‘BETTER SIDE BY SIDE’: An Integrative Framework Between Lean Manufacturing and Circular Economy

Funding: This work was supported by Coordenação de Aperfeiçoamento de Pessoal de Nível Superior, This study was financed in part. Finance Code 001.

ABSTRACT

The integration of Lean Manufacturing (LM) and the Circular Economy (CE) represents a promising strategy to foster more sustainable production systems aligned with the principles of cleaner production. This study conducts an integrative systematic literature review, based on the PRISMA protocol, with the aim of mapping, organizing, and consolidating existing knowledge on the convergence between LM and CE. A total of 51 articles indexed in the Scopus and Web of Science databases were analyzed. The results reveal that lean practices support the adoption of circular principles by promoting waste elimination, resource efficiency, and environmental impact reduction, with positive effects on organizations' operational, economic, and environmental performance. However, significant gaps remain, particularly concerning the scarcity of empirical studies, the limited diversity of geographic and sectorial contexts, and the lack of assessments regarding the social and organizational impacts of LM–CE integration. In response to these gaps, the study presents 10 recommendations to guide future research and practice, including the adoption of mixed-methods approaches, the exploration of under-investigated sectors (such as agriculture, construction, remanufacturing, and textiles), and the incorporation of socio-environmental performance metrics. Moreover, this study proposes, innovatively, an integrative conceptual framework grounded in the Resource-Based View (RBV), which positions the LM–CE synergy as a strategic, valuable, and hard-to-imitate organizational capability, capable of generating sustainable competitive advantage. The proposed model offers theoretical contributions by expanding the understanding of sustainable value creation mechanisms and provides relevant managerial and practical implications, offering robust guidance for managers, policymakers, and researchers committed to the transition toward circular production models.

1 Introduction

Organizations face an increasing need for flexibility, whether in response to external market forces or the demands of a modern, progressive society. This increasingly attentive and critical society expects companies not only to deliver high-quality products and services but also to adopt socially and environmentally responsible practices (Litvinova et al. 2024). In other words, while quality and productivity remain fundamental for organizational competitiveness and profitability, companies must also prioritize sustainability by adopting practices that reduce waste, conserve resources, and minimize environmental impacts from production processes (Skalli et al. 2024), as outlined by the United Nations' 2030 Agenda, particularly Sustainable Development Goal (SDG) 12, which emphasizes responsible production and consumption to enhance resource efficiency and reduce environmental degradation (Panchal et al. 2021).

One approach to addressing these organizational and societal demands for quality, flexibility, and productivity while reducing waste and enhancing sustainability is the integration of Lean Manufacturing (LM) and Circular Economy (CE) principles (Sehnem et al. 2025; Salman et al. 2025; Sasso et al. 2025; Kalemkerian et al. 2024).

Lean Manufacturing has been extensively studied as a dominant management paradigm in industry (Frank et al. 2024). Authors such as Razali and Chi (2021) and Singh et al. (2021) emphasize that by optimizing resource efficiency, LM becomes essential for waste reduction across production chains. Furthermore, LM focuses on enhancing customer value creation, leading to improved performance (Marodin et al. 2023).

Studies have documented LM implementation benefits. Badhotiya et al. (2024), for instance, reviewed 78 case studies from the last decade (2010–2020) and found that LM adoption improved manufacturing capabilities across sectors, with reported gains in productivity, quality, delivery, flexibility, and cost reduction.

Tardio et al. (2023) surveyed 110 Brazilian manufacturing managers to analyze LM and Industry 4.0 (I4.0) impacts on product development and market performance. Results indicate that manufacturers require LM implementation in product development for a balanced approach, while LM–I4.0 integration enhances both product development and market outcomes.

LM also benefits employee well-being. Bento and Tontini (2024) surveyed 520 workers across 23 Brazilian industrial sectors to evaluate LM's relationship with employee well-being through job characteristics. Findings reveal that LM independently influences satisfaction, commitment, and engagement, thereby improving worker welfare.

LM's contributions to sustainability are also evident. Costa et al. (2024) developed an I4.0-LM integration model for sustainability through a systematic literature review and case validation. The proposed model demonstrated enhanced environmental sustainability, process optimization, and waste reduction, underscoring the importance of circular strategies.

Díaz-Reza et al. (2024) highlighted LM's sustainability benefits through waste reduction, production efficiency, and quality improvement. Tools like 5S, TPM, Quick Changeover, and One-Piece Flow positively impact worker health/safety, workplace organization, and operational flow, elevating employee well-being, strengthening engagement, and thereby promoting social sustainability in labor-intensive industries.

The Circular Economy (CE) aims to replace the traditional so-called linear production model, questioned due to its various negative environmental impacts (Congiu et al. 2025). According to Hossain et al. (2024), CE is a regenerative paradigm that replaces “end-of-life” concepts with material reduction, reuse, recycling, and recovery across production chains. Its goals include preserving resource value, fostering sustainable development, and balancing environmental quality, economic growth, and social equity for current and future generations. CE has gained significant academic and professional recognition as an evolving model combining economic development and sustainability (Kirchherr et al. 2023) and as a critical research field for building a sustainable future (Hossain et al. 2024).

In practice, studies indicate that Lean Manufacturing (LM) practices significantly impact the advancement of the Circular Economy (CE) (Farrukh et al. 2023, Ghaithan et al. 2023; de Mattos Nascimento et al. 2022). This occurs through the elimination of various types of waste (Sehnem et al. 2025; Deng et al. 2022), resource optimization, significant raw material savings, and improved environmental performance (Sasso et al. 2025). Additionally, LM enhances processes and worker empowerment (Sehnem et al. 2025), reduces costs, improves energy efficiency, and customer satisfaction (Ferlito 2024), and fosters greater sustainability (Skalli et al. 2022).

Maldonado-Guzmán and Garza-Reyes (2023) empirically examined LM, sustainable development, and CE relationships among 460 Mexican automotive managers. Results suggest LM implementation positively affects sustainable performance, with CE mediating stronger outcomes.

Sehnem et al. (2025) conducted an agri-tech case study on integrating CE and I4.0 via LM and human-centric approaches. Findings show that this integration reduces waste, optimizes resources, empowers workers, and boosts operational efficiency while reinforcing sustainability through continuous improvement.

Both LM and CE facilitate transitions toward sustainable, circular business models (Farrukh et al. 2023), potentially contributing to global sustainability (Salman et al. 2025). However, research on LM-CE intersections remains limited (Nadeem 2019; Kurdve and Bellgran 2021; Hedlund et al. 2020; E Silva et al. (2024)), and while some studies support their synergy, none have proposed a clear, integrative framework connecting these fields.

This systematic integrative review analyzes relevant literature to investigate research trends and connections, exploring how LM-CE synergies can address global environmental challenges like climate change, waste mismanagement, and global warming (Hossain et al. 2024).

Thus, this study aims to bridge this gap by proposing a theoretically grounded, systematic framework integrating LM and CE. The central research questions (RQ) are:

RQ1.Which Lean Manufacturing practices most significantly contribute to Circular Economy?

RQ2.What is currently known about Lean Manufacturing and Circular Economy synergies?

RQ3.What are future research trends for Lean Manufacturing and Circular Economy?

RQ4.How does LM-CE synergy positively affect organizational performance?

RQ5.Is it possible to create an integrative LM-CE framework?

The Resource-Based View (RBV) theory (Barney 1991) underpins this study, highlighting how integrating organizational resources and capabilities generates competitive advantages (Sasso et al. 2025; Yadav et al. 2020; Caldera et al. 2019).

This work's originality lies in employing RBV theory alongside an integrative systematic review to identify, synthesize, expand, and integrate understanding of how lean and circular strategies complement each other in mitigating environmental impacts and optimizing production processes. It proposes a relational framework for empirical testing in future research.

2 Theoretical Foundation

2.1 Circular Economy

The first study mentioning the Circular Economy (CE) on the Scopus platform dates back to 2001, but the first article to substantively address the topic was published in 2004. In this work, Dajian (2004) highlights the emergence of CE as a groundbreaking methodology in developed markets such as Germany and Japan. The author argues that CE could enable the construction of a sustainable society, contrasting with the prevailing consumerist model of the time.

According to the Ellen MacArthur Foundation, a global reference institution in the promotion of CE among decision-makers, governments, and academia, the three principles that guide CE are: (a) regeneration of natural capital, balancing the consumption of renewable and non-renewable resources; (b) increasing the useful life of products and materials through biological and technical cycles; and (c) eliminating negative impacts of production systems, such as waste and pollution (MacArthur et al. 2015).

