Application of the Active Edible Film Reinforced With Nanoparticles and Nanoemulsions as the Coating Systems to Improve the Quality and Shelf Life of Fruits and Vegetables

Abstract

The increasing consumer interest in maintaining a nutritious diet has prompted scholarly investigation into innovative methodologies for the preservation of fruits and vegetables, aiming for minimal processing and the omission of preservatives. Emulsion-based food coating technology emerges as a significant and promising alternative for safeguarding the quality of freshly cut vegetables and fruits. This review endeavors to elucidate some of the contemporary advancements in ensuring the safety and quality of fresh cut fruits and vegetables through the utilization of emulsions as edible coatings that serve as carriers for functional constituents, including antimicrobial and antioxidant agents. Notably, there is a pronounced emphasis on the identification and application of natural functional compounds in food preservation as a substitute for synthetic additives. Essential oils (EOs)–characterized nanoemulsions (NEs) possess antimicrobial and antioxidant attributes, which are recognized as pivotal indicators within the realm of food studies. The concept underlying active edible films (AEFs) fundamentally revolves around the preservation of food while providing a robust protective barrier. Serving as a natural substitute for synthetic preservatives, edible oils exhibit environmentally sustainable and cost-effective properties, aimed at fostering sustainable food safety, security, packaging, and storage. Edible EOs demonstrate the capacity to supplant artificial antimicrobials and possess characteristics that contribute to the reduction of environmental pollution. The antimicrobial efficacy of AEF integrated with nanoparticles such as TiO2, silver (Ag nanoparticle), and zinc oxide (ZnO nanoparticles), as developed by various researchers, has been scrutinized. Researchers have documented the antimicrobial activity of AEF containing nanoparticles against the microorganisms subjected to testing. Furthermore, the attributes encompassing gas modification, induced defense mechanisms, and ion release from AEF with nanoparticles have also been examined. Conversely, findings from supplementary research suggest that the applications of AEF incorporating diverse nanoparticles may offer a viable and effective strategy to mitigate quality degradation in postharvest fruits and vegetables.

1. Introduction

Today, the demand for healthy products such as fresh vegetables and fruits is growing rapidly worldwide. In general, consumers have understood the optimal features of these categories of food products, including their freshness, nutritional importance, and original taste with a similar appearance and have become oriented toward it. In this regard, vegetables and fruits should be kept at a relatively lower temperature immediately after processing to prolong their useful life [1]. When food components such as polysaccharides or proteins are absorbed individually or in combination with other food components at a standard level and are applied through specific mechanisms to form a suitable coating on fruits or vegetables, edible coating is formed. Edible coatings have significant functional and medicinal properties that are vital for enhancing and/or maintaining the quality of the coated food products [2, 3]. If they are prepared as a thin sheet, an edible film is formed, but if they are prepared as a viscous liquid solution and the fruits are dipped or sprinkled with it, it is called a coating. Fruits and vegetables and may be coated by various methods such as dipping, brushing, and spraying. Edible coatings have certain disadvantages such as partial protection or breakage, while coatings through an edible solution can fully protect food [4].

These coatings and edible films have achieved extraordinary results and thus have become an attractive and new area for further research and study. These coatings and films have unique functions such as preventing moisture, oxygen, and loss of ingredients and help to maintain and improve the physical, quality, and sensory properties of food. The type of edible coating can be selected based on the food and the purpose, which has special usage and basic advantages to prevent quality reduction. According to the studies, in the future, the use of artificial packaging with edible coatings may be replaced because it can introduce the best material to prevent quality loss and the necessary requirements to prevent deterioration, maintain quality, effective storage, and shelf life, as well as provide compatibility characteristics such as environment friendly and cost-effective [5].

As soon as the fresh fruit is cut, it is very sensitive to the activity of enzymes and spoilage because this cut damages the internal tissues of the fruit and makes oxygen available to the enzymes [5, 6] and the activity of pathogens is enhanced. In general, enzymes can be stabilized by thermal processing as well as by incorporating special protective materials and many different packaging types to control the process of spoilage and tissue degradation. When heat processing is omitted directly in the treatment of fresh cut fruits, it may cause a decrease in the nutritional characteristics of fresh fruits. Therefore, the increasing demand for less manipulated or less processed food products has brought researchers closer to different measures to achieve this goal to ultimately ensure the safety and quality of food products [7].

In the past few decades, the food industry has encountered significant challenges related to the decline in both the quality and quantity of food, particularly concerning perishable items, during the intervals between harvesting and consumption within the supply chain [8, 9]. These losses are predominantly attributable to food degradation resulting from microbial contamination, the oxidation of molecules, and the deterioration of sensory attributes [10, 11]. Such detriments compromise the safety of food products, pose threats to human health, and adversely influence consumer acceptance [11]. In light of the requirements of both consumers and industry stakeholders, edible coatings have been proposed as a viable alternative to conventional plastic packaging and the synthetic preservatives typically utilized to extend the shelf life of various food items [12].

