The entrainment and evolution of gas bubbles in bread dough—A review

Abstract

Background and Objective

For control of bread quality to achieve high loaf volume and uniform crumb structure, gas bubble dynamics in dough needs to be better understood throughout different breadmaking processes. The objective of this review was to establish a solid theoretical basis on how flour type, water and salt content, and mixing conditions affected the incorporation, evolution, and stabilization of gas bubbles in a dough.

Findings

Bubble dynamics including entrainment, disentrainment, break-up, disproportionation, growth, and coalescence were outlined and their effects on the gas phase of the dough were assessed. The application, advantages, and disadvantages of microscopy, magnetic resonance imaging (MRI) and X-ray microtomography techniques for qualitatively or quantitatively characterizing the void fraction and bubble size distribution (BSD) in the dough at various stages of the breadmaking process have been discussed.

Conclusions

Since the BSD evolution in bread dough is associated with the quality of the resultant products, to devise strategies for improving the product quality, dough formulation, and mixing conditions need to be considered.

Significance and Novelty

Due to the obvious challenges of monitoring the fast evolution of BSD in yeasted dough, future research needs to focus on the effects of yeast activity on dough's BSD.

1 INTRODUCTION

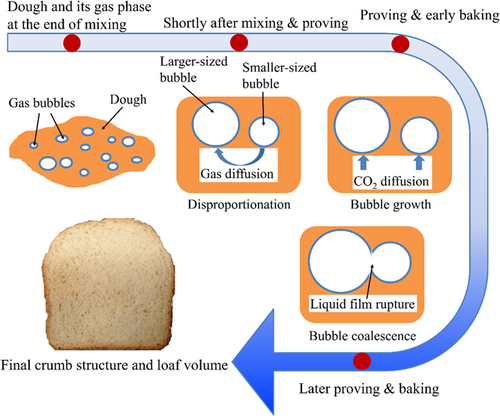

Gas bubbles are a significant ingredient for breadmaking (Chevallier et al., 2012; Romano et al., 2013) as they contribute to approximately 9%–20% of bread dough's total volume at the end of mixing (Whitworth & Alava, 1999). Subdivision of gas bubbles that are entrained during mixing occurs throughout later breadmaking processes, that is, punching, sheeting, and molding, leading to changes in the number and distribution of gas bubbles (Chiotellis & Campbell, 2003a). The contribution of these bubbles to total gas volume increases toward the end of breadmaking, accounting for 70%–75% at the end of proving, due to bubble inflation from CO2 production by yeast (Campbell & Shah, 1999; Sroan et al., 2009). During baking, as temperature increases, gas in the bubbles expands, resulting in a final baked loaf containing 75%–85% gas by volume (Campbell & Shah, 1999; Sroan et al., 2009).

The involvement of the gas phase in the mixing process of dough can be considered as three concurrent events: gas entrainment, gas disentrainment, and bubble break-up (Campbell, 1999). Entrainment is defined as the process that entraps a certain volume of gas into the dough when surfaces of the dough approach each other and adjoin during mixing (Chin et al., 2004), indicating that there is a positive relationship between bubble entrainment and the volume of gas in the dough, that is, dough's void fraction (VF). Disentrainment leads to the removal of gas in the dough, and thus it has a negative relationship with VF (Campbell, 1999; Chin et al., 2004). A balance between entrainment and disentrainment of gas bubbles during mixing affects the VF (Campbell, 1999; Campbell & Shah, 1999), whereas bubble break-up together with entrainment and disentrainment affect the size distribution of bubbles in the dough (Chin et al., 2004; Martin et al., 2004; Trinh et al., 2013).

In addition to their contribution to the VF, and thus the dough volume, the presence of gas bubbles in the dough also affects the volume, appearance, taste, and texture of bread (Cauvain et al., 1999; Demirkesen et al., 2014; Scanlon & Zghal, 2001). Obtaining an appealing cell structure in the bread crumb, that is, small cells (1–2 mm) within the crumb, requires not only a homogenous mixture of ingredients within the dough but also an incorporation of small-sized bubbles into the dough followed by their subdivision (Cauvain et al., 1999; Cauvain, 1998). During proving and baking, the growth and coalescence of gas bubbles cause further changes in the size distribution of bubbles and the total VF, and this, in turn, affects the cell structure of the resulting bread crumb (Babin et al., 2008; Scanlon & Zghal, 2001; Whitworth, 2008).

The overall objective of this review was to provide a solid theoretical foundation on how basic ingredients (i.e., flour, water, and salt) and mixing conditions (i.e., mixing time, work input, mixing speed, and headspace pressure) affect the entrainment, evolution, and stabilization of gas bubbles in dough during breadmaking. In addition, how the bubble size distribution (BSD) in the dough during breadmaking can be characterized using a variety of advanced techniques, that is, microscopy, magnetic resonance imaging (MRI), and X-ray microtomography techniques were discussed. A more recent advancement in imaging dough and bread microstructure, i.e., synchrotron X-ray microtomography, has also been examined as a powerful technique to quantitatively characterize and monitor the fast evolution of BSD. Finally, future perspectives on the investigation of the effects of yeast activity on dough's BSD have also been considered.

2 GAS BUBBLE ENTRAINMENT AND VOID FRACTION IN THE DOUGH

Gas bubbles are entrained into the dough during the process of mixing. The rate of bubble entrainment varies at different mixing stages (Koksel & Scanlon, 2012). During the early stages of mixing, the entrainment of gas bubbles is relatively slow because the dough is still hydrating. Then the rate of bubble entrainment greatly increases until the dough reaches its maximum resistance to mixing (optimal development of gluten proteins). After maximum dough resistance to mixing is reached, the bubble entrainment rate decreases (Chin & Campbell, 2005a).

