Battery Selection for Energy-Efficient IoT Devices: A Comparative Study of Longevity Across Environmental Conditions

Abstract

Energy efficiency is one of the main challenges for Internet of things (IoT) devices and sensors, particularly those requiring long-term, stable operation without frequent battery replacement. This paper examines the energy challenges faced by IoT devices under diverse environmental conditions and provides a practical framework for optimizing battery selection by systematically analysing the performance. The study provides a comparative analysis of popular primary battery (interchangeably called nonrechargeable battery) technologies, such as Li-SOCl2 and Li-MnO2, alongside rechargeable (interchangeably called secondary) options such as LFP, NMC and NCA. Key parameters are evaluated, including energy density, self-discharge rate, operating voltage and temperature ranges, cost, and reliability. The findings address a critical research gap by recommending tailored battery solutions for specific IoT applications: Li-SOCl2 batteries for low-power, long-term deployments in extreme environments due to their superior lifespan and stability and rechargeable options such as LFP, NCA and NMC for high-power applications requiring frequent cycling. By explicitly linking battery chemistries to application-specific needs, this study delivers actionable insights that enhance IoT performance, extend operational lifespans, and improve sustainability, paving the way for more reliable and efficient IoT systems across industries.

1. Introduction

The Internet of things (IoT) and sensor industry are among the most significant global developments, profoundly impacting various aspects of life through their expanding applications. These applications span intelligent cities, smart homes, smart factories, healthcare, agriculture, smart metering in the automotive industry and many other fields [1–3]. However, despite their transformative potential, IoT devices and sensors face substantial energy and power management challenges. These challenges are particularly pronounced in environments where stable, continuous performance is required over long periods, often under harsh or remote conditions. The need for efficient power solutions is vital, as frequent battery replacements and recharging are often impractical in many IoT deployments [4, 5]. For example, environmental monitoring sensors deployed in remote locations, such as arctic weather stations, must operate for years without human intervention, necessitating batteries with low self-discharge rates and exceptional temperature tolerance. Similarly, industrial IoT devices exposed to high levels of vibration, heat, or chemical environments require durable and reliable energy sources to maintain consistent performance.

Healthcare IoT devices, such as implantable medical sensors, face unique challenges, where compact size, biocompatibility and long operational lifespans are critical. In contrast, high-power IoT applications, including autonomous drones and vehicles, demand rechargeable batteries capable of delivering high energy densities and frequent cycling without compromising performance or safety. Agricultural IoT systems, including soil moisture and weather sensors, operate in highly variable environmental conditions, requiring cost-effective and long-lasting energy solutions to minimize maintenance and operational disruptions. These diverse scenarios highlight the necessity of matching battery technologies to specific IoT use cases to optimize performance and longevity.

The energy consumption of IoT devices varies widely depending on their function and operating environment. For example, a simple temperature sensor might consume only a few microwatts, while a more complex device with data processing and wireless communication capabilities could require several milliwatts or more [6–8]. This diversity in power requirements necessitates a range of energy solutions tailored to specific IoT applications.

Various solutions have been proposed to address these challenges, including optimising hardware and software, enhancing energy management algorithms and using advanced materials in device construction. Recent advancements in low-power microcontrollers (MCUs) and communication protocols, such as bluetooth low energy (BLE) and long-range wide area networks (LoRaWAN), have significantly reduced the energy requirements of IoT devices [9–12]. Advanced materials and technologies in IoT device design and manufacturing can also enhance efficiency and longevity [13]. Emerging nanomaterials and flexible electronics enable new form factors and energy-efficient designs for IoT sensors [14].

High-capacity batteries with rapid charging capabilities represent another crucial solution for extending IoT device lifespans and reducing maintenance needs [15–17]. Advanced energy storage and management technologies, including research into fast-charging batteries, increased energy density and reduced losses, offer promising solutions to enhance battery performance [18–20]. Recent developments in solid-state batteries and novel electrode materials show potential for higher energy densities and improved safety in IoT applications [21]. Using photovoltaic, piezoelectric and thermoelectric can extend device lifetimes [22].

Despite extensive research into energy-efficient IoT technologies, there remains a notable gap in systematically aligning battery technologies with the diverse operational and environmental requirements of IoT devices. Many existing studies focus on individual battery chemistries or hardware optimizations without offering a holistic approach to battery selection tailored to specific IoT applications.