Edible coatings consist of thin layers that are applied directly onto the surface of food materials. A food packaging system is classified as “edible” if it forms an integral component of the food that can be ingested along with it [13]. This material serves to preserve and enhance food quality, being extensively employed as a postharvest intervention, particularly for perishable items such as fruits and vegetables. Edible coatings provide protection against microbial contaminants, prolong shelf life, mitigate deterioration effects, and diminish lipid oxidation and moisture loss [9]. Similar to the production of any other food film, the formulation of edible coatings necessitates consideration of various parameters, including barrier properties (permeability to oxygen and carbon dioxide), optical characteristics (they should be transparent and colorless), and sensory attributes (they must be devoid of flavor, taste, and odor) [14]. Furthermore, edible coatings can augment the sensory characteristics of the product, such as appearance and biochemical, physicochemical, and microbial stabilities. The nontoxicity and safety of this material, coupled with its low processing costs and practicality, render edible coatings a favorable alternative to plastic packaging [13].

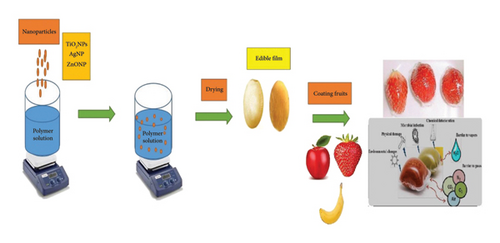

Fruits and vegetables are products rich in vitamins, dietary fiber, phytochemicals, antioxidants, and minerals, the consumption of which is associated with various health benefits, including the enhancement of human immune function and a reduction in the risks of cardiovascular and cancer-related diseases, rendering them essential for human nutrition [15]. While fruits and vegetables are widely consumed, they present significant management challenges throughout the supply chain due to their classification as living tissues whose metabolic activities, such as CO2 production and O2 consumption during respiration, persist postharvest. Additionally, due to their high water content, fruits and vegetables are deemed highly perishable products [16, 17]. The degradation that transpires following harvest can be alleviated through the regulation of respiration rates, ethylene production, moisture loss, and microbial load. The establishment of optimal storage conditions alongside the implementation of advanced postharvest technologies is essential for guaranteeing the stability of storage and prolonging the shelf life of these products [18]. Moreover, fruits and vegetables are vulnerable to contamination by both Gram-positive and Gram-negative bacteria, fungi, yeasts, and molds due to the physiological and compositional transformations that occur throughout the supply chain, thus making these commodities conducive to microbial growth [19]. Numerous studies have proposed potential environmentally sustainable alternatives, such as edible coating film (ECF) matrices, which encompass but are not limited to carbohydrate-based polymers like chitosan (CS), starch, and β-cyclodextrin (β-CD) [20]. For instance, CS possesses the ability to establish a thin film on the surfaces of fruit pulps, which may effectively regulate decay and preserve the quality of fruits by impeding the proliferation of bacteria and fungi, as well as diminishing their respiration rates [21]. Furthermore, starch has been recognized as an additional viable coating material attributable to its characteristics of extensive availability, renewability, and biodegradability, coupled with its cost-effectiveness. Nevertheless, numerous obstacles have been identified, including inadequate barrier properties, diminished mechanical attributes, and insufficient antimicrobial efficacy, thereby necessitating the innovation and deployment of edible coatings infused with inorganic nanofillers [22]. The schematic representation of the utilization of edible films incorporating nanoparticles as a coating for fruits and vegetables is encapsulated in Figure 1.

The formulation and utilization of bio-nanocomposite packaging composed of polymeric matrices and inorganic nanoparticles (Nanoparticles) for the preservation of food are anticipated to be advanced in forthcoming studies [23]. Among the diverse categories of inorganic Nanoparticles, titanium dioxide (TiO2) is frequently employed as an antimicrobial agent for the coating of various materials intended for subsequent applications in numerous food products. The photocatalytic activity of TiO2 is significantly contingent upon the irradiation of visible light, as well as ultraviolet (UV) light, which is instrumental in activating its antimicrobial capabilities. In general, the mechanisms of the antimicrobial action of TiO2 nanoparticles include contact, photocatalytic, and reactive oxygen species (ROS) effects, and their antibacterial and antifungal properties also depend to a small extent on the type of microorganism against which they are used. Therefore, TiO2 nanoparticles can be introduced as a potent antimicrobial agent with a wide range of effects. Their size affects their antimicrobial properties to some extent. In general, the shape, synthesis method, and modification of the composition of TiO2 nanoparticles have a more significant effect on their antibacterial and antifungal activities. The highest antimicrobial potential has been reported for amorphous nanoparticles with particle sizes of 20–60 nm, modified with metals or components of plant extracts and/or compounds of bacterial nature [24]. In addition, the electrocatalytic properties of silver nanoparticles (Ag Nanoparticles) may confer exceptional antimicrobial characteristics, facilitating their extensive application when integrated into edible polymers for use as active food packaging. Silver nanoparticles (Ag), which are known as the most commonly used metal nanoparticles in industries, can significantly increase the permeability of cell membranes through the cell adhesion surface and are lethal to a variety of foodborne pathogens through the degradation of lipopolysaccharide. By entering the bacterial cell, they can damage DNA and also release antimicrobial silver ions, which can bind to nitrogen, oxygen, or sulfur containing electron-donating groups in molecules, ultimately disrupting DNA replication and ATP synthesis [25]. Zinc oxide (ZnO), in association with its antimicrobial properties, can serve as a permeation barrier for subsequent applications. Furthermore, it has been observed by various researchers that the dimensions of nanoparticles significantly influence their mechanical and physical attributes, their capability to filter UV light, as well as their antimicrobial effectiveness [26].