In this context, CE can be defined as:

A regenerative economic system which necessitates a paradigm shift to replace the end-of-life concept with reducing, alternatively reusing, recycling, and recovering materials throughout the supply chain, with the aim to promote value maintenance and sustainable development, creating environmental quality, economic prosperity, and social equity, to the benefit of current and future generations. It is enabled by an alliance of stakeholders (industry, consumers, policymakers, academia) and their technological innovations and capabilities (Kirchherr et al. 2023, p. 4).

In recent years, a significant volume of research has been published, 36,146 documents (keyword: “Circular Economy,” database: Scopus, filter: Title/Keywords/Abstract, period: 2020–2025, date: March 28, 2025). Many studies seek to identify CE's benefits and interfaces with other themes. Winkler (2011) emphasizes its relationship with sustainable supply chain networks, which can enhance organizations' environmental and economic performance. Mathews (2011) suggests that CE could refine capitalism to benefit society. Su et al. (2013) note that CE practices are applicable at micro and macro levels, requiring support from non-governmental organizations (NGOs) and governments. Ghisellini et al. (2016) assert that decoupling environmental pressure from economic growth is a core objective of CE.

Schroeder et al. (2019) identify CE as a driver for implementing the Sustainable Development Goals (SDGs), while Bag et al. (2021) highlight how artificial intelligence, powered by big data analytics, positively impacts sustainable manufacturing and CE.

Vanapalli et al. (2021) underscore challenges posed by the COVID-19 pandemic to effective plastic waste management. The authors emphasize that transitioning to green materials and developing sustainable technologies are critical to mitigating future crises. During the pandemic, single-use plastic consumption surged; though temporary, this trend may alter consumer perceptions and hinder CE transition goals.

The literature analysis reveals CE's thematic evolution. However, studies remain concentrated in Europe, China, and the United States, indicating the need for research in other contexts. Moreover, CE's interdisciplinary nature underscores its analytical complexity. Few studies explore its application to production and operations management (Lim et al. 2022a), where CE emerges as a viable alternative to linear production models, fostering a more sustainable society.

2.2 Lean Manufacturing

Although it is a well-established topic, Lean Manufacturing (LM) continues to attract the attention of the international scientific community. Between 2020 and 2025, 2315 documents related to the theme were published, according to a survey conducted in the Scopus database (keyword: “Lean Manufacturing”; filters applied: title, keywords, and abstract; search date: February 4, 2025). Among this total, approximately 338 publications exhibit some interface with the theme of sustainability, indicating potential contributions of lean practices to sustainability.

Moreover, many of these studies converge in defining Lean Manufacturing as a set of managerial principles and practices aimed at waste elimination, customer value enhancement, and continuous process improvement (Alshammari et al. 2025; Carrijo et al. 2024; Ferrazzi et al. 2025; Gama and Bonamigo 2025; Halim-Lim et al. 2025; Reza et al. 2025; Songkhwan et al. 2025; Yang et al. 2025). Therefore, LM focuses on eliminating waste throughout the production chain while simultaneously increasing the value perceived by customers through the optimized use of resources (Razali and Chi 2021; Singh et al. 2021), aligning production with organizations' strategic objectives through the application of tools such as Kaizen, TQM, Kanban, among others (Reza et al. 2025).

Ferrazzi et al. (2025) emphasize that LM has evolved into a philosophy with strong synergy with environmental sustainability by minimizing resource use and reducing environmental impacts. Gama and Bonamigo (2025) reinforce this perspective, highlighting that LM contributes to sustainability by reducing waste, optimizing resources, and promoting operational excellence. Salman et al. (2024) associate LM drivers with improved circular performance in sectors such as pharmaceuticals. Carrijo et al. (2024) examine LM in agribusiness, relating it to productivity and rural sustainability. Halim-Lim et al. (2025) underscore the prominent role of LM in the transition toward a circular economy.

Thus, LM demonstrates strong interdisciplinarity, interfacing with various other fields of study such as environmental management, sustainability, quality, CE, and Industry 4.0. Given this context, the relevance of the topic stands out for both academic literature and organizations, highlighting its potential to significantly contribute to reconciling economic gains with sustainability.

2.3 Interface Between Lean Manufacturing and the Circular Economy

The global economy faces a dilemma between the need for production and the scarcity of natural resources (Jabbour et al. 2020). In this context, resource conservation becomes essential for sustainable development (Farrukh et al. 2023). In response, many organizations are incorporating environmental considerations throughout the product life cycle, seeking not only to reduce impacts but also to gain competitive advantages, cost savings, and risk mitigation (Dahmani et al. 2022).

The need for a business strategy that integrates waste reduction, efficient resource use, and environmental protection is evident (Kazancoglu et al. 2018; Lim et al. 2022a). In this regard, the integration of Lean Manufacturing (LM) and the Circular Economy (CE) emerges as a promising approach to achieving these objectives, promoting greater sustainability and efficiency in production processes (Lim et al. 2022a).

LM is the most dominant production strategy in global organizations (Hu et al. 2015), as its practices enhance efficiency by eliminating waste and focusing on delivering customer value (Goshime et al. 2019). Conversely, CE seeks to redefine economic growth by decoupling it from the consumption of finite resources and promoting a more sustainable model of production and consumption (MacArthur 2013).

E Silva et al. (2024) developed the Lean-Circular Maturity Model (LCMM). Their study found that integrating LM and CE enables companies to continuously improve their processes, optimize resource utilization, and enhance both economic and environmental performance.

Ghaithan et al. (2023) highlight that the LM practices with the greatest impact on CE aim to eliminate waste, reduce emissions, and polluting materials, thereby strengthening environmental sustainability. The implementation of LM in production not only improves operational efficiency by reducing costs and increasing profit margins but also streamlines production flow, enhances the work environment, and promotes occupational health and safety.

Dos Santos and Ramos (2020) argue that, given the current globalized scenario in which organizations must keep pace with constant changes and technological innovations, solid strategies are necessary to adapt to such trends. According to the authors, LM is one of these strategies. Reyes et al. (2021) support this view by pointing out that LM and Industry 4.0 can enable organizations and researchers to improve the planning and management of lean production and supply processes.

Lim et al. (2022a) emphasize the importance of integrating LM with CE principles to drive operational sustainability in production. Furthermore, several studies show that the synergy between LM and CE can contribute to improvements in economic and environmental performance (e Silva et al. 2024; Skalli et al. 2022), operational performance (Nadeem et al. 2023), and social performance (Kalemkerian et al. 2022). Therefore, the specialized literature indicates that the joint adoption of LM and CE is essential for organizational prosperity and for achieving sustainable performance.

Despite the identified advances and benefits, studies exploring the intersection between LM and CE remain limited (Nadeem 2019; Kurdve and Bellgran 2021; Hedlund et al. 2020; e Silva et al. 2024), justifying the need for further research (Ghaithan et al. 2023; Maldonado-Guzmán and Garza-Reyes 2023) and concrete proposals that achieve a true fusion of LM and CE. Such integration would facilitate the adoption of business models and product strategies that promote reuse, recycling, and remanufacturing, as well as LM practices that contribute to resource efficiency and waste reduction.

3 Resource-Based View, Lean Manufacturing, and Circular Economy

Studies on resources, skills, and capabilities began with the work of Barney (1991). The Resource-Based View (RBV) theory focuses on organizational resources and capabilities, encompassing assets, organizational processes, business attributes, information, and accumulated knowledge. Resources are understood as organization-specific assets (Teece et al. 1997). For example, such resources may be tangible, such as infrastructure, or intangible, such as know-how and know-who (Chi 1994).

For organizations to achieve competitive advantages, these resources must be valuable, scarce or rare, and imperfectly imitable (Barney 1991). The integration of resources enables the acquisition of capabilities, which are generally developed through learning, knowledge exchange, and the continuous improvement of teams (Prieto-Sandoval et al. 2019), providing new competencies that, in turn, evolve into capabilities for achieving competitive advantages (Zott 2003).

The resources associated with LM include both human and technical aspects (Al-Hakimi et al. 2022). Lean practices are relevant technical elements that impact industrial operations (Bortolotti et al. 2015). Moreover, studies indicate that the implementation of LM and CE is influenced by factors, such as knowledge, resources, culture, and human attitude. In this context, the success of LM and CE implementation directly depends on the organization's ability to address these challenges (Abu et al. 2021).

Additionally, from the RBV perspective, it is argued that isolated resources are not, in themselves, sufficient to ensure a sustainable competitive advantage (Barney 1991). In this sense, the integration of Lean Manufacturing (LM) and the Circular Economy (CE) can be understood as a strategic configuration of organizational resources and capabilities capable of strengthening organizations' dynamic capabilities and operationalizing the adoption of circular practices, while simultaneously providing enduring competitive advantages.

