Improvement of Concrete Characterization Using Nanomaterials: State-of-the-Art

Abstract

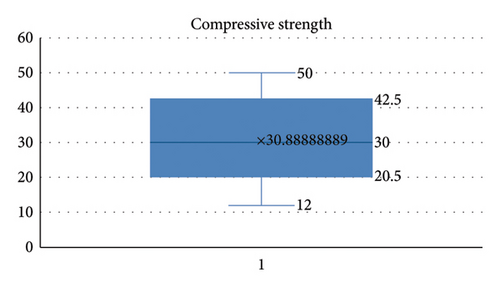

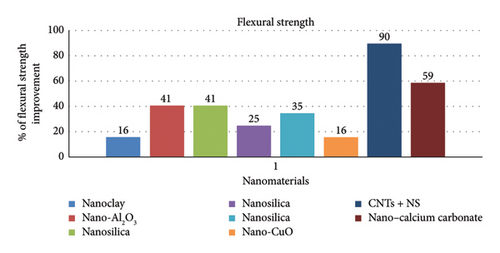

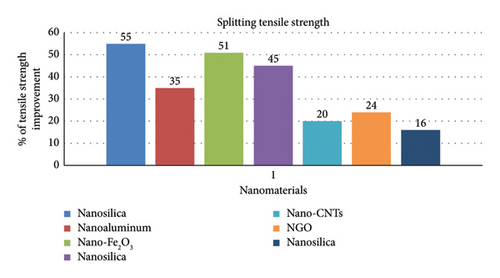

The utilization of nanomaterials in concrete has undergone extensive research to enhance its properties. Nanosilica (NS), nanoalumina, nanometakaolin (NMK), nanoclay (NC), and nanocarbon dioxide have demonstrated the ability to improve the compressive strength of concrete at different ages, with a more pronounced impact on early strength. This study aims to systematically analyze the influence of nanomaterial additions on concrete properties, including strength, durability, and resistance to environmental factors. Noteworthy improvements and challenges associated with nanomaterial usage are highlighted. In our findings, the incorporation of various nanomaterials resulted in a notable enhancement of compressive strength, ranging between 12% to 50% when compared to the reference mixture. Nanosilica, nano–titanium oxide, nanoalumina, nano-CaCO3, NC, and nanocarbons were investigated for their potential to increase flexural (2%–22%) and tensile (16%–55%) properties of cement and concrete. Moreover, combining nanomaterials and polypropylene fibers in concrete exhibited enhanced flexural, tensile, and compressive strength, along with improved split tensile strength and bond strength of reinforcement bars. The exploration of composite nanomaterials further demonstrated the capacity to elevate tensile properties, achieving high ultimate tensile strength and precise prediction accuracy. The unique properties of nanomaterials position them as superior alternatives to traditional materials, showcasing applicability in future construction endeavors. Continued research endeavors are anticipated to provide greater reliability and address significant challenges within the building and construction sector.

1. Introduction

At its core, nanotechnology involves working with matter at the nanometric scale, necessitating the deconstruction of materials and the ability to meticulously engineer their composition and structure. This level of precision empowers scientists to fabricate entirely new materials with unprecedented properties and extraordinary capabilities that were previously unattainable. It has been found that the addition of micromaterials has different effects on the mechanical and physical properties of concrete. Studies have shown that micromaterials containing calcium oxide improve chemical and physical properties and compressive strength. On the other hand, the study showed that micromaterials have negative effects on shrinkage and resistance because of the large size of their molecules so that they enter between the particles of the components of the concrete mixture and work to spread its particles apart which weakens the bonds of bonding in the microstructure and thus decreases strength [1]. While miniaturization is essential to nanotechnology, the ultimate objective goes beyond size reduction. The true essence lies in the profound ability to manipulate and explore matter, unveiling its hidden phenomena and properties at the nanometer scale. By harnessing nanotechnology, engineers and scientists can develop groundbreaking advancements in various fields. Due to some of its superior qualities, concrete is one of the most widely utilized building materials worldwide. However, because concrete has some tiny pores, aggressive compounds can seep in, especially in harsh environments, reducing the material’s longevity. Therefore, it is crucial to improve the mechanical and physical qualities of cement concrete, which largely relates to the nanotechnology or nanoscale features of the material. Lately, the ultimate aim of concrete nanotechnology has been to investigate concrete at the nanoscale and to study nanomaterials that can improve the properties of concrete.

In this study, the use of many nanomaterials, such as nanosilica (NS), nanometakaolin (NMK), nanoalumina (Al2O3), nano–calcium carbonate (CaCO3), nano–iron oxide (Fe2O3), nano–titanium dioxide (TiO3), and carbon nanotubes (CNTs), and their effects on the properties of conventional and lightweight concrete were investigated. The results showed that most of the nanomaterials had positive effects on the mechanical, physical, durability, density, and sulfate and chloride resistance properties of conventional and lightweight concrete. The study found that some nanomaterials, such as NS, NMK, and nanoalumina, could maintain compressive and flexural strength under fire exposure and reduce thermal conductivity.

Most previous studies have not focused primarily on the effects of nanomaterials on conventional and lightweight concrete at the same time. Moreover, the effects of specific nanomaterials on conventional and lightweight concrete have been studied separately. This paper aims to provide the latest comprehensive overview of the effect of incorporating nanomaterials on the mechanical properties of ordinary and lightweight concrete (compressive strength, flexural strength, tensile strength, and durability) and, in addition, studying various types of nanomaterials and their effect on physical properties (thermal conductivity and fire resistance). The study also aims to demonstrate the extent of the effect of nanomaterials on the ability to absorb and resist the penetration of chlorides.

- a.

Enhancement of Concrete Properties: At a microlevel, the primary motivation is to improve the mechanical, physical, and durability aspects of both conventional and lightweight concrete. The incorporation of various nanomaterials like NS, NMK, and nanoalumina could significantly elevate these properties. This enhancement is crucial because concrete, despite being one of the most widely used construction materials, has inherent weaknesses like porosity and susceptibility to environmental degradation.

- b.

Innovative Solutions for Construction Challenges: On a macro level, the research is driven by the broader goal of advancing construction technology. By integrating nanotechnology into concrete, you are aiming to solve larger structural problems, such as improving building longevity, resistance to environmental stresses, and overall material efficiency. This could have a transformative impact on the construction industry, leading to safer, more durable, and environmentally sustainable buildings.

- c.

Addressing Specific Concrete Weaknesses: Another motivation is to address specific weaknesses of concrete, such as its vulnerability to fire and thermal conductivity. Traditional concrete materials do not perform well under high temperatures or in fire scenarios. Your research into how certain nanomaterials can maintain compressive and flexural strength under fire exposure and reduce thermal conductivity is pivotal.

- d.

Environmental and Safety Considerations: Lastly, the research is motivated by the need to develop materials that are more resistant to aggressive compounds like chlorides, which can seep into concrete’s tiny pores, especially in harsh environments, reducing the material’s lifespan. By enhancing the concrete’s ability to resist these penetrations, the research contributes to creating more resilient and sustainable infrastructures.

Finally, the present research is guided by the objective of not only understanding the interactions of nanomaterials with concrete at a microscopic level but also solving practical, large-scale problems in the construction industry. This approach not only contributes to the scientific community but also has the potential to revolutionize building practices globally.

2. Literature Survey

Singh et al. [2] studied the effect of nanomaterials when mixed with concrete. The study showed that the addition of nano–calcium carbonate hydrates the mixed cement, which increases the temperature development and microhardness. The study also proved that the presence of multiwalled nanotubes increases compressive and tensile strength. In addition, increasing the amount of CNTs leads to greater improvement. The researchers also noticed that the presence of CNT modifies the microstructure of the mixture because it acts as bridges, enhancing durability. Nanographene and its derivatives also enhance the properties of cement materials through interaction.

Zhang et al. [3] studied the effect of adding nanomaterials on the mechanical properties of high-performance concrete (HPC). The authors found the addition of nanomaterials improves the mechanical properties of HPC while reducing its workability. There is an optimal dosage of nanomaterials for improving the mechanical properties of HPC. Also, adding nanomaterials can enhance the flexural and compressive strength of concrete, with an overall increasing trend followed by a decrease. An optimal content of nanomaterials is generally considered.

Onaizi et al. [4] conducted a comprehensive study on the effect of adding nanomaterials on the sustainability of concrete. The study showed that adding nanomaterials to concrete enhances its strength performance and durability. These materials also fill the pores, increasing the tightness of the transition zone between the aggregate and the cement paste and reducing the occurrence of cracks. Researchers showed an increase in compressive strength. In addition, the study showed that nanotitanium (NT) and NS reduce carbonation and increase concrete resistance against chloride penetration and chemical attacks, which enhances durability.

Tarangini, Sravana, and Srinivasa Rao [5] studied the effect of NS on frost resistance. The researchers conducted freezing and thawing tests on concrete in the laboratory. Several properties were measured, including compressive strength, weight reduction ratio, density, and ultrasonic pulse velocity (UPV). The results showed that adding NS increased durability by 70% compared to the control mixture. Also, researchers found improved resistance to freezing and thawing, resulting in reduced weight loss and compressive strength. The researchers justified this improvement due to the higher dynamic modulus of elasticity (DME) when adding NS. Overall, the results showed that previous concrete with NS performed better in terms of freeze-thaw resistance and durability factors compared to the control mix.

Chakravarty et al. [6] used NS with three different water ratios to demonstrate its effect on lightweight concrete. It was observed that the compressive strength was the highest in all mixtures containing 3% NS at 28 days of age. The highest compressive strength was recorded at a water percentage of 40% by weight of cement and a dose of 3%, which was 29% higher than the control mixture.

