analysis examines the mass loss and degradation behavior of the material over a given temperature range, thereby providing information on its thermal stability [38].

Infrared thermography (IRT) is a technique that employs thermal imaging to analyze the infrared radiation emitted by objects. This technique is employed to ascertain the heat storage performance of materials. The distribution of temperatures across the sample surfaces is illustrated through the use of infrared thermal imaging. This method enables the analysis of heat transfer properties through the visual presentation of temperature differences on the surface of the material [46].

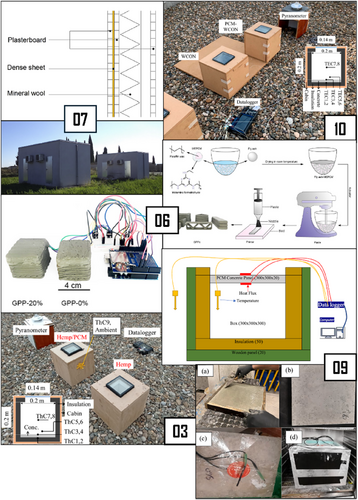

These analytical techniques are fundamental to ascertain the compatibility of the components employed in the manufacture of building materials and their thermal, chemical and physical properties. The repetition of such analyzes, particularly in the context of PCM-waste-based materials, is beneficial for the evaluation of the long-term performance and durability of the materials (Figure 3).

It can be observed that experimental studies are conducted within a laboratory setting in the majority of cases. Nevertheless, experimental setups designed to assess the performance of the materials under actual temperature conditions were incorporated into only half of the studies examined. The two distinct methodological approaches, namely theoretical and practical, yield results encompassing a multitude of parameters, including thermal, physical, chemical, acoustic, mechanical, and environmental properties of the materials under investigation (Table 2).

| Article ID | Test method | Laboratory analyzes | Investigated properties |

|---|---|---|---|

| {1} | — | XRD, FTIR, SEM, DSC | Thermal stability, latent heat storage, heat flux, melting point |

| {2} | — | TG, DSC, SEM, FTIR, leakage, thermal cycle | Latent heat storage, melting point |

| {3} | Experimental setup: MDF cubicles | SEM, DSC, TGA | Thermal conductivity, compressive strength, dry unit weight, thermal stability, melting point, latent heat capacity |

| {4} | — | Leakage, XRD, FTIR, SEM, DSC, TGA | Thermal conductivity |

| {5} | Dynamic simulation, environmental impact categories | — | Environmental impact |

| {6} | Experimental setup: 3D printed miniature houses | XRD, FTIR, DSC, TGA | Thermal conductivity, microstructure, thermal heat storage capacity, melting point |

| {7} | Experimental setup: dense sheet | Leaching | Acoustic performance, thermal performance |

| {8} | — | SEM, XRD, FTIR, DSC | Thermal stability, chemical stability, thermal degradation, thermal conductivity |

| {9} | Experimental setup: wooden panel | SEM, XRD, FTIR, DSC | Lifecycle energy, carbon emission, latent heat storage capacity, microstructure, thermal comfort, operational energy, embodied energy, thermal conductivity |

| {10} | Experimental setup: MDF cubicles | DSC, XRD, SEM, EDS | Thermal energy storage capacity, unit weight, porosity, water absorption, compressive strength, flexural strength, thermal conductivity, microstructure, chemical composition |

| {11} | Case study | TGA, DSC, SEM, IRT | Water absorption, leakage, density, flexural strength, compressive strength |

4 Results

This section addresses the impacts of waste-PCM composites in the field of sustainable architecture, as examined in the 11 studies reviewed. The aforementioned impacts are evaluated in terms of energy, water and material utilization, as well as environmental impacts and user health, economic impacts and comfort parameters.

4.1 Energy Efficiency

The utilization of building materials that are capable of storing energy and facilitating its subsequent utilization represents an effective strategy for the reduction of non-renewable energy resource consumption. A review of the numerical data reveals that a single gram of the building materials produced within the scope of the studies examined can store a range of energy between 10 and 193 J during a phase change. The number of thermal cycles tested ranged from 100 to 1200. It is possible that chemical interactions between PCM and waste materials may have an adverse effect on the thermal performance of the material, even if the interaction is weak. It is therefore crucial to ensure that the selected waste materials do not induce chemical incompatibility or instability during the thermal cycles of PCM [4]. In related studies, it has been demonstrated that the energy storage capacity of building materials exhibits minimal reduction during thermal cycling periods. Based on a phase change rate of 300 times per year [47], these findings indicate that waste-based PCM may have a functional lifespan of approximately 4 years.

