Thermal Efficiency and Water Output Improvement in Modified Solar Distillers: A Comparative Study

Abstract

This study evaluates the performance of a solar distiller-assisted by a concentrator system (SDACS) compared to a controlled solar distiller (CSD). Analysis of the temperatures of the distillers revealed that the SDACS maintained higher temperatures throughout the experiment, with the maximum water temperature reaching 86.3°C, compared to 76.1°C for the CSD. This improved thermal retention contributed to significantly higher hourly and accumulated water outputs in the SDACS, which reached 480 mL/h and a total accumulation of 5404 mL, respectively, compared to 192 and 1955 mL for the CSD. The SDACS also demonstrated higher thermal efficiency, peaking at 180% compared to 60% for the CSD. In addition, the exergy efficiency of the SDACS was significantly higher, reaching 12.39% compared to 3.32% for the CSD. The SDACS distiller yields much higher revenue than the CSD distiller due to its increased output, offering a short payback period of approximately 4 months and a strong return on investment (ROI) of 308%. These results highlight the effectiveness of the design improvements of the SDACS, which significantly improve its ability to convert solar energy into thermal energy and useful work, resulting in overall performance and production efficiency in freshwater.

1. Introduction

Access to clean and safe drinking water is crucial for human health and well-being, yet many regions face challenges from water scarcity and pollution. These issues complicate efforts to meet basic water needs, highlighting the importance of developing accessible and effective water treatment solutions. Such methods aim to eliminate impurities, contaminants, and harmful microorganisms to ensure water quality and safety. While traditional methods like filtration, chemical treatment, and disinfection are widely adopted, they often require complex infrastructure, substantial energy, and chemical additives. This makes them less practical and economically viable for regions with limited resources [1].

Utilizing solar energy, solar distillation leverages the natural processes of evaporation and condensation to transform contaminated or saline water into potable water [2, 3]. Solar stills, which capture solar radiation to drive this process, provide a sustainable and natural solution to water treatment challenges [4].

To enhance the efficiency of solar stills, researchers are exploring various methods that leverage materials with high thermal conductivity. Incorporating materials like pebbles, basalt, and aluminum dross has shown promising results; aluminum dross, in particular, significantly boosted productivity, thermal efficiency, and environmental sustainability, despite a slightly higher annual cost [5].

Other innovations include modifications to heating components, such as using phase change materials (PCMs), nanomaterials, and wicks, which further improve the heat transfer and retention properties within the still. As reviewed in recent studies, these components can increase productivity by up to 370% depending on the configuration, demonstrating solar stills’ adaptability to different climates and usage needs [6]. For example, natural carbon blocks have also been found effective. By adding these blocks to the still, researchers achieved an 8% increase in productivity due to improved heat absorption and retention [7].

To enhance the efficiency of solar stills, researchers are exploring various methods that leverage materials with high thermal conductivity. Adding such materials to the water improves heat transfer within the still, boosting evaporation and increasing overall distillation efficiency. For example, integrating metal fins expands the heat exchange surface, significantly accelerating evaporation rates [8, 9]. Similarly, PCMs are valued for their thermal storage capabilities, maintaining stable temperatures during phase transitions and optimizing the distillation process [10, 11]. Additionally, incorporating nanoparticles into the water enhances thermal conductivity due to their high surface area and excellent heat transfer properties, further improving distillation performance [12, 13].

Other straightforward modifications to solar stills have also proven beneficial. Adjusting the thickness and angle of the glass cover, for instance, optimizes solar exposure and improves heat retention [14, 15]. Further enhancements include positioning refractors to direct more sunlight onto the still, thus increasing efficiency [16, 17].

