Recent Advances in Phase Change Energy Storage Materials: Developments and Applications

Abstract

Phase change energy storage (PCES) materials have attracted considerable interest because of their capacity to store and release thermal energy by undergoing phase changes. This paper offers a thorough examination of the latest developments in PCES materials (PCESMs) and their wide-ranging applications in several industries. The text focuses primarily on the most recent advances in the design and creation of PCESMs. It emphasizes the investigation of new phase change materials (PCMs) that possess specific features, such as high latent heat, thermal conductivity, and cycling stability. The study investigates advanced methods such as nano structuring, hybridization, and encapsulation to improve the efficiency and dependability of PCESMs. PCESMs are employed in the construction industry for passive solar heating, thermal regulation, and energy-efficient building designs. They facilitate effective thermal dissipation in electronics, hence, improving the efficiency and durability of electronic devices. Moreover, PCESMs are essential in enabling the incorporation of intermittent energy sources like solar and wind power into the grid, hence, supporting renewable energy storage. Furthermore, the research examines upcoming patterns and potential outcomes in the domain of PCESMs, including the progress of versatile PCES composites, integration with intelligent materials, and breakthroughs in thermal energy conversion technologies. These advancements have enormous promise to tackle worldwide energy concerns, decrease greenhouse gas emissions, and promote sustainable development. Recent advancements in PCESMs have opened up opportunities for their extensive use in many industries, providing inventive solutions for effective energy storage, thermal regulation, and ecological sustainability. Ongoing research and technological breakthroughs in this field are anticipated to propel further advancements and facilitate the achievement of a more environmentally friendly and energy-efficient future.

1. Introduction

Phase change energy storage materials (PCESM) refer to compounds capable of efficiently storing and releasing a substantial quantity of thermal energy during the phase transition process. These materials are used in thermal energy storage (TES) systems to mitigate the discrepancy between energy production and consumption, thereby, enhancing energy efficiency. PCESM can exist in either solid–liquid or solid–solid forms and possesses a high energy storage density, high latent heat, and exceptional constant temperature performance [1]. Nevertheless, pure PCESM is constrained by drawbacks like leakage, limited thermal conductivity, and volume expansion when undergoing phase shift. In order to address these difficulties, scientists have investigated the application of composite PCESM by enclosing PCESM with porous substances. These composite materials serve to reduce leakage, boost heat transfer, and improve the thermophysical properties of PCESM. Various porous materials, including metal foam, porous polymer, carbon-based porous materials, and porous ceramic materials, have been studied as supports for SS-PCESM [2]. These materials have demonstrated encouraging outcomes in regards to thermal conductivity, latent heat, phase transition temperature, form stability, and thermal cycle stability. The utilization of porous materials in the production of SS-phase change materials (PCMs) has promise for diverse industries and presents avenues for additional investigation and advancement [1, 2].

In recent years, PCESM, or pumped compressed energy storage modules, have garnered much attention and advancement as a viable and environmentally friendly option for storing energy in several sectors. PCESMs, such as inorganic salt hydrates, possess excellent thermal conductivity and low flammability, which makes them well-suited for energy storage purposes in buildings and solar appliances [3]. Integrating PCESM into construction materials, such as mortars and concrete, has demonstrated encouraging outcomes in reducing energy usage in solar-powered buildings [4]. PCESMs have been widely used in TES because of their exceptional energy output stability and large storage capacity at a consistent temperature [5]. Furthermore, the combination of PCESM with solar dryers can improve energy efficiency by storing thermal energy and releasing it when there is not enough energy available [6]. In summary, PCESM provides a viable and long-lasting alternative for storing energy in several sectors, thereby, facilitating the shift towards environmentally friendly and renewable sources of energy.