The phase change temperatures of PCM are situated in proximity to indoor comfort ranges, thereby performing an efficacious function in ensuring thermal comfort. However, it is also necessary to consider the climatic characteristics when selecting or adjusting the phase change temperature. A review of the literature reveals that all of the PCM types under examination are organic in nature. It has been documented that the thermal conductivity of alcohol derivatives is less than that of fatty acid derivatives, whereas paraffin exhibits a thermal conductivity value that falls between these two categories.

The low thermal conductivity of PCM impedes effective heat transfer, thereby limiting the material's potential for heat storage [48]. The addition of certain waste materials has been shown to significantly enhance the thermal conductivity of the resulting material. For instance, the thermal conductivity of a material can be enhanced by incorporating apricot kernel shell or tire rubber. As illustrated in Table 3, the thermal conductivity of the material can be increased by up to 2.61 and 2.3 times, respectively.

| Article ID | PCM | Thermal conductivity (W/mK) | Thermal energy storage | Tested thermal stability (cycles) | Phase change temperature (°C) |

|---|---|---|---|---|---|

| {1} | Alcohol | n.a. | 145 J/g | 100 | 29.5–29.7 |

| {2} | Polyethylene glycol (PEG) | n.a. | 108.5 J/g | 100 | 19.6–28.3 |

| {3} | Lauryl alcohol (LA) | 0.18–0.40 | 99.5 J/g | 750 | 20.2 |

| {4} | Capric-Myristic acid, lauryl alcohol, n-octadecane, polyethylene glycol | 0.47, 0.48, 0.50, 0.58 | 193.7 J/g | 1200 | 20.2–26.6 |

| {5} | Glycerine and fatty acids | n.a. | 149–200 J/g | 500+ | 17.9–31.6 |

| {6} | Paraffin | 0.5 | 10 J/g | 100 | 21.2 |

| {7} | Paraffin | n.a. | n.a. | n.a. | n.a. |

| {8} | Alcohol | 0.43 | 181 J/g | 500 | 21.1 |

| {9} | Capric acid | 0.64 | 628 kJ/m3 | n.a. | 30–32 |

| {10} | Capric-Palmitic acid | 0.347 | 34 J/g | 300 | 21.6 |

| {11} | Paraffin | n.a. | 92.7 J/g | n.a. | 18–27 |

The utilization of waste materials enables the storage of energy without the loss of material that would otherwise occur during a change of state. The composite building material produced by impregnation method using bio-based waste materials, including cuttlebone and pomelo peel, demonstrated a 70% increase in thermal energy storage capacity compared to the reference case, where only PCM obtained from oil was utilized [4]. Similarly, it was demonstrated that the composite material obtained from coconut peat by vacuum impregnation has the potential to be employed as a wall panel that provides passive cooling in buildings, due to its energy storage capacity of over 100 J/g [37]. The heat storage capacity of another composite material produced by vacuum impregnation of alcohol into rubber was found to be 181 J/g, and a 2.3-fold increase in the thermal conductivity of the material was observed as a result of the waste material used [43].

The contribution of waste to the reduction of energy consumption is as significant in the production of building materials as it is in the operational phase of the building. Kumar et al. [44] asserted that the recycled expanded glass panels they produced in their study exhibited reduced embodied energy and carbon compared to the gypsum board panels currently available on the market. Furthermore, the energy consumption of active and passive houses during their respective use phases was calculated through the utilization of the EnergyPlus program for building energy simulation. In the study in which the life cycle energy and carbon emissions were calculated together, it was determined that the panel produced provided a 4.5% reduction in total energy and a 12% reduction in total carbon emissions in comparison to the reference. The aforementioned studies demonstrate that waste has yielded significant outcomes in the domain of thermal energy storage.