Therefore, this study considers LM and CE as complementary approaches that, when integrated, become difficult to imitate, in addition to being valuable and rare, thereby enhancing firms' competitiveness and facilitating the transition toward sustainability.

4 Methodology

To identify the main gaps and address the research questions of this study, the integrative systematic literature review methodology was applied (Dahmani et al. 2021; Touriki et al. 2021).

4.1 Integrative Systematic Review

To ensure a comprehensive literature review on LM and CE, both a systematic review (Sasso et al. 2025; Awan et al. 2021) and an integrative review (Alcayaga et al. 2019) were conducted. The systematic review aims to summarize the existing literature based on selected criteria and answer a scientific question (Koutsos et al. 2019), while the integrative review captures the diversity and development of more than one body of literature, culminating in a conceptual model or framework (Miles and Huberman 1994).

To ensure transparency, coherence, and replicability while minimizing bias (Cook et al. 1997), the PRISMA method was adopted, which is widely used to identify relevant studies (Moher et al. 2009; Lim et al. 2022b). Additionally, the classification and coding methodology proposed by Junior and Godinho Filho (2010), and later applied by Jabbour (2013) and Teixeira et al. (2020), was employed. For data collection, Scopus and Web of Science were selected due to their widespread use in literature reviews and recognized reliability (Mongeon and Paul-Hus 2016; Chadegani et al. 2013), and for including peer-reviewed scientific publications (Awan et al. 2021).

Given the recent integration of LM and CE (Marquina et al. 2021), and in order to avoid overlooking relevant works, no publication type restrictions were applied. Titles, abstracts, and keywords were analyzed without limiting the search periods, thus allowing for a comprehensive integrative systematic review.

The search terms used (keywords) were: “Lean Manufacturing”, “Lean Production”, and “Circular Economy”, which were combined in various ways, as detailed in Table 1.

| Item | Description |

|---|---|

| Analysis period |

First survey: july-2023 Second survey: july-2024 Third survey: january-2025 |

| Boolean Operators |

AND keyword. OR between database search. |

| Keywords used in searches | “Lean manufacturing” and “circular economy” or “Lean production” and “circular economy” |

| Research database | “Web of Science” and “Scopus” were searched for titles, abstracts and keywords. |

| Language | Everyone |

| Availability | Articles and reviews only |

| Research discipline | All |

| Software Tools |

MS Excel VOSviewer Bliblioshiny |

| Total number of articles evaluated | 51 |

- Note: Prepared by the authors.

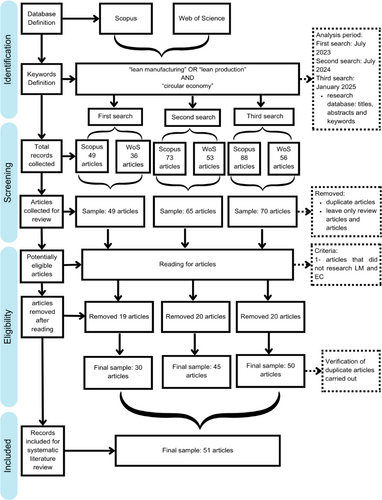

The initial search was conducted in July 2023 and retrieved 49 articles from Scopus and 36 from Web of Science, considering titles, abstracts, and keywords, and limited to articles and reviews. After the removal of duplicates and studies unrelated to LM and CE, 30 articles remained. A second search was conducted in July 2024, using the same criteria, identifying 73 articles in Scopus and 53 in Web of Science. After excluding duplicates and articles that did not relate to LM and CE, 45 publications remained.

Finally, a new (final) search was conducted in January 2025, following the same methodology. A total of 88 articles were retrieved from Scopus and 56 from Web of Science. After filtering duplicates and articles unrelated to LM and CE, 50 studies remained. A comparative analysis of all search rounds (July 2023, July 2024, and January 2025) revealed one article that had not appeared in the last January 2025 search, which was included in the final analysis, totaling 51 articles.

Figure 1 illustrates the stages of identification, screening, eligibility, and inclusion in the review process.

Source: Prepared by the authors.

In summary, it is worth emphasizing that, for the exclusion of the aforementioned studies, the following criteria were adopted: (1) duplicate studies, (2) not being articles or review articles, and (3) not being related to CE and LM—that is, studies that mention LM and CE without performing a joint analysis of both themes. Therefore, to ensure the reliability and feasibility of the integrative systematic review process, these inclusion and exclusion criteria were rigorously and carefully defined and consistently applied throughout the review. This process involved the participation of all co-authors, who assessed compliance with the established criteria. Any discrepancies were resolved through discussion. The articles that met the strict criteria were then selected for detailed analysis. The criteria are summarized in Table 2. It is noteworthy that this integrative systematic review differs from traditional approaches by updating the research in three distinct time periods, thereby offering a broader perspective on the themes.

| Classification | Meaning | Code |

|---|---|---|

| 1 | Country context |

A – Developed B – Emergent C—Not applicable |

| 2 | Type of Research |

A – Quantitative B—Qualitative C—Quantitative and qualitative D—Other |

|

3 |

Research Method |

A – Case Study B—Survey C—Revision D—Case Study and Survey E—Other |

| 4 | Economic activity (ISIC/UN) |

A—Agriculture, forestry and fisheries B—Mining and quarrying C—Manufacturing D—Supply of electricity, gas, steam and air conditioning E—Water supply; Sewerage, waste management and remediation activities F—Construction G—Wholesale and retail trade; Motor Vehicle & Motorcycle Repair H—Transport and storage I—Lodging and food activities J—Information and communication K—Financial and insurance activities L—Real estate activities M—Professional, scientific and technical activities N—Administrative and support service activities O—Public administration and defense; Mandatory Social Security P—Education Q—Human health and social service activities R—Arts, Entertainment & Recreation S—Other service activities T—Activities of families as employers; activities of production of goods and services not differentiated by families for their own use U—Activities of extraterritorial organizations and bodies V—Not applicable |

| 5 | Performances |

S-Sustainable E-Economy O-Operational EN-Environmental SO-Social OR-Organizational |

- Note: Prepared by the authors.

After data collection, information related to authors, countries, year of publication, source, and keywords was recorded in a database and analyzed using descriptive statistics in MS Excel, in accordance with methodologies adopted in related literature reviews (Sequeira and Santos 2018).

- Country context (1): (1A) developed country or (1B) emerging country;

- Type of research (2): quantitative (2A), qualitative (2B), both qualitative and quantitative (2C), or other (2D);

- Research method (3): case study (3A), survey (3B), literature review (3C), case study and survey combined (3D), or other (3E);

- Economic activity (4): The United Nations' International Standard Industrial Classification of All Economic Activities (ISIC/UN) was adopted for all economic activities;

- Performance dimensions addressed in the studies (5): Sustainable (5S), Economic (5E), Operational (5O), Environmental (5EN), Social (5SO), and Organizational (5OR).

| Item | Study | Country context | Type of research | Research method | Economic activity | Performance |