The final VF at the end of mixing is affected by mixing process parameters, that is, mixing speed, work input, mixer headspace pressure, and mixing time. This is illustrated in Table 1. For example, the VF of dough increases with increasing the mixing speed and work input (Chin & Campbell, 2005b), and with increasing the mixer headspace pressure (Campbell et al., 2001). It has also been shown that an increase in mixing time leads to an increase in VF as measured by dough density (Koksel & Scanlon, 2012), ultrasonic studies (Mehta et al., 2009) as well as fluorescence fingerprint imaging analyses (Kokawa et al., 2012).

| Effects | Dough's void fraction (VF) | Reference |

|---|---|---|

| Increased mixing speed and work input | Increased | Chin and Campbell (2005b) |

| Increased mixing headspace pressure | Increased | Campbell et al. (1999, 2001); Elmehdi et al. (2004) |

| Increased mixing time | Increased | Kokawa et al. (2012); Koksel and Scanlon (2012); Mehta et al. (2009) |

| Stronger wheat flour | Increased | Campbell et al. (1993) |

| Decreased | Campbell et al. (2001) | |

| Increased water content | Decreased | Peighambardoust et al. (2010) |

| Reduced salt content | Increased | Bellido et al. (2006); Koksel et al. (2014) |

Entrainment of gas bubbles into a dough is also affected by ingredients (e.g., flour type, and thus “dough strength”, water, and salt content as illustrated in Table 1. According to dough density measurements, doughs made from stronger flour have higher density and thus a lower volume of gas bubbles entrained (Campbell et al., 2001). Dough density was also observed to increase with increasing water content in the dough (Koksel & Scanlon, 2012), indicating that higher water content doughs had a lower volume of gas bubbles entrained during mixing (Peighambardoust et al., 2010). In terms of VF measurements, salt (NaCl) reduction leads to a higher volume of gas bubbles entrained into the dough (Bellido et al., 2006; Koksel et al., 2014).

The VF of dough, and how it is affected by mixing speed, mixing time, and ingredients, etc., influence dough's rheological properties (Chin, Martin et al., 2005; Elmehdi et al., 2004), and the quality of products baked from it (Sapirstein et al., 1994; Scanlon & Zghal, 2001; Zghal et al., 1999). Decreases in the longitudinal modulus and resistance to extension of doughs were observed with increased VF, as measured by low-intensity ultrasonic (Elmehdi et al., 2004) and large-deformation biaxial extension (Chin, Martin et al., 2005) measurements, respectively. The resistance of dough to biaxial extension positively correlated with its breadmaking performance (Kokelaar et al., 1996), suggesting that a lower volume of gas bubbles entrained into the dough favors better bread quality. In line with these findings, excessive entrainment of gas bubbles into the dough was also reported to cause a poor cell structure within the bread crumb (Williams, 1975).

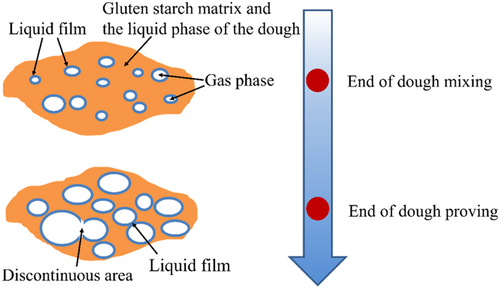

According to the liquid film hypothesis, (Gan et al., 1990; Gan et al., 1995) bread dough has been characterized as a soft material consisting of three phases: (1) the hydrated semi-solid phase of the gluten–starch matrix; (2) the liquid phase that consists of free water and surface active materials (e.g., soluble proteins); and (3) the gas phase which consists of gas bubbles lined with fragile liquid “films.” This is illustrated in Figure 1. By the end of mixing, individual small bubbles are entrained into the continuous network of the gluten–starch matrix and the liquid phase of the dough (MacRitchie, 1976). During the early stages of breadmaking and until the end of proving, the gas bubbles are surrounded by both the gluten–starch matrix and the liquid phase. If the gluten–starch matrix has good extensibility, it reinforces the liquid phase so that bubble stability is enhanced (Bloksma, 1990a; Gan et al., 1990; MacRitchie, 1976). Toward the end of proving, the growth of gas bubbles results in discontinuous areas in the hydrated gluten–starch matrix leaving only the liquid phase as ‘films’ between growing bubbles (Gan et al., 1995). Although the original gluten–starch matrix around a given bubble may no longer be intact at the end of proving and the early stages of baking, the liquid films at the gas–dough matrix interfaces are able to retain the integrity of the gas bubbles (Gan et al., 1990, 1995). This allows the release of gas from the dough to the surrounding atmosphere only at a critical point during baking (Mills et al., 2003), contributing to a bread loaf with a good volume and a uniform crumb cell structure (Gan et al., 1995; Hayman et al., 1998).

3 FACTORS AFFECTING GAS BUBBLE STABILIZATION

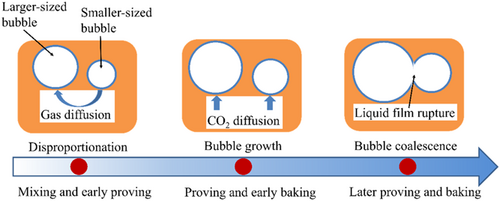

During breadmaking, any factor which affects the stability of gas bubbles, in turn, influences the cell structure of the resulting bread crumb (Hayman et al., 1998; Mills et al., 2003; Zghal et al., 1999). The stability of gas bubbles is affected by certain processes, that is, disproportionation, bubble growth, and coalescence (Mills et al., 2003; Shah et al., 1998; van Vliet, 2008; Vliet et al., 1992). This is illustrated in Figures 2 and 3. Disproportionation is defined as the pressure-driven diffusion of gas from smaller-sized to larger-sized bubbles, causing larger-sized bubbles with smaller internal pressures to grow as the gases in the smaller-sized bubbles with higher internal pressures dissolve into the dough matrix (Stevenson, 2010; Vliet et al., 1992). During breadmaking, bubble disproportionation starts right after mixing and continues during the early stages of proving (Mills et al., 2003; Vliet et al., 1992). During proving and the early stages of baking, bubble growth occurs due to the production of CO2 by yeast fermentation, its solubilization in the dough matrix, its diffusion from the surrounding dough matrix into the bubbles, and expansion of gas in the bubbles arising from increased temperature (Bloksma, 1990a, 1990b; Shah et al., 1998). During the later stages of proving and baking, bubbles coalesce due to the rupture of the liquid films between bubbles (Vliet et al., 1992; van Vliet, 2008).