Henegal et al. [7] published a study on adding nanoferrosilicon to high-performance heavy concrete. The addition of 3% ferrosilicon achieved 190 MPa after it was 160 MPa, an improvement of 19% over the control concrete.

Jakadish et al. [8] showed the effect of nano–titanium oxide and fly ash on the mechanical properties of fly ash and geopolymer concrete. The study found that replacing 3% nano–titanium oxide with the weight of fly ash improved the compressive strength by 46.8% for geopolymer concrete when adding 3% at 28 days of age. Also, observed decreased porosity and increased density.

Pathak and Vesmawala [9] studied the combined effect of NT and fly ash. The study showed that the best compressive, flexural, and tensile strength was obtained when adding 4% NT with 20% fly ash. The improvement in compressive strength reached 11% when adding the mentioned percentage at 28 days.

Liu et al. [10] showed the effect of adding nanomodified silicon on reducing water absorption in concrete. The study showed that the emulsion reduced water absorption by 19.49% when compared with the reference mixture. In addition, resistance to chlorides increased by 76.13%, which enhances durability. The freezing and thawing cycles increased by 150 times. The researchers attributed the increased durability to the nanoemulsion’s formation of a water-repellent layer, which also filled the pores of the concrete.

Xu et al. [11] demonstrated the effect of NS on rubberized concrete. The results showed a decrease in the width of cracks in the transition zone, as the decrease ranged between (3–10) micrometers, while its measurement was (35–45) in nano–free rubber concrete. The researchers justified this improvement to the increased density of the concrete texture and its tightness to the hydration products, especially in the initial hardening stage. Moreover, the compressive strength increased by 30.3% over the compressive strength of ordinary rubber concrete.

Zhao et al. [12] showed the effect of NS on the strength and durability of recycled aggregate on the strength of concrete. The study showed that the concentration and soaking time have a significant impact on the strength and durability of recycled aggregate. A concentration of 2% NS and a soaking time of 48 h had the best results, as the compressive strength, flexural strength, and modulus of elasticity increased by 31.8%, 33.2%, and 89.6%, respectively. Thermal differential, thermogravimetric, and scanning electron microscopy tests showed that the transition zone was denser, and this enhanced the strength of the concrete.

Zhang et al. [13] studied the effect of nanomaterials on the corrosion resistance of marine concrete under the influence of chloride attack and dry and wet cycles. The researchers found that the resistance to compression, bending, and corrosion increased with an increase in the content of NS and nano–iron oxide, up to a limit of 2%. Concrete corrosion rates decreased when adding NS and nano–iron oxide by 19.86% and 14.44%, respectively. Cui et al. [14] published a study on the effect of nanomaterials on the permeability of concrete. The study showed that the permeability of concrete improved significantly, its complexity increased, and its pores decreased. The researchers explained that this discovery has positive effects on tunnel engineering, especially in the winter when temperatures drop and frost increases. The study also highlights the importance of considering the interaction between solid and fluid molecules in determining the permeability of hydrated cement. The fractal analysis and capillary model used in the research provide a useful framework for understanding and predicting the seepage behavior of concrete.

Oh et al.[15] studied the effect of fiber-matrix bonding in HPC. The researchers noticed an increase in the packing density when different doses of 15% NS were added, after which it gradually decreased. The researchers noticed that the stable bonds of iron fibers increased by adding NS by up to 40%. Also, the shock resistance gradually increased to 30% NS. The study showed that the best pulling resistance was 10%–20% NS. The highest compressive strength was obtained when adding 15%, which increased by 5%.

Dahish and Almutairi [16] showed in their study the effect of high temperatures (25 to 800 degrees Celsius) on concrete modified with nanoclay (NC) and NS. The study showed that adding 4% NC and 1% NS gave the best results at 28 days of age and at various temperatures. The compressive strength was not affected when the temperature rose to 200 degrees Celsius when the ideal ratio was added, after which it began to decrease.

Hwangbo et al.[17] prepared a study to demonstrate the effect of nanomaterials on the behavior of bonds between concrete and iron bars. CNT, NS, and nanographene oxide (NGO) were used in this study. The study showed that drag slip decreased, but an increase in tensile strength of about 6.4% was recorded. The researchers justified the decrease in drag slip due to the increase in the density of the concrete, the cohesion of its particles, and the improvement of the area between the reinforcing steel and the concrete paste.

Nanoparticles such as nano-SiO2, nano-Al2O3, nano-CaCO3, nano-TiO2, NC, and nanocarbon have been found to enhance the mechanical properties and durability of concrete. The main goal of this paper is to demonstrate the ability of nanomaterials to change the properties of original materials to enhance their performance to meet the increasing demands of modern infrastructure. On the other hand, this study differed from previous ones by studying the effect of nanomaterials on the mechanical properties of concrete (compressive strength, tensile strength, bending, durability) and physical properties (thermal insulation). In addition, a review of the latest studies for effecting nanomaterials on concrete.

Nanoparticles such as nano-SiO2, nano-Al2O3, nano-CaCO3, nano-TiO2, NC, and NCTs have been found to enhance the mechanical properties and durability of concrete. The reason for preparing this paper is to demonstrate the ability of nanomaterials to change the properties of original materials to enhance their performance to meet the increasing demands of modern infrastructure. On the other hand, this study differed from previous ones by studying the effect of nanomaterials on the mechanical properties of normal and lightweight concrete such as (compressive strength, tensile strength, bending, and durability) and physical properties (thermal insulation). In addition, a review of the effect of many nanomaterials on concrete.

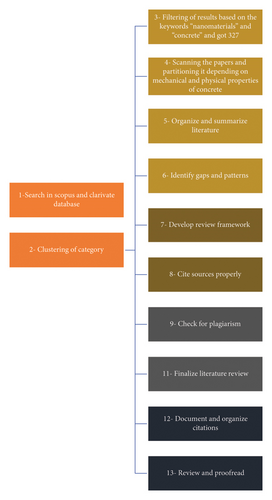

Nearly 327 articles were reviewed, some of which were research articles, some of which were reports, and most of which were reviews on the incorporation of nanomaterials into ordinary and lightweight concrete. 110 research papers were summarized that focused on the effect of incorporating nanomaterials on the mechanical and physical properties of light and ordinary concrete as shown in Figure 2.

The overview of the most recent research on the impact of different nanomaterials on the mechanical and thermal properties of normal and lightweight concrete that has been published through August 2023 sets this work apart from its predecessors.

2.1. Nanoscience and Nanotechnology

The world’s interest in nanoscience in the twenty-first century is the hope for technological development in various fields, especially engineering. After all, it is considered a revolution in the current and coming centuries. In order to understand this topic, the following terms must be addressed.

2.1.1. Nanoscience

Science studies and deals with materials at atomic and molecular levels at a scale not exceeding 100 nm. Nanoscience is considered twenty-first-century science because it reveals the secrets of materials, their interactions, and why they have different properties and specifications [18].

2.1.2. Nanotechnology

Nanotechnology enables us to exert direct control over materials, harnessing the unique properties of particles smaller than 100 nm. We can bestow matter with novel properties and behaviors by manipulating these tiny particles, smaller than characteristic lengths in various phenomena. The field delves into atomic assemblies, comprising five to a thousand atoms. Notably, nanotechnology operates on scales significantly smaller than bacteria and living cells, offering multiple dimensions of exploration.

Nanotechnology or miniature technology (microscopic) deals with atoms and single molecules that make up materials by using precise tools to build and operate a smaller group of materials with repetition of the process of building and operating for smaller groups of materials more than once to reach the required size or is the technology that is concerned about designing and manufacturing materials and machines at the nanometer scale, and in general, this technology aims to apply nanoscience to create and produce means, techniques, inventions, and useful products that are characterized by their extremely small size, as well as their economic cost that does not exceed the raw material and energy used in the manufacturing process of these means and products [18].

2.2. Nanotechnology in Various Scientific Fields

After getting acquainted with the principles of nanotechnology, many researchers have persevered to introduce this great technology into various aspects of life, for example, medicine, engineering, food, electronics, appliances, water and energy technologies, air purification techniques, and many other sciences that serve humans. Part of this science that nanotechnology has entered into and what beneficial aspects it has created will be reviewed in Table 1.

| Fields | Nanotechnology applications |

|---|---|

| Biomedical engineering |

|

| Textile innovation | - Making antibacterial, stain-resistant, wrinkle, and fuzz-resistant textiles: nanocoatings and nanofibers impart textiles with properties such as antimicrobial activity, stain resistance, and durability, enhancing performance and longevity |

| Advanced materials |

|

| Nanodevices |

|

| Nanosport innovation | - Lightweight bats, racquets, hockey sticks, and bicycles: nanocomposites and nanofibers reinforce sports equipment, making them lightweight, yet strong and durable, enhancing performance and reducing fatigue for athletes |

| Eco-nanotechnology |

|

2.3. Nanomaterials for the Construction Industry

Producing new, strong, lightweight, and long-lived materials that are easy to work with in the future in the concrete mixture, Professor (Karen Scrivener) indicated that studying the behavior of materials at the nanoscale will enable the construction industry to develop new materials with unique properties, will help reduce the environmental impacts of producing cement and concrete mix, and will also benefit in reducing the volume of carbon dioxide emissions in the manufacture of building materials and buildings, as well as in waste recycling systems and their environmental importance, which falls within the modern global trends, which aim to save in the consumption of electricity and energy used in cooling, lighting, and water heating, which reduces harmful carbon emissions, maintains the integrity of the ecosystem, and thus leads to prolonging building age [19, 20].

Additives for materials used in construction include silica, alumina, titanium dioxide, shale metals, and carbon tubes, and it uses “coatings, nanocomposites, additives for concrete mixtures, cement, and building adhesives,” for example, self-compact concrete mixtures, and building glass coatings, which is characterized by its thin shape, high transparency, extra protection, and reduced maintenance costs, as well as thermal insulation materials, such as “aerogel.”