This paper fills this gap by presenting a detailed comparative analysis of nine nonrechargeable and three rechargeable battery chemistries, including lithium manganese dioxide (Li-MnO2) and lithium thionyl chloride (Li-SOCl2), and three leading rechargeable battery technologies (lithium iron phosphate (LFP), nickel manganese cobalt (NMC) and nickel cobalt aluminium (NCA)), emphasizing their suitability for various IoT scenarios. By addressing the nuances of battery performance in extreme conditions, long-term applications and high-power cycling scenarios, this work provides a much-needed framework for IoT technology designers and industry practitioners to enhance energy efficiency, reliability and sustainability. Through this comparative-based analysis, it has been demonstrated that the importance of a correct type of battery selection addresses the immediate energy and power challenges and contributes to the long-term development and productivity of IoT systems across various industries.

2. Methodology

To ensure a robust and reliable analysis, this study employed a systematic approach to gather, evaluate, and compare data on battery technologies for IoT devices. Data were sourced from a combination of peer-reviewed journals, industry reports and technical datasheets provided by battery manufacturers such as Saft, Tadiran, Panasonic and others. These sources provided comprehensive information on key battery parameters, including energy density, self-discharge rates, temperature tolerance, cost per unit and lifespan. A detailed review of IoT-specific power requirements across diverse applications was conducted to identify typical usage scenarios. The battery technologies evaluated include nine primary battery chemistries (e.g., Li-SOCl2 and Li-MnO2) and three rechargeable chemistries (e.g., LFP, NMC and NCA), chosen based on their prevalence in IoT deployments.

The data analysis involved qualitative and quantitative assessments to determine the suitability of each battery type for specific IoT applications. Parameters such as energy efficiency, operational lifespan and environmental reliability were cross-referenced with IoT application requirements, including power demands, environmental conditions and operational constraints. Comparative tables and figures were developed to visualize key metrics such as energy density, cost per watt-hour (Wh) and self-discharge rates. The findings were synthesized to produce actionable recommendations tailored to low-power and high-power IoT devices, ensuring that the framework addresses both theoretical insights and practical considerations.

3. Energy and Battery Challenges in IoT

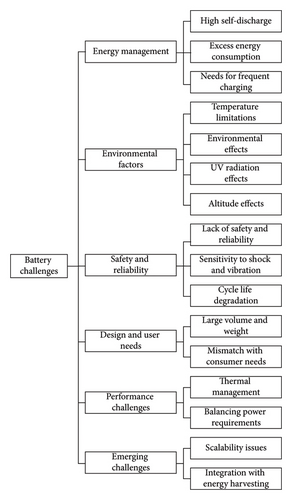

The IoT has revolutionised various sectors, from agriculture to smart cities [1, 2]. However, the widespread adoption of IoT devices faces significant challenges, particularly in energy management and battery technology [3, 4]. This section explores the essential challenges batteries face for IoT devices and sensors, supported by recent research and industry insights. Figure 1 illustrates these challenges in various categories.

3.1. Energy Management

IoT device batteries face significant energy management challenges, including high self-discharge, excess energy consumption and frequent replacement needs. Self-discharge causes batteries to lose energy, even when unused, reducing device efficiency and longevity. Some lithium-ion batteries lose up to a few per cent of their monthly self-discharge [7, 23–25]. Additionally, many IoT devices drain power rapidly, even in standby mode, due to inefficient power management and poorly optimised software, which can lead to higher maintenance costs and reduced reliability; optimising sleep modes and transmission protocols can mitigate this by reducing energy consumption by up to 70% [5, 10, 26–28]. Frequent replacement is another challenge, especially for devices in hard-to-reach locations or requiring continuous operation, inconveniencing users and increasing energy management costs. With the number of IoT devices projected to reach 75 billion soon, addressing these issues is essential for efficient and sustainable deployment [29–31].

