Atomically Dispersed Molybdenum Catalysts for Efficient Ambient Nitrogen Fixation

Dr. Lili Han

Center for Electron Microscopy and Tianjin Key Lab of Advanced Functional Porous Materials, Institute for New Energy Materials & Low-Carbon Technologies, School of Materials Science and Engineering, Tianjin University of Technology, Tianjin, 300384 China

Center for Functional Nanomaterials, Brookhaven National Laboratory, Upton, NY, 11973 USA

These authors contributed equally to this work.

Search for more papers by this authorDr. Xijun Liu

Center for Electron Microscopy and Tianjin Key Lab of Advanced Functional Porous Materials, Institute for New Energy Materials & Low-Carbon Technologies, School of Materials Science and Engineering, Tianjin University of Technology, Tianjin, 300384 China

These authors contributed equally to this work.

Search for more papers by this authorJinping Chen

Center for Electron Microscopy and Tianjin Key Lab of Advanced Functional Porous Materials, Institute for New Energy Materials & Low-Carbon Technologies, School of Materials Science and Engineering, Tianjin University of Technology, Tianjin, 300384 China

These authors contributed equally to this work.

Search for more papers by this authorDr. Ruoqian Lin

Center for Functional Nanomaterials, Brookhaven National Laboratory, Upton, NY, 11973 USA

Search for more papers by this authorHaoxuan Liu

Center for Electron Microscopy and Tianjin Key Lab of Advanced Functional Porous Materials, Institute for New Energy Materials & Low-Carbon Technologies, School of Materials Science and Engineering, Tianjin University of Technology, Tianjin, 300384 China

Search for more papers by this authorFang Lü

Center for Electron Microscopy and Tianjin Key Lab of Advanced Functional Porous Materials, Institute for New Energy Materials & Low-Carbon Technologies, School of Materials Science and Engineering, Tianjin University of Technology, Tianjin, 300384 China

Search for more papers by this authorDr. Seongmin Bak

Chemistry Division, Brookhaven National Laboratory, Upton, NY, 11973 USA

Search for more papers by this authorZhixiu Liang

Chemistry Division, Brookhaven National Laboratory, Upton, NY, 11973 USA

Search for more papers by this authorDr. Shunzheng Zhao

Department of Environmental Engineering, University of Science and Technology Beijing, Beijing, 100083 China

Search for more papers by this authorDr. Eli Stavitski

National Synchrotron Light Source II, Brookhaven National Laboratory, Upton, NY, 11973 USA

Search for more papers by this authorCorresponding Author

Prof. Jun Luo

Center for Electron Microscopy and Tianjin Key Lab of Advanced Functional Porous Materials, Institute for New Energy Materials & Low-Carbon Technologies, School of Materials Science and Engineering, Tianjin University of Technology, Tianjin, 300384 China

Search for more papers by this authorCorresponding Author

Prof. Radoslav R. Adzic

Chemistry Division, Brookhaven National Laboratory, Upton, NY, 11973 USA

Search for more papers by this authorCorresponding Author

Prof. Huolin L. Xin

Department of Physics and Astronomy, University of California, Irvine, CA, 92697 USA

Search for more papers by this authorDr. Lili Han

Center for Electron Microscopy and Tianjin Key Lab of Advanced Functional Porous Materials, Institute for New Energy Materials & Low-Carbon Technologies, School of Materials Science and Engineering, Tianjin University of Technology, Tianjin, 300384 China

Center for Functional Nanomaterials, Brookhaven National Laboratory, Upton, NY, 11973 USA

These authors contributed equally to this work.

Search for more papers by this authorDr. Xijun Liu

Center for Electron Microscopy and Tianjin Key Lab of Advanced Functional Porous Materials, Institute for New Energy Materials & Low-Carbon Technologies, School of Materials Science and Engineering, Tianjin University of Technology, Tianjin, 300384 China

These authors contributed equally to this work.

Search for more papers by this authorJinping Chen

Center for Electron Microscopy and Tianjin Key Lab of Advanced Functional Porous Materials, Institute for New Energy Materials & Low-Carbon Technologies, School of Materials Science and Engineering, Tianjin University of Technology, Tianjin, 300384 China

These authors contributed equally to this work.