4.2 Effective Water Use

The efficient utilization of water in buildings is of paramount importance in order to avert the looming threat of water scarcity, which is one of the most significant challenges of our time. In this study, the water efficiency of the wastes incorporated into the structure of PCM was evaluated through an assessment of their water retention properties. The majority of the waste materials employed in the studies were observed to have the capacity to trap water due to their porous structures. As a result of these characteristics, they are capable of providing impermeability to the material and preventing the necessity for water supplementation by ensuring the continuous utilization of water.

The use of shape stabilizers is frequently employed to avert leakage issues that may arise when PCM transitions to the liquid phase. The primary characteristics of the stabilizers employed include high porosity, recyclability, innocuousness, and economic viability [4]. It is feasible to employ a range of waste materials as shape stabilizers in the production of composite PCM. The aforementioned materials include hemp-shive, coconut peat, cuttlebone, and pomelo peel, which are biologically based wastes. Furthermore, fly ash and concrete powder, which are industrial by-products, can also be employed to impart sealing properties to the material.

Despite undergoing a drying process, coconut peat's hydrophilic structure enables it to resist evaporation, thereby allowing its incorporation into the PCM structure as a shape stabilizer [37]. Cuttlefish are renowned for their capacity to regulate the volume of water within their bones, enabling them to maintain a vertical position in aqueous environments. The capacity of this bone structure to retain water endows the PCM with a leak-proof quality, which can benefit up to 100 thermal cycles [4].

Conversely, the processing of waste materials entails the consumption of energy and water. Baldassarri et al. [40] posit that improvements can be made to the water, electricity, and natural gas consumption during the waste oil treatment process in order to facilitate the incorporation of waste oil into building materials and utilize it as thermal energy storage. Moreover, the utilization of waste materials in PCM production is of significant importance in ensuring the fluidity of materials processed by 3D printing. In a study where fly ash was incorporated into microencapsulated paraffin wax, it was observed that thermal stability and the desired viscosity were achieved over 100 thermal cycles in the production of miniature 3D-printed houses [41] (Table 4).

| Article ID | Waste | Explanation |

|---|---|---|

| {1} | Cuttlebone | Water absorption, prevention of leakage up to 100 cycles. |

| {2} | Coconut peat | Hydrophilic, resistant to evaporation, prevention of leakage. |

| {3} | Hemp-shives | Cellulosic, prevention of leakage. |

| {4} | Apricot kernel shells | Cellulosic, prevention of leakage. |

| {5} | Waste cooking oil | There is a need to improve the water and energy consumption used in the waste treatment process. |

| {6} | Fly ash | Desired viscosity is ensured up to 100 thermal cycles. |

| {7} | Electrical arc furnace dust | Prevention of leakage. |

| {8} | Tire rubber | Prevention of leakage up to 500 thermal cycles. |

| {9} | Recycled expanded glass | High water absorption, prevention of leakage. |

| {10} | Recycled concrete powder | Prevention of leakage up to 300 thermal cycles when used at 20% by weight. |

| {11} | Recycled expanded glass aggregate | High water absorption (80%), prevention of leakage. |

4.3 Raw Material Conservation

PCM optimizes the utilization of materials in the construction industry, thereby contributing to sustainability. The utilization of waste and recycled materials in the production of PCM serves to reduce the consumption of natural resources. The findings of studies conducted by Sarı et al. [43] and Baldassarri et al. [40] indicate that PCM produced from recycled materials exhibits enhanced energy storage capabilities while necessitating a reduced reliance on new materials. This constitutes a notable contribution to the conservation of natural resources. As materials with energy storage capacity, PCM reduces the necessity for insulation of buildings, thereby reducing the quantity of material utilized in construction projects. In a similar vein, Gencel et al. [38] posit that hemp-shive and PCM-based building materials can provide the same thermal performance with less material than conventional building materials. This contributes to environmental sustainability while reducing costs. The incorporation of PCM into building materials enhances their durability, thereby reducing the necessity for renovation. Kumar et al. [44] asserted that building materials incorporating PCM demonstrate prolonged performance, thereby reducing the necessity for the periodic replacement of building components. Consequently, the utilization of materials is also made more efficient.