Beyond structural innovations, a range of materials has been tested within solar distillation systems to assess their impact on water production. Improvements vary, with zinc showing a notable enhancement in efficiency [18]. Other materials, such as aluminum, sponge, and palm fiber, offered moderate improvements, with rates of 33.32%, 10%, and 36%, respectively [19–22]. Additional materials like rubber, cellulose cardboard, and carbon have also been studied for their efficiency contributions, with carbon displaying impressive rates between 18.18% and 79.39%, making it one of the most effective additives for solar stills [23].

Despite their advantages, traditional basin-type solar stills have relatively low efficiency. To address this, researchers worldwide are developing strategies to improve their performance, especially in hot regions. A study conducted in a cold Indian locale demonstrated that active solar stills systems, supplemented with external energy sources, achieved double the daily output of passive systems. Energy and exergy efficiencies in these active systems ranged between 1.95%–2.41% and 14.86%–16.18%, respectively. Increased productivity during nighttime was observed with deeper water levels, suggesting that design enhancements could further reduce energy losses. Comparative studies with simple and active solar stills for recovering freshwater from brines indicate similar challenges, with heat losses limiting evaporation rates relative to traditional ponds [24, 25].

The latest advancements in solar distillation from 2020 to 2023 incorporate passive techniques and integrated technologies, including concentrators, reflective mirrors, evacuated tube collectors, engineered nanoparticles, and thermal storage materials. These innovations aim to boost evaporation rates by introducing additional heat and retaining it efficiently. This ongoing research into heat confinement methods and absorptive materials offers promising directions for overcoming existing challenges and improving the performance of solar distillation systems. Future work will likely continue to refine these technologies, addressing limitations while exploring new opportunities for sustainable water purification [26].

The novelty of this work lies in integrating a solar concentrator with a modified solar still and a heat transfer circulation system to enhance distillation efficiency significantly. By directing concentrated sunlight to a heat exchanger and maintaining a continuous hot water flow within the modified distiller, the setup achieves higher temperatures and improved evaporation rates compared to traditional solar stills. The objective is to evaluate the practical impact of this configuration on water yield, thermal performance, and exergy efficiency, providing a viable and sustainable solution for water purification in sun-rich, water-scarce regions.

2. Methodology

2.1. Experimental Setup

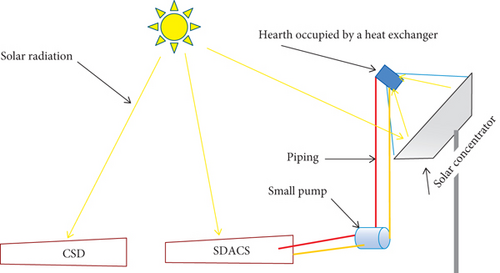

Active solar stills are innovative water purification systems designed to enhance the efficiency of traditional solar stills by incorporating external energy sources or mechanical systems such as pumps, fans, or heaters. These systems improve the evaporation and condensation process by actively managing the flow and temperature of water, unlike passive systems that depend solely on solar radiation for heating. Figure 1 illustrates an experimental setup carried out in July 2024, where two types of solar stills were tested to evaluate the effect of a solar concentrator on distillation efficiency. In this setup, one of the solar stills is connected to a solar concentrator called the solar distiller-assisted by a concentrator system (SDACS), which focuses additional sunlight onto the distiller, intensifying the heat and promoting a faster evaporation rate. This active system is compared against a controlled solar distiller (CSD), which operates passively by relying only on ambient solar radiation. This comparative study allows researchers to assess the potential efficiency gains of active solar stills over traditional, passive configurations.

2.2. Operating Principle

The operating principle of the system is illustrated in Figure 2. Solar radiation targets both the solar concentrator and two distillers. In the concentrator, sunlight is focused onto a heat exchanger, or “hearth,” creating a high-temperature zone. This hearth connects to a water circuit with a pump, circulating water between the hearth and the SDACS. Heated water from the hearth flows into the SDACS, transferring thermal energy to aid in water evaporation. After releasing heat, the cooler water cycles back to the hearth to be reheated, creating a continuous cycle that enhances temperature and evaporation rates within the SDACS. Meanwhile, the CSD is exposed solely to direct solar radiation, allowing for a comparative assessment of the concentrator’s effect on distillation efficiency.