3.1 Disproportionation

According to Henry's law, the higher pressure in the smaller-sized bubbles promotes a higher concentration of gas to dissolve into the interfacial volume of dough around them, resulting in additional dissolved gas in the liquid phase of the dough. This concentration gradient leads to the diffusion of dissolved gas through the liquid phase of the dough to regions of lower concentration that will be present in the environs of the larger-sized bubbles (van Vliet, 1999). As a result of gas diffusion, larger-sized bubbles keep growing, whereas smaller-sized bubbles shrink and ultimately disappear (Shimiya & Yano, 1987; Venerus & Yala, 1997; Venerus et al., 1998). As such, disproportionation results in changes in the size and the number of bubbles (Lemlich, 1978).

In a dough system, a significant reduction in the number of bubbles occurs due to disproportionation immediately after mixing (Koksel et al., 2016; Vliet et al., 1992). To maintain a sufficient number of bubbles in the dough during breadmaking processes, disproportionation needs to be prevented or retarded (Kokelaar et al., 1996; van Vliet, 2008). One way to achieve that is through a phenomenon called strain hardening. Strain hardening of the proteins at the surface of the expanding bubbles leads to the stress around a bubble that has grown substantially being greater than that at the surface of a bubble that has undergone limited growth, and this phenomenon slows the further growth of bubbles that are stretched substantially (Dobraszczyk & Roberts, 1994; Kindelspire et al., 2015; Kokelaar et al., 1996). This, in turn, decreases the driving force for gas transport between different-sized bubbles (van Vliet, 1999, 2008), leading to slower disproportionation and increased bubble stability during breadmaking (Kokelaar et al., 1996; van Vliet & Kokelaar, 1994; van Vliet, 1999). Biaxial extension tests have been conducted showing that doughs made from stronger wheat cultivars, or those made at lower water content, have higher strain hardening values against disproportionation (Janssen et al., 1996; Kokelaar et al., 1996; Sliwinski et al., 2004).

Increasing the concentration of surface active materials (e.g., proteins and lipids) in a dough formulation has been shown to slow down disproportionation through their role in reducing surface tension at a bubble interface (Kokelaar & Prins, 1995; Lucassen, 1981; Quoc et al., 2002). Soluble proteins are critical flour components that are involved in the formation of stable liquid films around the bubbles. This contributes to increasing bubble stability against disproportionation (Murray & Ettelaie, 2004).

3.2 Bubble growth

In yeasted doughs, bubble growth during proving is induced by yeast fermentation. As yeast produces CO2, the concentration of CO2 in the dough matrix increases (Mills et al., 2003; Shah et al., 1998). Since no new bubbles are entrained after mixing (Baker & Mize, 1941, 1946), according to Henry's law, CO2 solubilized in the liquid phase of the dough diffuses through to the bubble-dough matrix interface (Figure 2) and desorbs to cause an increase in the partial pressure of CO2 inside the bubbles (Amon & Denson, 1984). To achieve mechanical equilibrium between the inside and outside of bubbles, bubbles grow in size (Amon & Denson, 1984).

One of the factors that affect this CO2 diffusion-induced bubble growth is dough rheology around a growing bubble (Shimiya & Yano, 1987; Venerus & Yala, 1997; Venerus et al., 1998; Venerus, 2001, 2015). By taking the biaxial extensional properties of dough into account, a gas bubble growth model has been developed to predict the increase in dough volume during proving (Huang & Kokini, 1999). Higher biaxial extensional viscosity of dough increases the resistance of bubbles to grow (Huang & Kokini, 1999). Dough's strain hardening properties has also been reported to play an important role during bubble growth (Huang & Kokini, 1999; van Vliet & Kokelaar, 1994), that is, doughs with higher strain hardening values have shown lower bubble growth rates (Kokelaar et al., 1996).

The rate of bubble growth is also affected by yeast concentration (Chiotellis & Campbell, 2003a; Shah et al., 1998). Changes in the bubble size distribution (BSD) were modeled to show an increase in the rate of bubble growth with increased yeast concentration in the dough (Chiotellis & Campbell, 2003a). Increased yeast concentration increases the concentration of CO2 that is dissolved in the dough's liquid phase surrounding the bubbles, which promotes the mass transport of CO2 into the bubbles and increases the rate of bubble growth during proving (Chiotellis & Campbell, 2003b).

3.3 Coalescence

Due to the increased concentration of CO2 by yeast activity and increased desorption of water vapor from the inside to outside of dough due to the temperature rise, bubbles expand more rapidly during the early stages of baking (Mills et al., 2003). Meanwhile, the gas volume fraction in the dough increases and thus, bubbles become polyhedral with their surfaces separated by only thin layers of liquid films (Gan et al., 1990, 1995). As the liquid film between the two bubbles thins further, the distance between the two bubbles decreases (Örnebro et al., 2000; Walstra, 1989). While the attractive van der Waals forces between the two bubble–liquid interfaces increase, steric and electrostatic repulsive forces between the two bubble–liquid interfaces decrease (Örnebro et al., 2000; Walstra, 1989). When the repulsive forces are no longer able to maintain the separation between the two bubbles and when the liquid film fails to maintain the same expansion rate as the bubble growth rate, this film ruptures so that the two bubbles coalesce (Babin et al., 2006; Örnebro et al., 2000; Shehzad et al., 2010; Vliet et al., 1992).