In all of the studies reviewed, the utilization of waste material as a substitute for raw materials serves to reduce the necessity for raw materials and to guarantee the continuity of resources. Nevertheless, in certain studies, the characteristics of waste materials that enhance thermal performance also diminish the necessity for supplementary insulation. To illustrate, the utilization of carbonized waste rubber derived from tires to enhance thermal conductivity and serve as a PCM support represents a valuable contribution to the circular economy [43].

4.4 Environmental Impacts and User Health

A significant proportion of waste is generated by sectors such as agriculture, construction, and industry. In the construction sector alone, millions of tons of waste are generated worldwide every year as a consequence of the utilization of building materials [49]. The term “embodied energy” is used to describe the energy consumed during the production, use, and lifetime of building materials. This energy can be 20 to 50 times the annual operational energy consumption of a building [50]. It is therefore of great importance to consider the energy consumption and greenhouse gas emissions associated with the materials to be used in the construction of the building.

The utilization of waste materials can yield both beneficial and detrimental consequences for the natural environment. The incorporation of waste into the system can facilitate resource continuity, reduce the necessity for raw materials, and mitigate the burden on landfills. The negative effects of waste include the potential presence of harmful compounds, lack of biodegradability, and the release of volatile organic compounds into the environment. These factors, which also impact indoor air quality, are addressed in section 4.6 on comfort parameters. This section will examine the behaviors that fall within the scope of environmental impact classes as defined in international standards.

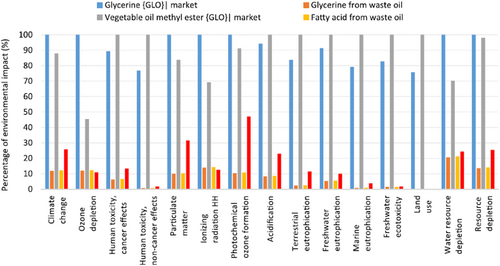

Kumar et al. [44] found that using waste can reduce lifecycle energy by 4.5%. Therefore, energy-related carbon emissions decreased 12%. In another study employing vegetable oils derived from waste cooking oil as phase-change materials (PCMs), wall panels were subjected to energy simulation in 50 distinct countries and four different climate zones [40]. In the study in which the environmental impacts of PCM-containing panels designed as single and double layers were tested, it was observed that the utilization of waste oils had a mitigating effect on the negative impacts, particularly in regard to poisoning, non-cancer health threats, eutrophication, clean water and land use. The study highlighted the potential for glycerin derived from waste oils to serve as a substitute for paraffin, a material currently prevalent in the market. It is hypothesized that the elevated levels of toxicity and non-cancer health risks associated with oil derivatives in the market are attributable to the nitrogen and phosphate fertilizers employed in the cultivation of the seeds from which the oil is derived. Furthermore, other activities, such as soil cultivation and irrigation, can result in eutrophication and significantly impact the availability of clean water and land use (Figure 4). In this regard, the selection of waste materials can be regarded as an environmentally benign decision.

Moreover, the utilization of waste as building materials within the context of circular economy principles confers environmental benefits, including a reduction in resource consumption and the circumvention of raw material processing. The recycling of waste materials and their utilization as building materials serves to reduce energy consumption and contribute to the conservation of natural resources and the advancement of environmental sustainability. Conversely, the disposal of waste materials in the natural environment can result in environmental contamination. Given their low economic value, coconut shells are discarded in considerable quantities on an annual basis, which can result in adverse environmental consequences. However, its cellulosic structure, biodegradability, ease of accessibility, and low cost make it a potentially viable bio-based PCM supporter [37].

No health analysis was conducted in the selected studies. However, Barreneche et al. [42] conducted a leaching test to find out if industrial waste used as wall material contained any hazardous substances.

4.5 Economic Perspective

One of the principal criteria for the utilization of PCM in construction projects is its economic viability. In the event that solutions designed to enhance the energy performance of buildings have a payback period that exceeds the lifespan of the building in question, the aforementioned solutions will effectively become devoid of any meaningful purpose. It is therefore of great importance to develop cost-effective solutions. Inorganic PCM types are typically less expensive than organic and eutectic types. However, the application method of PCM can also have a significant impact on the total cost [28]. For instance, while encapsulation techniques can assist in preventing leakage, they are typically not the preferred option due to the high initial costs involved [42, 44].