Every 30 min, we recorded temperature data and measured the distilled water flow rate from both stills to assess their performance. Each measurement captured the flow rate of both stills at regular intervals. For calibration purposes, we established the CSD as the baseline by assigning its total flow rate a value of 100%. This calibrated baseline allows all flow rates from the concentrator-assisted solar still (CAS) to be calculated and expressed as a percentage of the CSD, enabling a direct and consistent comparison of their performance.

2.3. Measuring Instruments

The measuring instruments utilized in this experiment inherently carry errors, quantified as percentages of uncertainties, which can influence the accuracy of the recorded values.

2.3.1. Pyranometer (Kipp & Zonen CMP-11)

The pyranometer is used to measure solar radiation, a crucial parameter for evaluating the energy input in the solar distillation system. This instrument is designed to measure the amount of solar radiation received by a surface, expressed in watts per square meter (W/m2). The CMP-11 model has a wide spectral range, allowing it to capture both direct and diffuse sunlight, making it particularly suitable for solar energy systems. The uncertainty of 0.15% refers to the precision of the radiation measurement, meaning that the recorded value could slightly vary within this range from the actual value.

2.3.2. Type K Thermocouple

The type K thermocouple is used to measure the temperatures of the glass surfaces and water in the distillation system. It is known for its wide temperature range (−40°C to 110°C) and durability, making it ideal for diverse working environments and accurate thermal readings. The high sensitivity of this thermocouple ensures reliable temperature measurements. However, the uncertainty of 3.84% indicates that the measured temperature may have an error of ± 1°C within the specified temperature range.

2.3.3. Graduated Tube

The graduated tube is a simple yet precise tool used to measure the volume of water produced by the distillers. It has visible gradations, allowing for direct and clear observations of the water output at different times during the experiment. The uncertainty of 2.69% means that the error in the volume measurement can vary by 5 mL for a total volume of 2000 mL, which represents a small deviation from the actual value.

3. Results

3.1. Solar Irradiance and Ambient Temperature

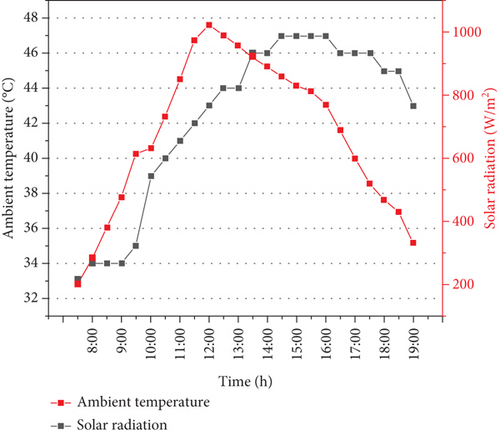

Figure 3 represents the evolution of solar radiation and ambient temperature concerning time, noting that throughout the experiment, solar radiation and ambient temperature were carefully monitored to evaluate their variations and their impacts. Solar radiation started at 200 W/m2, indicating a relatively low level of solar exposure to begin with. It then peaked at 1024 W/m2 around 13:00 h representing the maximum solar intensity of the day, and decreased to 300 W/m2 at the end of the experiment. This fluctuation in solar radiation reflects the typical daily cycle of solar exposure, with the highest intensity occurring at midday and decreasing as the day progresses toward evening. Meanwhile, ambient temperature showed a similar variation pattern. Initially, the temperature was 33°C, reaching a peak of 47°C at 14:00 h which corresponds to the period of highest solar radiation, suggesting a strong correlation between solar intensity and ambient temperature. As the experiment continued, the temperature gradually decreased, reaching 32°C at the end.