If bubbles coalesce at the surface of the dough, some gas is lost to the atmosphere during breadmaking, resulting in a lower loaf volume (Vliet et al., 1992). Extensive coalescence of bubbles in the interior of the dough results in a broad and uneven distribution of gas cells within the bread crumb (Hayman et al., 1998; Scanlon & Zghal, 2001; Vliet et al., 1992; Zghal, 2001). Accordingly, for a good loaf volume with an even crumb structure, bubble coalescence needs to be prevented. One way to prevent bubble coalescence, and to increase bubble stability, is to improve the properties of the liquid film at the bubble-dough matrix interface (Mills et al., 2003), through manipulation of dough's bulk or surface rheological properties (Dobraszczyk & Roberts, 1994; Kokelaar & Prins, 1995; Kokelaar et al., 1996; Vliet et al., 1992). A higher strain hardening value of proteins in the dough (Dobraszczyk & Roberts, 1994; Kokelaar et al., 1996; Vliet et al., 1992) and higher concentration of surface active materials in the dough (Hu et al., 2003; Örnebro et al., 2000) have been reported to increase bubble stability against coalescence.

4 EVOLUTION OF GAS BUBBLES IN DOUGH DURING PROVING AND BAKING

Evolution of gas bubbles in dough (Figure 3), both their size and number, is affected by the concentrations of water and lipids in the dough (Sahi, 1994; Sroan et al., 2009; Upadhyay et al., 2012), as well as the wheat cultivar (He & Hoseney, 1991; Zghal, Scanlon, & Sapirstein, 2001). This is illustrated in Table 2. Decreased water content, which possibly caused a lower surface tension, and led to more bubbles with a smaller mean size in a yeasted dough during proving (Upadhyay et al., 2012). During proving and baking, the expansion of bubbles is delayed for doughs made from wheat cultivars that have a higher content of endogenous lipids (Sahi, 1994). Increased content of added lipids has been reported to reinforce the dough liquid film around bubbles, contributing to the stabilization of expanding bubbles and the improvement in the dough's breadmaking performance (Sroan et al., 2009). Evolution of gas bubbles in a dough, which in turn affects the resulting loaf volume and crumb cell structure, is influenced by wheat cultivar (Campbell et al., 2001; He & Hoseney, 1991; Whitworth & Alava, 1999). For example, doughs made from stronger wheat flour are better at retaining the gas produced during breadmaking so that a higher volume of loaf is produced (He & Hoseney, 1991; Zghal et al., 2001).

| Effects | Gas bubble evolution | Reference |

|---|---|---|

| Decreased water content | Increased the number of smaller-sized bubbles | Upadhyay et al. (2012) |

| Higher content of endogenous flow lipids | Delayed bubble expansion | Sahi (1994) |

| Increased lipid content | Increased bubble stability | Sroan et al. (2009) |

| Stronger wheat flour | Better gas retention | He and Hoseney (1991); Zghal et al. (2001) |

5 BUBBLE SIZE DISTRIBUTION (BSD) AND ITS EVOLUTION IN BREAD DOUGH

As the gas phase of the dough at the end of mixing and how it evolves during later breadmaking processes directly influence crumb cell structure (Gan et al., 1995) and loaf volume (Mills et al., 2003), investigations of the gas phase of the dough and its evolution during breadmaking processes is of utmost importance to provide strategies for improvement of the quality of bakery products (Lim & Barigou, 2004; Örnebro et al., 2000; Scanlon & Zghal, 2001). Changes in the gas phase of the dough during breadmaking can be studied by investigations of the gas void fraction (VF) of the dough and the BSD (Campbell et al., 1991; Örnebro et al., 2000; van Vliet, 2008). The VF of dough can easily be determined from dough density measurements (Campbell et al., 2001; Leroy et al., 2008). However, the BSD of dough is much more challenging to obtain due to the fragility and opacity of dough (Bellido et al., 2006; Campbell et al., 1991).

5.1 Characterization of BSD

5.2 Determination of BSD in bread dough

Investigations of the BSD in bread dough have been conducted using various imaging techniques, for example, microscopy (Upadhyay et al., 2012), magnetic resonance imaging (MRI) (De Guio et al., 2009; van Duynhoven et al., 2003), and X-ray microtomography (Babin et al., 2006; Bellido et al., 2006; Koksel et al., 2016; Shehzad et al., 2010; Trinh et al., 2013; Turbin-Orger et al., 2012, 2015). Techniques for determining the bubble size distribution (BSD) in dough are illustrated in Table 3.

| Techniques | Description of dough's BSD | Reference |

|---|---|---|

| Light microscopy | Bubble diameter ≥ 45 μm Bubble diameter ≥ 39 μm Bubble diameter ≥ 3 μm; Lognormal BSD |

Carlson and Bohlin (1978) Campbell et al. (1991) Shimiya and Nakamura (1997) |

| Scanning electron microscopy (SEM) | 20 μm ≤ bubble diameter ≤ 1500 μm | Whitworth and Alava (1999) |

| Confocal laser scanning microscopy (CLSM) | Average and standard deviation of bubble diameters | Upadhyay et al. (2012) |

| Magnetic resonance imaging (MRI) | Bubble growth rate | Rouillé et al. (2005) |

| Normal BSD | De Guio et al. (2009) | |

| Bubble distribution and cell wall thickness | Bonny et al. (2004) Takano et al. (2002) |

|

Bench-top X-ray microtomography Synchrotron X-ray microtomography |

Time-dependent evolution of BSD Lognormal BSD; Resolution = 10 μm per pixel Lognormal BSD; Resolution = 6.5 μm per pixel Lognormal BSD; Resolution = 8.75 μm per pixel Growth of bubble sizes Resolution = 5 μm per pixel Resolution = 15 μm per pixel |

Bajd and Serša (2011) Bellido et al. (2006) Sun et al. (2020) Guillermic et al. (2018) Koksel et al. (2016) Babin et al. (2006) Turbin-Orger et al. (2012) Turbin-Orger et al. (2015) |

5.2.1 Microscopy

Microscopy is a widely used imaging technique for investigations of food structure (Kaláb et al., 1995). The BSD in bread dough has been investigated using microscopic techniques, including light microscopy (Campbell et al., 1991; Carlson & Bohlin, 1978; Shimiya & Nakamura, 1997), scanning electron microscopy (SEM) (Whitworth & Alava, 1999), and confocal laser scanning microscopy (CLSM) (Upadhyay et al., 2012). These microscopic techniques differ in their illumination source, that is, a beam of visible light for light microscopy, a beam of electrons for SEM, and a laser beam for CLSM (Falcone et al., 2006). These techniques require an element that focuses the illumination source onto the tested sample and an image generator that records the sample information (Falcone et al., 2006).