Consequently, more cost-effective techniques have been devised that can prevent leakage without the utilization of capsules in PCM production. One such method is the form-stabilization technique, whereby the PCM is impregnated into a porous matrix. An alternative approach is the shape-fixing method, whereby the PCM is melted and mixed with a supporting matrix [51]. Nevertheless, these techniques may result in a reduction in the heat transfer performance of the composite materials produced. Accordingly, the incorporation of fillers with high thermal conductivity may prove an effective means of enhancing heat transfer. Due to their low cost, these fillers are typically selected from waste materials [43].

Waste materials can be employed not only as filler material but also, on occasion, as PCM itself. For example, Baldassarri et al. [40] produced cement-based composite panels using waste cooking oil and employed this waste oil as a PCM. Such applications result in reduced material costs and contribute to environmental sustainability. Furthermore, the utilization of recyclable waste materials in PCM production renders these materials a more economically viable option. In conclusion, in order to achieve cost-effectiveness in PCM production, the utilization of waste materials, non-encapsulated fixation methods, and low-cost filler materials represents a significant contribution to the overall cost-effectiveness of the process.

4.6 Comfort Parameters

In the context of sustainable architecture, social sustainability is concerned with enhancing the quality of human life. Consequently, it is closely associated with human necessities pertaining to health and well-being, as well as cultural and psychological aspects [52]. The provision of thermal, acoustic, visual comfort and indoor air quality enables the design of comfortable buildings. A deficiency in thermal comfort can impede physical and mental work, whereas poor indoor air quality can endanger human health by precipitating a range of illnesses.

The quality of the air within buildings is of great importance. The utilization of waste materials in the production of building materials has the potential to negatively impact indoor air quality. It is therefore essential to ascertain whether the waste in question contains any harmful substances, and if so, to what extent, and whether such substances are released into the indoor or outdoor environment. In accordance with the European Directive, the heavy metal content of waste is categorized as inert, harmless, or harmful. In light of the aforementioned considerations, the present study was designed to assess the ability of heavy metals to be filtered through the use of a leaching test. A leaching test is a chemical analysis method that is used to detect the presence of hazardous substances in waste. In the study in which electrical arc furnace dust (EAFD), an industrial waste, was employed in the production of PCM, it was asserted that this material is hazardous and should be deposited in landfills with caution [42]. In order for such hazardous waste materials to be employed in construction projects, a number of remediation techniques can be proposed. One such method is encapsulation. Nevertheless, this approach represents a provisional solution, given its high cost and lack of specificity in addressing the issue of heavy metal removal [42]. While fixation and solidification techniques are relatively inexpensive, the elevated pH value of the leachate can potentially give rise to certain issues. It is therefore imperative that professionals from a range of disciplines, including environmental and materials engineers, collaborate to develop remediation methods that are tailored to the specific characteristics of the waste in question. Despite the utilization of waste in all of the reviewed studies, no supplementary studies were identified.

The concept of thermal comfort is defined as the condition of mind that expresses satisfaction with the thermal environment. The test cabinets produced in the studies allow for the determination of the temperature values and time delays reached in comparison to the reference situation. In a study conducted by Gencel et al. [38], two 20 × 20 × 20 cm modules were designed using hemp shive and lauryl alcohol (LA). The modules were equipped with skylights and examined under real atmospheric conditions to analyze the temperature behavior of the wall panels produced. One of the modules serves as a reference cube, devoid of PCM but containing solely hemp shive and encased in an outer layer of 5 cm-thick expanded polystyrene (EPS). The second comprises a cabin with 45% PCM (LA) and hemp shive. The experiment {3} was conducted over a four-day period in August in Bartın, Turkey. The temperature data obtained from the temperature meters placed on the inner surface of the prepared cabin revealed a temperature difference of 6°C between the two cabinets [38].

The configuration of {6}, comprising miniature test chambers produced via 3D printing, was evaluated within a temperature range of 15°C–30°C, reflecting typical diurnal fluctuations. The temperature transitions were conducted over a 12-h period. Among the tested cabinets, the GPP-0% model does not contain macroencapsulated PCM, whereas the GPP-20% model contains 20% PCM. The temperature differential between the two chambers was 1.2°C [41].