3.2. Environmental Factors

Batteries in IoT devices are significantly affected by environmental challenges, including temperature limitations, environmental effects, UV radiation and altitude effects, which can reduce their efficiency and lifespan. Temperature extremes, both hot and cold, impair battery performance; for instance, lithium-ion batteries can lose up to 50% of their capacity at −20°C and experience accelerated degradation at temperatures above 45°C, making them unsuitable for outdoor IoT deployments in regions with extreme climates [32–34]. Environmental factors such as humidity, dust and direct sunlight negatively impact battery efficiency and reliability. High humidity can increase self-discharge rates and risk short-circuiting, while dust accumulation hinders heat dissipation, leading to thermal management problems [19, 35–37]. UV radiation poses another challenge, as prolonged exposure can degrade polymer components and electrolytes in some batteries, reducing their quality and useful life, particularly in devices deployed in high UV environments [38–40]. IoT devices operating at high altitudes face unique difficulties due to reduced air pressure and oxygen levels, which affect the chemical reactions within batteries, making these conditions particularly problematic for aerospace or mountainous applications [35, 41]. Additionally, the increasing deployment of IoT devices raises concerns about the environmental impact of battery disposal, as improper handling contributes to toxic waste and resource depletion. Sustainable disposal methods, such as recycling and second-life applications, can mitigate these impacts by recovering valuable materials such as lithium, cobalt and nickel, reducing e-waste and the environmental footprint of IoT batteries [42–44]. Recycling technologies, combined with innovations in battery design, including biodegradable batteries, present promising opportunities to address these challenges and enhance the sustainability of IoT ecosystems.

3.3. Safety and Reliability

Batteries in IoT devices face serious issues related to safety, reliability, sensitivity to shock and vibration and cycle life degradation, all of which can impact their performance and long-term usability. Safety risks, such as leakage, explosion or fire, are inherent to batteries and can result from internal faults or external factors, posing severe dangers to users and the environment while eroding trust in IoT devices. Recent incidents involving lithium battery fires in consumer electronics emphasise the urgent need for robust safety measures [45–47]. Additionally, many batteries are sensitive to shock and vibration. This is a significant concern for IoT devices in industrial or transportation settings, where constant vibrations may cause internal damage and reduce battery lifespan [48–50]. Another significant issue is cycle life degradation, as repeated charging and discharging can lead to progressive capacity loss. This is particularly problematic for rechargeable batteries used in high-duty-cycle IoT applications, where shortened battery lifespans translate to increased maintenance costs and reduced operational efficiency [51, 52].

3.4. Design and User Needs

The design and compatibility of batteries in IoT devices face challenges related to large volume and weight and mismatches with consumer needs, limiting the development and efficiency of these technologies. Traditional batteries often have substantial size and weight, creating constraints in the design and usability of IoT devices, especially as these devices become smaller and more integrated into everyday objects. This issue necessitates compact energy solutions to align with the miniaturisation trend in IoT technologies [14, 53–55]. However, designing batteries with reduced size and weight often requires trade-offs in capacity, which can impact device functionality and performance [56, 57]. Additionally, many existing batteries need to meet the specific energy demands of various IoT applications. For instance, some devices require high pulse currents over short durations, while others need steady, low-level power for extended periods, leading to decreased performance, operational instability and insecurity [17, 58–60]. Addressing these design and compatibility issues is essential for advancing IoT technologies and meeting consumer expectations.

3.5. Performance Challenges

IoT devices face significant challenges in thermal management and balancing power requirements, which are significant factors for ensuring efficient and reliable operation. The compact design of many IoT devices makes heat dissipation difficult, leading to potential battery performance issues and reduced lifespan. Effective thermal management strategies are essential to maintain battery efficiency and prevent premature degradation caused by excessive heat [19, 61, 62]. IoT devices often operate with highly variable power needs, ranging from low-power sleep modes to high-power bursts during data transmission. Designing batteries capable of efficiently meeting these fluctuating demands is a considerable challenge [63–65]. Advanced power management techniques and energy-aware protocols are being developed to address this issue, aiming to optimise energy usage and improve the overall performance of IoT devices [11].

3.6. Emerging Challenges

The expanding deployment of IoT devices brings challenges in scalability, security and integration with energy harvesting technologies. As IoT networks grow, the environmental impact of battery disposal and replacement becomes significant, contributing to the global e-waste problem. Sustainable battery technologies and effective recycling strategies are required to mitigate these issues and ensure environmentally responsible IoT scalability [15, 42–44]. Security concerns also arise due to the limited energy resources of IoT devices, making them susceptible to energy-depletion attacks. These attacks, where malicious actors prematurely drain device batteries, highlight the intersection of energy management and security, necessitating innovative design solutions to protect functionality [13, 66, 67]. Integrating batteries with energy harvesting technologies offers promising ways to extend battery life but introduces challenges in power management, charging efficiency and system complexity. While energy harvesting reduces reliance on traditional batteries, it requires addressing additional design considerations and potential points of failure to ensure reliability [22, 68, 69].

- •

Decreased device efficiency: The inability to provide optimal and accurate performance, sudden destruction in time-sensitive conditions and increased probability of system failures [70].