Nanotechnology has managed to turn all countries of the world toward its uses in the field of construction to replace traditional building materials with modern building materials that are less expensive, more environmentally friendly and smarter, which work to give people comfort through a healthy, clean, low-cost building, and then control temperature. The temperature and humidity of the spaces according to climatic conditions, resistance to high temperatures, and harmful radiation also reduce emissions from carbon dioxide and neighboring buildings, fire protection, and the ability to self-clean through the self-cleaning glass. It also can reduce maintenance by treating any cracks and cracks early and repairing them directly and automatically, which leads to utilizing nanomaterials and their effect on architecture, making them lightweight, more robust, durable, and resistant to cracks and corrosion by using them to protect surfaces and walls from adhesion of dust and pollutants, maintain color stability, insulate the building thermally, and resist ultraviolet rays, moisture, and fog from on the glass, and then, you can clean the surfaces automatically.

2.4. Application of Nanotechnology in Construction

Research endeavors in nanotechnology have expanded to include many aspects and disciplines. The research included sustainable building in the environment and civil engineering for the great achievements that adopted nanotechnology, where few of these discoveries have been achieved. However, there are great areas in which nanotechnology can be used. Some research types included using nanotechnology to enhance concrete’s strength, smoothness, and durability properties, as it was found that any change at the nano level or its components affects its behavior. Researchers expect that the performance of building materials will significantly improve by treating them with nanotechnology. Table 2 shows the anticipated benefits of some materials by adding nanoparticles [21, 22].

| Construction material | Nanoparticle | Expected benefit |

|---|---|---|

| Concrete | SiO2 | Corrosion reduction; improved strength |

| TiO2 | Fast hydration; self-cleaning; increased durability | |

| Fe2O3 | Abrasion resistance; increased compressive strength | |

| CNTs | Crack prevention; increased durability | |

| Ceramic | SiO2 | Coolant; light transmission; fire resistance |

| CNTs | Improved thermal and mechanical properties | |

| Glass | SiO2 | Antireflection glass; fire protection; self-cleaning |

| TiO2 | Superhydrophilicity; antifogging; fouling resistance | |

| Coating | SiO2 | Self-cleaning; fire retardant |

| TiO2 | Self-cleaning; hydrophobic properties | |

| Ag | Biocidal activity | |

| Steel | Cu | Weldability; corrosion resistance; formability |

| Solar cell | TiO2 | Nonunity electricity generation |

| CNTs | Effective electron mediation | |

2.4.1. Nanomaterials for Concrete

Using nanotechnology in the building and construction field leads to the creation of improved concrete with technical characteristics that differ from ordinary concrete and are environmentally friendly. This trend comes after studying the negative effects of the toxic gases that pollute the environment and pose a great danger to natural resources because they play a vital role in developing infrastructure. Nanomaterials are considered one of the best solutions when mixed with cement because studies have proven mechanical and chemical activation processes for concrete and its materials, as they improve tensile and shear resistance, durability, and bending strength. In addition, it was noted that these materials have found the solution to many complex structural designs, heralding a promising future for producing concrete with new and desirable specifications [23].

2.4.2. Use of Nanomaterials to Improve the Mechanical Properties of Concrete

Nanotechnology has played an important role in enhancing the mechanical properties of concrete, thanks to which it has enhanced strength, durability, resistance to bending and tensile strength, resistance to corrosion and spalling, and reduced carbon dioxide emissions, which cause global warming. From this point of view, nanomaterials have been adopted to solve many problems, especially those related to complex structural designs, and used to produce environmentally friendly concrete. The reason for this improvement in the properties of concrete is due to the direct effect of nanomaterials on the particles of concrete materials, as they rearrange them, strengthen the interconnections between their particles, and increase the permeability resistance [6].

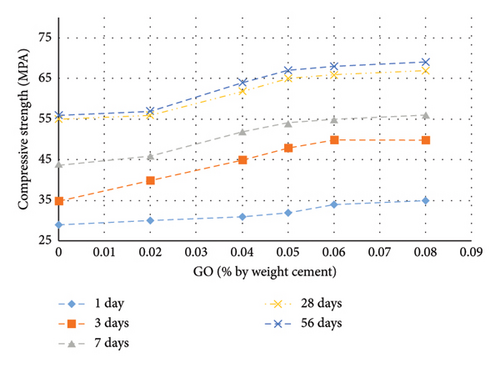

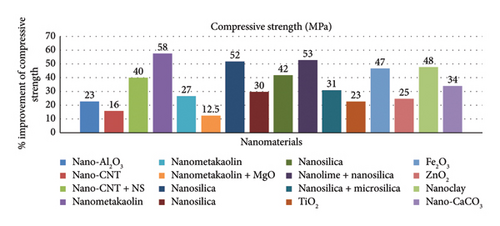

2.4.3. Improvement of Compressive Strength Concrete

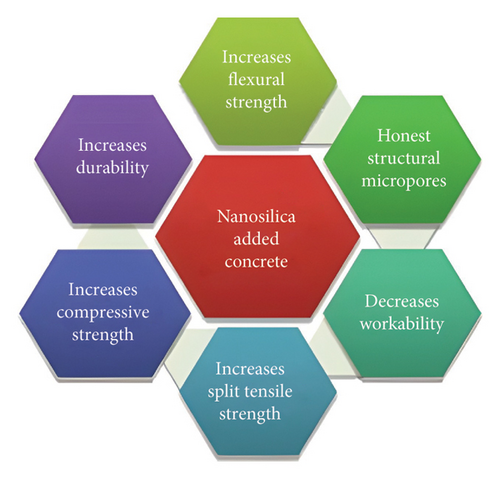

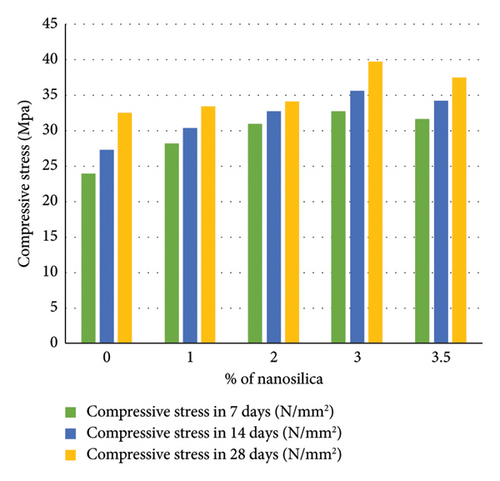

Nanomaterial is one of the most important and latest means to increase the compressive strength of concrete. Many studies have shown that replacing cement with different nanomaterials enhances compressive strength, Figure 3.

Narasimhan et al. [24] studied the effect of CNTs and NS on the compressive strength of lightweight concrete. The researchers noted that the concrete containing 1% NS and 2% CNT achieved the highest compressive strength, recording an improvement rate of 39% over the reference mixture. The study showed that increasing the content of nano-CNTs to 3%, while the remaining 1% NS reduces the compressive strength by 16%. The researchers showed that the increase in compressive strength was due to good packing, which enhanced the microstructure and density and thus improved the compressive strength.

Medah et al. [25] studied the replacement of nanoalumina with Al2O3 and its effect on compressive strength. Replacing 3% nanoalumina led to an improvement in compressive strength by 35%. This improvement occurred in the presence of rice straw ash, which was 10% of the weight of the cement. The decrease in calcium hydroxide crystals was due to the pozzolanic reaction, which produced calcium hydrate in abundance, so the strength increased. Adhikary, Rudzionis, and Ghosh [26] published a study on the use of CNTs and graphene nanosheets and the extent of their effect, together and individually, on the compressive strength of concrete. The data showed that using 2% CNTs gave the highest compressive strength, recording a 10% improvement over the control mixture, indicating that the rest of the percentages (4%, 6%) gave a good improvement. While only 2% of graphene improved the compressive strength, the rest of the percentages (4.6)% reduced the compressive strength. The process of combining the two nanomaterials (1% + 1%, 2% + 2%, and 3% + 3%) improved the compressive strength by (4%, 6.5%, and 7.5%), respectively.

Sugumaran et al. [27] studied the effect of NMK and NGO on the compressive strength of lightweight self-compacting concrete. Models were evaluated at 180 days of age. The results showed that using 2% NMK + 2% MgO recorded the highest compressive strength, which increased by 11%. The researchers attributed this improvement to the quality of packing, the consistency of the mixture, and the increase in density, which improved the microstructure and thus the resistance to erosion.

Albaijan et al. [28] used nanoattapulgite (NAT) to demonstrate its effect on compressive strength. The study showed that NAT enhanced the strength of concrete by 16% when the replacement of coarse aggregate was 50% and NAT was 6%. The researchers attributed this improvement to the nanomaterial filling the cracks and pores, which strengthened the interfacial transition zone (ITZ), and led to improved compressive strength.

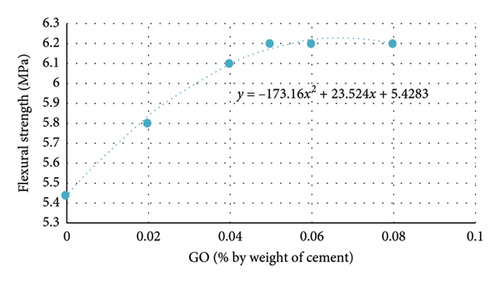

Yoo, Oh, and Banthia [29] studied the effect of nanomaterials on the compressive strength of HPC. The researcher showed the addition of 0.04 graphene oxide (GO) increased compressive strength by 14.5% at 90 days, but a further increase in GO content decreased compressive strength. Also, incorporating 0.15 nanocellulose filaments increased compressive strength by approximately 10%, but at a higher dosage of 0.3, the strength was reduced.