Pumped hydroelectric storage (PHS) systems have superior efficiency and reduced cost in comparison to conventional advanced adiabatic compressed air energy storage integrated with a solar collector (AA-CAES-SC) system [7]. A shared energy storage management (SESM) system is utilized in a grid-connected microgrid to optimize the use of renewable energy and minimize expenses [8]. When comparing energy efficiency, double-layer capacitors (EDLC) and kinetic energy storage systems (KESSs) have been found to have different levels of efficiency, with EDLCs being more efficient [9]. The significance of energy storage lies not only in its ability to provide arbitrage benefits but also in its capacity to effectively decrease overall system costs, particularly in power systems characterized by substantial wind generation [10]. An innovative energy storage system that integrates several energy storage devices has been suggested. This system improves efficiency and reduces expenses and losses compared to traditional systems [11]. The environmental consequences of using PCESM as a renewable energy storage option vary depending on the specific technology and its life cycle. Massive storage technologies, such as pumped hydro and compressed air storage, may require extensive civil construction and might cause significant local disturbance during the construction phase [12, 13]. Less physically impactful are smaller installations, such as flywheels or supercapacitors [14]. Electrochemical accumulators, such as batteries, raise concerns about the use of heavy metals and other chemical constituents that may pose environmental risks [15]. Furthermore, when considering PCESM systems, it is important to take into account the overall environmental sustainability of the final energy output. Due to energy mix and material choices, these systems’ environmental impacts can vary [16].

PCESMs, such as thermal batteries and composite tire pressure monitoring system (TPMS)–based systems, provide effective and economical options for storing energy [17–19]. Heat batteries employ phase changing substances to store heat energy, offering a durable and economical option. Combining PCM and graphite in a high-temperature thermal storage system has potential for large-scale utilization, but the expensive nature of graphite is still a hurdle to overcome [20, 21]. Composite TPMS–based solutions increase the effectiveness of PCM (PCESM) latent heat use, hence, enhancing the efficiency of battery TES systems. These materials for storing energy through phase change have costs that are similar to other storage technologies, and there is a possibility of reducing expenses even more if the expenses associated with graphite and steel can be decreased. PCESMs offer efficient and cost-effective alternatives to conventional battery technology for energy storage applications [20, 21].

Current developments in PCESMs research include improving PCM thermal conductivity, investigating their use in solar energy systems, creating composite PCMs utilizing polyethylene glycol (PEG), and employing additive manufacturing methods for PCM composites and devices. Scholars have examined the mechanisms and prediction models of thermal conductivity in PCMs [22]. PCMs have been extensively utilized in many solar energy systems, including SCs and solar air heaters, to augment energy storage and enhance system efficiency [23]. The primary objective in the development of PEG–based composite PCESM has been to improve thermal conductivity while also addressing concerns like supercooling and flame resistance [24]. The utilization of additive manufacturing techniques has been employed to enhance the material properties and geometry of PCESM composites and devices, additive manufacturing techniques have been employed. This enables the simultaneous optimization of energy and power density [25]. The integration of PCESM in building applications has been studied in relation to TES, specifically focusing on the building envelope and its effects on energy efficiency and thermal comfort [26].

PCESMs, such as PCMs, can be easily expanded for utilization in larger energy storage systems. PCMs make use of their latent heat properties to store and control thermal energy. They have been effectively utilized in a wide range of applications, such as solar appliances, buildings, battery thermal management, and waste heat recovery systems [27, 28]. Nevertheless, there are obstacles that must be confronted in order to expand on a larger scale. The compatibility between PCMs and the materials used for containing or encapsulating them is an obstacle that arises. Container materials, such as carbon steel and copper, have been reported to undergo corrosion and degradation as a result of the corrosive attack by PCMs [6]. One further difficulty is the limited ability of PCMs to transfer heat; however, this can be enhanced by using substances such as graphite or utilizing metal foam structures beneath them [29]. Furthermore, the feasibility, durability, and security of PCMs must be taken into account for extensive implementations [1]. Additional research is required to address these issues and create energy storage systems using PCMs that are both highly efficient, cost-effective, and dependable. PCESM provides substantial technological advancements in multiple solar energy methods, including SCs, solar stills, solar ponds, solar air warmers, and solar chimneys [23]. Enhancing the low thermal conductivity of PCESM during phase shift is a significant obstacle. However, various strategies have been suggested to address this issue, such as using nanoparticles, integrating foam structures, and applying external fields [22]. Eutectic PCMs (EPCMs) are mixes of binary, ternary, or multiple-component PCMs. They have demonstrated exceptional performance in TES applications, offering a wider range of temperatures for phase transition and enhanced phase stability [30]. PCMs have been combined with functional supporting materials to enable transdisciplinary applications, such as those in the fields of optics, electronics, magnetism, acoustics, medicine, mechanics, and catalysis [31]. Furthermore, PCMs have been employed in latent heat storage systems to promote energy conservation, as well as in solar heating systems and waste heat recovery systems. Ongoing research is focused on enhancing their efficiency and integrating them with solar water collectors [32]. Table 1 displays comparison table of critical studies.