Search for more papers by this authorDr. Ruoqian Lin

Center for Functional Nanomaterials, Brookhaven National Laboratory, Upton, NY, 11973 USA

Search for more papers by this authorHaoxuan Liu

Center for Electron Microscopy and Tianjin Key Lab of Advanced Functional Porous Materials, Institute for New Energy Materials & Low-Carbon Technologies, School of Materials Science and Engineering, Tianjin University of Technology, Tianjin, 300384 China

Search for more papers by this authorFang Lü

Center for Electron Microscopy and Tianjin Key Lab of Advanced Functional Porous Materials, Institute for New Energy Materials & Low-Carbon Technologies, School of Materials Science and Engineering, Tianjin University of Technology, Tianjin, 300384 China

Search for more papers by this authorDr. Seongmin Bak

Chemistry Division, Brookhaven National Laboratory, Upton, NY, 11973 USA

Search for more papers by this authorZhixiu Liang

Chemistry Division, Brookhaven National Laboratory, Upton, NY, 11973 USA

Search for more papers by this authorDr. Shunzheng Zhao

Department of Environmental Engineering, University of Science and Technology Beijing, Beijing, 100083 China

Search for more papers by this authorDr. Eli Stavitski

National Synchrotron Light Source II, Brookhaven National Laboratory, Upton, NY, 11973 USA

Search for more papers by this authorCorresponding Author

Prof. Jun Luo

Center for Electron Microscopy and Tianjin Key Lab of Advanced Functional Porous Materials, Institute for New Energy Materials & Low-Carbon Technologies, School of Materials Science and Engineering, Tianjin University of Technology, Tianjin, 300384 China

Search for more papers by this authorCorresponding Author

Prof. Radoslav R. Adzic

Chemistry Division, Brookhaven National Laboratory, Upton, NY, 11973 USA

Search for more papers by this authorCorresponding Author

Prof. Huolin L. Xin

Department of Physics and Astronomy, University of California, Irvine, CA, 92697 USA

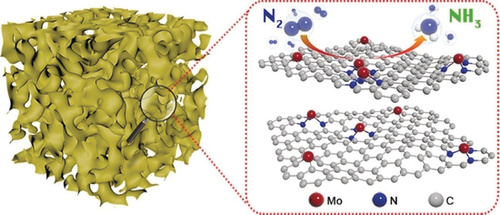

Search for more papers by this authorGraphical Abstract

Single molybdenum atoms anchored on nitrogen-doped porous carbon were designed and synthesized for the electrocatalytic reduction of N2 to NH3. The catalyst exhibited high electrocatalytic activity and stability, which is attributed to its structure, conductive carbon support, high porosity, and well-dispersed single molybdenum atoms.

Abstract

NH3 synthesis by the electrocatalytic N2 reduction reaction (NRR) under ambient conditions is an appealing alternative to the currently employed industrial method—the Haber–Bosch process—that requires high temperature and pressure. We report single Mo atoms anchored to nitrogen-doped porous carbon as a cost-effective catalyst for the NRR. Benefiting from the optimally high density of active sites and hierarchically porous carbon frameworks, this catalyst achieves a high NH3 yield rate (34.0±3.6 μg h−1 mgcat.−1) and a high Faradaic efficiency (14.6±1.6 %) in 0.1 m KOH at room temperature. These values are considerably higher compared to previously reported non-precious-metal electrocatalysts. Moreover, this catalyst displays no obvious current drop during a 50 000 s NRR, and high activity and durability are achieved in 0.1 m HCl. The findings provide a promising lead for the design of efficient and robust single-atom non-precious-metal catalysts for the electrocatalytic NRR.

h−1 mgcat.−1) and a high Faradaic efficiency (14.6±1.6 %) in 0.1 m KOH at room temperature. These values are considerably higher compared to previously reported non-precious-metal electrocatalysts. Moreover, this catalyst displays no obvious current drop during a 50 000 s NRR, and high activity and durability are achieved in 0.1 m HCl. The findings provide a promising lead for the design of efficient and robust single-atom non-precious-metal catalysts for the electrocatalytic NRR.

Supporting Information

As a service to our authors and readers, this journal provides supporting information supplied by the authors. Such materials are peer reviewed and may be re-organized for online delivery, but are not copy-edited or typeset. Technical support issues arising from supporting information (other than missing files) should be addressed to the authors.

| Filename | Description |

|---|---|

| anie201811728-sup-0001-misc_information.pdf2.1 MB | Supplementary |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1R. F. Service, Science 2014, 345, 610–610.

