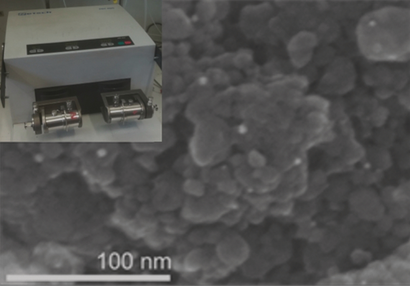

Milling Down to Nanometers: A General Process for the Direct Dry Synthesis of Supported Metal Catalysts

Graphical Abstract

Abstract

Supported catalysts are among the most important classes of catalysts. They are typically prepared by wet-chemical methods, such as impregnation or co-precipitation. Here we disclose that dry ball milling of macroscopic metal powder in the presence of a support oxide leads in many cases to supported catalysts with particles in the nanometer size range. Various supports, including TiO2, Al2O3, Fe2O3, and Co3O4, and different metals, such as Au, Pt, Ag, Cu, and Ni, were studied, and for each of the supports and the metals, highly dispersed nanoparticles on supports could be prepared. The supported catalysts were tested in CO oxidation, where they showed activities in the same range as conventionally prepared catalysts. The method thus provides a simple and cost-effective alternative to the conventionally used impregnation methods.