Prasanna Kumar and Rajasekhar [30] studied the effect of colloidal NS on the compressive strength of concrete. The researchers found that replacing NS from 0% to 2.5% enhanced the compressive strength. Increasing the dose of the additive led to a decrease in the compressive strength. The optimum dosage of colloidal silica was determined to be 2.5% by weight of cement, as it showed improved strengths in the compression of concrete by reducing voids.

Feng et al. [31] published the effect of nanomaterials on the compressive strength of HPC containing recycled sand. The results showed that adding 1% NS increased the compressive strength by 14% at the age of 28 days. The researchers justified this improvement to the improvement of the microstructure and density and the production of C-S-H in large quantities, which increased the compressive strength.

Luo et al. [32] studied the effect of nanomaterials on the early compressive strength of HPC. The researchers found that the 1-day compressive strength of UHPC samples with 0.3 wt% C-S-H seeds and NS increased by 457% and 25%, respectively, compared to the control sample. C-S-H seeds were more effective in accelerating the early hydration of UHPC compared to NS, producing hydrates and refining the pore structure.

Nanomaterials such as NS, nanoalumina, NMK, CNTs, and nano–titanium oxide have been shown to effectively improve the compressive strength of concrete [29–31]. These nanomaterials enhance the mechanical characteristics of concrete by increasing its strength and durability [33]. The addition of nanopowders, such as nano-SiO2, nano-Fe2O3, and nano-TiO2, to concrete, has been found to significantly enhance its compressive strength [31]. Graphical representations of the effects of oxide nanoparticles on concrete have facilitated the comparison of their impact on compressive strength. Additionally, the incorporation of nanomaterials in recycled sand ultra-HPC (RSUHPC) has been shown to counteract the negative impact of increased recycled sand content on compressive performance. Overall, these studies demonstrate that various nanomaterials can effectively improve the compressive strength of concrete, making them promising additives for enhancing the quality and performance of concrete structures, as shown in Table 3.

| No. | Nanomaterials used | Replacement % of nanomaterials | Compressive strength before adding nanomaterials (MPa) | Compressive strength after adding nanomaterials (MPa) | % Improvement | References |

|---|---|---|---|---|---|---|

| 1 | — | 2, 4, 6 | 16.96 | 25.8 | +22–52 | [34] |

| — | 1, 2 | 61 | 68.9 | +7.7–13.3 | [35] | |

| Nanosilica | 15 | 12.9 | 19.8 | +53 | [36] | |

| 0.05, 0.1, 0.2, 0.5 | 28 | 35 | +25 | [37] | ||

| — | 23 | 35 | +52 | [38] | ||

| 1, 2, 3 | 100 | 125 | +4–25 | [39] | ||

| 1, 2, 4 | 35 | 46.35 | +21.49–32.45 | [40] | ||

| 1, 2, 3 | 49.50 | 60.45 | +22 | [6] | ||

| 2 | — | 5, 10 | 30 | 46 | +53 | [41] |

| Nanometakaolin | 2–14 | 35 | 48 | +12–37 | [42] | |

| Nanosilica | 5 | 33 | 41.7 | +25.4 | [42] | |

| — | 19 | 28.45 | +48 | [43] | ||

| 3 | Metakaolin + nanosilica | NS 1%–2% + MK 5%–10% | 90 | 105 | +17 | [44] |

| 4 | Nano Al2O3 | 1.5 | — | — | +49 | [45] |

2.4.4. Improvement of Flexural Strength for Concrete

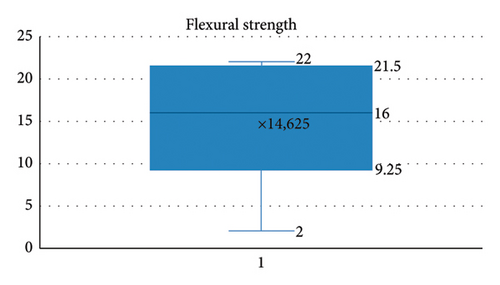

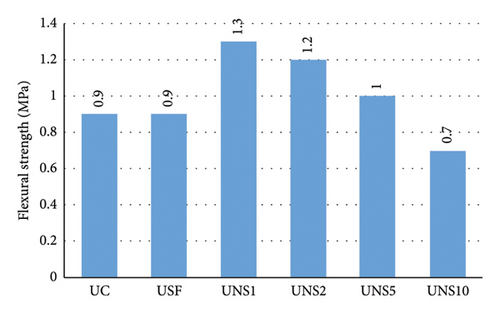

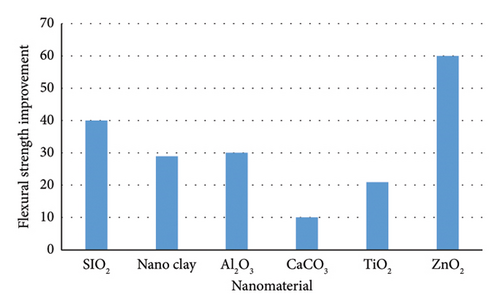

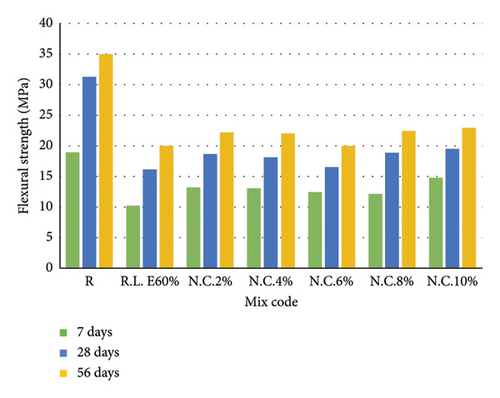

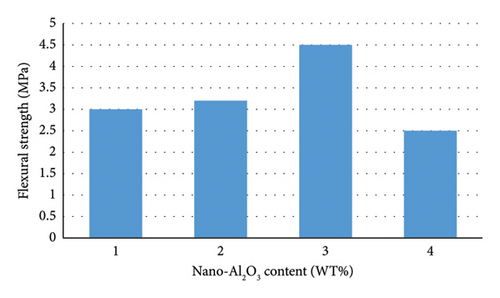

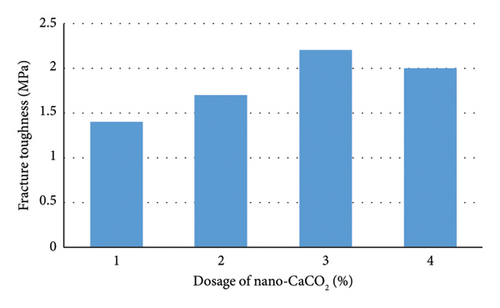

Flexural strength is one of the important properties of concrete, and the concrete mix must be designed in an amount commensurate with the requirements of ASTM No. C78 and C293. Many researchers have been using a lot of natural and industrial materials in the concrete mixture to enhance the bending properties of the concrete; some of them got good results, and others failed to achieve their goal of enhancing this property. After the advent of nanomaterials, some researchers resorted to using them to enhance the mechanical properties of concrete, including bending resistance, Figures 4, 5, 6, 7, and 8 and Table 4.

| No. | Nanomaterials used | Replacement % of nanomaterials | Flexural strength before adding nanomaterials (MPa) | Flexural strength after adding nanomaterials (MPa) | % Improvement | References |

|---|---|---|---|---|---|---|

| 1 | Nanosilica | 3 | 12.9 | 19.8 | +53 | [36] |

| 0.1 | 3.75 | 5.5 | +47 | [37] | ||

| 3 | 11 | 18 | +63 | [46] | ||

| 2, 4 | 9.2 | 14.1 | +53 | [39] | ||

| 2 | Nanosilica + metakaolin | 10% MK + 1% NS | 5.43 | 7.7 | +42 | [44] |

| 3 | Fe2O3 | 1.5 | 4.7 | 6 | +28 | [47] |

| 4 | Ni ferrite | 2 | 20.1 | 22 | +9 | [36] |

| 5 | Cu-Zn ferrite | 2 | 19.2 | 19.7 | +2 | [36] |

| 6 | Nano-ZnO2 | 4 | — | — | +59 | [45] |

| 7 | CaCO3 TiO2 | — | — | — | +10 | [45] |

| 8 | TiO2 ZnO2 | 5 | — | — | +22 | [45] |

| 9 | Nanoclay | 20 | 6.5 | 8 | +23 | [48] |

| 5 | — | — | +29 | [45] | ||

| 10 | Nano-CaCO3 | 0.5 | 7.12 | 8.73 | +22 | [49] |

| 11 | Nano-TiO2 | 2 | 7.12 | 8.57 | +20 | [49] |

Mohseni et al. [50] studied the effect of nanoaluminum and rice husk ash on flexural strength. Nanoaluminum and rice husk ash were added in proportions of (1%, 2%, 3%) and (19%, 20%, 30%), respectively. The maximum bending resistance recorded in this study was when (3% NS + 10% rice husk ash) was added, where the bending strength recorded an improvement value of 41%. The researchers attributed this improvement to the improvement of the microstructure, density, and homogeneity of the mixture.

Elrahman et al. [39] studied the effect of NS on the flexural strength of light concrete. Two doses (2% and 4%) were used. The 4% NS ratio was ideal for giving the best flexural strength, with an improvement rate of up to 25% when compared with the reference mixture. The study also showed that resistance remained stable at this point when evaluated at 90 days.

Ghanbari, Kohnehpooshi, and Tohidi [51] studied the effect of NS on the flexural strength of concrete. Three mixtures were designed, each containing (2%, 4%, and 6%) NS. The researchers noted that the highest bending resistance recorded at 28 days of age was 35% when 4% NS was added. Improvement in microstructure, density, and bonding of components was the main reason for this condition. In addition, improving the contact area between the aggregate and the cement paste increased the strength of their adhesion, thus increasing the bending resistance.