2. Preparation of Active Edible Film (AEF) Containing Nanoparticles

Numerous varieties of edible coatings, both inclusive and exclusive of antimicrobial agents such as EOs, have been developed and scrutinized [27]. In recent years, the literature concerning Nanoparticles as antimicrobial agents and the preparation of AEFs incorporating distinct Nanoparticles has proliferated [28]. In this segment, the various Nanoparticles and primary edible-based materials utilized in the formulation of coating films are delineated and introduced as follows. However, the uniform distribution of Nanoparticles remains a pivotal challenge within the solution system. Additionally, the conventional methodologies for the preparation of AEF with Nanoparticles have been synthesized and documented, encompassing several phases such as the modification of nanoparticle surfaces, dissolution of coating materials, formation of emulsions, and evaporation of solvents. These preparative steps were executed with the aim of addressing the aggregation of Nanoparticles and advancing the development of these intricate coatings/films with enhanced antimicrobial activity for practical application.

2.1. Films With TiO2 Nanoparticles

Yemmireddy and Hung [29] synthesized a total of six distinct suspensions by amalgamating TiO2 Nanoparticles with shellac, polyurethane, and polyacrylic in a porcelain mortar for approximately 15 min. The resulting suspensions underwent further treatment in an ultrasonic water bath for 1 h to prevent the aggregation of TiO2 Nanoparticles. It is evident that if particles undergo aggregation, the particle size will increase substantially, thus precluding the attainment of nanoscale dimensions. The CMC–well-dispersed ternary nanocomposite (NC) coating films incorporating sodium montmorillonite (Na-MMT)–TiO2 were formulated by Achachlouei et al. [30]. Initially, nano-TiO2 powder and ternary NC films containing Na-MMT were dispersed in distilled water through stirring and sonicating, respectively. Subsequently, CMC was introduced into distilled water heated to 95°C and mixed for 1 h. The sonicated solutions of Na-MMT and TiO2 were sequentially incorporated into the CMC solution. Following the addition of glycerol and stirring for 15 min, the solutions were allowed to cool to room temperature. The resulting solutions were cast onto a polystyrene Petri dish and dried at 50°C for a duration of 30 h within an oven.

2.2. Films With Silver Nanoparticle

Silver nanoparticles stabilized with β-cyclodextrin (AgNP–β-CD) were synthesized by Andrade et al. [31]. Aqueous solutions of NaOH, glucose, and β-cyclodextrin were amalgamated and subjected to heating. Subsequently, an aqueous solution of silver nitrate (AgNO3) was added dropwise once the temperature of the solution attained 60°C. Following this, the resulting reaction product underwent dialysis utilizing deionized water. Thereafter, the stabilized silver nanoparticles (Ag Nanoparticles) were subjected to lyophilization, yielding silver nanoparticle–β-CD powder. Orsuwan et al. [32] formulated films composed of a composite of agar and banana powder integrated with silver nanoparticles. Initially, the film-forming solution was prepared by dissolving agar and banana powder in distilled water, followed by heating at 90°C for a duration of 20 min while stirring. Subsequently, after the incorporation of glycerol, an aqueous solution of AgNO3 was introduced into the agar and banana powder (A/B) film solution and subjected to heating at 90°C for 4 h while stirring. The resulting solutions were cast onto flat Teflon-coated glass plates and allowed to dry at an ambient temperature for 48 h.

2.3. Films With ZnO Nanoparticle

Composite films constituted of fish protein isolate (FPI) and fish skin gelatin (FSG) blend, which were integrated with basil leaf EO (BLEO) and zinc oxide nanoparticles (ZnO nanoparticle), were prepared by Arfat et al. [33]. Initially, FPI was combined with distilled water and homogenized for 1 min, followed by the adjustment of its pH to 3. The resulting solution was filtered, and the protein concentration was adjusted accordingly. Subsequently, glycerol was incorporated as a plasticizer. The mixtures were agitated for 30 min at room temperature and utilized for the preparation of the blend film-forming suspension (FFS). In parallel, FSG powder was dissolved in distilled water, after which its pH was adjusted to 3 and heated at 70°C for 30 min. Following this, glycerol was introduced, and the FPI and FSG solutions were combined. Additionally, the previously suspended ZnO nanoparticle in distilled water was incorporated into this mixture. The resulting FPI/FSG/ZnO nanoparticle suspension was stirred for 5 min and subsequently homogenized for 30 s. Furthermore, BLEO, which had been previously amalgamated with Tween 20, was added to the aforementioned suspension. The FFS was acquired through homogenization and agitation.

Espitia et al. [34] engineered NC films of methyl cellulose (MC) that were infused with pediocin and ZnO nanoparticle. The ZnO nanoparticle were combined with deionized water, to which sodium pyrophosphate was subsequently added. The dispersion of the ZnO nanoparticle was subjected to sonication for 23 min. Following this, glycerol was incorporated into the nanoparticle solution, which was heated to 80 ± 2°C to facilitate the solubilization of the MC. Pediocin was added to this solution with MC.

