Efficient Nanostructuring of Silicon by Electrochemical Alloying/Dealloying in Molten Salts for Improved Lithium Storage

Yating Yuan

Department Hubei Key Laboratory of Electrochemical Power Sources, College of Chemistry and Molecular Sciences, Wuhan University, Wuhan, 430072 P. R. China

Search for more papers by this authorDr. Wei Xiao

Department Hubei Key Laboratory of Electrochemical Power Sources, College of Chemistry and Molecular Sciences, Wuhan University, Wuhan, 430072 P. R. China

Search for more papers by this authorDr. Zhiyong Wang

Department Hubei Key Laboratory of Electrochemical Power Sources, College of Chemistry and Molecular Sciences, Wuhan University, Wuhan, 430072 P. R. China

Search for more papers by this authorProf. Derek J. Fray

Department of Material Sciences and Metallurgy, University of Cambridge, Cambridge, CB3 0FS UK

Search for more papers by this authorCorresponding Author

Prof. Xianbo Jin

Department Hubei Key Laboratory of Electrochemical Power Sources, College of Chemistry and Molecular Sciences, Wuhan University, Wuhan, 430072 P. R. China

Department of Material Sciences and Metallurgy, University of Cambridge, Cambridge, CB3 0FS UK

Search for more papers by this authorYating Yuan

Department Hubei Key Laboratory of Electrochemical Power Sources, College of Chemistry and Molecular Sciences, Wuhan University, Wuhan, 430072 P. R. China

Search for more papers by this authorDr. Wei Xiao

Department Hubei Key Laboratory of Electrochemical Power Sources, College of Chemistry and Molecular Sciences, Wuhan University, Wuhan, 430072 P. R. China

Search for more papers by this authorDr. Zhiyong Wang

Department Hubei Key Laboratory of Electrochemical Power Sources, College of Chemistry and Molecular Sciences, Wuhan University, Wuhan, 430072 P. R. China

Search for more papers by this authorProf. Derek J. Fray

Department of Material Sciences and Metallurgy, University of Cambridge, Cambridge, CB3 0FS UK

Search for more papers by this authorCorresponding Author

Prof. Xianbo Jin

Department Hubei Key Laboratory of Electrochemical Power Sources, College of Chemistry and Molecular Sciences, Wuhan University, Wuhan, 430072 P. R. China

Department of Material Sciences and Metallurgy, University of Cambridge, Cambridge, CB3 0FS UK

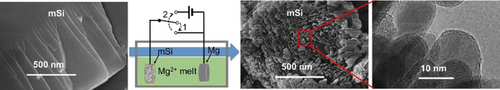

Search for more papers by this authorGraphical Abstract

Bulk silicon can be nanostructured in a comparatively low-energy and environmentally benign approach of electrochemical Mg alloying/dealloying in molten salts at moderate temperatures. For lithium storage, the nanostructured Si exhibits a combination of high initial Coulombic efficiency, high specific capacity, and long cycling stability.

Abstract

Application of nanostructured silicon (nSi) is significantly retarded by challenges in the production of affordable nSi. We herein report a high-yield (ca. 100 %) and low-energy (2 kWh Kg-nSi−1) nanostructuring of industrial microsized silicon (mSi) through a closed-loop electrochemical Mg alloying/dealloying in molten MgCl2/NaCl/KCl at 773 K. The resulting nSi unexpectedly shows a salt-unwetted character, allowing an automatic separation from the melts. Thus water washing and accompanying oxidation of the nSi can be avoided. The final product has a nanoporous structure and comprises Si nanorods (ca. 30 nm in diameter) with an ultrathin oxide coating. It can be used for Li storage giving a combination of high initial coulombic efficiency, high specific capacity, and long cycling stability. This nanostructuring process consumes very few chemicals except for the mSi and produces almost zero waste.

Supporting Information

As a service to our authors and readers, this journal provides supporting information supplied by the authors. Such materials are peer reviewed and may be re-organized for online delivery, but are not copy-edited or typeset. Technical support issues arising from supporting information (other than missing files) should be addressed to the authors.

| Filename | Description |

|---|---|

| anie201809646-sup-0001-misc_information.pdf705.4 KB | Supplementary |

Please note: The publisher is not responsible for the content or functionality of any supporting information supplied by the authors. Any queries (other than missing content) should be directed to the corresponding author for the article.