Light microscopy was used to study the BSD in dough slices (30 μm of thickness), the bubble diameters were measured (Carlson & Bohlin, 1978), and their distribution was fitted using a function with one parameter, that is, the mean bubble diameter (Carlson & Bohlin, 1978). Based on 2D cross-sectional dough images, a mean bubble surface area of 41 cm2 per cm3 of the dough was reported (Carlson & Bohlin, 1978). However, bubbles with diameters smaller than 45 μm were not counted due to resolution limitations. When measuring the BSD in frozen dough slices (also 30 μm of thickness), light microscopy enabled the measurement of bubbles corresponding to diameters as small as 39 μm (Campbell et al., 1991). This work provided a higher resolution for BSD determination compared to the work conducted by Carlson and Bohlin (1978), who had reported the mean diameter for bubbles in the dough as 90 μm. However, both studies were conducted on dough that had to be thinly sliced, resulting in damage to the dough structure and in turn changes to the fragile gas phase of the dough.

Compared to previous studies of BSD in doughs (Campbell et al., 1991; Carlson & Bohlin, 1978), light microscopy with higher resolution was used to measure bubbles as small as 3 μm in diameter (Shimiya & Nakamura, 1997). The BSD was characterized with a lognormal distribution function using two parameters, that is, the median bubble size and the standard deviation of the distribution (Shimiya & Nakamura, 1997). Immediately after mixing non-yeasted doughs, the median bubble diameter was measured as 15 μm, whereas it increased to 38 μm due to disproportionation during 160 min resting of the dough (Shimiya & Nakamura, 1997). Over this period, the width of the lognormal BSD slightly decreased from 0.18 to 0.16 (Shimiya & Nakamura, 1997)

Scanning electron microscopy (SEM) and X-ray microtomography were also used to measure the evolution of bubble sizes during breadmaking (Whitworth & Alava, 1999). Combined use of light microscopy (bubble diameters of 20 to 1500 μm), SEM (bubble diameters of 50–3500 μm), and X-ray microtomography (bubble diameters larger than 1000 μm) aimed to investigate a wide range of bubble sizes and their evolution throughout breadmaking processes (Whitworth & Alava, 1999). At the end of mixing, the entrained bubbles in the dough were reported to have a maximum diameter of 2500 μm (Whitworth & Alava, 1999). Due to the considerable expansion of bubbles during proving, a doubling in the maximum bubble diameter was observed by the end of proving (Whitworth & Alava, 1999).

Confocal laser scanning microscopy (CLSM) was used to investigate the evolution of bubbles in yeasted doughs during breadmaking (Heertje et al., 1987). Bread dough was prepared by mixing wheat flour with water, yeast, and a fluorescent dye to label proteins and starch (Heertje et al., 1987). In the CLSM images, gas bubbles (darker color) were easily identified (qualitatively) in the protein-starch matrix (strong-faint fluorescence). The increase in dough volume was also observed as a result of bubble expansion during proving (Heertje et al., 1987). Unlike previous CLSM studies that did not quantify the size distribution of bubbles (Heertje et al., 1987; Thorvaldsson et al., 1999), Upadhyay et al. (2012) acquired the BSD by tabulating the frequency of bubble sizes in ascending order of diameters, and then grouping them into 10 μm-wide size classes. Rather than using a normal or lognormal probability density function for characterizing the BSD, they calculated the arithmetic average and standard deviation of bubble diameters in the dough (Upadhyay et al., 2012).

5.2.2 Magnetic resonance imaging

Magnetic resonance imaging (MRI) is a non-destructive imaging technique that is widely used for medical diagnosis and also for analysis of food materials (Rouillé et al., 2005; Takano et al., 2002). Using MRI, the internal structure of soft materials can be investigated (Takano et al., 2002). In a strong magnetic field as employed by an MRI scanner, the density and the relaxation dynamics of protons can be mapped based on their alignment in the magnetic field, and their relaxation once the magnetic field is removed (Falcone et al., 2006). This map is constructed in the form of a 2D plot which is composed of several pixels whose intensity (i.e., gray level) corresponds to the NMR signal intensity of the food components in the corresponding scanned volume, and thus depicts the food's inner structure (Rouillé et al., 2005; Takano et al., 2002). Accordingly, the intensity of a pixel in an MRI image can be used to quantify the volume of gas bubbles in the dough (Grenier et al., 2003), where bubbles are characterized by a relatively lower signal intensity in an MRI image (Rouillé et al., 2005).

The MRI images of frozen and nonfrozen doughs were used to depict the evolution of bubble sizes during proving and to link the growth of bubble sizes with the development of the gluten network during punching and molding (Takano et al., 2002). MRI combined with digital image analysis was used to show that molding and kneading processes produce a more homogeneous distribution of bubble sizes in the dough (van Duynhoven et al., 2003). A larger number of bubbles and a better-developed gluten network were observed in nonfrozen doughs, which favored bubble stability during dough expansion so that a good crumb cell structure was developed (Ishida et al., 2001; Takano et al., 2002).

A combination of MRI and digital image analysis was also used to investigate the effect of flour components on the growth of gas bubbles in dough during proving and the crumb cell structure of the resultant bread (Rouillé et al., 2005). Bubble sizes in the dough and cell sizes in the crumb were quantified from 2D MRI images to confirm that when there was an increase in the amount of endogenous soluble fractions (i.e., low-molecular-weight sugars, pentosans, and soluble proteins such as globulins and albumins in the flour) in the dough, the bubble growth rate increased and the crumb structure became coarser (Rouillé et al., 2005).