2.4. Films With Mixed Nanoparticles

Lin et al. [35] have synthesized a Ag–TiO2–CS NC intended for use as an antibacterial coating. Following the modification of CS, an aqueous solution of CS adipate was formulated and subsequently combined with a solution of silver nitrate (AgNO3). The resulting amalgamation was subjected to stirring at a temperature of 50°C for a duration of 1 h. Concurrently, titanium dioxide nanoparticles (TiO2 Nanoparticles) were dispersed in distilled water through the application of sonication. Subsequently, the TiO2 dispersion was incorporated into the Ag/CS adipate solution. The composite solution underwent treatment with UV radiation for a period of 10 min. The resulting silver was deposited onto the surface of the TiO2 Nanoparticles, forming a complex with CS via Ag-NH3 coordination bonds facilitated by the amino groups present in CS. In a parallel study, refs. [36, 37] employed a similar technological approach to fabricate CS/Ag/ZnO composite coating films.

Chi et al. [38] have formulated PLA/bergamot essential oils (BEOs)/NC films. In summary, polylactic acid (PLA) and BEOs were solubilized in dichloromethane. Subsequently, 2% nano-TiO2 and 1% nano-Ag, calculated based on the dry mass of PLA, were incorporated into the PLA/BEOs dichloromethane solution, which was stirred for a duration of 10 h at an ambient temperature. Ultimately, the solutions were transferred onto a plate and allowed to dry at room temperature.

3. Effect of AEF With Nanoparticles on the Quality of Fruits and Vegetables

3.1. Antimicrobial Activity of AEF With Nanoparticles

Given that postharvest fresh produce is susceptible to a myriad of microorganisms responsible for spoilage, its quality may be significantly compromised, resulting in a reduced shelf life. Edible coatings, particularly those derived from polysaccharides and proteins, can be employed to fabricate thin films that adhere to the surfaces of fruits, thereby inhibiting the proliferation of bacteria, yeast, and molds [39]. The antimicrobial efficacy of these coatings is influenced by a multitude of factors. Moreover, the effectiveness of these coatings in mitigating microbial growth is likely contingent upon the type, concentration, and intrinsic properties of the coating films, as well as the characteristics of the incorporated nanoparticles (Nanoparticles), including their type, size, shape, concentration, chelation capacity, release behavior, and photocatalytic properties [40]. Additionally, the antimicrobial performance of edible coatings is modulated by the synergistic interactions between the coating materials and Nanoparticles, the specific types and structures of the microorganisms under investigation, and the conditions during testing [41].

3.2. Antimicrobial Mechanism of AEF With Nanoparticles

A multitude of predominant mechanisms has been elucidated and articulated by scholars in the field. Initially, the electrostatic interactions between positively charged cationic polymers or free metal ions and negatively charged bacterial membranes have the potential to compromise cellular integrity. This phenomenon may result in an enhancement of pore formation and increased membrane permeability [42]. Subsequently, the photocatalytic reactions of nanoparticles under UV and visible lights may facilitate the generation of ROS and hydrogen peroxide at the surfaces of these particles [43]. Such oxidative damage to cellular proteins and DNA may serve as a primary contributor to the antimicrobial potency of nanoparticles. Finally, the liberation of free metal ions may disrupt the mechanisms involved in DNA replication. Nonetheless, ongoing research initiatives are being pursued to garner further insights and deepen the comprehension of the antimicrobial mechanisms associated with nanoparticles [44].

3.3. Defense Mechanisms in AEC With Nanoparticles

Throughout the entirety of the storage duration, ROS possessing enhanced oxidizing capabilities inflicted considerable detriment to the cellular membranes of perishable goods. Protective enzymes, including peroxidase (POD), superoxide dismutase (SOD), and catalase (CAT), exhibited the capacity to neutralize the agents responsible for deterioration. Furthermore, the findings of Hong et al. [45] elucidated that lipid peroxidation, an oxidation phenomenon yielding unsaturated fatty acids through free radical interactions, was deleterious to the cellular integrity of pulp. The encapsulating film containing nanoparticles (Nanoparticles) has the potential to mitigate the generation of free radicals and stimulate the activity of defense-associated enzymes in fruits, which may be ascribed to either the individual or synergistic effects of the coating carriers and Nanoparticles. In addition, CS treatment precipitated a noteworthy elevation in the enzymatic activities of CAT and SOD while concurrently suppressing the synthesis of superoxide radicals, which likely contributed to the postponement of alterations in malondialdehyde (MDA) levels and the permeability of the fruit cell membranes. This effectiveness correlated with the concentration of CS applied. The molecular weight of CS may play a pivotal role in the antioxidative efficacy of the active constituents within the coating matrix and the transfer of free electrons from the peroxide to the electron sink of CS. Singh et al. [46] noted that no substantial loss in moisture content was observed in vegetables packaged with Nanoparticles, whereas a significant reduction was evident in those devoid of Ag Nanoparticle impregnation. The regulation of moisture levels and the nutritional composition in packets containing Nanoparticles may be related to the cellular permeability characteristics of the vegetables.

