A Room-Temperature Lithium-Restocking Strategy for the Direct Reuse of Degraded LiFePO4 Electrodes

Dan Yang

Institute of New Energy for Vehicles, School of Materials Science and Engineering, Tongji University, Shanghai, 201804 China

Search for more papers by this authorZhou Fang

State Key Laboratory of Material Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 China

Search for more papers by this authorYongsheng Ji

Institute of New Energy for Vehicles, School of Materials Science and Engineering, Tongji University, Shanghai, 201804 China

Search for more papers by this authorYing Yang

Institute of New Energy for Vehicles, School of Materials Science and Engineering, Tongji University, Shanghai, 201804 China

Search for more papers by this authorJingrong Hou

Institute of New Energy for Vehicles, School of Materials Science and Engineering, Tongji University, Shanghai, 201804 China

Search for more papers by this authorZhenyan Zhang

State Key Laboratory of Material Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 China

Search for more papers by this authorWeichen Du

State Key Laboratory of Material Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 China

Search for more papers by this authorXiaoqun Qi

State Key Laboratory of Material Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 China

Search for more papers by this authorZhenglu Zhu

Institute of New Energy for Vehicles, School of Materials Science and Engineering, Tongji University, Shanghai, 201804 China

Search for more papers by this authorCorresponding Author

Prof. Renyuan Zhang

Institute of New Energy for Vehicles, School of Materials Science and Engineering, Tongji University, Shanghai, 201804 China

Search for more papers by this authorPei Hu

School of Science, Hubei University of Technology, Wuhan, Hubei, 430068 China

Search for more papers by this authorCorresponding Author

Prof. Long Qie

State Key Laboratory of Material Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 China

Search for more papers by this authorProf. Yunhui Huang

State Key Laboratory of Material Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 China

Search for more papers by this authorDan Yang

Institute of New Energy for Vehicles, School of Materials Science and Engineering, Tongji University, Shanghai, 201804 China

Search for more papers by this authorZhou Fang

State Key Laboratory of Material Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 China

Search for more papers by this authorYongsheng Ji

Institute of New Energy for Vehicles, School of Materials Science and Engineering, Tongji University, Shanghai, 201804 China

Search for more papers by this authorYing Yang

Institute of New Energy for Vehicles, School of Materials Science and Engineering, Tongji University, Shanghai, 201804 China

Search for more papers by this authorJingrong Hou

Institute of New Energy for Vehicles, School of Materials Science and Engineering, Tongji University, Shanghai, 201804 China

Search for more papers by this authorZhenyan Zhang

State Key Laboratory of Material Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 China

Search for more papers by this authorWeichen Du

State Key Laboratory of Material Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 China

Search for more papers by this authorXiaoqun Qi

State Key Laboratory of Material Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 China

Search for more papers by this authorZhenglu Zhu

Institute of New Energy for Vehicles, School of Materials Science and Engineering, Tongji University, Shanghai, 201804 China

Search for more papers by this authorCorresponding Author

Prof. Renyuan Zhang

Institute of New Energy for Vehicles, School of Materials Science and Engineering, Tongji University, Shanghai, 201804 China

Search for more papers by this authorPei Hu

School of Science, Hubei University of Technology, Wuhan, Hubei, 430068 China

Search for more papers by this authorCorresponding Author

Prof. Long Qie

State Key Laboratory of Material Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 China

Search for more papers by this authorProf. Yunhui Huang

State Key Laboratory of Material Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, Hubei, 430074 China

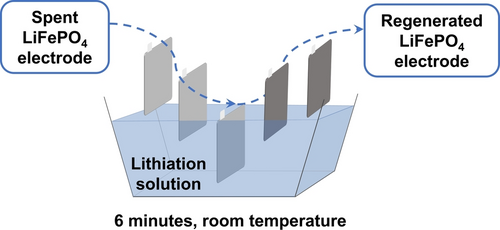

Search for more papers by this authorGraphical Abstract

A facile strategy for the direct reuse of spent LiFePO4 electrodes is developed by simply soaking the spent electrodes in a lithiation reagent solution at room temperature for 6 min. Being reused directly, the regenerated LiFePO4 electrode delivers a high specific capacity of 162.6 mAh g−1 even after being exposed in air for 3 months.

Abstract

The sustainable development of lithium iron phosphate (LFP) batteries calls for efficient recycling technologies for spent LFP (SLFP). Even for the advanced direct material regeneration (DMR) method, multiple steps including separation, regeneration, and electrode refabrication processes are still needed. To circumvent these intricacies, new regeneration methods that allow direct electrode reuse (DER) by rejuvenating SLFP electrodes without damaging its structure are desired. Here, a 0.1 M lithium triethyl borohydride/tetrahydrofuran solution, which has the proper reductive capability to reduce Fe3+ in SLFP to Fe2+ without alloying with the aluminum current collector, is selected as the lithiation/regeneration reagent to restock the Li loss and regenerate SLFP electrodes. By soaking the SLFP electrodes in the lithiation solution, we successfully rejuvenated the crystal structure and electrochemical activity of SLFP electrodes with structural integrity within only 6 minutes at room temperature. When being directly reused, the regenerated LFP electrodes deliver a high specific capacity of 162.6 mAh g−1 even after being exposed to air for 3 months. The DER strategy presents significant economic and environmental benefits compared with the DMR method. This research provides a timely and innovative solution for recycling spent blade batteries using large-sized LFP electrodes, boosting the closed-loop development of LFP batteries.