|---|---|---|---|---|---|---|

| 1 | Sehnem et al. (2025) | 1B | 2B | 3A | 4A | 5S, 5O, 5OR |

| 2 | Prashar and Chaudhuri (2025) | 1B | 2A | 3B | 4C | 5O, 5EN |

| 3 | Salman et al. (2025) | 1B | 2B | 3E | 4C | 5S, 5OR |

| 4 | Sasso et al. (2025) | 1C | 2B | 3C | 4C | 5S, 5E, 5O, 5EN, 5OR |

| 5 | Shabur (2024) | 1C | 2B | 3C | 4 V | — |

| 6 | Costa et al. (2024) | 1A | 2B | 3A; 3C | 4C | 5S |

| 7 | Ferlito (2024) | 1A | 2B | 3A | 4C | — |

| 8 | Arora et al. (2024) | 1C | 2B | 3C | 4C | — |

| 9 | Kalemkerian et al. (2024) | 1A | 2B | 3A; 3C | 4A | 5S, 5O, 5EN |

| 10 | Paraschos et al. (2024) | 1A | 2A | 3E | 4C | — |

| 11 | Skorupińska et al. (2024) | 1C | 2B | 3C | 4C | — |

| 12 | Gatell and Avella (2024a) | 1C | 2B | 3C | 4 V | — |

| 13 | Gatell and Avella (2024b) | 1C | 2B | 3C | 4C | — |

| 14 | E Silva et al. (2024) | 1B | 2B | 3C | 4C | 5E, 5EN |

| 15 | Skalli et al. (2022) | 1B | 2B | 3A, 3C | 4C | 5E, 5O, 5EN |

| 16 | Maldonado-Guzmán and Garza-Reyes (2023) | 1B | 2B | 3A | 4C | 5S |

| 17 | Niekurzak et al. (2023) | 1B | 2C | 3D | 4C | — |

| 18 | Farrukh et al. (2023) | 1A | 2B | 3A | 4C | — |

| 19 | Ghaithan et al. (2023) | 1B | 2B | 3A | 4C | 5S |

| 20 | Nadeem et al. (2023) | 1A | 2C | 3A, 3E | 4C | 5S |

| 21 | Khanzode et al. (2023) | 1B | 2A | 3E | 4C, 4P, 4 M | 5EN |

| 22 | De Mattos Nascimento et al. (2022) | 1B | 2B | 3A, 3C | 4 J | — |

| 23 | Kalemkerian et al. (2022) | 1C | 2B | 3C | 4 V | 5SO, 5O, 5EN |

| 24 | Deng et al. (2022) | 1A, 1B | 2A | 3E | 4C | 5E, 5O |

| 25 | Lim et al. (2022a) | 1B | 2D | 3A, 3E | 4C | 5EN |

| 26 | Pawlik et al. (2021) | 1A, 1B | 2C | 3D | 4S | — |

| 27 | Abideen et al. (2021) | 1B | 2B | 3A | 4C | — |

| 28 | Marquina et al. (2021) | 1C | 2C | 3E | 4 V | 5S |

| 29 | Ciliberto et al. (2021) | 1C | 2B | 3C | 4 V | 5E |

| 30 | Dahmani et al. (2021) | 1C | 2B | 3C | 4 V | 5E |

| 31 | Touriki et al. (2021) | 1C | 2B | 3C | 4 V | 5O, 5EN |

| 32 | Schmitt et al. (2021) | 1A | 2B | 3A, 3C | 4C | 5EN |

| 33 | Agyabeng-Mensah et al. (2021) | 1B | 2A | 3B | 4C | 5S, 5EN, 5OR |

| 34 | Akkalatham and Taghipour (2021) | 1B | 2A | 3B | 4E | 5EN |

| 35 | Benachio et al. (2021) | 1C | 2B | 3C | 4F | — |

| 36 | Abu et al. (2021) | 1C | 2B | 3C | 4 V | — |

| 37 | Agrawal and Vinodh (2021) | 1C | 2A | 3B | 4C | — |

| 38 | Tseng et al. (2021) | 1A | 2A | 3B | 4F | 5EN |

| 39 | Nayal et al. (2025) | 1B | 2A | 3E | 4C | 5S, 5E, 5EN |

| 40 | Lee et al. (2021) | 1C | 2B | 3C | 4 V | 5S, 5E, 5O, 5EN |

| 41 | Hedlund et al. (2020) | 1A | 2B | 3A; 3C | 4S | 5EN |

| 42 | Gimpel et al. (2020) | 1C | 2A | 3E | 4 V | 5E |

| 43 | Bhatt et al. (2020) | 1C | 2B | 3C | 4 V | 5EN |

| 44 | Marrucci et al. (2020) | 1A | 2C | 3A; 3E | 4G | 5E, 5EN |

| 45 | Yadav et al. (2020) | 1B | 2B | 3A; 3C | 4C | 5OR |

| 46 | Wang et al. (2019) | 1C | 2B | 3C | 4 V | — |

| 47 | Caldera et al. (2019) | 1A | 2B | 3A | 4C | 5S, 5O, 5EN |

| 48 | Nascimento et al. (2019) | 1B | 2B | 3A, 3C | 4C | — |

| 49 | Hong et al. (2018) | 1B | 2A | 3B | 4C | 5S, 5OR |

| 50 | Kurilova-Palisaitiene et al. (2018) | 1A | 2B | 3A; 3C | 4C | — |

| 51 | Minunno et al. (2018) | 1C | 2B | 3C | 4F | — |

- Note: Author's own elaboration.

Table 4 presents the classification of the 51 selected articles based on the dimensions established in Table 3 (Classification and Coding). The next section details the classified and coded aspects (Stage 4), as well as the main gaps identified and potential directions for future research.

| LM Practice | Summary | Frequ. | Authors |

|---|---|---|---|

| Waste and residue disposal | It focuses on the systematic reduction of waste, emissions and polluting materials, promoting more efficient and sustainable production processes. It contributes directly to the mitigation of environmental impacts and to the sustainability of the value chain. | 25 | Sehnem et al. (2025); Kalemkerian et al. (2024); Ferlito (2024); Arora et al. (2024); Skorupińska et al. (2024); Maldonado-Guzmán and Garza-Reyes (2023); Niekurzak et al. (2023); Farrukh et al. (2023); Ghaithan et al. (2023); Nadeem et al. (2023); Khanzode et al. (2023); de Mattos Nascimento et al. (2022); Lim et al. (2022a); Skalli et al. (2024); Deng et al. (2022); Skalli et al. (2022); Palma-Tafur et al. (2022); Shabur (2024); Lee et al. (2021); Pawlik et al. (2021); Agrawal and Vinodh (2021); Nayal et al. (2025); Marrucci et al. (2020); Hedlund et al. (2020); Minunno et al. (2018) |

| Search for continuous improvement (kaizen) | It encourages the constant review of production processes, optimizing the use of resources and reducing losses. Its application favors the continuous adaptation of industrial processes to meet the principles of the CE. | 14 | Sasso et al. (2025), Salman et al. (2025); Costa et al. (2024); Skorupińska et al. (2024); Nadeem et al. (2023); Kalemkerian et al. (2022); Maldonado-Guzmán and Garza-Reyes (2023); Farrukh et al. (2023), de Mattos Nascimento et al. (2022); Lee et al. (2021); Dahmani et al. (2021); Marquina et al. (2021); Bhatt et al. (2020); Caldera et al. (2019) |

| Value Stream Mapping | Essential tool to identify inefficiencies and opportunities to close production cycles. It facilitates the implementation of sustainable practices, such as recycling and reuse, increasing operational efficiency. | 10 | E Silva et al. (2024); Farrukh et al. (2023); Nadeem et al. (2023); Kalemkerian et al. (2024); de Mattos Nascimento et al. (2022); Kalemkerian et al. (2022); Pawlik et al. (2021); Hedlund et al. (2020); Bhatt et al. (2020); Caldera et al. (2019) |

| Just-in-Time (JIT) | Minimizes inventories and excess production, ensuring an efficient flow of materials and inputs. In line with CE principles, it reduces waste and improves resource management along the supply chain. | 8 | Sasso et al. (2025); Costa et al. (2024); Skorupińska et al. (2024); Farrukh et al. (2023); Ghaithan et al. (2023); Kalemkerian et al. (2022); Deng et al. (2022); Nayal et al. (2025) |

| Reuse, recycle, remanufacture | It promotes the extension of the life cycle of products and components, reducing the need to extract new resources. It encourages sustainable business models, such as the sharing economy and circular manufacturing. | 16 | Shabur (2024); Kalemkerian et al. (2024); Paraschos et al. (2024); Gatell and Avella (2024a, 2024b); Salman et al. (2025); de Mattos Nascimento et al. (2022); Kalemkerian et al. (2022); Deng et al. (2022); Agrawal and Vinodh (2021); Nayal et al. (2025); Schmitt et al. (2021); Gholami et al. (2021); Yadav et al. (2020); Hedlund et al. (2020); Marrucci et al. (2020); Nascimento et al. (2019) |

| Principles 5 S | It ensures the efficient organization of the work environment, optimizing the use of materials and reducing waste. It facilitates the implementation of lean and sustainable processes. | 6 | Skorupińska et al. (2024); Farrukh et al. (2023); Nadeem et al. (2023); Kalemkerian et al. (2022); Pawlik et al. (2021); Caldera et al. (2019) |

| Promoting flexibility and agility | It allows production to be adapted to different conditions and scenarios, including the reuse and remanufacturing of end-of-life products. Reduces waste and enhances the reuse of components. | 2 | Maldonado-Guzmán and Garza-Reyes (2023); Deng et al. (2022) |

| Single Minute Exchange of Die (SMED) | It drastically reduces setup times and tool changes, increasing production efficiency. It reduces waste associated with long and complex changeovers, making processes more agile and sustainable. | 2 | Costa et al. (2024); Molina and Pascua (2022) |

| Lean Design | It develops products strategically, maximizing customer value and minimizing waste throughout the life cycle. It supports eco-design and the use of recyclable or biodegradable materials. | 3 | Costa et al. (2024); Dahmani et al. (2021); Minunno et al. (2018) |