| Year | Materials | Key findings | Limitations | Applications | Reference |

|---|---|---|---|---|---|

| 2024 | Carbon-based porous materials | Reviews CPCMs with carbon-based porous supporting materials and discusses challenges and prospects of CPCMs for thermal energy storage (TES). | Low thermal conductivity and poor shape stability. | It is used in various thermal management application. | [33] |

| 2024 | Renewable organ phase change materials (PCMs) | Diesters of sebacic acid have appropriate thermal properties for storage. | Melting onset temperatures range from 30 to 58°C. | TES applications. | [34] |

| 2023 | Phase change energy storage materials (PCESMs) in building energy conservation | Introduces concept, classification, and specific applications of PCMs. | Problems with PCMs. | PCMs in building energy conservation. | [21] |

1.1. Justification Section

Despite all the progress recent research has brought to light, there are still several important gaps in the field. Table 1 illustrates how prior research has mostly concentrated on improving particular qualities. For instance, we provide reviews of CPCMs with carbon-based porous supporting materials, discuss the challenges and potential of CPCMs in TES, highlight the suitable thermal properties of diesters of sebacic acid for storage and introduce the concept, classification, and specific applications of PCMs. To overcome these current constraints, our work offers a novel strategy that takes advantage of the high latent heat, grid-scale energy storage, transportation sector, and important PCESMS features. Our work makes a valuable contribution to the field of PCESMs by optimizing key properties of PCESMS, grid-scale energy storage, the transportation sector, and high latent heat. This greatly enhances the development and applications of PCESMS.

2. Key Properties of PCESMS

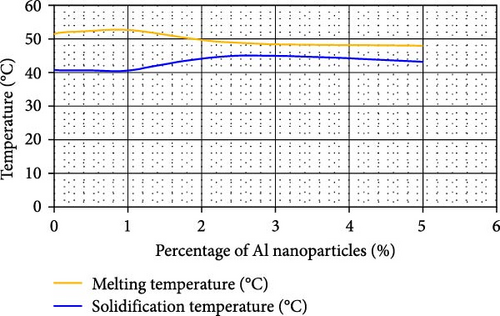

PCESMs possess crucial features that significantly impact their performance. These properties encompass a high capacity for storing energy, a high amount of latent heat, and an exceptional ability to maintain a constant temperature throughout a phase shift [35]. Furthermore, it is crucial to take into account parameters such as thermal conductivity, phase transition temperature, undercooling, form stability, thermal cycle stability, and chemical compatibility [1]. This is achieved by encapsulating the materials to prevent leakage and enhance heat transfer, as stated in [36]. Additional considerations that should be taken into account include the temperature range at which phase transition occurs, the amount of heat required for fusion, the stability of the materials, and their level of safety [37]. Nanoparticles, such as aluminum (Al) and copper, can be added to PCMs to improve their thermophysical properties. However, this addition can also lead to an increase in the dynamic viscosity of the material [38]. Figure 1 illustrates the fluctuations in the melting and solidification temperatures of the Al-nano and paraffin samples, as reported in [38].