Hamad and Sarhan [52] published a study on the effect of NC on the flexural strength of concrete. The models were evaluated at 7, 28, and 56 days of age. The researchers used doses of (2%–19%) NC. The researchers found that 10% NC gave the best results. The highest improvement in bending resistance (16%) was recorded at 56 days.

Oh et al. [15] explored the effect of CNTs at different percentages (0.05%, 0.15%, and 0.45%) on flexural strength when mixing them with NS at percentages (0.2%, 0.6%, and 1%). The improvement rate ranged between 10% and 50% when using both nanomaterials. The highest bending resistance was recorded when 0.15% CNTs + 0.2% NS were added, where the improvement amounted to 90%. The researchers noted that increasing the nanoparticle content leads to a decrease in flexural strength.

Othman Mydin et al. [53] used nanoscale calcium carbonate to demonstrate its effect on flexural strength. The researchers added (1%–6%) of CCNP. The study showed an improvement in mixtures from 7.2%–58.75%. 4% was ideal and gave an improvement in bending resistance of 64%. The researchers explained that the reason for this improvement is due to the strength of the calcium carbonate network, which led to improved contact between the particles and thus increased flexural strength.

2.4.5. Improvement of Tensile Strength for Concrete

Nanomaterials, such as NS, polypropylene fibers, and various nanoparticles, have been found to improve the tensile strength of concrete, Table 5. Studies have shown that the addition of NS to concrete mixes can significantly increase the initial compressive strength and splitting tensile strength of the concrete, leading to improved mechanical properties [55]. Similarly, the use of NS material and polypropylene fibers in concrete mixes has been found to enhance the split tensile strength and flexural tensile strength of the concrete [56]. Additionally, the addition of nanomaterials like nanocement, NS fume, nano-fly ash, and NMK as partial replacements for cement has been shown to improve the impact strength of concrete at elevated temperatures [56]. Overall, the incorporation of nanomaterials in concrete has demonstrated the potential to enhance its tensile strength and durability, making it a promising approach for improving the quality of traditional concrete [57].

| No. | Nanomaterials used | Replacement % of nanomaterials | Tensile strength before adding nanomaterials (MPa) | Tensile strength after adding nanomaterials (MPa) | % Improvement | References |

|---|---|---|---|---|---|---|

| 1 | — | 4 | — | — | +41 | [45] |

| — | 2 | 19.3 | 27.8 | +45 | [54] | |

| Nanosilica | 3 | 4.1 | 6.9 | +68 | [36] | |

| 3 | 8 | 13.8 | +72 | [46] | ||

| 2 | Ni-ferrite granite | 10 | 4.1 | 8.5 | +107 | [36] |

| 3 | Cu-Zn ferrite | 10 | 4.1 | 8.5 | +107 | [36] |

| 4 | Nanosilica + nanometakaolin | NS 1%–2% + MK 5%–10% | 5.25 | 6.5 | +24 | [44] |

| 5 | Nanometakaolin | 10 | 3.2 | 4.3 | +(8.46–34.35) | [42] |

The main reason behind the improvement of the mechanical properties of concrete when adding nanomaterials is the improvement of the porous structure of the cement matrix and ITZ through the formation of C-S-H. The use of nanomaterials such as NS increased the compressive strength of concrete. Studies showed that using nanomaterials reduced the workability of concrete and its flowability.

Saad et al. [58] showed the effect of NS on tensile strength. Different doses of NS were used (0.75%, 1.5%, and 2%) by weight of cement. All doses recorded an improvement in tensile strength, but the highest improvement in strength was recorded when adding 2% NS, where the improvement rate reached 45% at the age of 28 days, and as the age increased, the tensile strength increased.

Mansi et al. [59] studied the effect of CNTs on the tensile strength of concrete containing geopolymer and basalt fibers. The researchers noted that the tensile strength increased by 32% over its counterpart without CNTs and that the highest tensile strength chosen was when adding 0.15% CNs + 0.6% basalt fibers. The researchers found that CNTs reduced cracks and formed a dense structure, which enhanced tensile strength.

Othman Mydin et al. [60] published a study on the effect of nano-iron oxide (Fe2O3) on tensile strength. The researchers used different doses ranging from (0.1%–0.%3). The study recorded the highest increase in tensile strength (51%) when adding 0.25% nano-iron oxide at 56 days of age. The improvement in tensile strength came due to the production of large quantities of calcium hydrate (S-C-H), which is responsible for the strength of concrete.

Hong et al. [14] studied the effect of doses of NGO on tensile strength. Five doses were used (0.02%, 0.04%, 0.05%, 0.06%, and 0.08%). A dose of 0.05 achieved an improvement of 24%, which is the highest tensile strength. Consumption of calcium hydroxide by NGO and production of calcium hydrate played the main role by increasing the tensile strength.

Ali and Awad [61] studied the effect of NS on the tensile strength of lightweight concrete. Doses less than 1% were used in this study. Forms are evaluated for up to 90 days. The study showed that adding NS at various doses enhanced tensile strength for all ages, but the highest improvement rate (11%) was recorded when 1% was added at 90 days. Ali justified this improvement to the improvement of the transitional zone between the aggregate and the cement paste, which improved the microstructure and thus increased the tensile strength.

Nanomaterials such as nano-SiO2, nano-Fe2O3, nano-TiO2, NC, and nano-Al2O3 have been found to be effective in improving the tensile strength of concrete [62]. Nanoparticles have a high potential for enhancing concrete properties due to their small fragment size and increased surface area [33]. In particular, nano–titanium dioxide and nanoalumina have been shown to significantly improve the tensile properties of concrete members, with ultimate tensile strengths reaching 11.54 and 9.56 MPa, respectively [17]. Additionally, nano–titanium dioxide and nanoalumina can be used to replace cement in concrete, reducing its carbon footprint and improving its mechanical response [63]. Overall, the addition of nanomaterials such as nano-SiO2, nano-Fe2O3, nano-TiO2, NC, nano-Al2O3, nano–titanium dioxide, and nanoalumina can effectively enhance the tensile strength of concrete.

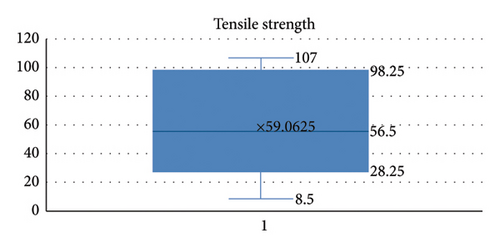

Finally, the key findings from the mentioned studies provide some statistical components, Table 6.

| Compressive strength studies | Flexural strength studies | Tensile strength studies |

|---|---|---|

|

|

|

|

|

Aseel et al. [59]: increase in tensile strength: 32% with 0.15% CNs + 0.6% basalt fibers |

| Al-Athkari et al. [26]: optimal mix: 2% CNT |

|

|

|

|

|

|

|

|

|

|

|

|

Liu et al. [32]: 1-day strength increase with 0.3 wt% C-S-H seeds and NS | |

|

||

| Funk et al. [31]: 1% nanosilica: increase by 14% at 28 days | ||

2.4.5.1. General Observations

Nanomaterials Impact: Nano-SiO2, nanoalumina, NMK, CNTs, and various oxide nanoparticles effectively improve the compressive, flexural, and tensile strengths of concrete.

Optimization: Optimal dosages are critical, with variations affecting strength positively or negatively.

Early Strength: Some nanomaterials show significant improvements in early compressive strength.

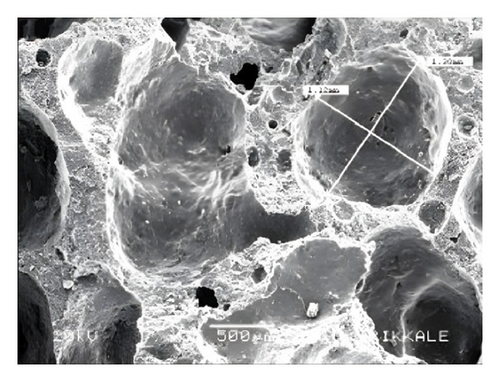

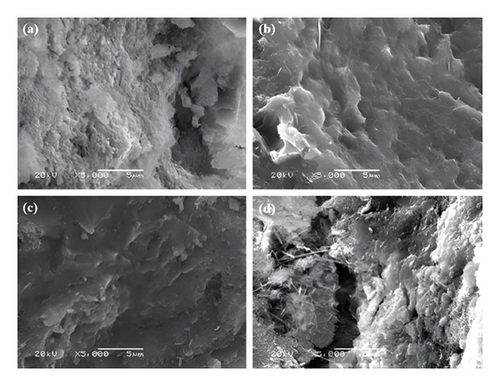

2.4.6. Improvement of the Microstructure of Concrete

The microstructure of concrete can be improved through the incorporation of nanomaterials, such as NS and NC, which enhance the hydration reaction and promote the formation of more hydration products [30]. These nanomaterials act as fillers, making the concrete matrix more compact and uniform, resulting in a decrease in porosity and an increase in packing density [32]. Additionally, nanomaterials provide extra nucleation sites, leading to the generation of more C-S-H gel clusters and a finer pore structure [29]. The improved microstructure of the concrete matrix, achieved through the refinement of microcracks and pore filling, enhances the homogeneity and compactness of the concrete [31]. This, in turn, improves the mechanical properties and durability of the concrete, making it more resistant to deterioration and extending its service life [4].

Wang et al. [64] used three types of nanomaterials (nanoaluminum (Al2O3), NMK, and NS) to investigate their effect on the ITZ between aggregate and cement paste. The researchers found that the best additive was NS among the three materials. The researchers found that NS increased the bond strength of concrete by 109% when compared with the reference mix. The researchers indicated that the rest of the materials, such as NMK, improved the bond strength, but by 31%, and Al2O3, by 20%.