References

- 1

- 1aZ. Bao, M. R. Weatherspoon, S. Shian, Y. Cai, P. D. Graham, S. M. Allan, G. Ahmad, M. B. Dickerson, B. C. Church, Z. Kang, H. W. Abernathy III, C. J. Summers, M. Liu, K. H. Sandhage, Nature 2007, 446, 172–175;

- 1bA. I. Boukai, Y. Bunimovich, J. Tahir-Kheli, J.-K. Yu, W. A. Goddard III, J. R. Heath, Nature 2008, 451, 168;

- 1cF. Priolo, T. Gregorkiewicz, M. Galli, T. F. Krauss, Nat. Nanotechnol. 2014, 9, 19–32;

- 1dX. Liu, P. R. Coxon, M. Peters, B. Hoex, J. M. Cole, D. J. Fray, Energy Environ. Sci. 2014, 7, 3223–3263;

- 1eU. Kasavajjula, C. Wang, A. J. Appleby, J. Power Sources 2007, 163, 1003–1039.

- 2

- 2aJ. M. Ko, S. Chae, J. Ma, N. Kim, H.-W. Lee, Y. Cui, J. Cho, Nat. Energy 2016, 1, 16113;

- 2bH. T. Nguyen, F. Yao, M. R. Zamfir, C. Biswas, K. P. So, Y. H. Lee, S. M. Kim, S. N. Cha, J. M. Kim, D. Pribat, Adv. Energy Mater. 2011, 1, 1154–1161.

- 3

- 3aN. Lin, Y. Han, J. Zhou, K. Zhang, T. Xu, Y. Zhu, Y. Qian, Energy Environ. Sci. 2015, 8, 3187–3191;

- 3bG. Song, J. Ryu, J. C. Kim, J. H. Lee, S. Kim, C. Wang, S. K. Kwak, S. Park, Nat. Commun. Chem. 2018, 1, 42.

- 4

- 4aF. Dai, J. Zai, R. Yi, M. L. Gordin, H. Sohn, S. Chen, D. Wang, Nat. Commun. 2014, 5, 3605;

- 4bD. S. Jung, M. H. Ryou, Y. J. Sung, S. B. Park, J. W. Choi, Proc. Natl. Acad. Sci. USA 2013, 110, 12229–12234;

- 4cZ. Favors, W. Wang, H. H. Bay, Z. Mutlu, K. Ahmed, C. Liu, M. Ozkan, C. S. Ozkan, Sci. Rep. 2014, 4, 5623;

- 4dJ. Ryu, D. Hong, S. Choi, S. Park, ACS Nano 2016, 10, 2843–2851.

- 5

- 5aV. Lehmann, H. Föll, J. Electrochem. Soc. 1990, 137, 653–659;

- 5bX. Li, M. Gu, S. Hu, R. Kennard, P. Yan, X. Chen, C. Wang, M. J. Sailor, J.-G. Zhang, J. Liu, Nat. Commun. 2014, 5, 4105;

- 5cX. Li, P. W. Bohn, Appl. Phys. Lett. 2000, 77, 2572–2574;

- 5dB. M. Bang, H. Kim, S. Park, J. Electrochem. Sci. Technol. 2011, 2, 157–162.

- 6J. Liang, X. Li, Z. Hou, C. Guo, Y. Zhu, Y. Qian, Chem. Commun. 2015, 51, 7230–7233.

- 7T. Wada, T. Ichitsubo, K. Yubuta, H. Segawa, H. Yoshida, H. Kato, Nano. Lett. 2014, 14, 4505–4510.

- 8

- 8aJ. Liang, X. N. Li, Z. G. Hou, W. Q. Zhang, Y. C. Zhu, Y. T. Qian, ACS Nano 2016, 10, 2295–2304;

- 8bZ. Huang, N. Geyer, P. Werner, J. de Boor, U. Gosele, Adv. Mater. 2011, 23, 285–308;

- 8cL. Lin, X. Xu, C. Chu, M. K. Majeed, J. Yang, Angew. Chem. Int. Ed. 2016, 55, 14063–14066; Angew. Chem. 2016, 128, 14269–14272.

- 9D. J. Bradwell, H. Kim, A. H. C. Sirk, D. R. Sadoway, J. Am. Chem. Soc. 2012, 134, 1895–1897.