3.2. Water and Glass Temperatures

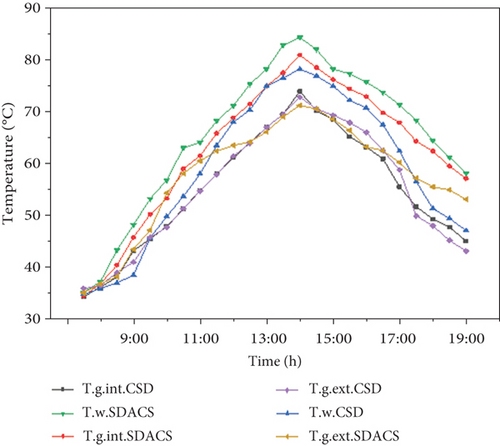

Figure 4 illustrates the temperature progression of various components in the two solar stills: the water, the inner glass, and the outer glass temperatures for both the CSD and the SDACS. The experiment began at 08:30 h and concluded at 19:30 h, capturing the temperature changes in both distillers throughout the day. Early in the experiment, the maximum temperatures recorded for the CSD were 78.1°C for the water, 73.8°C for the inner glass, and 71.1°C for the outer glass. In comparison, the SDACS reached higher peak temperatures of 86.3°C for the water, 80.1°C for the inner glass, and 71.1°C for the outer glass. By the end of the experiment, temperatures in both systems had decreased substantially. The CSD measured final temperatures of 47°C for the water, 45°C for the inner glass, and 43°C for the outer glass, while the SDACS maintained higher residual temperatures, with 58°C for the water, 57°C for the inner glass, and 53°C for the outer glass.

The high water temperature value in the SDACS indicates that the evaporation rate is higher than in the CSD.

3.3. Horary Output

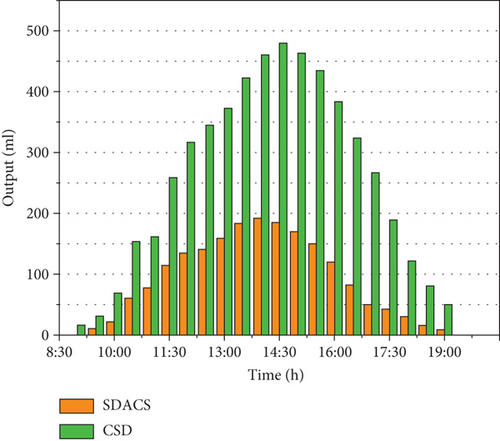

Figure 5 shows the variation in hourly water production for both solar stills, SDACS and CSD, throughout the experiment. The results reveal that SDACS consistently outperformed CSD in terms of hourly water yield. At 14:00 h, which corresponds to the maximum sunlight intensity, SDACS reached its highest flow rate of 480 mL/h, a substantial increase over CSD’s peak of 192 mL/h at the same time. This represents a 250% improvement in SDACS’ hourly efficiency. The improved performance can be attributed to the SDACS concentrator, which focuses sunlight onto the evaporation surface, increasing the energy available for the water distillation process. In addition, design features such as optimized piping and active air circulation via a 12-V fan contribute to uniform heat distribution and improved condensation rates. These modifications allow the SDACS to maintain higher productivity throughout the day, making it a viable solution for applications requiring rapid water distillation.

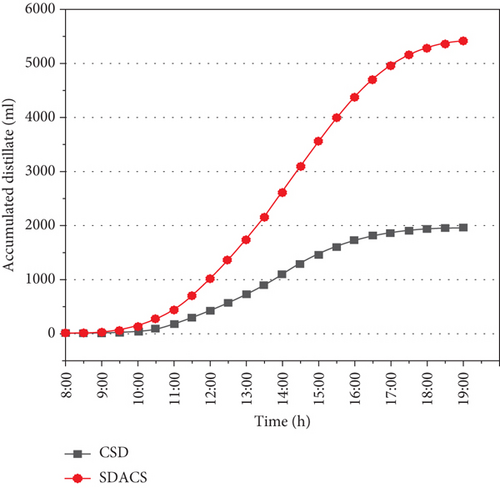

3.4. Accumulation Output

Figure 6 provides a cumulative comparison of total water production for the SDACS and CSD systems over the experimental period. At the end of the experiment, the SDACS system produced a total of 5404 mL, while the CSD system only achieved 1955 mL. This demonstrates that the SDACS offers a 2.7-fold increase in water flow rate compared to the CSD system.