Conflict of Interests

The authors declare no conflict of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to privacy or ethical restrictions.

Supporting Information

As a service to our authors and readers, this journal provides supporting information supplied by the authors. Such materials are peer reviewed and may be re-organized for online delivery, but are not copy-edited or typeset. Technical support issues arising from supporting information (other than missing files) should be addressed to the authors.

| Filename | Description |

|---|---|

| anie202409929-sup-0001-misc_information.pdf2 MB | Supporting Information |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1

- 1aTesla China, “Tesla Model 3”, can be found under https://www.tesla.cn/model3, 2024 (accessed 24 May 2024);

- 1bBYD Co., Ltd, “Dynasty Series Vehicles”, can be found under https://www.bydauto.com.cn/pc/configCar?id=111&networkType=dynasty, 2024 (accessed 24 May 2024).

- 2MarketsandMarkets, “Lithium Iron Phosphate Batteries Market”, can be found under https://www.marketsandmarkets.com/Market-Reports/lithium-iron-phosphatebatteries-market-77659282.html, 2023 (accessed 24 May 2024).

- 3

- 3aMarketsandMarkets, “Lithium-ion Battery Recycling Market”, can be found under https://www.marketsandmarkets.com/Market-Reports/lithium-ion-battery-recycling-market-153488928.html, 2023 (accessed 24 May 2024);

- 3bX. Wu, J. Ma, J. Wang, X. Zhang, G. Zhou, Z. Liang, Glob. Chall. 2022, 6, 2200067.

- 4

- 4aM. Chen, X. Ma, B. Chen, R. Arsenault, P. Karlson, N. Simon, Y. Wang, Joule 2019, 3, 2622;

- 4bZ. J. Baum, R. E. Bird, X. Yu, J. Ma, ACS Energy Lett. 2022, 7, 712;

- 4cD. H. S. Tan, P. Xu, Z. Chen, MRS Energy Sustain. 2020, 7, 27.

- 5W. Lv, Z. Wang, H. Cao, Y. Sun, Y. Zhang, Z. Sun, ACS Sustain. Chem. Eng. 2018, 6, 1504.

- 6

- 6aH. Gao, D. Tran, Z. Chen, Curr. Opin. Electrochem. 2022, 31, 100875;

- 6bP. Xu, D. H. S. Tan, B. Jiao, H. Gao, X. Yu, Z. Chen, Adv. Funct. Mater. 2023, 33, 2213168.

- 7

- 7aP. Xu, Q. Dai, H. Gao, H. Liu, M. Zhang, M. Li, Y. Chen, K. An, Y. S. Meng, P. Liu, Y. Li, J. S. Spangenberger, L. Gaines, J. Lu, Z. Chen, Joule 2020, 4, 2609;

- 7bK. Jia, J. Ma, J. Wang, Z. Liang, G. Ji, Z. Piao, R. Gao, Y. Zhu, Z. Zhuang, G. Zhou, H.-M. Cheng, Adv. Mater. 2023, 35, 2208034;

- 7cG. Ji, J. Wang, Z. Liang, K. Jia, J. Ma, Z. Zhuang, G. Zhou, H.-M. Cheng, Nat. Commun. 2023, 14, 584;

- 7dD. Tang, G. Ji, J. Wang, Z. Liang, W. Chen, H. Ji, J. Ma, S. Liu, Z. Zhuang, G. Zhou, Adv. Mater. 2024, 36, 2309722.

- 8

- 8aX. Zhang, Q. Xue, L. Li, E. Fan, F. Wu, R. Chen, ACS Sustain. Chem. Eng. 2016, 4, 7041;

- 8bD. Yu, Z. Huang, B. Makuza, X. Guo, Q. Tian, Miner. Eng. 2021, 173, 107218;

- 8cY. He, X. Yuan, G. Zhang, H. Wang, T. Zhang, W. Xie, L. Li, Sci. Total. Environ. 2021, 766, 142382.

- 9C. Wang, L. He, H. Sun, P. Lu, Y. Zhu (BYD Co., Ltd.), CN 110165118A, 2019.

- 10A. K. Padhi, K. S. Nanjundaswamy, J. B. Goodenough, J. Electrochem. Soc. 1997, 144, 1188.

- 11J. Wang, X. Sun, Energy Environ. Sci. 2015, 8, 1110.

- 12

- 12aH. Liu, F. C. Strobridge, O. J. Borkiewicz, K. M. Wiaderek, K. W. Chapman, P. J. Chupas, C. P. Grey, Science 2014, 344, 1252817;

- 12bL.-X. Yuan, Z.-H. Wang, W.-X. Zhang, X.-L. Hu, J.-T. Chen, Y.-H. Huang, J. B. Goodenough, Energy Environ. Sci. 2011, 4, 269.