BSDs in non-yeasted and yeasted doughs at the early stages of proving were seen to fit well into a normal distribution (De Guio et al., 2009). MRI was also used to investigate the effect of dough composition on the number and size evolution of bubbles during proving (Bonny et al., 2004). The BSD in different doughs was determined during proving and larger bubble diameters were observed for defatted doughs when compared to regular doughs (Bonny et al., 2004). The time-dependent evolution of BSD in dough during proving as measured by MRI was also studied by Bajd and Serša (2011). As the proving time increased, the mean bubble size shifted toward the larger bubble sizes as expected (Bajd & Serša, 2011).

5.2.3 X-ray microtomography

X-ray microtomography is a non-destructive imaging technique that is widely used for medical diagnosis and biological material microstructure characterization (Fitzgerald, 2000; Gundogdu et al., 2007; Karunakaran et al., 2015; Kashyap et al., 2008). During imaging by X-ray microtomography, the X-ray beam and radioscopic detector are located at opposite sides of the sample being tested (Falcone et al., 2006). The X-ray beam focuses on the sample located placed on a rotation stage and the radioscopic detector determines the attenuation of the X-rays passing through the sample along various beam paths and directions as the sample is rotated (Barigou & Douaire, 2013; Lim & Barigou, 2004). Higher-density materials attenuate X-rays to a greater degree, leading to brighter regions in the resultant X-ray radiograph (Falcone et al., 2006). A continuous series of 2D radiographs are produced for different viewing angles of the sample (Falcone et al., 2006). By mapping the X-ray attenuation, a reconstruction step using a computer converts the 2D radiographs into a 3D volume of interest in the sample (Barigou & Douaire, 2013; Falcone et al., 2006; Martz et al., 2017).

The source of the X-ray beam, that is, bench-top (Pinzer et al., 2012; Trater et al., 2005) versus synchrotron X-ray source (Babin et al., 2007; Maire, 2003), determines the quality and resolution limit of the images obtained by X-ray microtomography (Barigou & Douaire, 2013; Falcone et al., 2006). A synchrotron is a type of charged particle accelerator, which can accelerate electrons up to the speed of light (Martz et al., 2017). Compared with lab-scale sources, synchrotron radiation sources produce a much larger photon flux density and thus substantially higher intensity and brightness of X-rays (Babin et al., 2006, 2008; Falcone et al., 2006). As such, synchrotron X-ray microtomography provides higher-resolution (i.e., smaller size of a pixel or voxel) images at a much shorter scanning time.

Bench-top X-ray microtomography has been used to investigate the evolution of gas bubbles in doughs during breadmaking (Bellido et al., 2006; Trinh et al., 2013; Whitworth, 2008). At a spatial resolution of 10 μm per pixel, the median diameter of a lognormal BSD in the dough was determined as 100.00 ± 1.79 μm for a “stiff” dough formula of 63% water and 2.4% NaCl (flour weight basis) and 109.30 ± 1.62 µm for a “slack” dough formula of 67.4% water and 0.75% NaCl (Bellido et al., 2006). This indicates that increased water content and decreased salt content in the dough lead to a shift of the BSD median toward larger bubble sizes.

Due to its higher resolution than bench-top X-ray microtomography, synchrotron X-ray microtomography has been used for qualitative and quantitative studies of the size distribution and rapid evolution of gas bubbles in the dough during breadmaking as well as the crumb cell structure of bread. BSDs in non-yeasted bread and noodle doughs were measured using synchrotron X-ray microtomography at a spatial resolution of 6.5 μm and 8.75 μm per pixel, and BSDs were fitted well using a lognormal distribution (Guillermic et al., 2018; Koksel et al., 2016; Sun et al., 2020). With pixel resolutions of 15 µm (Babin et al., 2006; Turbin-Orger et al., 2015) and 5 µm (Turbin-Orger et al., 2012, 2015), synchrotron X-ray microtomography was used to assess the growth of bubble sizes in dough during proving and show the increase in bubble sizes as a function of proving time. The mean bubble diameter was seen to increase from 410 to 675 μm over 140 min (Turbin-Orger et al., 2012).

6 EFFECTS OF BASIC INGREDIENTS ON THE GAS PHASE OF THE DOUGH

In non-yeasted doughs, the number and size distribution of bubbles at the end of mixing depend on the type of wheat flour (Chin & Campbell, 2005b) and other ingredients, that is, the content of water and salt (Bellido et al., 2006; Chin, Campbell et al., 2005; Koksel & Scanlon, 2012; Koksel et al., 2014; Thorvaldsson et al., 1999), shortening (Mehta et al., 2009) and sugar (Shehzad et al., 2010; Turbin-Orger et al., 2012, 2015). This is illustrated in Table 4. During proving, the evolution of bubble sizes in dough not only depends on these basic ingredients but also on leavening agents (Bellido et al., 2009) and surface active materials such as diacetyl tartrate esters of monoglyceride (DATEM) and sodium stearoyl lactylate (SSL) (Campbell et al., 2001).

| Effects | Changes in dough's gas phase | Reference |

|---|---|---|

| Stronger wheat flour | Higher gas volume | Chin and Campbell (2005b) |

| Flour with better baking performance | Lower bubble growth rate | Kokelaar et al. (1996); Sroan et al. (2009) |

| Flour higher in proteins and lipids | Higher bubble growth rate | Rouillé et al. (2005) |

| Higher water content | Higher gas volume Slower bubble expansion Faster disproportionation |

Chin and Campbell (2005a) Peighambardoust et al. (2010) Sun et al. (2020) |

| Higher salt content | Lower gas volume |

Chin, Campbell et al. (2005) Koksel et al. (2014) |

Smaller median and larger width for lognormal BSD Slower disproportionation Slower bubble expansion |

Koksel et al. (2014) Sun et al. (2020) Calderon-Dominguez et al. (2005) |

|

Higher sugar content |

Slower bubble expansion |

Shehzad et al. (2010) |

Longer mixing time |

Higher gas volume |

Koksel and Scanlon (2012) Mehta et al. (2009) Trinh et al. (2013) |

Larger mean bubble size Faster disproportionation |

Kokawa et al. (2012) Sun et al. (2020) |

|

Higher mixing work input |

Higher gas volume Smaller bubble sizes Better bubble stability |

Chin and Campbell (2005b) Shehzad et al. (2010) |

6.1 The effect of flour quality on the gas phase of the dough

The effects of flour type on the entrainment of gas bubbles differ due to the difference in flour strength between wheat cultivars (Chin & Campbell, 2005b). From dough density measurements, doughs made from a stronger wheat cultivar were observed to entrain a higher volume of gas bubbles (Chin & Campbell, 2005b). In addition, increased gluten content in protein-starch blended doughs was also reported to increase the dough's VF (Koksel & Scanlon, 2012).

