Reshaping of Metal Nanoparticles Under Reaction Conditions

Dr. Beien Zhu

Shanghai Advanced Research Institute, Chinese Academy of Sciences, 201210 Shanghai, China

Division of Interfacial Water and Key Laboratory of Interfacial Physics and Technology, Shanghai Institute of Applied Physics, Chinese Academy of Sciences, Shanghai, 201800 China

These authors contributed equally to this work.

Search for more papers by this authorJun Meng

Division of Interfacial Water and Key Laboratory of Interfacial Physics and Technology, Shanghai Institute of Applied Physics, Chinese Academy of Sciences, Shanghai, 201800 China

University of Chinese Academy of Sciences, Beijing, 100049 China

These authors contributed equally to this work.

Search for more papers by this authorDr. Wentao Yuan

State Key Laboratory of Silicon Materials, School of Materials Science and Engineering, Zhejiang University, Hangzhou, 310027 China

These authors contributed equally to this work.

Search for more papers by this authorDr. Xun Zhang

State Key Laboratory of Silicon Materials, School of Materials Science and Engineering, Zhejiang University, Hangzhou, 310027 China

Search for more papers by this authorProf. Hangsheng Yang

State Key Laboratory of Silicon Materials, School of Materials Science and Engineering, Zhejiang University, Hangzhou, 310027 China

Search for more papers by this authorCorresponding Author

Prof. Yong Wang

State Key Laboratory of Silicon Materials, School of Materials Science and Engineering, Zhejiang University, Hangzhou, 310027 China

Search for more papers by this authorCorresponding Author

Prof. Yi Gao

Shanghai Advanced Research Institute, Chinese Academy of Sciences, 201210 Shanghai, China

Division of Interfacial Water and Key Laboratory of Interfacial Physics and Technology, Shanghai Institute of Applied Physics, Chinese Academy of Sciences, Shanghai, 201800 China

Search for more papers by this authorDr. Beien Zhu

Shanghai Advanced Research Institute, Chinese Academy of Sciences, 201210 Shanghai, China

Division of Interfacial Water and Key Laboratory of Interfacial Physics and Technology, Shanghai Institute of Applied Physics, Chinese Academy of Sciences, Shanghai, 201800 China

These authors contributed equally to this work.

Search for more papers by this authorJun Meng

Division of Interfacial Water and Key Laboratory of Interfacial Physics and Technology, Shanghai Institute of Applied Physics, Chinese Academy of Sciences, Shanghai, 201800 China

University of Chinese Academy of Sciences, Beijing, 100049 China

These authors contributed equally to this work.

Search for more papers by this authorDr. Wentao Yuan

State Key Laboratory of Silicon Materials, School of Materials Science and Engineering, Zhejiang University, Hangzhou, 310027 China

These authors contributed equally to this work.

Search for more papers by this authorDr. Xun Zhang

State Key Laboratory of Silicon Materials, School of Materials Science and Engineering, Zhejiang University, Hangzhou, 310027 China

Search for more papers by this authorProf. Hangsheng Yang

State Key Laboratory of Silicon Materials, School of Materials Science and Engineering, Zhejiang University, Hangzhou, 310027 China

Search for more papers by this authorCorresponding Author

Prof. Yong Wang

State Key Laboratory of Silicon Materials, School of Materials Science and Engineering, Zhejiang University, Hangzhou, 310027 China

Search for more papers by this authorCorresponding Author

Prof. Yi Gao

Shanghai Advanced Research Institute, Chinese Academy of Sciences, 201210 Shanghai, China

Division of Interfacial Water and Key Laboratory of Interfacial Physics and Technology, Shanghai Institute of Applied Physics, Chinese Academy of Sciences, Shanghai, 201800 China

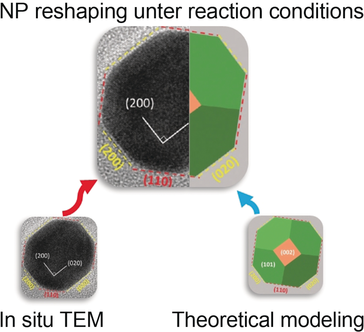

Search for more papers by this authorGraphical Abstract

Getting into shape: This Minireview gives a summary of the latest progress in characterizing and modeling the equilibrium shape of metal nanoparticles (NPs) in reactive environments through the combination of state-of-the-art in situ environmental transmission electron microscopy (ETEM) experiments and the multiscale structure reconstruction (MSR) model.

Abstract

The shape of metal nanoparticles (NPs) is one of the key factors determining their catalytic reactivity. Recent in situ TEM observations show that dynamic reshaping of metal NPs occurs under the reaction conditions, which becomes a major hurdle for fully understanding catalytic mechanisms at the molecular level. This Minireview provides a summary of the latest progress in characterizing and modeling the equilibrium shape of metal NPs in various reactive environments through the joint effort of state-of-the-art in situ environmental transmission electron microscopy experiments and a newly developed multiscale structure reconstruction model. The quantitative agreement between the experimental observations and theoretical modeling demonstrate that the fundamental mechanism of the reshaping phenomenon is driven by anisotropically changed surface energies under gas adsorption. The predictable reshaping of metal NPs paves the way for the rational design of truly efficient nanocatalysts in real reactions.