- •

Increased maintenance and repair costs: The need to replace batteries frequently adds to the overall cost of IoT deployments [71].

- •

Shortened IoT device working life: Rapid wear of batteries and the need for frequent replacements reduce the operational lifespan of devices [72].

- -

Reduced ability to provide optimal performance and better customer service [73].

- -

Increased e-waste and environmental pollution due to premature device wear [74].

- -

Potential risks to information and data security due to sudden breakdowns and malfunctions [75].

- -

Reduced user confidence in IoT and sensor technologies, as reduced service life and increased maintenance costs can cause frustration [76].

Addressing these challenges is crucial for IoT technologies’ widespread adoption and long-term success across various industries and applications [77].

4. Addressing Energy Challenges in IoT

As mentioned in the above section, energy-related challenges often limit IoT devices’ widespread adoption and effectiveness. This section explores comprehensive solutions to these challenges, focussing on advanced battery technologies, energy harvesting techniques and system-level optimisation.

4.1. Advanced Lithium Battery Technologies

Both primary and secondary lithium batteries have become a cornerstone in powering IoT devices due to their superior characteristics [7, 8]. One of their most notable advantages is their high energy density, allowing them to store more energy per unit weight and volume than other battery types. This feature is mainly required for compact IoT devices, with recent advancements achieving energy densities exceeding 700 Wh/kg [52, 54]. Additionally, lithium batteries boast a long service life, lasting up to 20 years or more without significant self-discharge. This longevity reduces the need for frequent replacements, making them ideal for IoT devices deployed in hard-to-reach locations or requiring minimal maintenance [56, 78]. Their adaptability to a wide range of operating temperatures, from −60°C to +150°C, further enhances their utility. Specialised formulations can even function at temperatures as low as −60°C, broadening their applicability in extreme environments [32, 35].

Safety and reliability are other significant strengths of lithium batteries. Built-in safety mechanisms prevent risks such as leakage, explosion or fire, which is vital for some IoT applications [36, 47]. Recent advancements, such as the development of solid electrolytes, have further improved the safety profile of these batteries [60]. Furthermore, their low maintenance requirements, resulting from their long lifespan and stability, reduce the total cost of ownership for IoT deployments. This is especially important as IoT networks grow in size and complexity, demanding power sources that are both durable and cost-effective [20, 38]. These attributes underline why lithium batteries remain a preferred choice for powering IoT devices and advancing the field of connected technologies.

4.2. Emerging Lithium Battery Technologies

Several emerging lithium battery technologies hold significant promise for enhancing future IoT applications. Among these, solid-state lithium batteries are particularly noteworthy, offering improved safety, higher energy density and greater temperature tolerance than traditional liquid electrolyte batteries [16, 58]. Recent advancements in ceramic electrolytes have further increased their potential for IoT applications, making them a leading candidate for next-generation devices [60]. Another promising development is lithium-sulphur batteries, which boast theoretical energy densities of up to 2600 Wh/kg, presenting a revolutionary opportunity to enhance the performance and capabilities of IoT devices [61]. However, widespread adoption is hindered by challenges such as limited cycle life and high self-discharge rates that must be resolved through further research and innovation.

Lithium-air batteries, though still in their early research stages, represent another groundbreaking possibility for IoT power sources. These batteries promise energy densities comparable to gasoline, supporting ultra-long-life IoT devices and unlocking new possibilities for applications requiring extended operational durations [62]. While their potential is immense, significant technical hurdles remain, including stability, scalability and efficiency. Despite these challenges, developing these advanced lithium battery technologies underscores the rapid progress to meet the growing demands of IoT systems, paving the way for safer, more efficient devices capable of handling increasingly complex tasks.

4.3. Energy Integration

Combining advanced lithium batteries with energy harvesting technologies can create hybrid power solutions for IoT devices, significantly extending their operational lifespan and reducing maintenance requirements [22, 76]. Photovoltaic energy, for example, uses solar cells to supplement or recharge batteries in outdoor IoT applications. Recent advances in flexible and high-efficiency solar cells have made them suitable for integrating with IoT devices, especially in wearable technology and environmental monitoring systems [63]. Similarly, piezoelectric energy harvesting, which converts mechanical vibrations into electrical energy, effectively powers IoT sensors in industrial and transportation environments. Innovations in nanomaterials have dramatically improved the efficiency of piezoelectric harvesters, making them a viable option for low-power IoT devices [23, 64].