Onizaz et al. [4] studied the effect of calcined NAT. The researchers found that the nanomaterial filled the cracks and pores inside the concrete mortar and the ITZ, and thus improved the harmful pores and cracks as well as the density, which reflected positively on the strength of the concrete.

Goel et al. [33] published a review to demonstrate the effect of nanomaterials on concrete. The study showed that many nanomaterials have been found to enhance the pore structure and density of concrete, acting as a filler and reducing porosity.

Huo et al. [65] studied the effect of nano-SiO2 and nano-Al2O3 on concrete microstructure. The researchers observed that the addition of nanomaterials increased the gelatinous products containing calcium in the geopolymer concrete matrix, resulting in a denser and more uniform microstructure. The researchers found that this improvement was due to reducing the number of pores and their fractal dimension. The researchers found that increasing the dose of NS leads to agglomeration of the material, which weakens the microstructure and creates heterogeneity in it.

Wang et al. [66] found that adding nanomaterials has a positive effect on concrete that contains recycled bricks. The researchers found that concrete devoid of nanomaterials contains small cracks and defects in the concrete, especially the interstitial area between the aggregate and the cement paste. The SEM examination showed that the nanoconcrete was denser and had fewer cracks due to nanomaterials filling these cracks and that the transition zone was more compact and durable.

Du et al. [67] studied the effect of NS and nano–iron oxide, together and individually, on the microstructure of concrete. The researchers found that the ideal percentage (3.45% NS, 4.24% nano–iron oxide) that achieved the highest strength of concrete was the same and showed the best improvement in microstructure. The researchers also found that the two nanomaterials improved the microstructure when added individually. The researchers justified this improvement by saying that the nanomaterials filled the small pores, making them more cohesive.

Kishori et al. [68] studied the dispersion and agglomeration of nanomaterials in geopolymer concrete and its effect on the microstructure and thus its effect on the strength of the concrete. Through the researchers’ use of the transmission electron microscope (TEM) technique, the researchers found that the dispersion of nanomaterials is of great importance for concrete, as it helps speed up the interaction with concrete components and the formation of C-S-H, which is responsible for strength, and that their agglomeration forms weak areas and hinders the performance of the compounds.

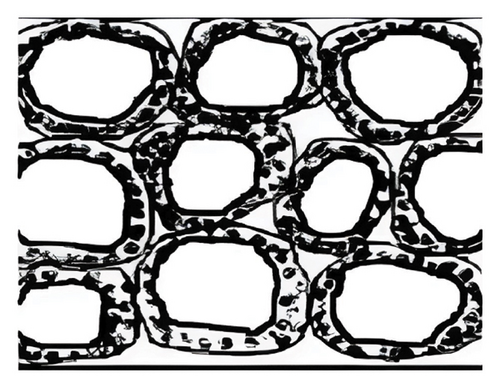

Chen et al. [69] studied the effect of adding nano–calcium carbonate (CaCO3) (CN) to concrete reinforced with polypropylene fibers. The results showed that NC improved the concrete hydration rate and heat of hydration in the early stage, and also participated in the chemical reactions of hydration in the late stages, which enhanced the hydrate production and microstructure, Figure 8, 9, and 10 [70, 71].

2.4.7. Effect of Nanomaterials on Water Absorption of Concrete

Al-Jabri and Shoukry [72] published a study on the effect of NMK on water absorption. The results showed that the use of the additive reduced water absorption. This is attributed to the improvement of the microstructure of the concrete mixture. It is known that the microstructure improves due to the pozzolanic interactions of the cement dough.

Diab et al. [73] studied the effect of NMK and NS on the water absorption capacity of HPC. The researchers added nanomaterials in different doses. The researchers found that adding NS reduced water absorption by (7%, 11.4%, 16.8%, and 21.1%) for mixtures containing (0.5%, 1%, 1.5%, and 2%), respectively, compared to the reference mixture. The researchers also showed that using NMK had the same effect on water absorption when using the same doses. The researchers attributed the reason for this decrease to the increase in solid volume and improvement of the microstructure, which in turn reduces the movement of water within the concrete.

Vanitha et al. [74] published a study on the effect of nano-TiO3, Al2O3, and CaCO3 on water absorption capacity. The researchers found that NT reduces water absorption by (4.5%, 7.5%, and 13.6%) when used by (2%, 4%, and 6%), respectively, when compared with the reference mixture. The study also showed that the effect of NC was clear, as the water absorption rate decreased by 16%, 23%, and 31% when doses of 2%, 4%, and 6% were used. In addition, the study showed that nanoaluminum was the most effective additive in reducing water absorption. The percentage of decrease in water absorption reached (31%, 35%, and 38%) at levels of (2%, 4%, and 6%). The researchers justified that the reason for this decrease was that nanomaterials filled the tiny gaps, which impeded the transfer of water.

Abdullah et al. [75] studied the effect of several nanomaterials on the ability of concrete to absorb water. The researchers found that incorporating 2% NS reduced water absorption by 85%, while 0.08% CNTs reduced water absorption by 36%. Also, NGO reduced water absorption by 46% when a dose of 0.8% was added to it. 3% nano-calcium carbonate reduced water absorption by 65–70%. Adding 4% of nano–iron oxide achieved a reduction in water absorption of 74%, while nanoalumina had a negative effect on water absorption.

2.4.8. Improvement of Sulfate and Chloride Penetration of Nanoconcrete

Diab et al. [73] studied the effect of NMK and NS on the sulfate resistance of HPC. The researchers added nanomaterials in different doses. The researchers found that adding NS reduced the loss of compressive strength by 4.6%, 11%, 15%, and 18.6% for mixtures containing 0.5%, 1%, 1.5%, and 2% NS, respectively, compared to the reference mixture. Adding doses of NMK also showed the same effect, as the amount of loss of compressive strength was reduced by 11.4%, 20.7%, 32.5%, and 41.4% for an NMK content of 1%, 3%, 6%, and 9%. This positive improvement was linked to suppressing the growth of gypsum and ettringite when exposed to sulfates.

Maiti et al. [76] presented a study on the effect of NT permeable geopolymer concrete against chlorides and harmful compounds. The study showed that adding NT increased the ability of geopolymer concrete to resist the penetration of chlorides, which contributes to the possibility of treating the environment. It also increases the possibility of using geopolymer concrete modified with NT in combating water pollution.

Abdullah et al. [75] studied the effect of several nanomaterials on the ability of concrete to resist chloride permeation. The researchers found that incorporating 0.3% NS increased concrete’s resistance to permeability by 29%, while incorporating 0.03% GO reduced chloride penetration by 52%. The researchers noted that CNTs (0.05% to 0.1%) reduced the penetration of chlorides by 12%. Nano-iron oxide (2%) reduced the permeation of chlorides into concrete by 44%, while NT reduced the permeation of chlorides by 88%.

Wu et al. [77] developed concrete containing capillary crystalline cement insulation agents and studied the effect of five compounds including NS (EDTA, aspartic acid, sodium sulfate, sodium silicate, and NS) on the permeability of concrete. The researchers determined the ideal amounts for each compound (0.5 EDTA, 2% aspartic acid, 3% sodium sulfate, and 2% sodium silicate). The resistance of concrete against penetration was enhanced by EDTA 225%, L-aspartic acid 200%, sodium sulfate 150%, sodium sulfate 130%, and NS 125%. It was found that NS enhanced the penetration resistance by 125%. This is a positive development that indicates the effectiveness of nanomaterials in enhancing the properties of concrete against the penetration of harmful substances.

Qu et al. [78] studied the effect of NS and NT on enhancing concrete resistance against chlorides and carbonation. Nanomaterials have been used to enhance concrete coatings. The results indicated a significant improvement in resistance to carbonation and chlorides, as penetration decreased by 38% and carbonation by 12.8%. The researchers also noted that nanomaterials reduced the damage of ultraviolet rays. Moreover, the study showed that the effect of NT on resistance to carbonation and chlorides is higher than the effect of NS.

Han et al. [79] studied the effect of CNTs on enhancing the resistance of concrete against chloride penetration. The researchers found that the diffusion coefficient and diffusion depth of chloride ions decreased by 19% and 26%, respectively, when incorporating a 0.15% CNT into concrete. The study showed that the additive improved the microstructure and thus reduced self-shrinkage and improved porosity and pore size distribution, which had a positive impact on resistance to chloride penetration.

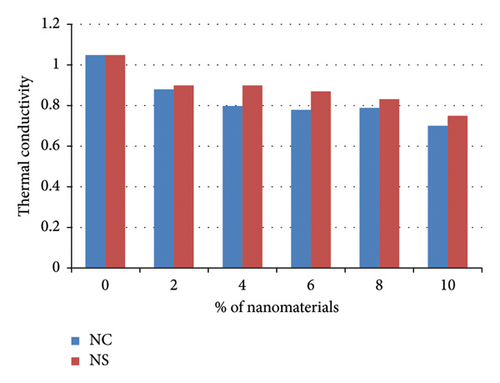

2.4.9. Improvement of Thermal Insulation of Concrete

The building and construction sector poses the greatest danger to the environment and to energy and natural resources. The reason is due to several factors, the most important of which is the consumption of large quantities of natural resources such as wood, stone, soil, rubber, and many other materials to comfort humans. The second main reason is the consumption of energy sources such as oil and its derivatives and electrical energy closely related to oil and its derivatives. As a result of providing the necessary electrical energy, large quantities of fuel must be consumed, which results in burning huge quantities of natural and industrial fuels, which causes pollution of the environment with carbon dioxide and the rest of the gases that pose the threat of the environment and increases the global warming. Therefore, it has become necessary to find radical solutions to reduce the emission of heat and toxic gases into the atmosphere and reduce the consumption of electrical energy and natural resources. The researchers sought to find a material with properties that enhance the ability of thermal insulation and resistance to high temperatures and are environmentally friendly. The researchers found that nanomaterials significantly improve the mechanical ability of concrete. When studying them in a focused manner, they found that they significantly improved the resistance of cement compounds to high temperatures. The nanosized materials contributed to the modulation of cement hydration, the degree of compaction of its structure, and the improvement of cement compounds’ mechanical and fracture properties, thus improving their strength and mechanical performance under high-temperature conditions, Figure 11.