| Lean Product Development | It emphasizes the reduction of inventories and the adoption of lean practices in the development of new products. It ensures lower environmental impact and greater efficiency in the production chain. | 5 | Sehnem et al. (2025); Paraschos et al. (2024); Skalli et al. (2022); Agyabeng-Mensah et al. (2021); Bhatt et al. (2020) |

| Incorporation of Industry 4.0 technologies | It uses tools such as the Internet of Things (IoT), automation, and data analytics to integrate lean methodologies and sustainable practices. It facilitates the implementation of reverse logistics and circular economy. | 9 | Sehnem et al. (2025); Shabur (2024); Ferlito (2024); Kalemkerian et al. (2024); Khanzode et al. (2023); Paraschos et al. (2024); Skalli et al. (2022); de Mattos Nascimento et al. (2022); Ciliberto et al. (2021) |

| Standardization of operations | Essential to ensure efficient and consistent processes, especially in activities such as remanufacturing and reuse of components. Reduces variations and cycle times, improving production sustainability. | 4 | Salman et al. (2024), Gatell and Avella (2024a, 2024b); Pawlik et al. (2021); Kurilova-Palisaitiene et al. (2018) |

| Advance planning | It allows aligning industrial practices with the UN Sustainable Development Goals (SDGs), anticipating demands and reducing environmental impacts along the production chain. | 1 | Elmaraghy et al. (2018) |

| Employee engagement and human capital enhancement | Crucial for the effective implementation of lean and sustainable methodologies. It encourages the active participation of employees in the optimization of processes and in the culture of continuous improvement. | 2 | Sehnem et al. (2025); Ghaithan et al. (2023) |

| Training and Education | Ensures that employees understand and apply the principles correctly to optimize resources and reduce waste. | 3 | Salman et al. (2024); Marrucci et al. (2020); Kurilova-Palisaitiene et al. (2018) |

| Automation and digitalization | Technologies such as the Internet of Things (IoT), Cloud Computing, and Direct Digital Manufacturing (DDM) are pointed out as ways to integrate lean manufacturing with sustainable practices. | 3 | Arora et al. (2024); Costa et al. (2024); Nayal et al. (2025) |

| Lean Six Sigma | It combines Lean and Six Sigma philosophies to improve production processes through the application of rigorous metrics. It reduces defects, waste and rework, optimizing resources and improving industrial sustainability. | 3 | Skorupińska et al. (2024); Skalli et al. (2024); Farrukh et al. (2023); Khanzode et al. (2023) |

- Note: prepared by the authors.

5 Results

5.1 Initial Research Results

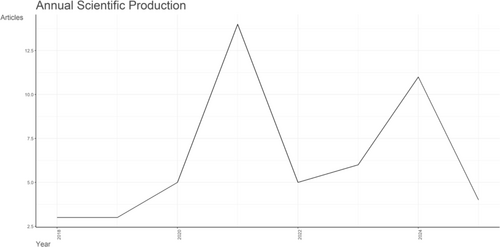

Figure 2 illustrates the temporal distribution of publications on the topic.

Source: Prepared by the author. The graph illustrates the temporal distribution of publications on this topic, with data obtained using the Biblioshiny tool. The number of articles published per year is represented on the vertical axis (unit: number of articles), while the publication years are shown on the horizontal axis. A significant increase in research interest is observed from 2020 onward, peaking in 2021 with 14 publications. The curve fluctuates in the following years, reflecting the evolution of this research field

.Research integrating Lean Management (LM) and Circular Economy (CE) are relatively recent, with a significant increase in publications over the past 5 years. However, only one study has directly compared the two concepts, underscoring the relevance of this investigation. The first study on this interface, conducted by Minunno et al. (2018), identified barriers to the adoption of CE in construction. While LM contributes to waste minimization, traditional buildings, characterized by non-standardized on-site assembled components, hinder its effective implementation.

Annual research contributions were analyzed using Biblioshiny. From 2018 to 2019, scientific output remained low. However, from 2020 onward, interest grew, peaking in 2021 with 14 publications. In 2023, 7 studies were identified, followed by 11 in 2024. In 2025, 4 publications were recorded, indicating that the integration of LM and CE remains a promising and academically relevant field.

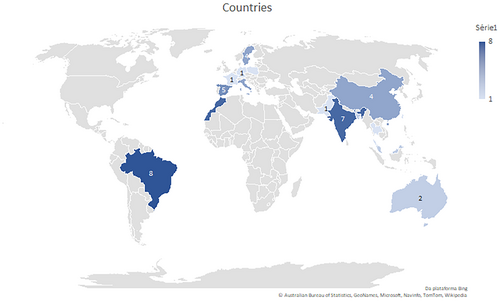

To illustrate the geographical distribution of publications on LM and CE based on the affiliation of the first author, a choropleth map was created (Figure 3). Darker shades of blue indicate countries with a higher number of contributions.

Source: Prepared by the authors. The choropleth map displays the number of publications per country, based on the affiliation of the first author. Darker shades of blue indicate a higher number of contributions, with Brazil leading (8), followed by India and Morocco (7 each). The scale ranges from 1 to 8 publications

.Brazil leads with 8 publications, followed by India and Morocco (7 each). The research is geographically diverse, with Spain (5), Italy, China, and Greece (4 each), and Bangladesh, Malaysia, and Australia (2 each). In addition, France, Germany, Taiwan, Poland, Thailand, and Pakistan contributed one study each, reflecting the advancement of the topic across other global regions.

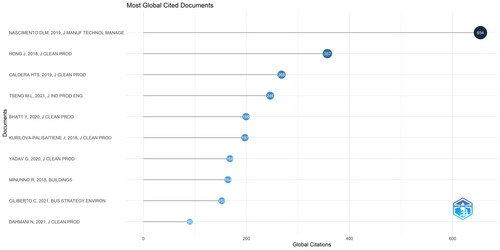

To identify the most cited documents, an analysis was conducted using Biblioshiny (Figure 4). The results show that the most cited article is Nascimento et al. (2019), with 654 citations. This study proposes a circular model for the reuse of electronic scrap devices, integrating web technologies and reverse logistics to support CE practices.

Source: Prepared by the author. The chart displays the most cited documents, with the x-axis representing global citation counts and the y-axis listing article titles. Bubble size indicates the number of citations, with Nascimento et al. (2019) leading (654 citations)

Hong et al. (2018), with 356 citations, highlight the role of LM and CE in enhancing economic performance and reducing environmental impact. The authors emphasize that extending the lifespan of resources through these practices supports both economic and social sustainability.

Caldera et al. (2019), with 268 citations, conclude that integrating LM with sustainable practices extends the lifecycle of resources and enables small and medium-sized enterprises to adopt sustainable business models, reinforcing the CE framework.

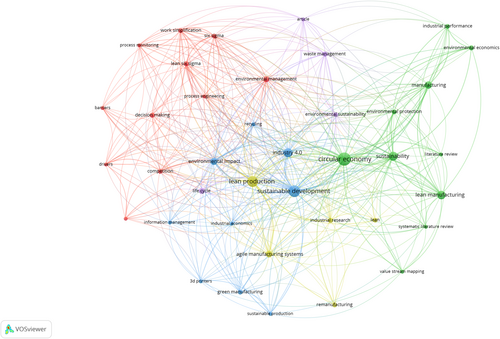

To analyze keyword co-occurrence, the VOSviewer software was used. The software identifies clusters as groups of interconnected nodes, where proximity within a cluster indicates thematic similarity (Van Eck and Waltman 2017). Figure 5 presents the five main keyword clusters. The most frequently used keywords were circular economy, lean production, sustainable development, environmental impact, lean manufacturing, agile manufacturing systems, Industry 4.0, sustainability, and manufacturing.

Source: Prepared by the authors. The network visualization, generated using VOSviewer, identified five thematic clusters represented by different colors: Circular Economy (green), Lean Production (yellow), Sustainable Development (blue), Environmental Management (red), and Waste Management (purple). Node size indicates keyword frequency, while proximity reflects thematic similarity. Stronger connections highlight closely related concepts in sustainability, manufacturing, and Industry 4.0.

- Cluster 1: Circular Economy (green) – Includes sustainability, waste management, lean manufacturing, environmental management, value stream mapping, and industrial performance. This cluster focuses on waste reduction and resource efficiency within lean manufacturing systems to achieve sustainability.

- Cluster 2: Lean Production (yellow) – Encompasses agile manufacturing, remanufacturing, industrial research, and lean systems, emphasizing the growing role of industrial agility and remanufacturing processes.