In a separate study {7}, the temperature differential between two cabinets, one equipped with PCM and the other without, tested at a temperature differential of 18°C–28°C was found to be 3°C [42]. In the experimental setup {9} consisting of a wood panel and insulation material, tested in a simulated environment in Australia, it was found that extreme temperatures were reduced by 12.4% and carbon emissions from cooling could be reduced by 14% thanks to the concrete panel with PCM [44]. Finally, in {10}, which was constructed with material comprising MDF, EPS, and recycled concrete powder, a 5°C decrease in the highest daily temperatures and a 3.6°C increase in the lowest temperatures were observed in the PCM-containing cabinet in comparison to the reference cabinet without thermal storage [45]. The manufactured experimental cabinets are illustrated in Figure 5.

The acoustic comfort of the environment is a key consideration in the design of any acoustic space. In their 2016 study, Barreneche and colleagues observed that the industrial waste (EAFD) utilized in their investigation provided 4 dB of acoustic insulation in the PCM-containing cabin when compared to the reference cabin. The high density of heavy metal oxides present in the material has an effect on the improvement of the acoustic performance of the waste material.

5 Discussion of the Results

The results and evaluations of the 11 studies on PCM present disparate findings with regard to energy storage capacities, thermal comfort, environmental impact, and cost analysis. The studies encompass both bio-based and industrial waste-derived materials.

In the initial investigation, the researchers observed a 70% increase in thermal energy storage capacity relative to the baseline PCM, accompanied by a volumetric efficiency of 90%. The material was demonstrated to remain stable for 100 thermal cycles. Nevertheless, cost analysis, environmental impact assessment, and health risk analysis have yet to be conducted. In the study employing coconut peat (2), the latent heat storage capacity was determined to be 108.5 J/g. It was established that a material suitable for passive cooling with minimal leakage was produced and could be utilized as a building slab. No leakage was observed in the bio-based PCM produced with 45% weighted shape-stabilized PCM (SSPCM). In terms of thermal comfort, when the external temperature exceeded 50°C, the experimental chamber remained 4°C cooler than the reference chamber. Conversely, when the external temperature was 20°C, the internal temperature of the chamber was 2°C higher than that of the reference chamber. Industrial and bio-based phase-change materials. The material demonstrated a latent heat storage capacity of 193.7 J/g. Nevertheless, cost analysis, an environmental impact assessment and a health risk assessment were not conducted.

The potential of heat storage materials derived from bio-based waste was assessed across 15 distinct environmental impact categories, with climate-based evaluations conducted for 50 cities. The present study offers a significant contribution to the environmental analysis of sustainable heat storage systems. The product, comprising 20% by volume of PCM, exhibits a latent heat storage capacity of 10 J/g. The substance in question has a melting temperature of 21.2°C and a thermal conductivity of 0.5 W/mK. The material has demonstrated thermal stability over 100 cycles.

In the study (7), which examined the use of industrial PCM and acoustic insulation, a reduction in indoor temperature of 3°C was observed. Furthermore, the results of the leakage test indicated that the material was not hazardous. Furthermore, the EAFD was observed to provide 4 dB of sound insulation due to its heavy metal content. In the study (8), which is notable for its high heat storage capacity, a latent heat capacity of 181 J/g was obtained. The thermal conductivity of this PCM was found to be 2.3 times higher than that of conventional materials and remained stable for 500 cycles. Furthermore, it did not leak until the weight of alcohol reached 78%.