Sikora, Elrahman, and Stephan [80] used nanomaterials in vacuum insulation panels or polystyrene foam, as they showed a significant decrease in the thermal conductivity coefficient, and the electrical energy consumption decreased to 23%, compared to ordinary insulated walls. On the other hand, nanoglass was applied instead of the two-layer glass used for insulation. This type of nanoglass saved approximately 11% of the value of the average energy consumption. If two layers were used, the insulation and conductivity would be reduced by less than half. In addition, when using insulating panels and insulating nanoglass, the study showed a decrease in energy consumption to 47.5%, with a decrease in thermal conductivity to more than half. This process was described as an efficient way to isolate buildings and consume less energy.

Bhutto, Alsaadi, and Erklig [81] studied the effect of NC and NS on the thermal properties of concrete. The study showed that adding NS and NC to the mixture reduced the thermal conductivity coefficient to 0.5%, indicating that using nanomaterials contributed to reducing heat transfer. The contrast in mitigating heat transfer between the materials above is noteworthy. The research demonstrates that incorporating NC results in a more pronounced reduction in the thermal conductivity coefficient compared to NS. This disparity arises from an augmented bonding between the matrix and the epoxy resin due to NS, alongside the influence of weight content.

Saleh et al. [40] published a study on the effect of NS on the thermal properties of concrete (thermal conductivity, specific heat capacity, and thermal diffusivity). The researchers used 3% (1%, 2%, and 3%). The results showed a clear decrease in thermal conductivity values from (0.9–0.5) W/m. Kelvin. The decline rates were 42%, 53%, and 66%, and the replacement rates were 1, 2, and 3, respectively. The highest reduction was achieved by a dose of 3%. In addition to thermal conductivity, heat capacity was measured, as it increased with higher replacement ratios. The increase in heat capacity recorded values of 21.5%, 24.25%, and 32.45% for the three ratios.

Babalu and Pimplikar [82] studied the effect of NS on the thermal properties of concrete. Three mixtures were designed containing NS (1%, 2%, 3%). The researchers noted that increasing the percentage of added nanomaterial reduces the conductivity coefficient. The percentage of decrease in the conductivity coefficient was 9%, 24%, and 39% when the dose was increased from 1%–3%. Another study showed that the thermal conductivity coefficient decreased from 15% to 59% when the dose of NS was increased. The researchers attributed this improvement in thermal insulation to the presence of air voids that prevent heat transfer. In addition, the air voids increase the ability of concrete to store heat without transferring it, which enhances thermal insulation.

2.5. Nanomaterials and Lightweight Concrete

Nanotechnology has been used with light concrete, which is a research case to consider whether there is any change in the properties of concrete. In a study prepared in 2020, NS was used with lightweight concrete to study its effect on mechanical properties (tensile strength, bending resistance, and compressive resistance). In addition, the improvements in the transport properties of light concrete and the thermal insulation properties were studied. The results showed that with the addition of NS to lightweight concrete, there was a significant improvement in the mechanical and transport properties of lightweight concrete; moreover, depending on the dosage of NS, it was found that it had a little decreasing effect on concrete shrinkage after 28 days of curing. Microstructure studies confirmed that using NS significantly affects the porous properties of concrete, resulting in dense concrete with a precise and strong structure [80]. The main reason behind improving the mechanical properties of light concrete when adding nanomaterials is the improvement of the porous structure of the cement matrix and ITZ through the formation of C-S-H. Using nanomaterials such as NS increased the compressive strength of lightweight concrete by 20%. Studies showed that using nanomaterials reduced the workability of concrete and its flowability. Lightweight concrete is known to have properties, characteristics, structure, and porous systems that differ from ordinary concrete, but with the use of nanomaterials, many of its defects can be eliminated [83].

Narasimhan et al. [24] indicated in their statement published in 2020 that adding nanomaterials to the concrete mixture increased the mechanical properties (compressive strength, tensile strength, and bending resistance) in most of the samples. Still, within known and specific ratios, they also showed that concrete density decreases when adding nanomaterials to the mixture.

In a study prepared by researchers in Egypt on lightweight structural concrete, it was shown that the addition of NS material enhanced the mechanical properties and that the ideal dose ratio was 0.75% of the weight of the cement. Enhancing the mechanical properties when adding NS is due to the enhancement of the microstructure and the bonding strength between the different concrete parts. The study showed that adding NS improved the bending behavior and the last ductile failure and delayed the first cracking time, which was attributed to the better correlation in the beam state. On the other hand, the study showed that the ideal ratio of the NS dose is affected by several factors, including the density of the lightweight aggregate, the water content, and the surface area of NS particles [58].

Zhang et al. [37] published a study indicating the possibility of changing the mechanical properties of lightweight concrete when adding nanomaterials, even if the dose is much lower than the weight of cement. The microstructure analysis showed that increasing the dose of nanomaterials from the upper limit causes a decrease in the reinforcement effect. The study showed that the enhancement of the mechanical properties of lightweight concrete when adding nanomaterials is due to the formation of a new type of hydration product, and it is in the form of fibers in the interfacial region between the lightweight aggregate and the cement paste, which works to strengthen the light concrete.

2.5.1. Background of Lightweight Concrete

Over two thousand years have passed since the invention of lightweight concrete. Its technical development is still going on. Although it is well known that it has the potential to perform well in these areas, there are still many uncertainties and hesitations in its implementation. One of the main challenges the developers face is adapting lightweight concrete’s design and production rules to accommodate their varying requirements [84].

Lightweight concrete is not considered one of the modern achievements, but it has been known since ancient times, as it was invented two thousand years ago. The first references to light concrete were invented in the early Roman Empire, and there are pillars of these buildings until now, such as the Pantheon in Rome, one of the most famous buildings in this style, as it showed wonderfully the regular use of lightweight natural aggregates. In the 19th and 20th centuries, lightweight concrete became a historical turning point that kept pace with materials and technology [84].

The successful use of lightweight concrete in shipbuilding greatly aided its introduction into the construction industry. The first factory to produce expanded aggregate was established in 1920 in Kansas, USA, where experiences have proven that the quality and uniform composition of industrially produced aggregate is more beneficial than natural aggregate. Expanded slabs have been used as lightweight concrete on many bridges. More than 200 lightweight concrete bridges have been built in the United States and Canada. In the middle of the twentieth century, the use of lightweight concrete increased in structural engineering, as the high-rise Marina City Towers building in Chicago is considered one of the distinctive buildings built with light concrete, and the Prudential Plaza building is also one of the giant towers in light concrete. Its concept has remained largely confined to individual cases despite using light concrete for structural reasons. Technical regulations for lightweight concrete were modified in the nineties in Germany, which witnessed a qualitative leap due to the issuance of these new regulations and the continued development of science and technology. Despite all these improvements, the number of buildings and facilities remained relatively low in terms of the use of light concrete. Recent developments have focused on reducing concrete density while retaining as high and sufficient strength as possible. Monolithic structures made of lightweight concrete with a glazed face have recently gained great popularity in Europe. Low density, high resistance to loads and fires, and excellent durability are the main characteristics of the promising material. Recent developments aim to find appropriate solutions for thermal insulation using lightweight concrete, as this technology has helped many engineers and researchers to find appropriate solutions without the need to add insulating layers to the origin. However, obtaining this concrete requires technical approvals related to the project [84].

2.5.2. Properties of Lightweight Concrete

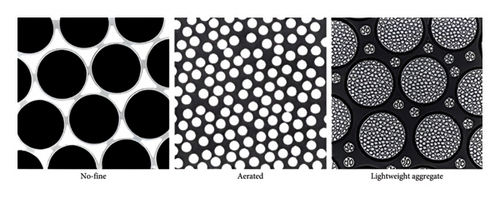

- •

Fine Aggregate Free Concrete is a lightweight concrete invented in 1924 by WIMPEY in the United Kingdom. This method consists of removing the finer part of the weight of the natural fine aggregate to create gaps that will reduce weight.

- •

Foam or cellular concrete, which is concrete that contains in its structure approximately 30% to 50% of voids.

- •

Lightweight concrete containing lightweight aggregate. This concrete is formed by replacing the usual natural coarse aggregate, in whole or in part, with lightweight aggregate having many voids.

These properties of lightweight concrete can be exploited in several ways as a structural material primarily or used to enhance thermal insulation when incorporated into the structure. In this research, lightweight concrete with lightweight aggregate will be one of the most important materials used in thermal insulation and reducing the conductivity coefficient because of its great insulating properties, as shown in Figure 12 [85].

2.5.3. Types of Lightweight Concrete

Three types of lightweight concrete will be mentioned.