- 13

- 13aH. Zhang, J. Cheng, H. Liu, D. Li, Z. Zeng, Y. Li, F. Ji, Y. Guo, Y. Wei, S. Zhang, T. Bai, X. Xu, R. Peng, J. Lu, L. Ci, Adv. Energy Mater. 2023, 13, 2300466;

- 13bW. M. Dose, C. S. Johnson, Curr. Opin. Electrochem. 2022, 31, 100827.

- 14

- 14aC. Xin, J. Gao, R. Luo, W. Zhou, Chem.-Eur. J. 2022, 28, e202104282;

- 14bY. Shen, J. Zhang, Y. Pu, H. Wang, B. Wang, J. Qian, Y. Cao, F. Zhong, X. Ai, H. Yang, ACS Energy Lett. 2019, 4, 1717;

- 14cY. Huang, C. Liu, F. Wei, G. Wang, L. Xiao, J. Lu, L. Zhuang, J. Mater. Chem. A 2020, 8, 18715;

- 14dG. Wang, F. Li, D. Liu, D. Zheng, Y. Luo, D. Qu, T. Ding, D. Qu, ACS Appl. Mater. Interfaces 2019, 11, 8699.

- 15

- 15aN. Paul, J. Wandt, S. Seidlmayer, S. Schebesta, M. J. Mühlbauer, O. Dolotko, H. A. Gasteiger, R. Gilles, J. Power Sources 2017, 345, 85;

- 15bJ.-H. Kim, S. C. Woo, M.-S. Park, K. J. Kim, T. Yim, J.-S. Kim, Y.-J. Kim, J. Power Sources 2013, 229, 190.

- 16

- 16aK.-Y. Park, I. Park, H. Kim, H.-D. Lim, J. Hong, J. Kim, K. Kang, Chem. Mater. 2014, 26, 5345;

- 16bJ. Owen, A. Hector, Science 2014, 344, 6191.

- 17L. Lin, K. Qin, Q. Zhang, L. Gu, L. Suo, Y. S. Hu, H. Li, X. Huang, L. Chen, Angew. Chem. Int. Ed. 2021, 60, 8289.

- 18

- 18aC. Wu, J. Hu, L. Ye, Z. Su, X. Fang, X. Zhu, L. Zhuang, X. Ai, H. Yang, J. Qian, ACS Sustain. Chem. Eng. 2021, 9, 16384;

- 18bJ. Jang, I. Kang, J. Choi, H. Jeong, K. W. Yi, J. Hong, M. Lee, Angew. Chem. Int. Ed. 2020, 59, 14473.

- 19H. C. Brown, S. Krishnamurthy, J. Am. Chem. Soc. 2002, 95, 1669.

- 20A. Ait-Salah, J. Dodd, A. Mauger, R. Yazami, F. Gendron, C. M. Julien, Z. Anorg. Allg. Chem. 2006, 632, 1598.

- 21L. Castro, R. Dedryvère, M. El Khalifi, P.-E. Lippens, J. Bréger, C. Tessier, D. Gonbeau, J. Phys. Chem. C 2010, 114, 17995.

- 22

- 22aC. V. Ramana, A. Mauger, F. Gendron, C. M. Julien, K. Zaghib, J. Power Sources 2009, 187, 555;

- 22bC. M. Burba, R. Frech, J. Electrochem. Soc. 2004, 151, A1032;

- 22cD. Lepage, C. Michot, G. Liang, M. Gauthier, S. B. Schougaard, Angew. Chem. Int. Ed. 2011, 50, 6884.

- 23K. Jia, J. Wang, J. Ma, Z. Liang, Z. Zhuang, G. Ji, R. Gao, Z. Piao, C. Li, G. Zhou, H.-M. Cheng, Nano Lett. 2022, 22, 8372.

- 24Argonne National Laboratory, “EverBatt Argonne's closed-loop battery life-cycle model”, can be found under https://www.anl.gov/amd/everbatt, 2020 (accessed 24 May 2024).

- 25

- 25aY. Yang, X. Zheng, H. Cao, C. Zhao, X. Lin, P. Ning, Y. Zhang, W. Jin, Z. Sun, ACS Sustain. Chem. Eng. 2017, 5, 9972;

- 25bJ. Zhang, J. Hu, Y. Liu, Q. Jing, C. Yang, Y. Chen, C. Wang, ACS Sustain. Chem. Eng. 2019, 7, 5626.

- 26

- 26aP. Liu, Y. Zhang, P. Dong, Y. Zhang, Q. Meng, S. Zhou, X. Yang, M. Zhang, X. Yang, J. Alloy. Compd. 2021, 860, 157909;

- 26bQ. Sun, X. Li, H. Zhang, D. Song, X. Shi, J. Song, C. Li, L. Zhang, J. Alloy. Compd. 2020, 818, 153292.

- 27J. Moellmann, S. Grimme, J. Phys. Chem. C 2014, 118, 7615.

- 28Z. Wang, W. Chen, T. Sang, Z. Zhang, M. Li, H. Tian, Z. Ming, Surf. Interfaces 2023, 39, 102893.