The PCM derived from construction waste was evaluated for use in the building sector and was found to result in a 4.5% reduction in the life cycle energy. The application of the material resulted in a reduction of carbon emissions by 12% and a reduction in the incidence of summer overheating by 12.4%. The cost of the panel containing the PCM is 11% higher than that of the base panel. Another PCM under investigation exhibits a latent heat capacity of 34 J/g and no leakage when utilizing 20% PCM. The material has demonstrated stability over 300 cycles, exhibiting a decrease of 5°C at the highest temperatures and an increase of 3.6°C at the lowest temperatures. The economic analysis revealed that the payback period of the PCM obtained from construction waste {11} was 25 years. The findings of the studies that contribute to architectural sustainability are summarized in Table 5.

| Article ID | Proposed material features (Waste type) | Findings and evaluation |

|---|---|---|

| {1} | Environmentally friendly, cost-effective, efficient (biobased) | Energy storage: Biodegradable and renewable composite production. 70% of thermal energy storage capacity and 90% of volumetric efficiency compared to base PCM. Water efficiency: Stabilization is ensured for 100 thermal cycles. PCM ratio is 80% by weight. |

| {2} | Less environmental pollution (biobased) | Energy storage: Latent heat storage is 108.5 J/g. Potential material for passive cooling in buildings. Can be used as a wallboard. Water efficiency: Minimal leakage when waste-PCM ratio is 3:7. |

| {3} | High thermal energy storage (biobased) |

Water efficiency: No leakage at 45% weight SSPCM. Thermal comfort: When the outside temperature is more than 50°C, inside of the experimental cabin is 4°C cooler than the reference cabin. When outside is 20°C, inside temperature is 2°C higher than the reference cabin. |

| {4} | No leakage and high thermal conductivity (industrial-biobased) | Energy storage: Latent heat storage is 193.7 J/g. Water efficiency: No leakage at 70%–75% PCM ratio. |

| {5} | Climate-sensitive, spatially and environmentally efficient (biobased) | Environmental analysis: Waste oil can be a counterpart of paraffin in terms of environmental performance. Raw material use: Insulation thickness can be reduced 25% without reducing thermal performance. |

| {6} | Ensures thermal comfort, energy efficiency and sustainability (industrial) | Energy storage: The latent heat of the product with PCM at 20% by volume is about 10 J/g. Thermal comfort: Melting temperature is 21.2°C, thermal conductivity is 0.5 W/mK. Water efficiency: Stability is achieved for more than 100 cycles. |

| {7} | High acoustic and thermal performance (industrial) | Thermal comfort: Indoor air temperature decreased 3°C. Health analysis: According to leaching test, this material is not hazardous. Acoustic comfort: EAFD can insulate sound up to 4 Db due to its heavy metal content. |

| {8} | No leakage (industrial) | Energy storage: Latent heat capacity is 181 J/g. Thermal conductivity is 2.3 times higher. Water efficiency: Stable for 500 cycles. No leakage until alcohol weight reached 78%. |

| {9} | Low embodied energy, low CO2 emission and high thermal performance (constructional) | Environmental analysis: Lifecycle energy is found to be 4.5% lower than the base case. Carbon emission is reduced by 12%. Thermal comfort: Summer overheating is decreased 12.4%. Cost analysis: The proposed precast panel has 11% more initial cost than the reference panel. |

| {10} | High energy efficiency and thermal performance (constructional) | Energy storage: The composite has approximately 34 J/g of latent heat capacity. Water efficiency: No leaks when waste-PCM ratio is 20% by weight. Stable for more than 300 cycles. Thermal comfort: Highest temperature is reduced 5°C and lowest temperature is increased 3.6°C. |

| {11} | No leakage and high thermal storage capacity (constructional) | Cost analysis: Payback period of the produced PCM is 25 years. |

- Energy: Waste-based building materials can absorb thermal energy between 10 and 193 J per gram. The phase change temperature should be within the comfort range.

- Water: Utilization of porous waste helps to keep the water within the material. Thus, less water is consumed. Thermal cycles range from 100 to 1200 without any leakage.

- Raw material: The use of biobased and industrial-based waste reduces the need for raw materials. This ensures circular economy and resource sustainability.

- Environment and user health: There is not enough study on the health effects of waste-based materials. However, production and use stages of the waste-based building materials have been studied. It is proved that in most of the environmental impact category, using waste is more environmentally friendly than buying raw materials from the market.

- Economy: Wastes are effective in minimizing the economic burden of building materials both in the production and the use stages. However, methods such as encapsulation may require high initial costs.

- Comfort: Waste-based building thermal energy-storing building materials can be beneficial in ensuring thermal and acoustic comfort. However, studies examining the effects on indoor air quality should be diversified.