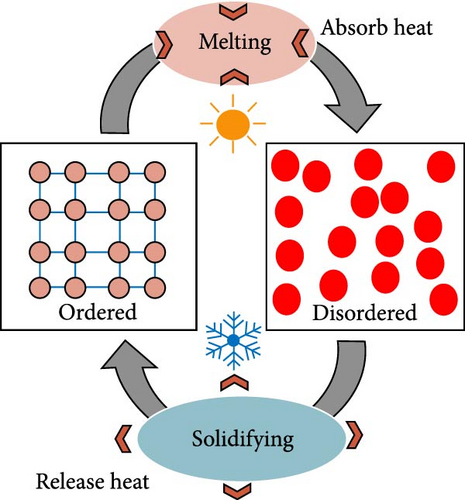

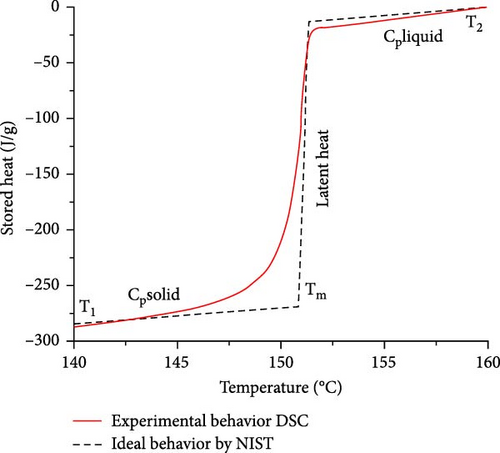

PCESMs have distinct characteristics that set them apart from other forms of energy storage technology. PCMs possess the capacity to store thermal energy by utilizing the latent heat produced during phase transitions. PCMs have the ability to undergo multiple cycles of melting and solidification without any significant changes in their thermal, chemical, and physical properties. This characteristic is referred to as cyclic stability [2]. Due to their high energy storage density, high latent heat, and outstanding constant temperature performance during phase shift, they are well-suited for TES applications [35]. PCMs that have a melting point within the range of 100–220°C are especially valuable for addressing the problem of irregular energy supply from wind and solar sources. These PCMs have the ability to store thermal or electrical energy obtained from renewable sources in the form of heat [1]. Calorimetric methods, particularly, differential scanning calorimetry (DSC), are commonly employed to reliably assess the thermal properties of PCMs, including transition temperatures, enthalpy of transition, and heat capacity [39]. In summary, the distinct characteristics of PCMs make them a highly favorable choice for effective and dependable storage of thermal energy [40]. Figure 2 depicts the transition from a solid to a liquid state in a PCM. It includes a schematic representation of the solid–liquid phase shift and a graph showing the amount of heat stored as a function of temperature. The graph compares the ideal phase change of adipic acid, as determined by the National Institute of Standards and Technology (NIST), with the actual phase change observed (shown by a continuous line) [40].

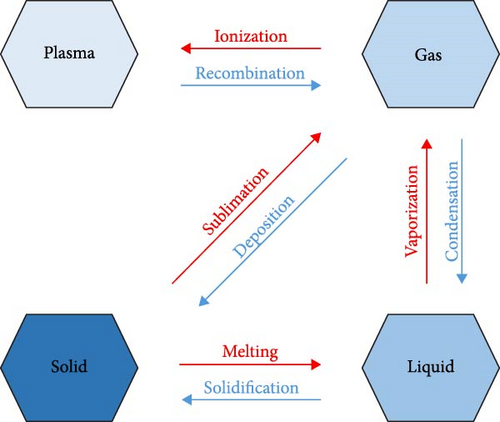

Composite phase transition materials were produced by combining decorative mica with PEG. Thermal conductivity and storage capacity were enhanced by the inclusion of expanded graphite [41]. The research examines the utilization of PCMs for the purpose of storing renewable energy. The article examines the criteria for selecting PCMs, their thermal capabilities, and durability. It also explores the usage of PCMs in solar water heating systems [42, 43]. Phase transition materials have TES capabilities that are equivalent to those of batteries. The phase change properties, such as melting temperature and enthalpy of fusion, are affected by the molecular structure [44]. The phase transition properties of PCESMs greatly influence their performance in many applications. PCMs are utilized for the purpose of TES because of their elevated latent heat capacity. Single-component PCMs have a distinct temperature at which they undergo phase change. On the other hand, EPCMs are mixes of PCMs that melt at a specified temperature that is lower than the melting point of any of the individual components. Enhanced PCMs (EPCMs) exhibit higher performance in comparison to PCMs consisting of a single component. They have a wider range of temperatures at which they undergo phase change and also show improved stability during phase transition [30, 45]. The working temperature range for solidification and melting applications varies based on the specific application, such as refrigeration, air-conditioning, SCs, and heat recovery [46, 47]. By incorporating PCMs into several low-temperature applications, such as building envelopes and solar photovoltaic systems, their performance and overall efficiency are enhanced [48, 49]. Composite PCMs (ss-PCMs) are created by enclosing PCMs with porous materials, resulting in stable forms. These composites effectively address issues such as volume expansion, leakage, and low thermal conductivity that occur during phase transition [35, 50]. PCM nanocomposites, fabricated by mixing, encapsulation, and impregnation techniques, effectively tackle problems such as leakage and low thermal conductivity, hence, improving the thermal buffering capability of PCMs [51]. Figure 3 depicts the phase change transitions [48].