Thermoelectric energy, which generates power from temperature differentials, is another promising avenue for industrial IoT applications and wearable devices. Recent advancements in nanostructured thermoelectric materials have enhanced conversion efficiencies, broadening their potential applications [65]. Additionally, RF energy harvesting, which captures ambient radio frequency signals, is gaining traction in urban environments with high RF density. Advanced rectenna designs have significantly improved harvesting efficiencies, even at low power levels, making this technology increasingly practical for IoT systems [43]. Together, these energy harvesting methods, combined with advanced lithium batteries, represent a significant step forward in creating sustainable and efficient power solutions tailored to the unique demands of IoT devices.

4.4. Power Management Strategies

Effective power management is essential for maximising IoT devices’ energy efficiency and longevity [31, 79]. One key strategy involves using ultra-low-power MCUs specifically designed for IoT applications. These next-generation MCUs can operate at submicrowatt power levels, significantly extending battery life and enabling more sustainable device operation [44]. Another approach is adaptive power management, which leverages dynamic voltage and frequency scaling (DVFS) techniques to optimise power consumption based on real-time workload and environmental conditions. This ensures that energy usage is minimised without compromising performance [66].

Intelligent sleep modes also play a vital role in reducing power consumption. IoT devices can dramatically lower their average energy use by employing advanced sleep strategies that balance responsiveness with energy conservation while remaining operational when needed [67]. For networked IoT systems, energy-aware routing protocols offer additional opportunities for optimisation. These algorithms consider factors such as battery levels and energy costs, extending the overall lifetime of the network while maintaining functionality [68]. Together, these strategies demonstrate the importance of integrating energy-efficient technologies and intelligent power management techniques to meet the demands of IoT applications.

4.5. Design and Material Innovations

Advancements in battery design and materials are unlocking innovative possibilities for IoT devices, enabling new applications and addressing environmental challenges. Flexible and stretchable batteries represent a significant breakthrough, allowing seamless integration into wearable IoT devices and intelligent textiles. These new form factors enhance device usability and open doors for more versatile, ergonomic designs [69]. Printable batteries are another critical innovation, leveraging advancements in printed electronics to create cost-effective, customisable energy solutions tailored to specific IoT applications. This technology reduces production costs while supporting diverse deployment scenarios [70].

Biodegradable batteries address growing environmental concerns by providing a sustainable alternative for powering IoT devices. These batteries are designed to safely decompose after their useful life, significantly reducing e-waste associated with large-scale IoT deployments [71]. These battery design and materials advancements help overcome traditional limitations, enabling the next generation of IoT devices to be more efficient, versatile and environmentally friendly.

4.6. System-Level Optimizations

Optimising the IoT ecosystem can result in substantial energy savings by addressing multiple device operation and communication aspects. Edge computing, which involves processing data locally on IoT devices, minimises energy-intensive data transmissions and helps extend battery life [72]. Similarly, compressed sensing employs advanced signal processing techniques to reduce the volume of data that needs to be transmitted, lowering communication power requirements [73]. Additionally, energy-efficient communication protocols such as LoRaWAN and narrowband IoT (NB-IoT) are specifically designed for long-range, low-power IoT applications, significantly cutting energy consumption during data transmission [12, 74]. Dynamic network optimisation, leveraging real-time analytics and machine learning, further improves communication efficiency and adapts to varying workloads. These strategies collectively enhance the energy efficiency of IoT systems, supporting sustainable and long-lasting deployments across diverse industrial, agricultural and urban applications.

4.7. Sustainability and Lifecycle Considerations

As the number of IoT devices grows, ensuring sustainability is becoming increasingly essential. Efficient battery recycling and exploring second-life applications for IoT batteries can significantly enhance sustainability by reducing waste and maximising resource use [42, 49]. Designing IoT devices for disassembly with easily replaceable batteries extends device lifespans, facilitates recycling and reduces environmental impact [75]. Additionally, combining energy-harvesting technologies with ultra-efficient devices can create self-sustaining or even energy-positive IoT systems, paving the way for more sustainable and innovative network solutions [76]. Incorporating renewable energy sources, such as solar and kinetic energy, into IoT ecosystems minimises dependency on finite resources and enables more eco-friendly operations across diverse applications.