Conflict of interest

The authors declare no conflict of interest.

References

- 1A. R. Tao, S. Habas, P. Yang, Small 2008, 4, 310–325.

- 2Y. Xia, Y. Xiong, B. Lim, S. E. Skrabalak, Angew. Chem. Int. Ed. 2009, 48, 60–103; Angew. Chem. 2009, 121, 62–108.

- 3B. R. Cuenya, Thin Solid Films 2010, 518, 3127–3150.

- 4M. Chen, B. Wu, J. Yang, N. Zheng, Adv. Mater. 2012, 24, 862–879.

- 5Z. W. Seh, J. Kibsgaard, C. F. Dickens, I. Chorkendorff, J. K. Nørskov, T. F. Jaramillo, Science 2017, 355, eaad 4998.

- 6N. Kamiuchi, K. Sun, R. Aso, M. Tane, T. Tamaoka, H. Yoshida, S. Takeda, Nat. Commun. 2018, 9, 2060.

- 7Y. Kuwauchi, H. Yoshida, T. Akita, M. Haruta, S. Takeda, Angew. Chem. Int. Ed. 2012, 51, 7729–7733; Angew. Chem. 2012, 124, 7849–7853.

- 8T. Uchiyama, H. Yoshida, Y. Kuwauchi, S. Ichikawa, S. Shimada, M. Haruta, S. Takeda, Angew. Chem. Int. Ed. 2011, 50, 10157–10160; Angew. Chem. 2011, 123, 10339–10342.

- 9H. Yoshida, Y. Kuwauchi, J. R. Jinschek, K. Sun, S. Tanaka, M. Kohyama, S. Shimada, M. Haruta, S. Takeda, Science 2012, 335, 317–319.

- 10B. Eren, D. Zherebetskyy, L. L. Patera, C. H. Wu, H. Bluhm, C. Africh, L.-W. Wang, G. A. Somorjai, M. Salmeron, Science 2016, 351, 475–478.

- 11F. Tao, S. Dag, L.-W. Wang, Z. Liu, D. R. Butcher, M. Salmeron, G. A. Somorjai, Nano Lett. 2009, 9, 2167–2171.

- 12H. Yoshida, K. Matsuura, Y. Kuwauchi, H. Kohno, S. Shimada, M. Haruta, S. Takeda, Appl. Phys. Express 2011, 4, 065001.

- 13T. Avanesian, S. Dai, M. J. Kale, G. W. Graham, X. Pan, P. Christopher, J. Am. Chem. Soc. 2017, 139, 4551–4558.

- 14P. L. Hansen, J. B. Wagner, S. Helveg, J. R. Rostrup-Nielsen, B. S. Clausen, H. Topsøe, Science 2002, 295, 2053–2055.

- 15S. B. Vendelbo, et al., Nat. Mater. 2014, 13, 884–890.

- 16F. Tao, M. E. Grass, Y. Zhang, D. R. Butcher, J. R. Renzas, Z. Liu, J. Y. Chung, B. S. Mun, M. Salmeron, G. A. Somorjai, Science 2008, 322, 932–934.

- 17T. Wang, C. Lee, L. D. Schmidt, Surf. Sci. 1985, 163, 181–197.

- 18W. Albrecht, A. van de Glind, H. Yoshida, Y. Isozaki, A. Imhof, A. van Blaaderen, P. E. de Jongh, K. P. de Jong, J. Zečević, S. Takeda, Ultramicroscopy 2018, 193, 97–103.

- 19S. Takeda, Y. Kuwauchi, H. Yoshida, Ultramicroscopy 2015, 151, 178–190.

- 20S. Takeda, H. Yoshida, Microscopy 2013, 62, 193–203.

- 21M. L. Taheri, et al., Ultramicroscopy 2016, 170, 86–95.

- 22R. Schlögl, Angew. Chem. Int. Ed. 2015, 54, 3465–3520; Angew. Chem. 2015, 127, 3531–3589.

- 23K. Golibrzuch, N. Bartels, D. J. Auerbach, A. M. Wodtke, Annu. Rev. Phys. Chem. 2015, 66, 399–425.

- 24Z. W. Seh, J. Kibsgaard, C. F. Dickens, I. B. Chorkendorff, J. K. Nørskov, T. F. Jaramillo, Science 2017, 355, eaad 4998.

- 25S. Zafeiratos, S. Piccinin, D. Teschner, Catal. Sci. Technol. 2012, 2, 1787–1801.

- 26F. Tao, S. Dag, L.-W. Wang, Z. Liu, D. R. Butcher, H. Bluhm, M. Salmeron, G. A. Somorjai, Science 2010, 327, 850–853.

- 27M. A. Newton, C. Belver-Coldeira, A. Martinez-Arias, M. Fernandez-Garcia, Nat. Mater. 2007, 6, 528–532.

- 28P. Nolte, A. Stierle, N. Y. Jin-Phillipp, N. Kasper, T. U. Schulli, H. Dosch, Science 2008, 321, 1654–1658.