The significant difference can be directly related to the solar concentrator’s ability to intensify solar radiation on the evaporating surface, thereby increasing evaporation rates. In addition, the system’s improved thermal design maintains high internal temperatures, allowing for continued and efficient operation even when sunlight decreases. This higher cumulative flow rate is particularly beneficial for regions with limited access to potable water.

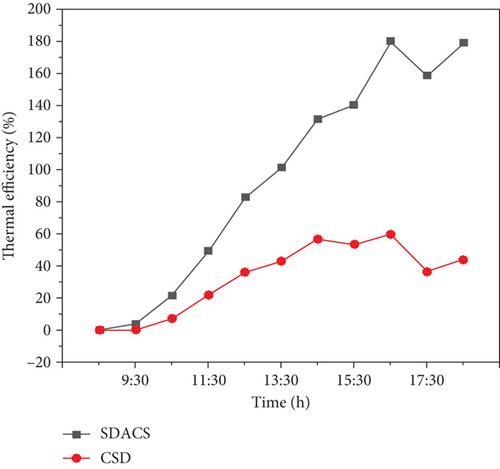

3.5. Thermal Efficiency

Figure 7 depicts the variation in thermal efficiency for both the SDACS and the CSD over the experiment. The SDACS exhibits a significant improvement in thermal efficiency, peaking at 180% at 13:30 h, compared to the CSD, which reaches a maximum efficiency of only 60% at the same time. This represents a 200% increase in peak thermal efficiency for the SDACS over CSD.

- •

ηth: thermal efficiency of the solar still.

- •

m: mass of distilled water produced per unit time (kg/s).

- •

hfg: latent heat of vaporization of water (J/kg) at the operating temperature.

- •

G: solar radiation intensity or solar flux incident on the still (W/m2).

- •

A: area of the solar still exposed to sunlight (m2).

The higher efficiency of SDACS is attributed to its design enhancements, such as the solar concentrator, which intensifies solar radiation on the evaporation surface, and the selective coatings that minimize heat losses. Additionally, the inclusion of insulation and active airflow via a 12-V fan ensures that the captured thermal energy is effectively utilized for evaporation. These features allow SDACS to maintain higher efficiency throughout the day, even during periods of declining sunlight. The steep increase in thermal efficiency for SDACS around noon demonstrates its ability to capitalize on peak solar radiation more effectively than CSD.

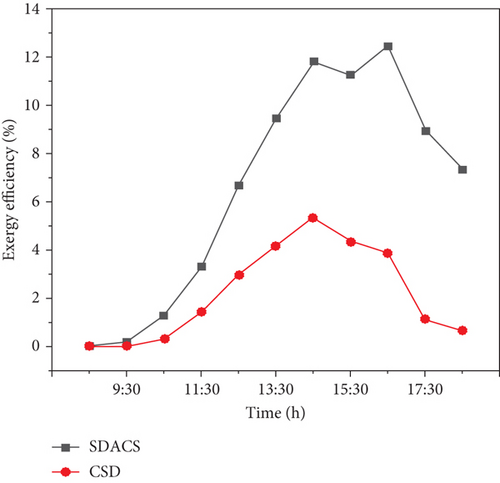

3.6. Exergy Efficiency

Figure 8 shows the variation in exergy efficiency between the CSD and the SDACS over the course of the experiment. At the start, both distillers demonstrate similar exergy efficiency, indicating an equal baseline in initial performance. However, as the experiment progress, a clear divergence appears: the exergy efficiency of SDACS significantly surpasses that of CSD, reaching a peak of 12.39%. This higher exergy efficiency demonstrates SDACS’ enhanced ability to convert thermal energy into useful work, reflecting its superior performance in effectively utilizing available solar energy. In comparison, the exergy efficiency of CSD remains notably lower, peaking at just 3.32%, underscoring its relative inefficiency in energy conversion.