- 2J. Li, H. Li, G. Zhan, L. Zhang, Acc. Chem. Res. 2017, 50, 112–121.

- 3D. Zhu, L. Zhang, R. E. Ruther, R. J. Hamers, Nat. Mater. 2013, 12, 836–841.

- 4J. G. Chen, R. M. Crooks, L. C. Seefeldt, K. L. Bren, R. M. Bullock, M. Y. Darensbourg, P. L. Holland, B. Hoffman, M. J. Janik, A. K. Jones, M. G. Kanatzidis, P. King, K. M. Lancaster, S. V. Lymar, P. Pfromm, W. F. Schneider, R. R. Schrock, Science 2018, 360, eaar 6611.

- 5P. J. Chirik, Nat. Chem. 2009, 1, 520–522.

- 6C. J. M. van der Ham, M. T. M. Koper, D. G. H. Hetterscheid, Chem. Soc. Rev. 2014, 43, 5183–5191.

- 7N. Cao, G. Zheng, Nano Res. 2018, 11, 2992–3008.

- 8Y. Yao, S. Zhu, H. Wang, H. Li, M. Shao, J. Am. Chem. Soc. 2018, 140, 1496–1501.

- 9B. Di, Z. Qi, M. Fan-Lu, Z. Hai-Xia, S. Miao-Miao, Z. Yu, Y. Jun-Min, J. Qing, Z. Xin-Bo, Adv. Mater. 2017, 29, 1604799.

- 10S. Mukherjee, D. A. Cullen, S. Karakalos, K. Liu, H. Zhang, S. Zhao, H. Xu, K. L. More, G. Wang, G. Wu, Nano Energy 2018, 48, 217–226.

- 11R. Manjunatha, A. Schechter, Electrochem. Commun. 2018, 90, 96–100.

- 12Z. Wang, F. Gong, L. Zhang, R. Wang, L. Ji, Q. Liu, Y. Luo, H. Guo, Y. Li, P. Gao, X. Shi, B. Li, B. Tang, X. Sun, Adv. Sci. 2018, 1801182.

- 13H. K. Lee, C. S. L. Koh, Y. H. Lee, C. Liu, I. Y. Phang, X. Han, C. K. Tsung, X. Y. Ling, Sci. Adv. 2018, 4, eaar 3208.

- 14M. Nazemi, S. R. Panikkanvalappil, M. A. El-Sayed, Nano Energy 2018, 49, 316–323.

- 15Z. Geng, Y. Liu, X. Kong, P. Li, K. Li, Z. Liu, J. Du, M. Shu, R. Si, J. Zeng, Adv. Mater. 2018, 30, 1803498.

- 16H. Tao, C. Choi, L.-X. Ding, Z. Jiang, Z. Han, M. Jia, Q. Fan, Y. Gao, H. Wang, A. W. Robertson, S. Hong, Y. Jung, S. Liu, Z. Sun, Chem 2019, 5, 204–214.

- 17H.-M. Liu, S.-H. Han, Y. Zhao, Y.-Y. Zhu, X.-L. Tian, J.-H. Zeng, J.-X. Jiang, B. Y. Xia, Y. Chen, J. Mater. Chem. A 2018, 6, 3211–3217.

- 18S. Chen, S. Perathoner, C. Ampelli, C. Mebrahtu, D. Su, G. Centi, Angew. Chem. Int. Ed. 2017, 56, 2699–2703; Angew. Chem. 2017, 129, 2743–2747.

- 19H. Cheng, L.-X. Ding, G.-F. Chen, L. Zhang, J. Xue, H. Wang, Adv. Mater. 2018, 30, 1803694.

- 20C. Lv, C. Yan, G. Chen, Y. Ding, J. Sun, Y. Zhou, G. Yu, Angew. Chem. Int. Ed. 2018, 57, 6073–6076; Angew. Chem. 2018, 130, 6181–6184.

- 21X. Li, T. Li, Y. Ma, Q. Wei, W. Qiu, H. Guo, X. Shi, P. Zhang, A. M. Asiri, L. Chen, B. Tang, X. Sun, Adv. Energy Mater. 2018, 8, 1801357.

- 22Y. Luo, G.-F. Chen, L. Ding, X. Chen, L.-X. Ding, H. Wang, Joule 2018, https://doi.org/10.1016/j.joule.2018.09.011.