- Cluster 3: Sustainable Development (blue) – Includes Industry 4.0, environmental impact, recycling, green manufacturing, and 3D printing, highlighting how digital technologies enhance industrial sustainability.

- Cluster 4: Environmental Management (red) – Comprises Lean Six Sigma, process engineering, decision-making, and sustainable manufacturing, with a focus on optimizing production processes and environmental performance.

- Cluster 5: Waste Management (purple) – Covers life cycle analysis and environmental sustainability, reinforcing the link between waste management and sustainability.

Figure 5 visually maps these thematic relationships, demonstrating the interconnection of LM, CE, and sustainability concepts.

5.2 Content Analysis Results and Research Recommendations

5.2.1 Country Context

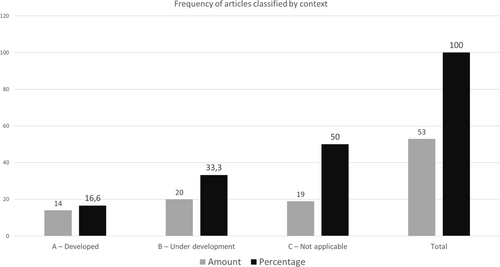

The analysis revealed that most articles addressing LM and CE were not conducted within a specific national context, consisting predominantly of conceptual and review studies (50%), as illustrated in Figure 6. Articles focused on developing markets (33.3%) and developed markets (16.6%) were less common. A total of 53 articles were analyzed, as two studies compared the topic across different national contexts. These findings led to the first recommendation of this study:

R1.There is a need for more studies in both developed and developing countries, comparing different contexts and analyzing variations in the integration of LM and CE.

Source: Prepared by the authors. The bar chart categorizes the 53 articles analyzed based on their specific national context. The categories include developed countries (A), developing countries (B), and studies without a specific national focus (C). The x-axis represents these categories, while the y-axis shows the number of articles. Black bars indicate the percentage of the total articles, with 50% classified as not applicable, 33.3% addressing developing countries, and 16.6% focusing on developed countries.

5.2.2 Types and Methods of Research

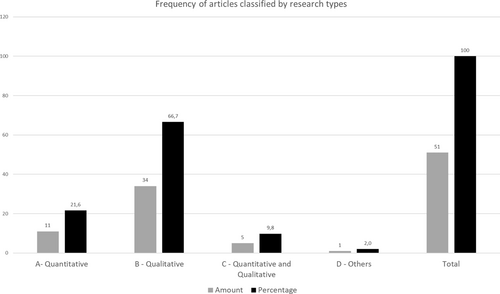

Regarding research types, the results indicate that most articles addressing the concepts of LM and CE adopt a qualitative approach (66.7%), followed by a quantitative approach (21.6%). Only 9.8% of the studies employ a mixed-methods approach, combining both qualitative and quantitative techniques (Figure 7).

Source: Prepared by the authors. The bar chart categorizes 51 analyzed articles based on their research approach: quantitative (A), qualitative (B), mixed methods (C), and others (D). The x-axis represents these categories, while the y-axis shows the number of articles. Black bars indicate the percentage of total studies, with qualitative research being the most common (66.7%), followed by quantitative (21.6%) and mixed methods approaches (9.8%).

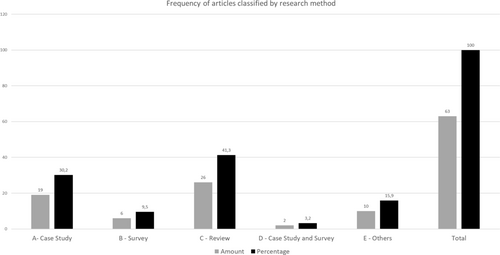

As for the research methods employed (Figure 8), the majority of articles concerning LM and CE are literature reviews (41.3%), followed by case studies (30.2%). Only two articles (3.2%) used a combination of methods (case study and survey). Mixed-methods research (quantitative/survey and qualitative/case study) enables methodological complementarity and reduces biases associated with single-method approaches (Teixeira et al. 2020), thus making studies more robust. The total frequency was 63, as some articles employed more than one research method.

Source: Prepared by the authors. The bar chart categorizes 63 analyzed articles based on their research method: case study (A), survey (B), literature review (C), case study combined with survey (D), and others (E). The x-axis represents these categories, while the y-axis indicates the number of articles. Black bars show the percentage of total studies, with review articles being the most common (41.3%), followed by case studies (30.2%).

In light of this scenario, the second recommendation is proposed:

R2.Future research on LM and CE should adopt mixed research methods, particularly the combination of case studies and surveys, as well as data analysis techniques such as structural equation modeling and fuzzy logic, to deepen the understanding of the LM–CE relationship and strengthen the evidence base for this integration.

5.2.3 Analyzed Sector

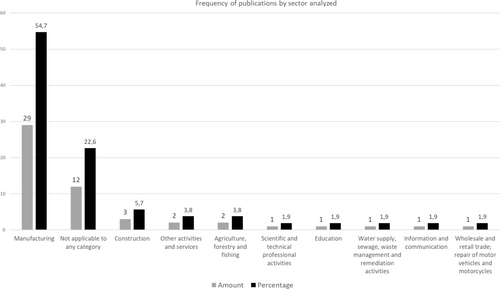

Figure 9 shows that 54.7% of the 53 economic activities identified in the 51 articles analyzed focused on the manufacturing sector (C). The number of activities recorded exceeds the number of articles because some studies addressed multiple sectors. The second most represented category was “V” (not assigned to a specific category), with 22.6%, followed by “F” (Construction) with 5.7%, and “S” (Other activities and services) and Agriculture, Forestry and Fishing, each with 3.8%.

Source: Prepared by the authors. The bar chart categorizes 53 economic activities identified across 51 analyzed articles. The x-axis represents different economic sectors, including manufacturing (C), construction (F), other activities and services (S), and agriculture, forestry, and fishing (4A). The y-axis indicates the percentage of studies addressing each sector. The manufacturing industry is the most studied sector (54.7%), followed by services and construction. Some studies covered multiple sectors, resulting in a total number of activities higher than the number of articles.

Other categories had only one occurrence (1.9%) each: M (Professional, Scientific and Technical Activities), P (Education), E (Water Supply, Sewerage, Waste Management and Remediation Activities), J (Information and Communication), and G (Wholesale and Retail Trade; Repair of Motor Vehicles and Motorcycles). Although manufacturing was predominant, studies on SMEs in this sector were scarce (Ferlito 2024; Nadeem et al. 2023; Lim et al. 2022a; Agyabeng-Mensah et al. 2021; Caldera et al. 2019), highlighting a research gap (Ghaithan et al. 2023) and supporting the third recommendation:

R3.Explore the integration of LM and CE in SMEs, given the scarcity of studies addressing the combined application of these approaches in this context.

Only two studies examined the remanufacturing sector (Kurilova-Palisaitiene et al. 2018; Pawlik et al. 2021), a key CE practice (Yadav et al. 2020). As LM mitigates remanufacturing challenges (Kurilova-Palisaitiene et al. 2018), further investigation is required, supporting the fourth recommendation:

R4.Analyze the application of LM and CE in the remanufacturing sector, considering its relevance to the Circular Economy and the specific challenges of this segment.

Few studies analyzed manufacturing and services together (Agyabeng-Mensah et al. 2021; Hong et al. 2018), and only one focused exclusively on the services sector (Marrucci et al. 2020). Although LM is predominantly applied in industry (Prashar and Chaudhuri 2025), evidence suggests its growing relevance in services (Marrucci et al. 2020). Expanding research in both sectors could significantly contribute to the literature, justifying the fifth and sixth recommendations:

R5.Jointly investigate the manufacturing and service sectors to identify gaps, synergies, and shared practices across these two economic segments.

R6.Examine the service sector independently, given the scarcity of studies exclusively focused on this area and its increasing involvement in CE practices.

The construction sector was examined in three studies (Benachio et al. 2021; Tseng et al. 2021; Minunno et al. 2018), agriculture in two (Kalemkerian et al. 2024; Nayal et al. 2025), and the textile sector in one (Ferlito 2024). Given their substantial role in waste generation and resource extraction (Benachio et al. 2021; Nayal et al. 2025; Ferlito 2024), more research on their dynamics is essential, supporting the seventh recommendation:

R7.Expand research in underexplored sectors such as construction, agriculture, and textiles, considering their importance to CE and their significant environmental impact.