- 10

- 10aY. Dong, T. Slade, M. J. Stolt, L. Li, S. N. Girard, L. Mai, S. Jin, Angew. Chem. Int. Ed. 2017, 56, 14453–14457; Angew. Chem. 2017, 129, 14645–14649;

- 10bX. Yang, L. Ji, X. Zou, T. Lim, J. Zhao, T. Yu Edward, A. J. Bard, Angew. Chem. Int. Ed. 2017, 56, 15078–15082; Angew. Chem. 2017, 129, 15274–15278;

- 10cJ. Peng, H. Yin, J. Zhao, X. Yang, A. J. Bard, D. R. Sadoway, Adv. Funct. Mater. 2018, 28, 1703551.

- 11

- 11aT. Nohira, K. Yasuda, Y. Ito, Nat. Mater. 2003, 2, 397;

- 11bX. Jin, P. Gao, D. Wang, X. Hu, G. Z. Chen, Angew. Chem. Int. Ed. 2004, 43, 733–736; Angew. Chem. 2004, 116, 751–754;

- 11cJ. Yang, S. Lu, S. Kan, X. Zhang, J. Du, Chem. Commun. 2009, 3273–3275;

- 11dE. Juzeliunas, A. Cox, D. J. Fray, Electrochem. Commun. 2010, 12, 1270–1274;

- 11eJ. Zhao, J. Li, P. Ying, W. Zhang, L. Meng, C. Li, Chem. Commun. 2013, 49, 4477–4479.

- 12

- 12aV. Zorba, L. Persano, D. Pisignano, A. Athanassiou, E. Stratakis, R. Cingolani, P. Tzanetakis, C. Fotakis, Nanotechnology 2006, 17, 3234;

- 12bM. K. Dawood, H. Zheng, T. H. Liew, K. C. Leong, Y. L. Foo, R. Rajagopalan, S. A. Khan, W. K. Choi, Langmuir 2011, 27, 4126–4133.

- 13

- 13aJ. Zhu, C. Gladden, N. Liu, Y. Cui, X. Zhang, Phys. Chem. Chem. Phys. 2013, 15, 440–443;

- 13bS. H. Nguyen, J. C. Lim, J. K. Lee, Electrochim. Acta 2012, 74, 53–58;

- 13cZ. Jiang, C. Li, S. Hao, K. Zhu, P. Zhang, Electrochim. Acta 2014, 115, 393–398;

- 13dX. Li, C. Yan, J. Wang, A. Graff, S. L. Schweizer, A. Sprafke, O. G. Schmidt, R. B. Wehrspohn, Adv. Energy Mater. 2015, 5, 1401556;

- 13eY. Chen, L. Liu, J. Xiong, T. Yang, Y. Qin, C. Yan, Adv. Funct. Mater. 2015, 25, 6701–6709.

- 14

- 14aZ. Lu, J. Zhu, D. Sim, W. Zhou, W. Shi, H. H. Hng, Q. Yan, Chem. Mater. 2011, 23, 5293–5295;

- 14bQ. Xiao, M. Gu, H. Yang, B. Li, C. Zhang, Y. Liu, F. Liu, F. Dai, L. Yang, Z. Liu, X. Xiao, G. Liu, P. Zhao, S. Zhang, C. Wang, Y. Lu, M. Cai, Nat. Commun. 2015, 6, 8844;

- 14cW. Wang, Z. Favors, R. Ionescu, R. Ye, H. H. Bay, M. Ozkan, C. S. Ozkan, Sci. Rep. 2015, 5, 8781;

- 14dY. Yu, L. Gu, C. Zhu, S. Tsukimoto, P. A. van Aken, J. Maier, Adv. Mater. 2010, 22, 2247–2250.

- 15

- 15aW. Xiao, X. Jin, Y. Deng, D. Wang, X. Hu, G. Z. Chen, ChemPhysChem 2006, 7, 1750–1758;

- 15bW. Xiao, J. Zhou, L. Yu, D. Wang, X. W. Lou, Angew. Chem. Int. Ed. 2016, 55, 7427–7431; Angew. Chem. 2016, 128, 7553–7557.

- 16S. Jiao, D. J. Fray, Metall. Mater. Trans. B 2010, 41, 74–79.

- 17Y. An, H. Fei, G. Zeng, L. Ci, S. Xiong, J. Feng, Y. Qian, ACS Nano 2018, 12, 4993–5002.

- 18

- 18aG. Z. Chen, D. J. Fray, T. W. Farthing, Nature 2000, 407, 361;

- 18bF. Tailoka, D. J. Fray, Trans. Inst. Min. Metall. Sect. C 1995, 104, C 51–C58.

Citing Literature

November 26, 2018

Pages 15743-15748