3.4. Release of Metal Ions From Nanoparticles From AEF

Free metal ions liberated from the surface of delivery carriers assumed an antimicrobial function in the elimination of microorganisms residing on the surfaces of agricultural products. A study conducted by Cano et al. [47] demonstrated that simulants A (10% (v/v) ethanol), C (20% (v/v) ethanol), and D1 (50% (v/v) ethanol) exhibited analogous silver release profiles, whereas simulants B (3% (w/v) acetic acid with low pH) and D2 (oleic acid as a nonpolar vegetal oil medium) exhibited divergent behaviors. The liberation of silver was facilitated by the water absorption characteristics of the film in aqueous environments. The majority of the release transpired within the initial 60 min, with complete liberation of silver occurring after 60 min of exposure to the acidic medium (simulant B). Moreover, Liu et al. [48] investigated the release of silver ions from Ag/TiO2 composite films, observing a rapid increase in the quantities released during the initial 5 days, followed by a gradual decrease in the release rate. Additionally, Wei et al. [41] verified that copper ion concentrations were released from the plastic coatings at a rate of 1 wt %, with the release rate diminishing progressively after 5 hours. According to the investigation by Salarbashi et al. [49], no TiO2 was detectable by inductively coupled plasma optical emission spectroscopy (ICP-OES) in bread samples encased with the SSPS/TiO2 film and stored over a 6-month period. A negligible quantity of TiO2 released from the NC films was detected in water. Of particular significance, prolonged exposure of cells to uncoated Nanoparticles revealed the incorporation of TiO2 Nanoparticles within the plasma membrane of the epithelial cell line.

The liberation of nanoparticles or metal ions into a given system is influenced by a variety of factors. These factors encompass, but are not limited to, the microstructure of the coating carrier, the diffusion of particles and ions into the medium via the polymer, the migration of the medium into the polymer matrix, and its subsequent expansion, as well as the solubility of the polymer in the medium phase [47].

3.5. Examples of AEF With Nanoparticles on the Quality of Fruits and Vegetables

Coating films have the potential to serve as carriers for metallic nanoparticles functioning as antimicrobial agents, as well as protective barriers, which may facilitate the reduction of respiration rates, modulation of decay and color changes, preservation of storage quality, and extension of the shelf life of fresh produce [27]. Xu et al. [50] conducted a comparative analysis between uncoated strawberries and mangos and samples treated with NCs, stored at ambient temperature for a duration of 7 days. Their findings indicated that the coated samples demonstrated a reduced weight loss and maintained superior esthetic qualities, while polyphenol oxidase (PPO) activity was inhibited by the NC coating that incorporated graphene oxide (GO) and CS-loaded TiO2. The SOD activity in fruits coated with three distinct types of NC films was observed to yield higher values than those of the untreated samples, thereby signifying considerable potential within the food preservation sector.

4. Nanoemulsions (NEs) Formulation for Edible Coatings

Encapsulation in NEs has many advantages that enhance the use of functional compounds in the food industry area [51–54]. The newest research indicates the vital role of NEs in the production of a new version of active food packaging. This new method improves the physical resistance and beneficial effects of bioactive components in edible coating and enhances the nutritional value of food products. In general, researches have reported that NEs used in food coatings are able to increase the shelf life of various foods, but still other important areas, including their commercial application, need to be evaluated (Table 1). Most coatings enriched with NEs have antimicrobial properties, but the production of edible coatings fortified with health-improving compounds can also be important. But due to the possible toxicity of nanomaterials, more research should be done on the digestive activity of foods coated with NE-based edible coatings. Finally, more specialized investigations are needed regarding the effect of these coatings on the sensory characteristics of food [14].

| Fruit or vegetable | Bioactive components | Droplet size (nm) | Techniques | Polymer | Application | References |

|---|---|---|---|---|---|---|

| Plums (Prunus salicina) | Lemongrass essential oil | 56 | Dynamic high pressure | Carnauba wax | Enhance the antimicrobial efficacy of the essential oil while simultaneously augmenting the homogeneity and stability of the emulsion | [55] |

| Strawberry (Fragaria × ananassa) | Cinnamon essential oil | 162 | Ultrasound | Pullulan | Enhance the distribution of oil within the matrix and elevate its antimicrobial efficacy | [56] |

| Okra (Abelmoschus esculentus) | Basil essential oil | 416 | Ultrasound | Sodium alginate | Augment the antimicrobial efficacy of essential oil | [57] |

| Green beans (Phaseolus vulgaris) | Carvacrol, bergamot, mandarin, and lemon essential oils | 133, 161, 163, and 175 | High-pressure homogenization | Chitosan | Augment the antimicrobial efficacy of essential oils | [58] |

| Arugula leaf (Eruca sativa) | Lemon, mandarin, oregano, or clove essential oils | — | High-pressure homogenization (HPH) | Modified chitosan | Enhance the antimicrobial efficacy of the essential oil while simultaneously augmenting the homogeneity and stability of the emulsion | [1] |

| Bartlett pears (Pyrus communis) | Cellulose nanocrystal and oleic acid | 156 | Ultra turrax homogenizer | Chitosan | Enhance the stability of the coating under conditions of elevated humidity, improve adhesion to the surface of fruit, and retard the ripening process of pears | [59] |

| “Nova” mandarins (Citrus reticulata) and “unique” tangors (C. reticulata & C. sinensis) | Oleic acid and carnauba wax | 44 | High-pressure homogenization (HPH) | Carnauba wax | Enhance optical properties and the stability of the emulsion | [60] |

| Fresh cut pineapples (Ananas comosus) | Citral | 66–131 | Ultrasound | Sodium alginate | Augment the dispersion of the active compound within the matrix and elevate its antimicrobial efficacy | [61] |

| “Redtainung” papaya (Carica papaya) | Carnauba wax nanoemulsion | 40–400 | High-pressure homogenization (HPH) and mechanical stirring | Hydroxypropyl methylcellulose | Diminish gas permeability and moisture loss | [62] |

| Fresh cut Fuji apples (Malus domestica “Fuji”) | Lemongrass essential oil | 30–200 | Microfluidization | Sodium alginate | Enhance the stability of the emulsion while increasing the antimicrobial efficacy of the essential oil | [63] |

| Fuji apple (Malus domestica “Fuji”) | Extract of tarbush | 92 | High-speed stirrer | Candelilla wax | Improved the wettability characteristics of the nanocoating on the surface of fuji apples | [64] |

| Grape berry (Vitis labruscana Bailey) | Lemongrass essential oil | 30–400 | High shear probe and high-pressure dynamic processing (DHP) | Candelilla wax | Enhance the antimicrobial potency of essential oil | [65] |