When analyzing the recycling and waste management sector, we identified that they appeared in only three studies (Wang et al. 2019; Hedlund et al. 2020; Akkalatham and Taghipour 2021), despite their critical role in CE implementation (Ghaithan et al. 2023). LM-driven strategies, such as Total Quality Management, enhance efficiency, supplier relationships, and waste reduction (Akkalatham and Taghipour 2021). There is a need to broaden research in this area, justifying the eighth recommendation: Expand research on lm and ec implementation.

R8.Expand research on the implementation of LM and CE in the recycling and waste management sector, given its relevance to the efficiency of circular processes and the need for optimization in waste management.

5.2.4 Integration of LM and CE and Organizational Performance

According to Skalli et al. (2024), the integration of Lean Manufacturing (LM) and Circular Economy (CE) improves operational, environmental, and sustainable performance. However, the literature lacks in-depth studies on this interaction (e Silva et al. 2024; Maldonado-Guzmán and Garza-Reyes 2023).

Table 3 (Section 4.1) synthesizes the reviewed articles, describing the performance improvements resulting from LM-CE integration. The results indicate significant environmental benefits (Caldera et al. 2019; Marrucci et al. 2020; Bhatt et al. 2020; Hedlund et al. 2020; Lee et al. 2021; Nayal et al. 2025; Akkalatham and Taghipour 2021; Agyabeng-Mensah et al. 2021; Schmitt et al. 2021; Touriki et al. 2021; Dahmani et al. 2021; Lim et al. 2022a; Kalemkerian et al. 2022; Khanzode et al. 2023; Skalli et al. 2024; e Silva et al. 2024; Kalemkerian et al. 2024; Sasso et al. 2025; Prashar and Chaudhuri 2025).

Additionally, LM-CE integration positively impacts sustainable performance across both economic and environmental dimensions (Sehnem et al. 2025; Salman et al. 2025; Sasso et al. 2024; Costa et al. 2024; Kalemkerian et al. 2024; Maldonado-Guzmán and Garza-Reyes 2023; Ghaithan et al. 2023; Nadeem et al. 2023; Marquina et al. 2021; Agyabeng-Mensah et al. 2021; Tseng et al. 2021; Nayal et al. 2025; Lee et al. 2021; Caldera et al. 2019; Hong et al. 2018).

The integration also enhances economic (Sasso et al. 2025; e Silva et al. 2024; Ciliberto et al. 2021; Dahmani et al. 2021; Lee et al. 2021; Gimpel et al. 2020; Marrucci et al. 2020) and operational performance (Prashar and Chaudhuri 2025; Sehnem et al. 2025; Sasso et al. 2025; Kalemkerian et al. 2024; Salman et al. 2025; Skalli et al. 2024; Nadeem et al. 2023; Kalemkerian et al. 2022; Deng et al. 2022; Touriki et al. 2021; Lee et al. 2021; Caldera et al. 2019).

However, few studies examine the relationship between LM-CE integration and overall organizational performance (Hong et al. 2018; Yadav et al. 2020; Agyabeng-Mensah et al. 2021; Sasso et al. 2024; Salman et al. 2024; Sehnem et al. 2025), and only one identifies improvements in social performance (Kalemkerian et al. 2022). Based on these findings, the ninth recommendation is proposed:

R9.Further studies are needed to investigate the relationship between LM-CE integration and improvements in environmental, organizational, and social performance.

5.2.5 LM Practices That Most Contribute to CE

This section explores the main tools and methodologies from Lean Manufacturing that facilitate the transition to sustainable business models by minimizing waste, optimizing resource use, and increasing energy efficiency. The goal is to identify how these practices, when aligned with the principles of Circular Economy, positively impact industrial operations by promoting sustainability and reducing environmental impact. The focus is on determining which elements of LM exert the greatest influence on CE adoption.

The analysis highlights the critical role of LM-CE integration in improving industrial sustainability. The reviewed studies emphasize that LM tools such as value stream mapping, waste elimination, and energy efficiency strategies are fundamental to accelerating the transition to circular models.

In this context, Table 4 synthesizes the main LM practices identified in the literature as facilitators of CE, describing their impacts and benefits in advancing a sustainable economy.

Few studies have explored the contributions of LM-CE integration to broader research agendas, such as the United Nations Sustainable Development Goals (SDGs) (Farrukh et al. 2023; Bhatt et al. 2020) and Environmental, Social, and Governance (ESG) principles. This gap highlights the need for further investigation to better understand how the synergy between LM and CE can support these global strategic frameworks. Therefore, the following recommendation is proposed:

R10.Further research is required to explore how LM-CE integration contributes to broader agendas such as the SDGs, ESG, and Circular Supply Chains (CSC).

5.3 Proposal of an Integrative Framework

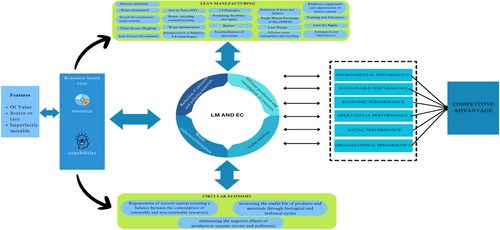

Based on the robust analysis conducted in this study, an integrative framework is proposed that connects Lean Manufacturing (LM) and the Circular Economy (CE) (Figure 10).

Source: Developed by the authors.

This framework highlights how lean practices (Just-in-Time, automation, and waste elimination) interact with circular strategies (remanufacturing, resource regeneration, and life cycle extension) creating synergies that enhance environmental, economic, operational, and social performance. This proposal serves as a theoretical guide for future research and corporate initiatives oriented toward sustainability and value creation through the integration of LM and CE, with potential to direct public policies, corporate strategies, and academic agendas focused on sustainable development.

Graphically, Figure 10 presents the synergy between Lean Manufacturing (LM) and the Circular Economy (CE), illustrating how this integration, grounded in the Resource-Based View (RBV), can generate substantial improvements across multiple domains of organizational performance (environmental, social, economic, operational, and sustainable) ultimately leading to the development of sustainable competitive advantage.

More specifically, the RBV functions as the theoretical foundation explaining how resources and capabilities that are valuable, rare, and imperfectly imitable become central enablers for the effective implementation of lean and circular practices. These resources include, for example, organizational capabilities, tacit knowledge, technologies, recycling infrastructure, and a culture of continuous improvement.

On the Lean Manufacturing side, practices, such as Just-in-Time, Kaizen, Value Stream Mapping, 5S, SMED, Six Sigma, digitalization, and standardized operations stand out, as they reduce waste, increase efficiency, and enhance process flexibility. These practices establish the ideal conditions for incorporating circular principles.

In turn, the Circular Economy amplifies the benefits by promoting the regeneration of natural capital, closing technical and biological cycles, and eliminating the negative externalities of production systems, such as waste and pollution. This leads to greater product durability, improved material utilization, and reduced dependence on non-renewable resources.

The LM–CE integration, therefore, enables a cyclical and virtuous logic of value creation: while Lean fosters efficiency and waste reduction, CE extends product life cycles, closes material loops, and contributes to environmental goals. This complementarity leads to value generation and drives performance improvements across multiple organizational dimensions, ultimately creating competitive advantage.

6 Discussions

Recent studies indicate a growing academic interest in the intersection of Lean Manufacturing (LM) and the Circular Economy (CE), with most publications emerging in the past 5 years, particularly in 2021 (Marquina et al. 2021). The research predominantly focuses on environmental benefits and waste reduction, while the financial and social dimensions remain underexplored. Geographically, publications are concentrated in Europe and Asia, notably in India, Spain, Italy, China, and Malaysia, with limited studies in Africa, highlighting opportunities for future research (Lee et al. 2021; Ciliberto et al. 2021; Minunno et al. 2018).

Most studies originate from developing markets (Kalemkerian et al. 2024; Sehnem et al. 2025; Salman et al. 2025), but few address the contexts of developed and underdeveloped countries (Deng et al. 2022; Pawlik et al. 2021), exposing a gap in the literature. LM is identified as a key enabler of CE, enhancing resource efficiency and maximizing value (Romero and Rossi 2017), while the absence of closed-loop products limits circular potential (Schmitt et al. 2021).

Regarding organizational performance, studies reveal that LM–CE integration yields positive environmental (Prashar and Chaudhuri 2025; Skalli et al. 2022), operational (Sehnem et al. 2025; Nadeem et al. 2023), and economic outcomes (Sasso et al. 2025; e Silva et al. 2024; Ciliberto et al. 2021). However, studies on social (Kalemkerian et al. 2022) and organizational performance (Yadav et al. 2020; Agyabeng-Mensah et al. 2021) remain limited. Sasso et al. (2025) confirm the importance of LM's role in CE, improving waste reduction, resource efficiency, and organizational performance.