- 29M. Knoll, E. Ruska, Ann. Phys. 1932, 404, 607–640.

10.1002/andp.19324040506 Google Scholar

- 30L. Marton, Bull. Cl. Sci. Acad. R. Belg. 1935, 21, 553–564.

- 31E. Ruska, Kolloid-Z. 1942, 100, 212–219.

- 32P. R. Swann, N. J. Tighe, Jernkontorets Ann. 1971, 155, 497.

- 33R. T. K. Baker, P. S. Harris, J. Phys. E 1972, 5, 793.

- 34E. D. Boyes, P. L. Gai, Ultramicroscopy 1997, 67, 219–232.

- 35J. F. Creemer, S. Helveg, G. H. Hoveling, S. Ullmann, A. M. Molenbroek, P. M. Sarro, H. W. Zandbergen, Ultramicroscopy 2008, 108, 993–998.

- 36N. de Jonge, W. C. Bigelow, G. M. Veith, Nano Lett. 2010, 10, 1028–1031.

- 37J. C. Yang, M. W. Small, R. V. Grieshaber, R. G. Nuzzo, Chem. Soc. Rev. 2012, 41, 8179–8194.

- 38H. L. Xin, K. Niu, D. H. Alsem, H. Zheng, Microsc. Microanal. 2013, 19, 1558–1568.

- 39T. W. Hansen, J. B. Wagner, ACS Catal. 2014, 4, 1673–1685.

- 40T. Akita, M. Kohyama, M. Haruta, Acc. Chem. Res. 2013, 46, 1773–1782.

- 41J. R. Jinschek, Chem. Commun. 2014, 50, 2696–2706.

- 42Y. Jiang, Z. Zhang, W. Yuan, X. Zhang, Y. Wang, Z. Zhang, Nano Res. 2018, 11, 42–67.

- 43H. Yoshida, H. Omote, S. Takeda, Nanoscale 2014, 6, 13113–13118.

- 44S. Giorgio, S. Sao Joao, S. Nitsche, D. Chaudanson, G. Sitja, C. R. Henry, Ultramicroscopy 2006, 106, 503–507.

- 45S. Giorgio, M. Cabié, C. R. Henry, Gold Bull. 2008, 41, 167–173.

- 46M. Cabié, S. Giorgio, C. R. Henry, M. R. Axet, K. Philippot, B. Chaudret, J. Phys. Chem. C 2010, 114, 2160–2163.

- 47T. Uchiyama, H. Yoshida, Y. Kuwauchi, S. Ichikawa, S. Shimada, M. Haruta, S. Takeda, Angew. Chem. Int. Ed. 2011, 50, 10157–10160; Angew. Chem. 2011, 123, 10339–10342.

- 48F. Tao, M. Salmeron, Science 2011, 331, 171–174.

- 49F. Tao, P. A. Crozier, Chem. Rev. 2016, 116, 3487–3539.

- 50D. S. Su, B. Zhang, R. Schlogl, Chem. Rev. 2015, 115, 2818–2882.

- 51J. Meng, B. Zhu, Y. Gao, J. Phys. Chem. C 2018, 122, 6144–6150.

- 52M. Duan, J. Yu, J. Meng, B. Zhu, Y. Wang, Y. Gao, Angew. Chem. Int. Ed. 2018, 57, 6464–6469; Angew. Chem. 2018, 130, 6574–6579.

- 53B. Zhu, J. Meng, Y. Gao, J. Phys. Chem. C 2017, 121, 5629–5634.

- 54B. Zhu, Z. Xu, C. Wang, Y. Gao, Nano Lett. 2016, 16, 2628–2632.

- 55G. Wulff, Z. Kristallogr. Mineral 1901, 34, 449.

- 56I. Langmuir, J. Am. Chem. Soc. 1918, 40, 1361–1403.

- 57R. H. Fowler, E. A. Guggenheim, Statistical Thermodynamics, Cambridge University Press, Cambridge, 1939, pp. 431–450.

- 58C. R. Henry, Prog. Surf. Sci. 2005, 80, 92–116.

- 59X. Zhang, J. Meng, B. Zhu, J. Yu, S. Zou, Z. Zhang, Y. Gao, Y. Wang, Chem. Commun. 2017, 53, 13213–13216.

- 60X. Zhang, J. Meng, B. Zhu, W. Yuan, H. Yang, Z. Zhang, Y. Gao, Y. Wang, Chem. Commun. 2018, 54, 8587–8590.

- 61A. Chmielewski, J. Meng, B. Zhu, Y. Gao, H. Guesmi, H. Prunier, D. Alloyeau, G. Wang, C. Louis, L. Delannoy, P. Afanasiev, C. Ricolleau, J. Nelayah, ACS Nano 2019, 13, 2024–2033.

- 62Y. Jiang, H. Li, Z. Wu, W. Ye, H. Zhang, Y. Wang, C. Sun, Z. Zhang, Angew. Chem. Int. Ed. 2016, 55, 12427–12430; Angew. Chem. 2016, 128, 12615–12618.