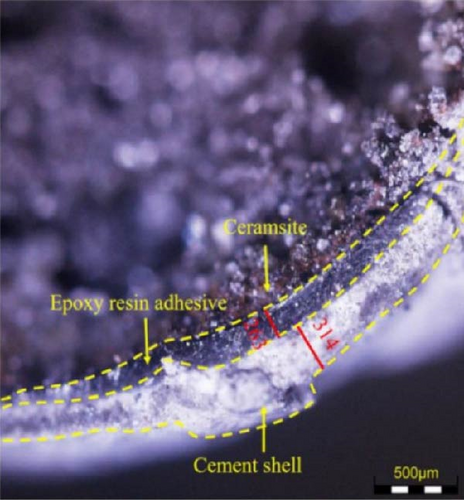

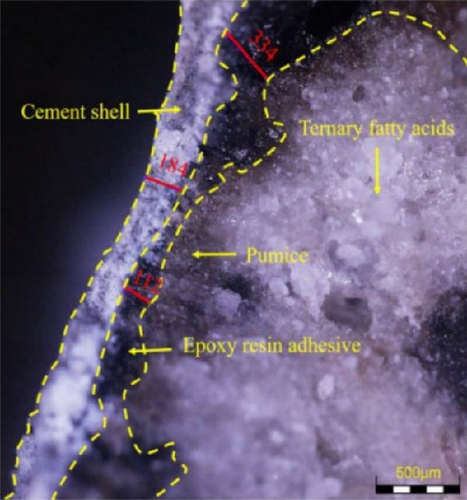

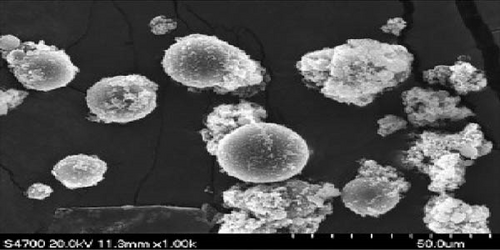

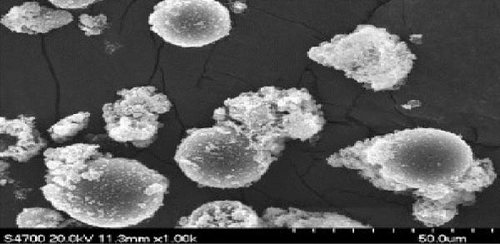

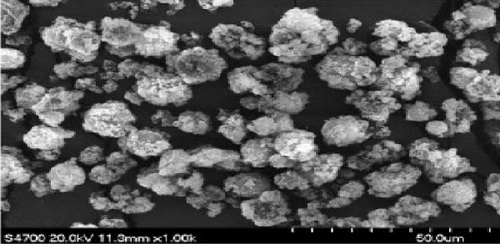

The thermal performance of shape-stabilized composite PCMs was improved by the addition of microparticles of copper oxide (CuO). The inclusion of CuO resulted in an elevation of the degradation temperature and an increase in the heat storage capacity, as reported in [52]. The surface of EG is coated with nano-alumina, which is combined with calcium nitrate tetrahydrate salt. The CPCM (MEG-CN4W) compound has excellent thermal stability and shows promising promise for many applications [53]. A study was conducted to investigate the impact of porosity and starting pressure on thermal performance [54]. Figure 4 shows the optical microscope images (OMIs) of the interfaces, where ceramsite-based aggregates (CBAs) and pumice-based aggregates (PBAs) are encapsulated [55].

PCESMs have garnered considerable interest due to their potential to mitigate the energy supply and demand disparity in renewable energy systems. Current breakthroughs in this subject involve the enhancement of PCMs in terms of their thermal efficiency, stability, and form stability. Various techniques, including encapsulation, incorporation of gelling and thickening agents (GTAs), and utilization of porous support materials, have been investigated to improve the thermal conductivity, stability, and heat transfer efficiency of PCMs [5, 35, 56]. The progress in this field has resulted in the effective utilization of PCMs in diverse sectors such as building climate control, solar energy generation, and energy recuperation [6, 23].