- 23W. Qiu, X.-Y. Xie, J. Qiu, W.-H. Fang, R. Liang, X. Ren, X. Ji, G. Cui, A. M. Asiri, G. Cui, B. Tang, X. Sun, Nat. Commun. 2018, 9, 3485.

- 24Y. Liu, Y. Su, X. Quan, X. Fan, S. Chen, H. Yu, H. Zhao, Y. Zhang, J. Zhao, ACS Catal. 2018, 8, 1186–1191.

- 25X. Yu, P. Hjuan, Z. Wei, L. Huang, Z. Gu, S. Peng, J. Ma, G. Zheng, Joule 2018, 2, 1610–1622.

- 26G.-F. Chen, X. Cao, S. Wu, X. Zeng, L.-X. Ding, M. Zhu, H. Wang, J. Am. Chem. Soc. 2017, 139, 9771–9774.

- 27H. Zhang, G. Liu, L. Shi, J. Ye, Adv. Energy Mater. 2018, 8, 1701343.

- 28L. Zhang, L. Han, H. Liu, X. Liu, J. Luo, Angew. Chem. Int. Ed. 2017, 56, 13694–13698; Angew. Chem. 2017, 129, 13882–13886.

- 29A. Wang, J. Li, T. Zhang, Nat. Rev. Chem. 2018, 2, 65–81.

- 30W. Chen, J. Pei, C.-T. He, J. Wan, H. Ren, Y. Zhu, Y. Wang, J. Dong, S. Tian, W.-C. Cheong, S. Lu, L. Zheng, X. Zheng, W. Yan, Z. Zhuang, C. Chen, Q. Peng, D. Wang, Y. Li, Angew. Chem. Int. Ed. 2017, 56, 16086–16090; Angew. Chem. 2017, 129, 16302–16306.

- 31M. B. Vukmirovic, K. M. Teeluck, P. Liu, R. R. Adzic, Croat. Chem. Acta 2017, 90, 225–230.

- 32D. V. Yandulov, R. R. Schrock, Science 2003, 301, 76–78.

- 33J. Zhao, Z. Chen, J. Am. Chem. Soc. 2017, 139, 12480–12487.

- 34J.-S. Li, Y. Wang, C.-H. Liu, S.-L. Li, Y.-G. Wang, L.-Z. Dong, Z.-H. Dai, Y.-F. Li, Y.-Q. Lan, Nat. Commun. 2016, 7, 11204.

- 35H. Wei, Q. Xi, X. Chen, D. Guo, F. Ding, Z. Yang, S. Wang, J. Li, S. Huang, Adv. Sci. 2018, 5, 1700733.

- 36L. Ji, D. Xin, G. Christopher, D. X. Wen, Q. S. Zhang, Adv. Mater. 2013, 25, 6226–6231.

- 37Y.-Y. Chen, Y. Zhang, W.-J. Jiang, X. Zhang, Z. Dai, L.-J. Wan, J.-S. Hu, ACS Nano 2016, 10, 8851–8860.

- 38Y. Lum, Y. Kwon, P. Lobaccaro, L. Chen, E. L. Clark, A. T. Bell, J. W. Ager, ACS Catal. 2016, 6, 202–209.

- 39M. Nazemi, M. A. El-Sayed, J. Phys. Chem. Lett. 2018, 9, 5160–5166.

- 40L. F. Greenlee, J. N. Renner, S. L. Foster, ACS Catal. 2018, 8, 7820–7827.

- 41L.-J. Huang, W.-L. Xue, Z.-X. Zeng, Fluid Phase Equilib. 2011, 303, 80–84.

- 42F. Zhou, L. M. Azofra, M. Ali, M. Kar, A. N. Simonov, C. McDonnell-Worth, C. Sun, X. Zhang, D. R. MacFarlane, Energy Environ. Sci. 2017, 10, 2516–2520.

- 43N. Zhang, A. Jalil, D. Wu, S. Chen, Y. Liu, C. Gao, W. Ye, Z. Qi, H. Ju, C. Wang, X. Wu, L. Song, J. Zhu, Y. Xiong, J. Am. Chem. Soc. 2018, 140, 9434–9443.

- 44T. Murakami, T. Nishikiori, T. Nohira, Y. Ito, J. Am. Chem. Soc. 2003, 125, 334–335.

- 45J. Yang, Y. Guo, R. Jiang, F. Qin, H. Zhang, W. Lu, J. Wang, J.-C. Yu, J. Am. Chem. Soc. 2018, 140, 8497–8508.