Design and properties of dynamic self-healing polyurea molecule based on disulfide bonds

Abstract

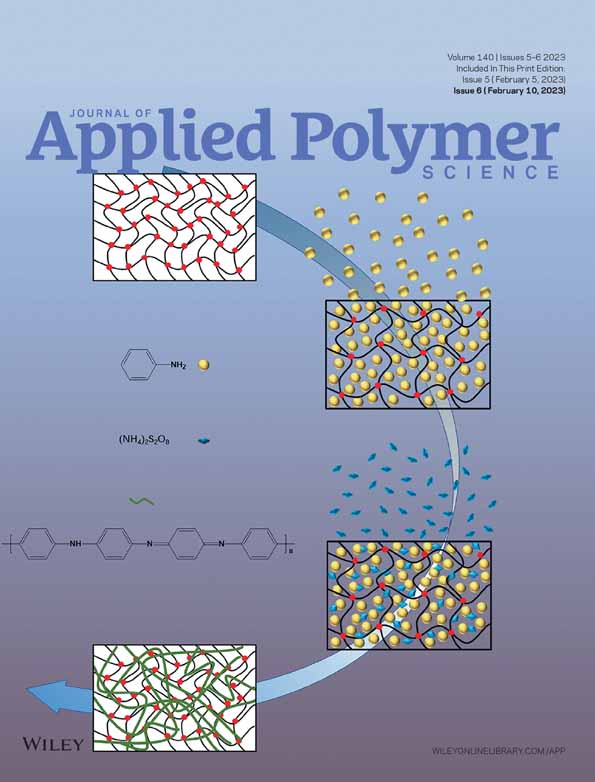

Although thermosetting polymer materials have excellent mechanical properties, they are less self-healing, recycling than thermoplastic polymer materials, which may cause a serious waste of resources. Herein, a series of polyurea materials with high mechanical strength, good properties of self-healing and recycling are prepared by adjusting the ratio of polyether polyol and introducing disulfides into the synthesis of polyurea prepolymer in an innovative way. The composite polyurea (FHPUA) materials with tensile strength over 47 MPa and elongation at break of 720% are prepared. The experimental results show that by adjusting the content of aromatic disulfide, the tensile strength is further increased to 52 MPa, and the heat resistance of the material is improved. Through five self-healing experiments, the surface of the material recovers as before even after continuous heating at 70°C for 1 h. In addition, the tensile strength of the material recovers 86.56% and the elastic modulus recovers 70.21% after four recycling experiments. In practical application, it is expected to fill the shortcomings of traditional polyurea such as micro cracks, short service life and poor performance, and have great potential applications in the fields of coating layer of heavy-duty conveyor belts, encapsulation film of electronic devices and building facade coating.

Open Research

DATA AVAILABILITY STATEMENT

Research data are not shared.