Three main components, dispersed phase, continuous phase, and also emulsifiers to stabilize both phases are required to form stable oil in water NEs for edible coatings: the emulsification process involves the dispersion of an oil fraction of the produced emulsion, which enables the addition of nonpolar active ingredients [66, 67]. On the other hand, lipophilic components can first be dissolved in carrier oils and then emulsions can be produced [68–70]. Polysaccharides such as gums, alginates, pectin, carrageenan, starches, and proteins such as soy proteins and whey proteins have been introduced as known materials that can be used in the aqueous continuous phase. These proteins and polysaccharides have the ability to create a structural support matrix for the production of NE-based food coatings [68, 71].

Emulsifiers including lecithin, Tweens, and spans can be used to produce food NEs [60, 72, 73]. Edible biopolymers with surface active (emulsifying) properties, including special gums and proteins, can be used in the production of NEs [74]. Previous literature recommends that NE-based edible coatings are designed using two main approaches. The first approach is to produce the coating in one step including emulsifier, continuous phase, and polymers. First, all the components are mixed and a coarse emulsion is produced; then, the premixture is homogenized until the droplet size reaches the nanoscale [75]. These types of NE coatings can be used directly on the food surface. The second method consists of two steps, in which the NEs are formed before adding edible biopolymer in the aqueous phase in the first step. Finally, these natural materials will be poured into the previous NEs [76]. In general, the encapsulation of lipophilic materials by edible coating is the main goal for both methods and approaches [77, 78]. An edible coating based on NEs significantly encloses natural antibrowning or antioxidant components including carotenoids and α-tocopherol in the lipid phase [79]. NE-based coating has the ability to significantly decrease the browning index of vegetables and freshly cut fruits compared to the antioxidant agents that are used alone [80].

Xu et al. [81] conducted a study to evaluate the influence of NEs containing cinnamon essential oil (0.1%, 0.2%, and 0.4%) in conjunction with 0.05% ascorbic acid on the activity of polyphenol oxidase in cloudy apple juice. The cinnamon essential oil NEs demonstrated stability in the presence of varying concentrations of ascorbic acid and exhibited an 80%–90% inhibition of polyphenol oxidase activity, an effect that, while significant, was insufficient to adequately mitigate browning in apple juice. The amalgamation of cinnamon essential oil NEs with 0.05% ascorbic acid facilitated ascorbic acid’s role as a reducing agent, resulting in the complete inhibition of polyphenol oxidase activity and preserving the coloration of apple juice for 48 h under storage conditions at 4°C. Additionally, the simultaneous application of cinnamon essential oil NEs at concentrations of 0.2% and 0.4%, along with ascorbic acid, was capable of diminishing the instability index of apple juice from 0.473 to 0.034 and 0.018, respectively. Finally, the aforementioned combined treatment delayed the degradation of total phenol and ascorbic acid content in apple juice.

Mendoza-Wilson et al. [82] integrated quercetin with various antioxidants derived from natural sources, possessing differing polarities, including quercetin-3-rhamnoside, ascorbic acid, and α-tocopherol, in the formulation of oil-in-water NEs to assess their influence on polyphenol oxidase activity and the browning phenomenon in Granny Smith apple fruits. NEs that contained a combination of four antioxidants exhibited the most significant effect on polyphenol oxidase, resulting in a 41% reduction in its activity and an inhibition of browning in apple flesh by 81%–74% over a 6-hour duration. Molecular modeling analyses suggest that quercetin may function as a more potent inhibitor than ascorbic acid and quercetin-3-rhamnoside, likely acting as a noncompetitive inhibitor of polyphenol oxidase, whereas quercetin-3-rhamnoside serves as a selective and competitive inhibitor of polyphenol oxidase. Ultimately, it can be concluded that the paramount role of α-tocopherol within NE formulations is likely the regeneration of quercetin, thereby extending its antioxidant efficacy.