3. Renewable Energy Integration

PCESMs provide great potential for mitigating the intermittent nature of renewable energy sources (RESs). PCESMs enhance the stability and reliability of integrating solar and wind power into the grid by effectively storing surplus energy during periods of high production and releasing it during times of high demand. Table 2 presents a summary of the latest studies on the integration of renewable energy.

| SL | Year | Findings | Reference |

|---|---|---|---|

| 1 | 2021 | Higher-efficiency air heating systems are provided by collector–storage based systems. Storage-based collectors are appropriate for applications with a medium operating temperature range. | [57] |

| 2 | 2023 | Building mixes with phase change composite fibers have better latent heat storage. Under artificial sunlight, the samples displayed enhanced heating and decreased cooling. | [58] |

| 3 | 2021 | Latent heat thermal energy storage (LHTES) is essential to the development of renewable energy. | [59] |

| 4 | 2021 | Phase change materials (PCMs) embedded in nanoparticles improve thermal conductivity. The TES capacity is enhanced by optimizing the concentration of nanoparticles. | [60] |

| 5 | 2019 | Leakage is avoided and storage capacity is increased by organic PCMs encapsulation. | [61] |

| 6 | 2018 | PCM in domestic solar hot water storage tank (DSHWST) lowers annual electricity useage by 6.5 MWh. About 5.5 tons of CO2 are eliminated annually by PCM in DSHWST. | [62] |

| 7 | 2019 | PCMs work well for storing solar energy. PCMs are utilized in cookers, dryers, solar power generation, and water heating. | [63] |

| 8 | 2020 | Solar energy is captured and stored using erythritol PCM. A new way of transferring solar energy is demonstrated. | [64] |

| 9 | 2022 | Latent TES PCM integration is still in its infancy. | [65] |

| 10 | 2022 | Improved storage materials’ thermophysical characteristics and absorption efficiency. Commercialization is hampered by issues with high prices, corrosion, erosion, and pressure loss. | [66] |