The evolution of bubble sizes in the dough during breadmaking is also affected by the flour type. The baking performance of flour, which determines the gas retention ability of the dough and the volume of the resultant loaf, differs due to the wheat cultivar (He & Hoseney, 1991, 1992). The volume and height of dough have been determined during breadmaking to show that the rate of bubble expansion is increased if a wheat cultivar with better baking performance is used (He & Hoseney, 1991, 1992). Doughs made from wheat flours with better baking performance have also been shown to possess better strain-hardening properties (Kokelaar et al., 1996). A higher strain hardening value of the dough contributes to bubble stability against disproportionation and/or coalescence during breadmaking (Dobraszczyk & Roberts, 1994), resulting in better control of bubble growth rate during proving and producing a loaf with higher volume (Sroan et al., 2009).

The stability of gas bubbles is increased if the surface tension of the bubble interface is decreased (Kokelaar & Prins, 1995). A lower surface tension of bubbles has been observed in doughs made from wheat cultivars with a higher content of endogenous soluble proteins and lipids (Sahi, 1994), indicating enhanced bubble stability, and thus better gas retention capacity during breadmaking for these cultivars. With increasing content of soluble proteins and/or increasing content of lipids, the specific volume of the dough (i.e., the reciprocal of density) increased due to a better gas retention capacity of the dough and a higher rate of bubble growth during proving (Rouillé et al., 2005).

6.2 The effect of water content on the gas phase of the dough

An increase in water content has been shown to cause an increase in dough development time (D'Appolonia & Gilles, 1971), resulting in a higher volume of gas bubbles entrained into the dough due to a longer time of mixing (Chin, Campbell et al., 2005; Mastromatteo et al., 2013). In addition to the effect on initial bubble entrainment during mixing, water content has an effect on bubble growth during the later stages of breadmaking (Peighambardoust et al., 2010). When dough volume was measured as a function of proving time, increasing the dough water content from 50% to 54.5% (flour weight basis) was seen to decrease the rate of bubble expansion at the later stages of proving (Peighambardoust et al., 2010). Throughout dough proving, the retarding effect of increased water content on bubble expansion was more noticeable for doughs made from flours with higher farinograph absorption (FAB) (Peighambardoust et al., 2010; Unbehend et al., 2004), indicating that this water-induced decrease in bubble expansion rate depends on the water absorption properties of the wheat flour. Using synchrotron X-ray microtomography, increased water content has been shown to promote disproportionation in non-yeasted doughs (Sun et al., 2020).

6.3 The effect of salt content on the gas phase of the dough

Increased salt (NaCl) content in the dough has been observed to increase dough density at the end of mixing (Chin, Campbell et al., 2005; Koksel et al., 2014), indicating that increased salt decreases the volume of gas bubbles entrained into the dough during mixing. The negative effect of increased salt content on gas bubble entrainment is attributed to NaCl-induced changes in the protein network (Beck et al., 2012). The Na+ and Cl− ions shield the positive charges on the surface of the gluten proteins, reducing the repulsive forces between them (Beck et al., 2012), so that increased salt content promotes hydrophobic interactions between gluten proteins, allowing them to approach each other more readily (Miller & Hoseney, 2008; Preston, 1981). The increase in protein-protein interactions reduces the surface sites of gluten proteins available for water molecules to interact with, and thus slows down flour hydration and results in longer mixing times to achieve optimal dough development (Farahnaky & Hill, 2007; Hlynka, 1962). When the mixing development time of dough is fixed (as opposed to mixing until optimal development), higher salt content doughs are relatively less developed, resulting in a lower volume of gas bubbles entrained (Koksel & Scanlon, 2012).

An ultrasonic transmission technique has been used to measure BSDs in nonyeasted doughs varying in formulation, and the BSDs have been fitted with a lognormal distribution (Koksel et al., 2014; Leroy et al., 2008). The evolution of BSD was investigated by measuring the median bubble size and the width of a lognormal distribution function fitted to the BSD (Koksel et al., 2014; Leroy et al., 2008). With increasing salt content from 0.8% to 2.4%, the median bubble radius decreased and the width of the BSD increased for well-aged nonyeasted doughs (Koksel et al., 2014). These findings are in agreement with those of Bellido et al. (2006) who reported that higher salt content results in a smaller median bubble diameter and larger width for the BSD in nonyeasted doughs as measured by benchtop X-ray microtomography. This salt-induced decrease in median bubble size indicates that increased salt content retards or prevents disproportionation in the dough (Sun et al., 2020). This outcome can be attributed to a reduction in the surface tension of the dough liquid film around the bubbles and to an increase in the stability of bubbles in the liquid phase of the dough (Salt et al., 2006).

The expansion and retention of gas bubbles in yeasted doughs have been investigated by examining the maximum dough height as a function of proofing time using a Chopin rheofermentometer (Lynch et al., 2009). Increased salt content (from 0%, 0.3%, 0.6%, to 1.2% NaCl) has been shown to lower the maximum dough height (Lynch et al., 2009), indicating that increased salt content decreases the expansion rate of gas bubbles (Calderon-Dominguez et al., 2005). The retarding effect of increased salt content on bubble expansion has been attributed to the salt-induced inhibition of yeast activity (Lynch et al., 2009; Miller & Hoseney, 2008). Increased NaCl content hinders the metabolic activity of yeast due to an increase in osmotic pressure that causes water loss in yeast cells (Hutton, 2002).