Among these sustainability criteria, energy is the most studied subject, followed by water absorption, and comfort. Biobased wastes are popular, especially in the production of composite materials. It is known that industrial-based wastes are used in various fields such as composite, adhesive, and panel production. On the other hand, construction waste can improve the thermal properties of concrete, by incorporating it into the structure (Figure 6).

6 Conclusions and Recommendations

This comprehensive study illuminates the potential of integrating waste-based PCM into building materials for sustainable architectural design. The findings of the 11 studies demonstrate the considerable environmental, social, and economic advantages of these materials in construction applications. The waste-based PCM demonstrated effective thermal energy storage capabilities, with latent heat storage capacities within the range of 10 to 193 J/g. The utilization of these materials facilitates the storage and subsequent release of excess heat, thereby reducing the necessity for mechanical heating and cooling systems. As evidenced by multiple studies, PCM has the capacity to reduce indoor temperatures by up to 5°C during periods of high external temperature and increase them by up to 3.6°C during periods of low external temperature.

The incorporation of waste materials into PCM has been demonstrated to markedly diminish the carbon emissions and embodied energy associated with structural components. The utilization of biodegradable, renewable, and recycled waste materials (e.g., hemp shive, coconut peat, apricot kernel shell) serves to mitigate environmental degradation by facilitating the reuse of industrial and organic waste.

Although economic analysis of waste-based PCM is scarce, the potential for long-term savings in energy consumption and building maintenance has been identified. While the utilization of waste materials may result in cost savings, the economic implications of the selected PCM can be a significant consideration, particularly in relation to the specific materials employed. The incorporation of waste-based PCM into construction materials is aligned with the global sustainability objectives of reducing the environmental impact of the construction industry. By enhancing energy efficiency, curbing carbon emissions, and leveraging waste materials, these materials facilitate the transition towards greener and more sustainable construction practices.

It would be beneficial for future projects to investigate the thermal stability and mechanical durability of PCM in different climatic conditions and over an extended period of time. In particular, studies examining the durability of PCM subjected to environmental conditions over 1000 cycles are becoming increasingly significant. A number of existing studies provide only limited information on the costs and life cycle analysis. In future research, a more comprehensive analysis of the costs associated with the production, application, and recycling of PCM is required. Furthermore, life cycle assessments of PCM should be conducted, incorporating a greater number of cities and climatic conditions. It is of great importance for sustainability that efforts to utilize recyclable and bio-based wastes in PCM production are increased. In particular, it would be beneficial to investigate whether new waste types and industrial by-products can be integrated into PCM.

There is a paucity of information regarding the effects of PCM on indoor air quality (IAQ) and human health. It would be beneficial for future research to analyze the potential long-term health risks associated with building materials containing PCM, as well as examining whether these materials release toxic substances. Further life cycle assessments (LCA) are required to gain a full understanding of the environmental impacts of PCM-containing building materials. It is recommended that future assessments include parameters such as recycling processes, the amount of energy and water used in the production processes of materials, and carbon footprint.

In order to enhance the contribution of PCM to sustainable architecture, it is essential to establish global collaborations between researchers, industry partners, and governments. Such collaborations can facilitate the exchange of knowledge across different regions, thereby promoting the wider adoption of PCM. It would be beneficial for local and international regulatory bodies to provide incentives for the wider use of waste-based PCM in the construction sector. It is within the power of governments and environmental agencies to offer financial support programs and tax benefits with the intention of increasing the use of sustainable construction materials. In order to ascertain the suitability of PCM for different climatic and regional conditions, it is essential to develop application guidelines based on local climatic characteristics. The objective of these guidelines is to optimize the thermal and environmental impacts of PCM in the context of building material selection. It would be beneficial to implement training and awareness-raising programs for architects, civil engineers, and professionals in the building industry, with a focus on PCM technologies and their advantages.

Author Contributions

Ebru Kılıç Bakırhan: conceptualization, investigation, writing – original draft, visualization, methodology, writing – review and editing, data curation. Merve Tuna Kayılı: writing – review and editing, methodology, project administration, writing – original draft.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

Data sharing is not applicable to this article as no new data were created or analyzed in this study.