Methodologically, studies using mixed methods are scarce, with only two employing both case study and survey approaches (Niekurzak et al. 2023; Pawlik et al. 2021), and one utilizing action research. Further research is needed in remanufacturing (Farrukh et al. 2023; Kurilova-Palisaitiene et al. 2018) and recycling (Hedlund et al. 2020).

Despite the complementary nature of LM and CE in promoting waste reduction, efficiency, and resource optimization (Sasso et al. 2025), the literature on circular practices within Lean Manufacturing frameworks remains underdeveloped (Hedlund et al. 2020; Kurdve and Bellgran 2021), particularly in small and medium-sized enterprises (Ghaithan et al. 2023) and sectors such as construction (Minunno et al. 2018; Tseng et al. 2021), agriculture (Kalemkerian et al. 2024), and textiles (Ferlito 2024). These gaps underscore the need for further research integrating LM and CE across diverse sectors.

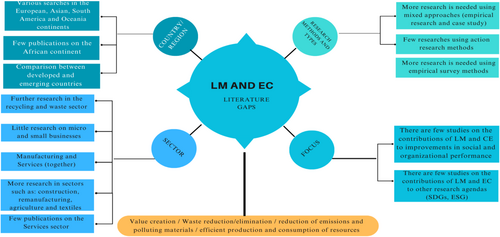

Figure 11 summarizes and categorizes the research gaps in the LM and CE literature identified in this study into four main areas: country or region, sector, methods and types of research, and focus. The gaps include the lack of studies in African countries, limited research on micro and small enterprises, and insufficient exploration of the construction, remanufacturing, agriculture, and textile sectors. Methodological gaps highlight the need for more mixed-methods approaches, empirical research, and action research. Furthermore, few studies address the contributions of Lean Manufacturing and the Circular Economy to social and organizational performance, as well as to broader research agendas such as the Sustainable Development Goals (SDGs) and Environmental, Social, and Governance (ESG) criteria.

Source: Developed by the authors.

7 Final Considerations

This research aimed to identify, systematize, and integrate studies addressing the relationship between Lean Manufacturing (LM) and the Circular Economy (CE). Studies of this nature are important for mapping and categorizing existing literature on the topics and for proposing directions for future research.

Based on a search of the two main global databases, Scopus and Web of Science, 51 studies were selected and analyzed in detail to understand the state of the art in the field. To the best of our knowledge, this is the first study to systematize and integrate the relationship between LM and CE while proposing a structured framework to be tested in future research. Furthermore, we propose ten (10) recommendations that can significantly guide and support scholars and practitioners in developing their activities more effectively and in a way that meaningfully contributes to advancing topics at the intersection of LM and CE.

7.1 Theoretical Implications

This article fills a relevant gap in the literature by demonstrating the importance of integrating LM and CE as a strategic approach to addressing sustainability challenges. It suggests that LM practices align with CE principles, promoting waste and emission reduction, minimizing the use of polluting materials, and optimizing raw materials, natural resources (such as energy and water), production processes (operational efficiency), and supply chains, thereby facilitating the transition from linear to circular production systems.

Thus, this study expands the theoretical understanding of LM and CE by showing that integrating these two research areas can help extend CE practices beyond recycling and enhance organizational performance in social, environmental, and operational domains.

Additionally, from the perspective of the Resource-Based View (RBV) and Dynamic Capabilities, this study demonstrates that LM–CE integration constitutes a valuable, rare, and inimitable resource (Barney 1991) if structurally and strategically embedded at the core of organizations. In other words, organizations that develop expertise in this integration establish barriers to imitation, with rare and valuable resources strengthening their competitive advantage and improving sustainable performance.

Therefore, this work expands theoretical knowledge in both LM and CE by developing a framework that integrates LM–CE. This framework not only fills gaps identified in the literature but also establishes a systemic model capable of guiding the transition toward CE, offering a grounded theoretical foundation to be explored and refined in future empirical research.

7.2 Practical Implications

The main practical contribution of this study lies in demonstrating that the implementation of LM practices can accelerate organizations' transition toward CE, for instance, by identifying and eliminating waste along the production chain, promoting efficiency, and reducing the consumption of raw materials (Ghaithan et al. 2023).

Furthermore, it contributes to organizing and rationalizing factory layouts, creating an environment conducive to implementing reuse, remanufacturing, and recycling strategies (Deng et al. 2022). These practices not only reduce costs but also increase employee and stakeholder acceptance of CE, thus amplifying economic and environmental gains.

Thus, the LM–CE integration presents significant practical implications. For organizations, it offers an operational model that combines production efficiency with sustainability, for example, reducing costs by minimizing waste (LM) and valorizing waste as inputs (CE), thereby creating new revenue streams through the reuse of materials.

For managers and professionals, integrating LM–CE demands changes in mindset, organizational culture, and the development of new capabilities, such as design for disassembly and life cycle analysis, as well as the adoption of new performance metrics, such as resource efficiency and material recovery rates. Therefore, managers must also foster a culture of innovation and collaboration within and between organizations to drive progress toward circularity.

For governments, the proposed LM–CE framework can guide public policy that encourages the transition to a CE, for example, through tax incentives for companies that adopt sustainable LM practices, the promotion of applied research, or regulations that guide infrastructure development for waste collection and processing.

Finally, for society, this integration offers significant environmental and economic benefits: reduced environmental impact, such as decreased natural resource extraction and lower waste generation, results in a reduced ecological footprint and long-term cost savings for consumers. Additionally, the production of durable and repairable goods may generate employment opportunities in emerging business models such as specialized maintenance and repair services.

7.3 Impacts on Economic, Environmental, Social, and Operational Performance

The study's findings indicate that integrating LM and CE positively impacts economic, environmental, operational, social, organizational, and sustainable performance. Economically, LM optimizes production processes, reduces operating costs, and increases profitability. By minimizing waste and improving efficiency, the LM–CE synergy enhances market competitiveness, lowers raw material expenses, and increases financial sustainability (Maldonado-Guzmán and Garza-Reyes 2023).

Environmentally, strategies, such as waste reduction, energy efficiency, and minimized resource consumption enable organizations to meet ambitious sustainability targets. These initiatives not only mitigate environmental impacts but also respond to growing consumer and stakeholder demands (Lim et al. 2022a).

Operationally, the LM–CE integration improves production flexibility and resilience, shortens lead times, and enhances process predictability. Organizations adopting this approach demonstrate greater adaptability to sustainability and innovation challenges, aligning with Industry 4.0 trends (Kalemkerian et al. 2024). However, organizational and social performance still require further exploration (Sasso et al. 2025; Kalemkerian et al. 2022).

Despite these benefits, challenges remain, including cultural and structural barriers to jointly implementing LM and CE. Organizational resistance, limited knowledge of circular methodologies, and the absence of clear incentives hinder adoption, requiring strategic interventions to facilitate the transition to circular production models (Arora et al. 2024).

7.4 Limitations and Directions for Future Research

First, several areas for future research emerge from the gaps identified in our integrative systematic literature review, which revealed a predominance of studies on LM–CE integration in developed markets, with limited empirical research typically confined to emerging economies. Moreover, there are few qualitative and quantitative studies assessing the operational, economic, and environmental impacts of LM–CE integration. The review also revealed a lack of studies on LM and CE applications in specific sectors, particularly small and medium-sized enterprises (SMEs) and remanufacturing industries.

Like all research, this study has limitations. One relates to the choice of databases and keywords used in the search. Although the search was conducted in the two main global databases and followed a rigorous selection process, it is possible that some relevant studies may have been missed.

Another limitation concerns the use of a single theoretical lens—namely, the Resource-Based View, highlighting the need for alternative theoretical approaches. Additionally, the analysis focused exclusively on operational, environmental, social, sustainable, and economic performance.

Therefore, future studies are encouraged to use qualitative, quantitative, and especially mixed methods (i.e., combining both qualitative and quantitative research) to apply the proposed framework in organizations across different contexts (developed and developing countries/emerging markets) and of different sizes and sectors (micro, small, medium, and large enterprises), with the goal of testing its applicability and refining the model by incorporating new insights, such as best practices, applied strategies, lessons learned, and the barriers and benefits of LM–CE integration.

Lastly, longitudinal studies are recommended to explore the outcomes of the LM–CE synergy, such as waste reduction and the reuse of materials, inputs, and equipment within organizations. These studies would enable clearer and more precise quantification of the benefits and demonstrate the practical impacts of this integration.

Acknowledgments

The Article Processing Charge for the publication of this research was funded by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - Brasil (CAPES) (ROR identifier: 00x0ma614).

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

Data sharing not applicable to this article as no datasets were generated or analysed during the current study.