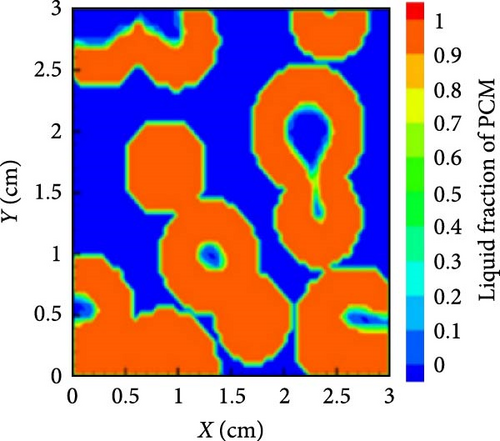

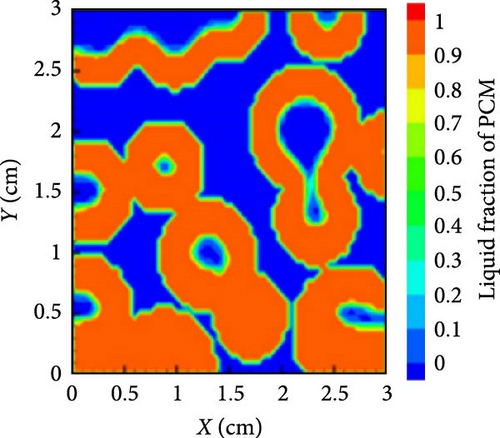

Current research on PCESMs for integrating renewable energy focuses on enhancing the thermal conductivity of PCMs to improve their performance [5, 22]. Several ways have been investigated, including encapsulation, incorporation of nanoparticles, embedding foam structures, and application of external fields [1]. Furthermore, there has been a particular emphasis on the advancement of PCMs that undergo melting within the temperature range of 100–220°C. These PCMs can store thermal or electrical energy derived from renewable sources and transform it into heat [67]. Nevertheless, numerous current PCMs are not feasible in practice because of issues regarding their stability and safety [68]. Combining PCMs with nanocomposites has demonstrated the potential to enhance heat conductivity and the overall performance of systems. The lattice Boltzmann method (LBM), among other numerical methods, has been employed to investigate the dynamic characteristics of PCMs and improve comprehension of their operational efficacy. Additional research is required to enhance the efficiency of these systems and fill in the gaps in experimentation and economic analysis. Research has demonstrated that incorporating PCMs and nanocomposite PCM into flat plate SCs (FPSCs) can increase the absorption of solar radiation and raise the overall efficiency of the system [67]. PCM has also been extensively studied for its use in thermal heating applications in buildings, where innovative methods have been used for underfloor heating, wall heating, and residential hot water tanks [69]. Solar desalination systems that incorporate PCMs can generate fresh water and store surplus thermal energy derived from solar power. This technology plays a significant role in achieving sustainable development objectives [70]. Figure 5 displays the melting front of metal foams with varying porosities after 163 s: (a) 50% porosity, (b) 60% porosity, and (c) 70% porosity [68].

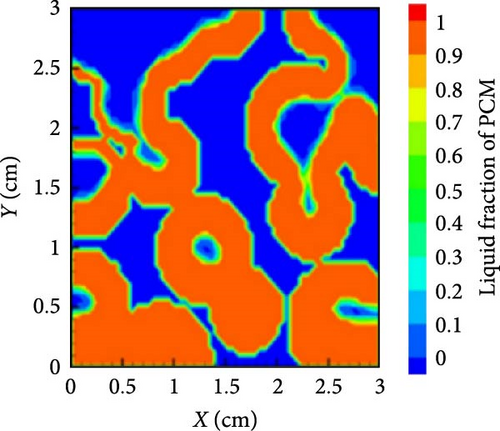

PCES technologies, including PCMs, have demonstrated potential in terms of being cost-effective and efficient for the integration of renewable energy. PCMs have the ability to store thermal energy derived from renewable sources and then release it as heat. This makes them highly valuable for applications that require heat as the final form of energy use [1]. Nevertheless, the limited heat conductivity of PCMs restricts their utility as standalone PCMs in industrial settings. Researchers have explored various strategies to improve the performance of PCM, such as enhancing thermal conductivity and utilizing numerical simulations like the lattice Boltzmann method (LBM) [50]. Furthermore, PCMs have been examined for their capacity to enhance energy efficiency and offset variations in solar energy availability in building envelopes [71, 72]. In addition, PCMs have been evaluated as potential solutions for storing thermal energy at high temperatures in concentrated solar power (CSP) plants. Some specific PCMs have been found as cost-effective and thermally viable choices [73]. PCESMs have the potential to be a cost-effective and efficient way to integrate renewable energy. PCESMs, such as PCMs, can potentially solve the problem of energy imbalance between supply and demand and help alleviate energy shortage difficulties in the integration of renewable energy [5]. PCMs exhibit exceptional energy output stability and possess a large capacity for storing energy, rendering them well-suited for applications involving TES [1]. Nevertheless, PCMs frequently exhibit inadequate thermal conductivity, hence, impacting their thermal efficiency during energy storage [4]. Efforts have been made to enhance the thermal conductivity and address other limitations of PCMs through the use of strategies such as encapsulation [68]. Utilizing PCMs in TES systems can effectively mitigate energy consumption in buildings and decrease dependence on non-RESs [74]. Moreover, waste plastics can serve as a supplementary substance for enclosing PCMs, offering a remedy for the issue of waste plastic pollution, while simultaneously generating an energy storage material. Additional investigation is required to create TES systems that are capable of operating on a large scale, while also being efficient and dependable, by utilizing PCMs. In general, PCMs provide environmental advantages in terms of clean and sustainable energy storage. However, there are still obstacles to overcome in terms of enhancing their thermal characteristics and scalability. Figure 6 depicts the architectural layout of a solar building envelope module [72].

Nevertheless, the integration of PCM in renewable energy systems faces numerous hurdles. An obstacle that arises is the limited ability of typical PCMs to conduct heat, but this can be overcome by integrating nanocomposites to improve thermal conductivity [67]. One further obstacle is to the stability and safety of PCMs, as numerous substances within the desired temperature range are not feasible in practical terms [1]. Furthermore, it is necessary to do optimization study and economic analysis of PCM integration in renewable energy systems [42]. In addition, there are issues linked to materials that must be resolved, including ensuring the reliable functioning of current PCM and the creation of new and innovative ones [75]. In conclusion, additional research and development are necessary to address these obstacles and facilitate the extensive incorporation of PCM in renewable energy systems [76].