5. Battery Selection for IoT

- •

Li-MnO2

- •

Li-SOCl2

- •

Lithium sulphur dioxide (Li-SO2)

- •

Lithium iron disulfide (Li-FeS2)

- •

Lithium polycarbon monofluoride (Li-(CF)x)

- •

Lithium copper oxide (Li-CuO)

- •

Lithium vanadium pentoxide (Li-V2O5)

- •

Lithium bromine chloride (Li-BrCl)

- •

Lithium iodine (Li-I2)

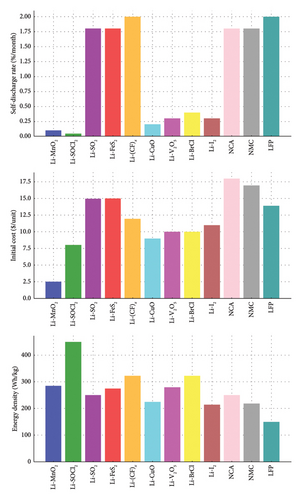

Figure 2 comprehensively compares various battery chemistries, including primary batteries, NCA, NMC and LFP, across key metrics such as self-discharge rate, initial cost and energy density. According to Figure 2, while LFP batteries offer safer chemistry with a longer cycle life, making them an attractive option for IoT applications, their lower energy density than NMC and NCA requires larger or heavier battery packs for the same capacity level.

This may result in a limitation in space-constrained applications, as most IOT-based devices must be compact and lightweight to minimise space usage without compromising performance quality or safety [4, 5].

According to this figure, it can be seen that most of the nonrechargeable batteries, such as Li-SOCl2 and Li-MnO2, have higher energy densities (from 215 to 450 Wh/kg). In contrast, the rechargeable NCA, NMC and LFP batteries offer more moderate energy densities (150 and 250 Wh/kg) [7, 8]. This suggests primary batteries for applications requiring limited power and a smaller footprint. It should be noted that while rechargeable battery technologies such as LFP, NCA and NMC have lower energy densities than primary batteries, their rechargeability offers an excellent benefit for IoT applications with higher power demands or frequent battery replacements.

While offering rechargeability, LFP, NCA and NMC batteries exhibit higher self-discharge rates than most nonrechargeable batteries. According to Figure 2, it can be seen that the self-discharge rates for NCA, NMC and LFP batteries are between 1.8% and 2.0% per month (more than 20% per year), while some primary batteries such as Li-SOCl2 and Li-MnO2 have much lower rates around 0.05%–0.10% per month (maximum 1.2% per year). This suggests primary batteries as a suitable solution for long-term, low-power IoT applications with infrequent use.

According to Table 1, the operation complexity introduced by LFP, NMC and NCA batteries is another consideration, particularly in remote or harsh environments, where dependence on reliable charging infrastructure can be a disadvantage. Nonrechargeable batteries, by contrast, offer greater simplicity and reliability in these settings. Nonrechargeable batteries are a competitive choice, especially for low-drain applications requiring long-term storage. Their simplicity, extended shelf life and low maintenance make them ideal for IoT devices with low-power, infrequent usage patterns, where maximising operational longevity is crucial.

| Factor | Li-MnO2 | Li-SOCl2 | NCA | NMC | LFP |

|---|---|---|---|---|---|

| Initial battery cost [7, 78, 80] | Low ($2-$3 per unit) | Moderate ($7–$9 per unit) | High ($10–$30 per unit) | High ($10–$30 per unit) | Moderate ($7–$20 per unit) |

| Charging circuit and solar panel cost [56] | N/A | N/A | High ($15–$50 per system) | High ($15–$50 per system) | High ($15–$50 per system) |

| Installation/complexity [42, 81] | Low | Low | High | High | High |

| Energy density [16, 17] | High | Very high | High | High | Moderate |

| Self-discharge rate [82] | Very low | Very low | Moderate/high | Moderate/high | Moderate/high |

| Lifespan (cycle) [7, 20, 21] | 1 | 1 | 500–1500 | 1000–3000 | 3000–10000 |

| Lifespan (years) [42, 78, 80] | 10–20 | 10–25 | 5–10 | 8–15 | 10–20 |

| Environmental impact [23, 79] | High (disposal issues) | High (disposal issues) | Lower (reduced waste) | Lower (reduced waste) | Lower (reduced waste and safer chemistry) |

| Total cost over 10 years, including charging and maintenance [56, 81] | Low (replacement needed) | Low (replacement needed) | High (including charging/control) | Moderate (including charging/control) | Moderate (including charging/control) |

To compare the cost of different battery types based on their energy density (Wh/kg), it is required to estimate the cost per Wh for each type of battery. This has been performed by dividing the cost per battery by the energy capacity in Whs, calculated from the energy density (Wh/kg) and the battery’s mass. Table 1 presents the simplified comparison assuming typical energy densities for these battery types. Looking at the initial cost per unit, the primary batteries have an advantage, with Li-SOCl2 and Li-MnO2 costing around $2.5–$8 per unit compared to $14–$18 per unit for LFP, NMC and NCA, with the same capacity for one cycle. This could make primary batteries more cost-effective in specific low-power IoT applications [7, 8].