7 EFFECTS OF MIXING ON THE GAS PHASE OF THE DOUGH

The effect of mixing process parameters on the gas phase of bread dough has been investigated using dough density measurements (Campbell et al., 2001; Campbell et al., 1993; Chamberlain et al., 1970; Chin & Campbell, 2005a, 2005b; Chiotellis & Campbell, 2003b) and ultrasonic studies (Elmehdi et al., 2004; Mehta et al., 2009). The mixing time and work input have been shown to be two important factors that affect the volume of gas bubbles in the dough. This is illustrated in Table 4.

7.1 The effect of mixing time on the gas phase of the dough

Increased mixing time has been observed to enhance the entrainment of gas bubbles into the dough (Koksel & Scanlon, 2012; Mehta et al., 2009), resulting in a higher gas volume fraction (VF) in doughs (Sun et al., 2020). This finding is also confirmed by low-frequency (50 kHz) ultrasonic investigations that showed an increase in the dough's attenuation coefficient (indicative of an increase in VF) when a longer mixing time was used (Mehta et al., 2009).

Digital image analysis (DIA) has been used to determine the relationship between mixing time and the bubble volume fraction in the dough (Kokawa et al., 2012; Trinh et al., 2013). When doughs were prepared at mixing times of 1 min (under-mixing), 2 min 30 s (optimal-mixing), and 7 min (over-mixing), the ratio of total bubble area in 2D dough images to total dough volume was ranked as: under- < optimal- < over-mixed doughs (Kokawa et al., 2012). The mean bubble size of the BSD was also shown to shift toward larger bubble sizes as the dough's mixing conditions changed from under- to over-mixing (Kokawa et al., 2012). Using X-ray tomography, the volume of gas bubbles in the dough was seen to increase with increasing mixing time (Trinh et al., 2013). A synchrotron X-ray microtomography investigation showed that disproportionation in the dough was faster if the dough had been mixed for a longer time (Sun et al., 2020).

7.2 The effect of mixing work input on the gas phase of the dough

Based on dough density measurements, for a given wheat flour, it was observed that the volume of gas bubbles entrained into the dough was higher for doughs that require a higher level of mixing work input until optimal development (Chin & Campbell, 2005b). Overmixing weakens the ability of the dough to entrain gas bubbles and results in a lower VF in the dough at the end of mixing (Chin & Campbell, 2005b). The response of dough's VF to mixing work input has been reported to differ according to the wheat cultivar (Chin & Campbell, 2005b).

By analyzing the images of dough samples that were acquired via a digital camera, the level of mixing work input has been shown to affect the BSD in the dough after mixing (Kansou et al., 2013) and the stability of bubbles during proving (Shehzad et al., 2010). The BSD in the dough was modeled to show that a higher level of mixing work input resulted in a larger number of smaller-sized bubbles entrained and a more homogenous distribution of bubble sizes (Kansou et al., 2013). As a result, increased mixing work input for dough preparation may increase bubble stability against disproportionation or coalescence in the dough (Shehzad et al., 2010). This finding is possibly due to better development of the gluten network and better strain hardening in the dough (Dobraszczyk & Roberts, 1994; Vliet et al., 1992; van Vliet, 2008) brought about by a greater amount of mixing work input.

8 CONCLUSIONS

The rationale for investigating the changes in dough's gas phase during breadmaking is that bread quality, that is, loaf volume and crumb structure, is dictated by the entrainment of gas bubbles during mixing, and the stabilization and evolution of gas bubbles throughout the breadmaking processes. Dough density measurements have shown a positive relationship between the volume of gas bubbles entrained in the dough and mixing parameters, that is, mixing time, work input, mixing speed, and headspace pressure. By manipulating the flour type, water, and salt content in the dough, the rate of disproportionation and bubble growth were modified, and thus the stability of gas bubbles was controlled. These outcomes contribute to better control of gas bubble evolution during breadmaking, resulting in bakery products with a higher loaf volume and finer crumb structure.

To better control the crumb structure of bakery products, the evolution of bubble size distribution (BSD) in the dough has been investigated using microscopy, magnetic resonance imaging (MRI), and X-ray microtomography techniques. Particularly, synchrotron X-ray microtomography is a powerful and non-destructive technique that provides high-resolution images for quantitatively characterizing and monitoring the fast evolution of BSD. The BSD evolution was shown to be affected by the basic bread ingredients (i.e., wheat cultivar, water, and salt) and mixing parameters (i.e., mixing time and work input). Since the BSD evolution in bread dough is associated with the quality of the resultant products, to devise strategies for improving the product quality, dough formulation, and mixing conditions need to be considered.

Although many studies have been conducted on gas bubble entrainment in the dough, there is still much room for investigations of dough's BSD during breadmaking. Compared to investigations of BSD in nonyeasted doughs, monitoring the faster evolution of BSD in yeasted doughs is much more challenging. As such, further investigations on how yeast activity affects dough's BSD are required.

ACKNOWLEDGMENTS

The authors acknowledge the financial support provided by Canada Bread Corp. (Toronto, Canada), the Saskatchewan Agricultural Development Fund, the Western Grains Research Foundation, and through a joint NSERC (Natural Sciences and Engineering Research Council of Canada)-CIHR (Canadian Institute of Health Research) Institute of Nutrition, Metabolism and Diabetes Funding Initiative for Sodium Reduction in the Canadian Food Supply, a China Scholarship Council fellowship, and support from the Natural Science Foundation of Jiangsu Province (BK20210672), the Agricultural Independent Innovation of Jiangsu Province (CX (22) 3067), and the Joint Laboratory for International Cooperation in Grain Circulation and Security.

CONFLICT OF INTEREST STATEMENT

The authors declare no conflict of interest.