Throughout the day, the SDACS consistently outperforms the CSD in exergy efficiency, with an average efficiency of 9.74% compared to the CSD’s 2.65%. This improvement is significant for practical applications, as it demonstrates SDACS’ capacity to maximize the utility of available solar energy, reducing wastage and improving overall performance. This marked difference underscores the effectiveness of the design modifications in SDACS, which result in improved energy use and overall distillation performance, clearly demonstrating the operational advantages of the enhanced system.

ηex: exergy efficiency of the solar still.

hfg: latent heat of vaporization of water (J/kg).

Cp: specific heat of water (J/kg·K), which is approximately 4186 J/kg·K.

Tw: temperature of the water inside the still (K).

Ta: ambient temperature (K).

G: solar radiation intensity or solar flux incident on the still (W/m2).

A: area of the solar still exposed to sunlight (m2).

Ts: temperature of the solar still’s surface or the absorber plate (K).

4. Discussion

The comparison in Table 1 summarizes the performance improvements observed in the CAS (SDACS) over the CSD. The SDACS achieved higher maximum water temperatures, significantly greater hourly and total water yields, and substantially enhanced thermal and exergy efficiencies. With water yield at 250% and total accumulation at 276% of the CSD’s output, the SDACS modifications boost water production. Additionally, the SDACS demonstrated optimized energy use, as shown by its peak thermal efficiency at 180% and exergy efficiency at 12.39%, well above the CSD values. These results confirm the SDACS’ superior capacity to utilize solar energy for efficient water distillation.

| Parameter | CSD | SDACS | Improvement |

|---|---|---|---|

| Maximum water temperature | 76.1°C | 86.3°C | Higher temperature achieved in SDACS |

| Maximum hourly water yield | 192 mL/h | 480 mL/h | SDACS yield is 250% of CSD yield |

| Total water accumulation | 1955 mL | 5404 mL | SDACS total yield is 276% of CSD yield |

| Peak thermal efficiency | 60% | 180% | SDACS shows 3× higher thermal efficiency |

| Peak exergy efficiency | 3.32% | 12.39% | SDACS exergy efficiency is significantly improved |

Thermal efficiency and water output in the modified solar stills reveal a direct correlation between energy use and productivity. The CAS (SDACS), with a maximum thermal efficiency of 180%, produced 5404 mL of distilled water, while the CSD, with a lower maximum efficiency of 60%, produced only 1955 mL. This 2.7-fold increase in water output for the SDACS is directly related to its ability to more efficiently convert solar energy into useful thermal energy, facilitated by features such as the solar concentrator, enhanced insulation, and active airflow. These improvements ensure that a higher proportion of the captured solar energy contributes to evaporation, leading to significantly higher water production compared to the CSD.

4.1. Economic Study

In Table 2, the costs of components for two solar distillation systems, SDACS and CSD, are compared. Both systems use essential materials like used iron ($111.00), aluminum ($33.26), and glass ($5.17). However, SDACS includes additional components such as a pump ($22.18), pipes ($4.43), extra glass pieces ($51.74), a 12-V fan ($29.56), and a sturdy structure ($73.94), bringing its total cost to $438.08, compared to $189.97 for CSD. While SDACS has a higher initial cost, it eliminates labor expenses included in CSD and significantly boosts water production capacity. This additional investment of $248.11 is offset by SDACS’ greater efficiency and rapid payback period, making it a more economically beneficial choice for solar distillation.