On the other hand, rechargeable batteries could be cycled thousands of times during their lifetime. This reusability is a crucial benefit for IoT applications that require higher power with frequent battery replacements and are not constrained by physical size. It should be noted that for rechargeable batteries, the cost of the electricity, initial charging equipment, and the maintenance cost for the charging devices should be considered. While the initial cost may be higher, the reusability of rechargeable batteries can offset this over the device’s lifetime [51, 53]. Additionally, advancements in battery management systems (BMS) and intelligent charging technologies have improved rechargeable batteries’ performance, longevity and efficiency, making them increasingly viable for IoT applications.

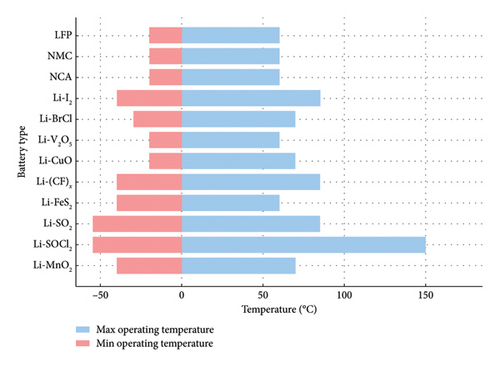

Figure 3 presents the comparison of the operating temperature ranges for primary and rechargeable batteries. It can be seen that some of the primary batteries exhibit a wide variety of temperature performance characteristics depending on their specific chemistry. For example, Li-SOCl2 batteries have a vast temperature range, performing efficiently from −60°C to +150°C [78]. According to [32, 33], the nonrechargeable options, such as Li-SOCl2 and Li-MnO2, tend to have higher reliability but lower design complexity. At the same time, the rechargeable NCA, NMC and LFP batteries offer more design flexibility but may require more complex charging infrastructure and maintenance. While Li-MnO2 does not offer as extreme a range of temperature as Li-SOCl2 and has a more moderate temperature range (−40°C and +80°C), this temperature range is still suitable for many standard IoT applications. The Li-SOCl2 batteries stand out with the broadest operating temperature span, followed by Li-MnO2, NCA, NMC and LFP [7, 8]. This makes Li-SOCl2 batteries well-suited for deployment in harsh environments with extreme temperatures, such as industrial settings or remote locations.

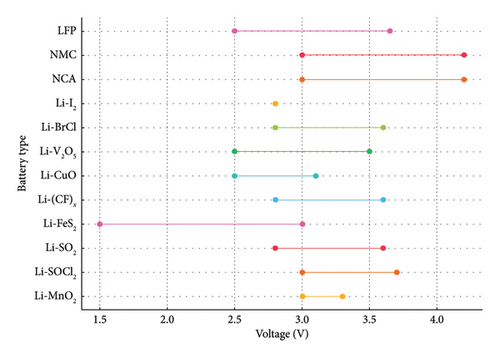

In addition to the factors mentioned above, it is crucial to consider the voltage characteristics of the battery chemistries. Figure 4 shows the typical voltage ranges for various battery types. It can be observed that Li-MnO2 and Li-SOCl2 batteries operate within a narrow voltage range of 3.0–3.3 V and 3.0–3.7 V, respectively, making them excellent choices for devices that require a constant voltage over an extended period. Similarly, most primary batteries exhibit relatively flat voltage curves throughout the majority of their capacity, followed by a sharp drop-off near the end of discharge. Rechargeable batteries, on the other hand, often demonstrate distinct, nonlinear profiles.

