Bio-based β-myrcene-modified solution-polymerized styrene–butadiene rubber for improving carbon black dispersion and wet skid resistance

ABSTRACT

β-Myrcene, a bio-based monoterpene derived from plants, was introduced to replace butadiene in the solution-polymerized styrene–butadiene rubber by using the conventional anionic copolymerization technique. The anionic copolymerization of β-myrcene was found to be stoichiometric and controllable. A series of solution-polymerized styrene–myrcene–butadiene rubber (S-SMBR) with 100% conversion, high-molecular weight (150 000–200 000 Da), low polydispersity, and uniform compositions was obtained. The glass transition temperature of S-SMBR exhibited imperceptible variation with different myrcene/butadiene ratios. Interestingly, the introduction of such a long nonpolar pendant group containing isopropylidene could greatly improve carbon black dispersibility in the rubber. Furthermore, the wet skid resistance of the rubber could be improved without impairing its low rolling resistance. The tensile strength of S-SMBR was found to be higher than that prepared by radical emulsion copolymerization. The S-SMBR prepared by anionic solution copolymerization is thus a promising material for tires to attain sustainable development. © 2019 Wiley Periodicals, Inc. J. Appl. Polym. Sci. 2019, 136, 48159.

HIGHLIGHTS

- A bio-based monomer was successfully introduced to replace diene part in SBR through anionic polymerization.

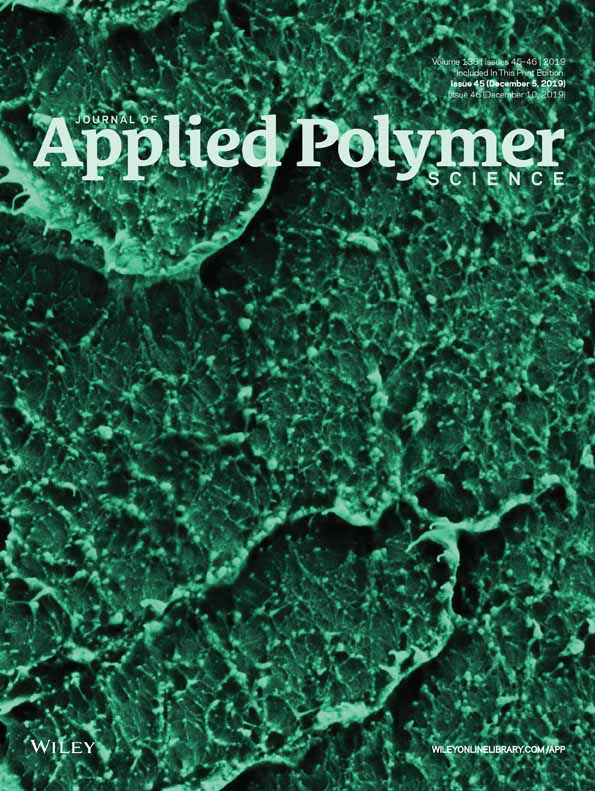

- Carbon black dispersibility in the rubber was greatly improved.

- The wet skid resistance of the rubber could be improved without impairing its low rolling resistance.

- Robust tensile behaviors were obtained compared with the rubber prepared by radical emulsion polymerization.