2.5.4. No-Fine Aggregate Concrete

Concrete free of fine aggregates has a relative density that varies according to the different mixing ratios, as its proportion decreases by increasing the cement, coarse aggregate, and water content. The relative density of concrete free of fine aggregate ranges from 1770 to 2015 kg/m3, and this density is much lower than the density of ordinary concrete, which is 2400 kg/m3, due to its high nails. As for the porosity, it is affected by the difference in the size of the coarse aggregate in the concrete mixture, where studies have shown that the porosity of concrete free of fine aggregate ranges between 27% and 36%. Figure 13 [86] shows a sketch of no-fine concrete. As for its mechanical properties, most studies focused on compressive strength depending on the type and size of coarse aggregate, as well as the weight of the concrete unit free of fine aggregate, the ratio of water to cement, and aggregate to cement. Studies have shown that the greater the volume of the coarse aggregate, the greater the compressive strength. Most of the mixing ratios that have been studied in which the compressive strength is lower than the compressive strength of ordinary concrete due to its low density. The best compressive strength for this type of concrete is 11.25 MPa. From the above, we conclude that light concrete free of fine aggregate cannot be used in structural parts that need high compressive strength, but it can be used in some nonstructural parts and for thermal insulation purposes [86].

2.5.5. Aerated Concrete

Many factors affect the strength of structural concrete. The sample size, shape, water content, properties of concrete components, method of concrete formation, loading direction, and curing method all affect the compressive strength of aerated concrete [70].

Aerated lightweight concrete does not contain coarse aggregate, and the difference in mixing properties is one of the most important features that distinguish it from ordinary concrete, its low density with high strength, and thermal and sound insulation. The lightness of the concrete weight reduces the dead load on the other concrete parts, which enhances this by reducing the structural elements, which reduces the loads on the foundations and increases its endurance [87].

2.5.6. Lightweight Aggregate Concrete

This concrete consists of cement, water, fine aggregate, and lightweight aggregate, completely or partially replaced with the usual heavy aggregate. The main purpose of using lightweight aggregate is to reduce the overall density of concrete, which in turn reduces the dead weight on the structure and, at the same time, increases the thermal insulation of concrete. Lightweight aggregates can be natural, such as scoria or pumice, as the origin of this aggregate is volcanic stones, or they can be made, such as kiln slag, vermiculite aggregate, and clinker. This aggregate is characterized by high porosity, which is used to reduce the total weight of concrete [88].

2.6. Improvement of Mechanical Properties of Lightweight Concrete by Using Nanomaterials

Recently, nanomaterials have been widely used to enhance the properties and behavior of concrete. The small size of nanomaterials enables them to improve the microstructure of concrete, which enhances its mechanical and physical properties and behavior. Many past and current studies are looking at adding nanomaterials to concrete and studying its effect on its properties and when the added percentages are useless. Nowadays, many researchers have added nanomaterials to lightweight concrete to enhance its behavior and improve its mechanical, physical, transport properties, and microstructure. The effect of nanomaterials on lightweight concrete will be clarified in terms of mechanical and physical properties, and the extent of their impact and the reason will be explained [89].

2.6.1. Improving Compressive Strength for Lightweight Concrete

Narasimhan et al. [24] studied the effect of CNTs and NS on compressive strength. Lightweight concrete is designed using expanded clay as a lightweight coarse aggregate. The researchers found that the LWC samples added to 1% NS and 2% CNTs gave the maximum compressive strength, as the improvement rate was 39% higher than the reference mixture. The results showed that increasing the additives more than the ideal percentage reduced the compressive strength to 16% higher than the reference mixture.

The impact of nano- and microsilica on the compressive strength of light concrete was examined by Afzaleh et al., 2029. Three different combinations were created, with 1%, 3%, and 5% NS in each; 10% of the microsilica was also included. The two additives were utilized both singly and in combination by the researchers. The researchers discovered that while mixing the two materials increased the compressive strength, doing so alone did not. When 3% NS and 10% microsilica were combined to create the optimal mixture, the improvement rate over the reference mixture was 31% [1].

Sugumaran et al. [27] published a study on the effect of NMK as an additive on the compressive strength of lightweight concrete. The researchers found that using this material by 15% improved the compressive strength by 15% when compared with the reference mixture. The researchers justified this improvement to the strengthening of the microstructure as well as the pozzolanic interactions that produced abundant calcium hydrate responsible for strength. In addition, the ITZ between the aggregate and the cement paste is improved.

Hong et al. [90] on the effect of using NGO in different proportions on compressive, tensile, and bending resistance. The results showed that using NGO, material increased the compressive strength in varying proportions according to the amount of NGO replacement from the cement weight. The results showed that the best compressive strength was obtained when replacing the NGO by 8% at 56 days, as the compressive strength increased by 24% compared to the reference mixture, as shown in Figure 14. This increase is because the nanomaterials regulated the formation and growth of flower-like crystals and filled the pores.

Zhang et al. [37] published an article about using NS in very low doses and investigating the improvement in concrete’s mechanical and physical properties. The results showed that the use of 0.1% of NS gave the best results for compressive strength when compared with the reference mixture, as well as when compared with other percentages of NS, where the compressive strength increased by up to 41%, as shown in Figure 14.

Najaf et al. [56] published about the addition of NS in lightweight concrete and its effect on compressive strength, and it was found that replacing 3% of NS increased the compressive strength to more than 47% at the age of 28 days when compared with the reference mixture, and then, the resistance begins to decrease when the dose of NS is increased.

Nour El-Din et al. [91] published an article about using NS material and studied its effect on lightweight concrete. They found that the optimal ratio that gave the best results for compressive strength is 3%, and then, higher percentages give a decrease in compressive strength. Nour El-Din et al. showed that doses of less than 3% are very useful for increasing compressive strength and that doses higher than 3% are useless, as shown in Table 7, Figure 15.

| No. | Nanomaterials used | Replacement % of nanomaterials | Compressive strength before adding nanomaterials (MPa) | Compressive strength after adding nanomaterials (MPa) | % Improvement | References |

|---|---|---|---|---|---|---|

| 1 | Nano–graphene oxide | 2, 4, 6, 8 | 55 | 69 | +25 | [90] |

| 2 | — | 0.2 | 29 | 35 | +21 | [37] |

| — | 3 | 38 | 64 | +68 | [56] | |

| — | 3 | 32.5 | 39 | +20 | [91] | |

| Nanosilica | 2-3 | 12.7 | 18.5 | +45 | [92] | |

| 3 | 61 | 66 | +8 | [93] | ||

| 2 | 12.7 | 18.5 | +46 | [54] | ||

| 1, 2, 3 | 12 | 18 | +50 | [89] | ||

2.6.2. Improving Flexural Strength for Lightweight Concrete

Nazari et al. [47] concluded that replacing 1% of nano-ferric material with lightweight concrete enhanced the flexural strength by 27% at the age of 90 days. The results also showed that increasing the replacement dose of nano-ferric material reduces the bending resistance, so 1% of nano-ferric material is considered the best replacement ratio.

Salman et al. [94] studied the effect of adding NT to lightweight concrete and investigated whether there was an improvement in the bending property of lightweight concrete. The results showed that the percentages of NT (0.25% and 0.75%) increased the bending resistance, and the best percentage added was 0.75%, as it improved the bending resistance by 15.1%. An increase of more than 0.75% of NT reduced the flexural strength, but there was an improvement when compared with the reference mixture, as shown in Table 8.

| Name | TiO2 | 7 days (MPa) | Enhanced extent (%) | 28 days (MPa) | Enhanced extent (%) |

|---|---|---|---|---|---|

| CM0 | 0 | 3.9 | — | 5.3 | — |

| NM1 | 0.25 | 4.4 | 12.8 | 5.8 | 9 |

| NM2 | 0.75 | 5.1 | 30.7 | 6.1 | 15.1 |

| NM3 | 1.25 | 4.5 | 15.4 | 6.0 | 13.2 |

| NM4 | 1.25 | 4.2 | 7.7 | 5.7 | 7.5 |

Zhang et al. [37] used NS in very low doses and studied the effect of the nanomaterial on flexural strength. The study showed that adding NS in doses (0.1%–0.5%) increased the bending resistance, especially by 0.2%, which gave the best results compared to the rest of the ratios. Increasing the dose by more than 2% has reduced the bending resistance, which indicates that the optimum ratio is 2%.

Alomayri [95] conducted a study on combining nanoalumina with geopolymer pastes in doses of 1% and 2% and showed that the bending strength increased by 5.6% when adding 1% nanoalumina and 44.5% when adding 2% nanoalumina. In the same study, Alomayri indicated that adding calcium carbonate nanomaterials in doses of 1%, 2%, and flexural strength increased by 88% and 151%, respectively. The study also showed that using calcium carbonate with glass fibers gave better flexural strength when compared with mixing nanoalumina only in concrete, as shown in Figure 16.

Hong Lee and Qian [90] published an article on the use of NGO in lightweight concrete and showed the effect of the nanomaterial on flexural strength. The results showed that the addition of 8% of NGO gave an increase in bending resistance of up to 20% when compared with the reference mixture, which is the highest result obtained when adding different percentages of nanomaterials (2,4,6%), respectively, as shown in Figure 17.

Alomayri and Adesina [96] stated that the addition of calcium carbonate nanoparticles to geopolymer pastes at a rate of 2% gave the best results in resisting bending, but when the dose was increased to more than 2%, the resistance to bending began to decrease. Alomayri explained in his article that the reason for the increase in the bending resistance was due to the improvement of the microstructure of the geopolymer upon the addition of nano-calcium carbonate, as well as the acceleration of the polymerization reaction, which works to densify the matrix. Al-Omairi indicated that the decrease in flexural strength when increasing the dose to 3% is due to the agglomeration of the nanoparticles, as shown in Table 9 and Figure 18.

| No. | Nanomaterials used | Replacement % of nanomaterials | Flexural strength before adding nanomaterials (MPa) | Flexural strength after adding nanomaterials (MPa) | % Improvement | References |

|---|---|---|---|---|---|---|

| 1 | Nano–graphene oxide | 2, 4, 6, 8 | 5.45 | 6.3 | +21 | [90] |

| 2 | Nanosilica | 0.1 | 3.75 | 5.25 | +40 | [37] |

| 3 | Nano-Fe2O3 | 1 | 4.7 | 6 | +27 | [47] |