4.1. NEs as Anti-Browning and Antioxidant Agents

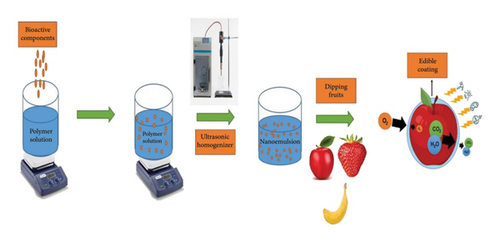

Color and appearance are the basic quality factors of vegetables and freshly cut fruits. It is known that the main reason for unwanted changes in the surface of vegetables and cut fruits is related to the oxidation caused by polyphenol oxidase enzyme, which converts phenolic compounds into black pigments in the presence of oxygen. A complete immersion of vegetables and cut fruits in an aqueous-based solution containing antioxidant/anti-browning agents is one of the common ways to control this undesirable color. The schematics of using NEs as an edible coating in fruits and vegetables are briefly introduced in Figure 2. Ascorbic acid is one of the most widely used antioxidants to minimize the enzymatic browning level of vegetables and cut fruits [83]. However, the effectiveness of such surface operations has drawbacks. Problems due to the functional component losses, low solubility, incomplete absorption and diffusion on the surface of fruits and vegetables, and their decomposition due to the auto-oxidation reaction with ambient oxygen when they are applied directly on the surfaces of fruits and vegetables are examples of these problems. Therefore, the development of new strategies to decrease their dosage in vegetables and fresh cut fruits is a fundamental issue. According to new studies, the immobilization of nanoparticles on the fresh food surface by NEs can be a fundamental potential approach for further studies. The NE-based edible coatings can be used as an efficient system for encapsulating natural antioxidants or anti-browning compounds including α-tocopherol and carotenoids in the lipid phase, which can limit the browning index in vegetables and fresh cut fruits in comparison with when the antioxidants were used alone [79].

4.2. NEs as Texture Enhancer Agent

Degradation of tissue and cell wall strength during the storage period caused by enzymatic decomposition causes a significant loss in consumer satisfaction of fresh cut fruits [84]. Edible coatings based on NEs have shown high potential as a texture enhancer in freshly cut fruits and vegetables. For example, it has been suggested for NE formulation of xanthan gum as a carbohydrate-based texture enhancer. According to the results, NEs containing xanthan gum have the ability to delay the loss of firmness of freshly cut apples [83]. Carnauba wax and xanthan gum and NEs have stored guava tissue at an 85% relative humidity and 10°C for 30 days [84]. Zambrano et al. [85] also reported that coating with NEs produced by xanthan gum, nopal mucilage extract, and α-tocopherol reduced the activity of polyphenol oxidase and pectin methyl esterase in freshly cut guava and apples. Softening of fruits is the result of enzyme activity. More enzyme activity leads to faster softening of fruits. The NEs containing xanthan gum have delayed enzyme activity by modifying the metabolism of cell wall destruction of guava and apple and thus maintaining higher firmness. Also, the produced NE droplets were probably activated at the molecular level in the cell wall of freshly cut fruits and had a more effective performance compared to conventional coatings.

4.3. NE of Essential Oil

Another class of compounds that have great opportunity for use in food edible coatings and can have antimicrobial properties are the essential oils (EOs), which have long been identified as natural antimicrobials. In Natrajan et al. [86] study, first, an oil-in-water NE was prepared by pregelatinization of alginate by adding calcium chloride, and after, CS was poured into the nanocapsules to create more connections. Finally, he designed alginate–CS nanocapsules for the nanocoating of lemongrass oil and turmeric oil. Other findings regarding the use of lime oil in the production of cellulose acetate nanoparticles by the nanoparticle process have also been reported [87]. The use of gum tragacanth as a biopolymer has been introduced for another method to form peppermint oil nanocapsules by the microemulsion process [88]. These nanocapsules have been widely used in the pharmaceutical industry, but no comprehensive results have been reported about the food applications of nanocapsules containing plant essential oils. In this regard, Mohammadi et al. [88] encapsulated the essential oil of Zataria multiflora in CS nanoparticles and confirmed the increase in antioxidant properties and consequently the longer shelf life of cucumbers.

4.4. Chitosan-Based NE System

CS, having acceptable tensile strength, high mechanical characteristics, and also suitable gas permeability, biodegradable and nontoxic material, and most importantly having antimicrobial properties, can have great potential to form matrices for covering sensitive food compounds as well as nanoparticles should be used. Various other preformed polymers are available in nature for the synthesis of polymeric nanoparticles. For several years, CS has been of great interest as a suitable substrate for carrying nanoparticles in the food applications. Also, edible coatings based on CS solution have been introduced for several decades [89, 90] and have used CS in the preparation of edible coatings. According to the obtained results, nanoparticles delayed the ripening process in coated fruits and maintained quality after harvest. Although the produced coating has weak adhesion and durability and its anti-moisture property has been lost, it can guarantee the support matrix.

4.5. Pectin-Based NE System

One of the important food emulsifiers that has roles such as a gel agent, a thickener, and a stabilizer is pectin. Pectin, having unique chemical and physical properties, can be considered the best choice for making edible films [91]. Performance enhancement in combination with other compounds has also been reported for pectin. It has also shown great potential to design the NE-based coatings or films to provide properties and common users. The NE-based coatings or films with suitable flexibility have been used in a wide range of fresh produce. Depending on the prices, design, features, special demands, and opportunities, the selection of correct emulsified layers for a specific product is chosen so that this technology can propose many benefits to consumers and manufacturers. A combination of hydrocolloids and lipids for the formulation of emulsion-based edibles has yielded more effective results than coatings or films alone, especially for their antimoisture properties [65].