| Components | SDACS (USD) | CSD (USD) |

|---|---|---|

| Used iron | $111.00 | $111.00 |

| Used aluminum | $33.26 | $33.26 |

| Glass | $5.17 | $5.17 |

| Insulating material | $3.69 | $3.69 |

| Pump | $22.18 | $0.00 |

| Pipes | $4.43 | / |

| Paint | $14.78 | / |

| Additional glass pieces | $51.74 | / |

| 12-V fan | $29.56 | / |

| Structure | $73.94 | / |

| Labor cost | / | $36.96 |

| Copper pipes | $14.78 | / |

| Total | $438.08 | $189.97 |

4.2. Calculate Daily and Annual Revenue for Each Distiller

• Cost of 1 L of water: $0.74 (100 Algerian dinars).

• Daily production of CSD: 1.955 L.

• Daily production of SDACS: 5.404 L.

4.3. Daily Revenue

• CSD daily revenue: 1.955L × $0.74 = $1.45.

• SDACS daily revenue: 5.404 L × $0.74 = $4.00.

4.4. Annual Revenue (Assuming 300 Operational Days)

• CSD annual revenue: $1.45/day × 300 days = $435.17.

• SDACS annual revenue: $4.00/day × 300 days = $1200.00.

4.5. Calculate the Additional Revenue Generated by SDACS

• Additional daily revenue of SDACS over CSD: $4.00 − $1.45 = $2.55.

• Additional annual revenue: $2.55/day × 300 days = $765.00.

4.6. Calculate the Payback Period

Given values in USD:

• Additional cost of SDACS = 33,600 DZD ≈ $248.22.

This means that, with the additional revenue generated by SDACS, the extra investment cost would be recovered in approximately 4 months.

4.7. Return on Investment (ROI) Calculation

- •

Total annual profit of SDACS (after subtracting CSD revenue as the baseline): $765.00.

This high ROI shows that the SDACS is a financially viable investment with a quick payback period and a strong return on the initial additional cost.

5. Conclusion

- •

Enhanced temperature performance: The modified solar still maintained consistently higher water temperatures throughout the experiment, reaching a maximum of 86.3°C compared to 76.1°C for the control still.

- •

The CAS (SDACS) significantly outperformed the CSD in terms of water production. The SDACS achieved a maximum yield of 480 mL/h, which is 250% of the CSD’s maximum yield of 192 mL/h. In terms of total water accumulation, the SDACS collected 5404 mL, which is approximately 276% of the CSD’s total yield of 1955 mL.

- •

Higher thermal efficiency: The modified still achieved a peak thermal efficiency of 180%, greatly surpassing the control still’s efficiency of 60%.

- •

Improved exergy efficiency: The exergy efficiency of the modified still peaked at 12.39%, compared to 3.32% for the control still, indicating enhanced energy utilization.

- •

Optimized energy consumption and performance: The modifications made to the solar still effectively optimized energy consumption, increased water output, and improved overall distillation performance, demonstrating substantial advantages over the unmodified control still.

- •

The SDACS generates significantly higher revenues compared to the CSD due to its higher output. With a payback period of about 4 months and a high ROI of 308%.

5.1. Future Work

Additional design optimizations and real-world testing are recommended to enhance practicality, address limitations, and further contribute to global water scarcity solutions.

Conflicts of Interest

The authors declare no conflicts of interest.

Funding

This research was conducted without any financial support from external funding agencies, organizations, or sectors. All aspects of the study, including data collection, analysis, and manuscript preparation, were independently carried out by the authors. No conflicts of interest related to funding influenced the research, and this statement ensures transparency regarding the study’s financial background.

Open Research

Data Availability Statement

The datasets from this study can be requested from the corresponding author. Requests will be evaluated for ethical compliance to maintain participant confidentiality and adhere to data protection standards, ensuring transparency.