NCA and NMC batteries, for example, feature relatively stable voltage plateaus during operation, characterised by a steep initial drop and a sharp decrease at lower capacities. LFP batteries are particularly notable for their flat voltage plateau, which remains steady through most of the capacity range (approximately 15%–85%). Careful voltage monitoring during charge and discharge is essential to prevent battery damage from overcharging or over-discharging [7, 8, 51, 53, 55]. Beyond energy density and cost, reliability is a critical factor for IoT device deployment, particularly in remote or challenging environments. Rechargeable batteries such as NCA, NMC and LFP can also be reliable, though their performance often depends on the availability and stability of charging sources such as solar panels. In contrast, nonrechargeable batteries, such as Li-SOCl2 and Li-MnO2, excel because they do not rely on external charging infrastructure and are less prone to degradation over time [78, 80]. Moreover, the primary lithium batteries feature a durable and stable design that withstands vibrations and shocks, making them ideal for harsh and unstable conditions as well as in remote or off-grid areas, where the simplicity and self-contained functionality of nonrechargeable batteries offer a significant advantage [32–38]. Other factors, such as shelf life, also affect battery selection for IoT applications. Nonrechargeable batteries typically have longer shelf lives and simpler designs, eliminating the maintenance burden of periodical charging to maintain the same capacity [27–29, 55].

6. Key Findings and Implications for Future IoT Battery Technologies

- •

Primary batteries: Li-MnO2 batteries are highlighted for their moderate energy density, simplicity and low cost, making them suitable for low-power IoT applications with moderate replacement needs. Li-SOCl2 batteries stand out for their extended lifespan, low self-discharge rates and superior temperature resilience, making them ideal for long-term, low-maintenance deployments in remote or harsh environments.

- •

Rechargeable batteries: Technologies such as NMC, NCA and LFP are emphasized for high-power applications, with LFP excelling in environments requiring enhanced safety, cycle stability and moderate cost. However, these technologies require advanced BMS and recharging infrastructure for optimal performance.

- •

Trade-offs: The review underscores critical trade-offs between cost, performance and environmental considerations, advocating for the selection of battery chemistries tailored to IoT application-specific requirements, such as power demands, environmental conditions and maintenance constraints.

- •

The findings emphasize the need for ongoing innovation in battery chemistries to address the unique challenges of IoT deployments, particularly in extreme environments.

- •

Advances in BMS and integration with renewable energy sources, such as solar and kinetic energy, are crucial for improving the sustainability and scalability of IoT systems.

- •

Recycling and second-life applications for batteries should be prioritized to mitigate environmental impacts, reduce e-waste, and enhance the sustainability of IoT technologies.

7. Conclusion

This article comprehensively reviews the challenges and solutions associated with lithium batteries in IoT devices and sensors, addressing crucial issues such as high self-discharge, temperature limitations, nonlinear voltage characteristics and safety concerns. These challenges often result in reduced device lifespans, lower efficiency and increased maintenance costs. With their high energy density, low self-discharge rates and reliable performance, lithium batteries emerge as a compelling solution for IoT applications requiring stability and durability. Among primary lithium batteries, Li-MnO2 offers moderate energy density, simplicity and lowest cost among primary batteries, making it ideal for low-power applications with moderate replacement needs. On the other hand, Li-SOCl2 provides an extended lifespan, low self-discharge and superior temperature resilience (−55°C–150°C), making it suitable for long-term, low-maintenance deployments in remote or harsh environments. Rechargeable batteries such as NMC, NCA and LFP cater to high-power applications, balancing energy density, safety and rechargeability, with LFP excelling in environments requiring safety, cycle stability and moderate cost. However, rechargeable batteries demand advanced BMS and recharging infrastructure, such as solar systems, to ensure optimal performance and longevity. Furthermore, these technologies must evolve to meet the increasing demands for efficiency and scalability in IoT networks.

This review highlights the importance of selecting the appropriate battery chemistry based on the specific requirements of IoT applications, such as power demands, environmental conditions and maintenance constraints. While primary batteries are favoured for compact, low-power designs with minimal footprints, rechargeable batteries are better suited for applications needing frequent recharging and high energy density. This study underscores the critical trade-offs between cost, performance and environmental considerations by comparing various chemistries, including Li-MnO2, Li-SOCl2, NMC, NCA and LFP. It serves as an essential resource for IoT technology designers, industry integrators and researchers aiming to tackle energy challenges and unlock the full potential of IoT technologies. The insights in this article can help choose efficient and sustainable energy solutions that support scalable IoT applications in various industries.

Conflicts of Interest

The authors declare no conflicts of interest.

Funding

This research received no external funding. The work was conducted solely based on the authors’ personal interest and initiative.

Open Research

Data Availability Statement

All data generated or analysed during this study are included in the manuscript.