4.6. Starch-Based NEs

Grain endosperm and plant tubers can be considered as the main sources for storing starch as carbohydrates from various sources such as cereals, cassava, potato, and corn [92]. The chemical structure of starch includes long-chain linear amylose and branched amylopectin. Starch consists of small granules, and its properties depend on the shape, distribution of granules, morphology, botanical origin, and size change. Other factors including weather and cultivation area can also determine the main characteristics of starch. Generally, 98%–99% of the dry weight of starch grains consists of two components: amylose, amylopectin, and two other polysaccharides. Almost 10.7 million tons of starch-containing products were produced by the European Union, an increase of 30% compared to 2004. It has been found that apart from byproducts, the consumption of starch increased to 9.3 million tons in Europe in 2018 [93].

5. Coating Based on Carboxy MC (CMC)

In this part, different biopolymers have been discussed. One of the most famous and economical polysaccharides is CMC, which is obtained from carboxymethylation of cellulose. CMC has advantages such as biodegradability, solubility in water, etc., and can be prepared as transparent films. There are those that can be overcome by combining similar materials (biopolymers) including collagen, CS, starch.

6. Coating Based on Gums

Gums are basically known as carbohydrate or polysaccharide polymer compounds that have a completely natural structure and are renewable. They also have the ability to dissolve in water, producing gels or stabilizing emulsion systems. In recent years, alternatives to petroleum-derived polymers have been introduced, whose gums and derivatives have been introduced as efficient compounds for control and bioavailability due to increased useful life and postharvest diseases. Polysaccharide gums have the ability to produce a coating or film with the ability of a semi-permeable barrier, and in this way, they have the ability to maintain nutritional value, control weight loss, and control the rate of respiration at the level of the product. Having said properties, gums have a clear advantage over synthetic polymers. Gums are recognized as GRAS by FAO and are environmentally friendly and safe for human consumption [93]. Recently, as a new strategy in advanced food packaging, edible gum-based coatings have been introduced to increase the shelf life of fruits and vegetables and control postharvest diseases. Edible coatings produced based on polysaccharides protect the quality of fruits and vegetables and at the same time have the ability to protect the environment. Researchers have focused on gum because of their compatibility with the environment and their effective performance, and as a result, the global demand for natural coating materials has increased. In general, edible coatings to increase the shelf life and maintain the quality of fruits and vegetables have been discussed from different angles in the last few years and different opinions have been reported [94, 95].

7. Conclusion

An in-depth exploration of the underlying mechanisms governing the antimicrobial, antifungal, and antioxidant properties inherent in edible essential oils, as well as their synergistic combinations, necessitates further scholarly investigation. The concurrent application of multiple flavoring agents can contribute to a palatable sensory profile in food products, devoid of adverse effects. Consequently, the worldwide demand for essential oils within the food industry is anticipated to experience a notable escalation in the foreseeable future. However, the diverse array of food packaging materials and systems, coupled with considerations regarding safe dosages, optimal application limits, potential allergic reactions, and the development of innovative methodologies for the encapsulation of edible essential oils to ensure controlled release, necessitate heightened scrutiny. The encapsulation of essential oils and their incorporation into edible coatings has witnessed a progressive increase, with researchers actively engaging in contemporary initiatives aimed at the formulation of such coatings, particularly focusing on NE-based edible coatings augmented with essential oils and enhancing the antimicrobial efficacy of these oils against specific resistant pathogens or foodborne microorganisms, thereby addressing practical challenges associated with the application of NEs in food systems. Therefore, it is essential to further evaluate and investigate the foundational principles surrounding novel microbial resistance or susceptibility, the preservation of the quality of plant-derived essential oils throughout food processing, and the examination of bacterial compatibility in the presence of these essential oils in food matrices. In this paper, the characteristics of primary edible-based coating materials are initially delineated. Subsequently, a comprehensive review of the AEFs incorporating nanoparticles such as TiO2, Ag, and ZnO, as developed by various researchers, is presented. The antimicrobial efficacy of these AEFs featuring nanoparticles against the microorganisms tested was meticulously observed by the researchers. A synthesis of several antimicrobial mechanisms is provided, encompassing the electrostatic interactions between the cationic polymer or free metal ions and the charged cellular membrane, the photocatalytic reactions of nanoparticles, and the liberation of free metal ions. Following this, an analytical discussion on the surface morphology and mechanical properties of AEFs containing nanoparticles is incorporated, highlighting their significance for applications involving fruits and vegetables during storage at both refrigerated and ambient temperatures. The attributes of gas modification, inductive defense, and ion release pertinent to AEFs featuring nanoparticles are further elaborated upon. Conversely, findings from supplementary studies suggest that the utilization of AEFs with various nanoparticles may offer a viable and effective approach to mitigate quality deterioration in postharvest fruits and vegetables. Notably, further exploration into the interactions between nanoscale particles and coating materials, as well as the antifungal mechanisms induced by UV or visible light, necessitates additional investigation. Future research should also encompass the standards established for the preparation and utilization of these coatings along with an assessment of their safety.

Conflicts of Interest

The authors declare no conflicts of interest.

Author Contributions

Hamed Hassanzadeh: conceptualization-equal, formal analysis-equal, software-equal, supervision-equal, and writing – review and editing-equal. Salar Ali Ahmed: data curation-equal, funding acquisition-equal, methodology-equal. Nian Sayfaddin Haji Qadir: validation-equal and writing – original draft-equal.

Funding

Salahaddin University-Erbil is appreciated for financial support.

Acknowledgments

Salahaddin University-Erbil is appreciated for financial support.

Open Research

Data Availability Statement

Data sharing is not applicable to this article as no datasets were generated or analyzed during the current study.