4. Grid-Scale Energy Storage

In recent years, there have been significant developments in grid-scale energy storage technology. These improvements seek to tackle the issues presented by the unpredictable and sporadic nature of RESs like solar and wind. The assessment parameters for energy storage systems encompass storage capacity, efficiency, response time, energy density, power density, input cost, economic value, emissions, ecological impact, employment generation, and societal acceptance. Energy storage systems have been categorized according to the type of energy storage and the length of time it may be stored and discharged. However, there has been research conducted on PCESMs due to its capacity to either move the timing or decrease the intensity of high thermal loads. The research has mostly concentrated on enhancing the material properties of PCM, such as the latent heat of fusion and thermal conductivity. Additionally, there has been a focus on developing additive manufacturing processes for composites and devices made from PCESMs. Researchers are currently investigating the future possibilities of using (PCESMs) additive manufacturing for TES and thermal management [25, 77–79]. Phase change thermal storage systems offer distinct advantages compared to sensible heat storage methods. An area that is now being extensively studied is the improvement of heat transmission in thermal storage systems that involve phase shift [80]. Phase shift energy storage technology enhances energy efficiency by using RESs. The utilization of porous supports in composite PCMs enables the enhancement of properties and the resolution of inherent challenges [35]. PCESMs have a substantial influence on the efficiency and cost-effectiveness of large-scale energy storage systems for the power grid. PCMs have the ability to store thermal energy obtained from renewable sources and subsequently release it as heat as required. This makes them well-suited for applications that rely on intermittent energy sources such as wind and solar [81]. PCMs that have a large amount of energy required for fusion and a temperature at which they undergo phase shift within the acceptable range are optimal for this purpose [1]. Nevertheless, there are obstacles linked to the practical feasibility of PCMs, such as stability, safety, and cost [75, 82]. Several restrictions, such as supercooling, limited thermal conductivity, phase segregation, fire safety, corrosion, and cost, require attention [82]. Additional research is required to create TES technologies that are cost-effective, dependable, and capable of operating on a large scale, utilizing PCMs. A paper details the utilization of microcapsules as a material for PCES. The temperature range for the phase transition of the material is from −10 to 74°C [21]. The PCES system reduces water evaporation during the phase shift operation. Table 3 displays the latest findings in grid-scale energy storage research.

| SL | Year | Findings | Reference |

|---|---|---|---|

| 1 | 2018 | Heat dissipation pipes and phase change material (PCM) are components of an energy storage system. Heat pipes for the dissipation of pulses that have parts for condensation, transmission, and evaporation. | [83] |

| 2 | 2019 | Materials with phase changes effectively store energy. Solar energy is used for air-conditioning and cooking, among other things. | [84] |

| 3 | 2017 | Latent energy storage is dependent on the storage medium’s phase transition. Acetate of metal or nonmetal, melting point 150–500°C, is used as a storage medium. | [85] |

| 4 | 2017 | Three phase changing eutectic composite materials with varying melting points. Temperature range for PCM stability tests: 15–40°C. | [86] |

| 5 | 2023 | Composite PCMs have a high loading capacity and phase transition enthalpy. Notable enhancement in the materials’ stability and thermal conductivity. | [87] |

| 6 | 2020 | Created CPCM for high-temperature energy storage using NaNO3. Diatomite was utilized as the carrier matrix to stop PCM leaks. | [88] |

| 7 | 2021 | Large latent heat PCMs are used to store thermal energy. The majority of PCMs that show promise have comparatively modest heat conductivity. | [89] |

| 8 | 2022 | A water PCM storage tank that included RT42 saw electricity savings of up to 4.75 kWh. There was a 25% gain in system efficiency and a 27% decrease in the average daily carbon footprint. | [90] |

| 9 | 2023 | Improving graphene oxide–based PCM microcapsules for better thermal performance. Explain heat-conducting qualities and preparation techniques for different uses. | [91] |

| 10 | 2023 | An increase in foam porosity from 50% to 70% results in a 5.41% increase in energy storage. There is a 211.99% increase in overall energy storage with a 7–11 mm increase in capsule inner diameter. | [92] |

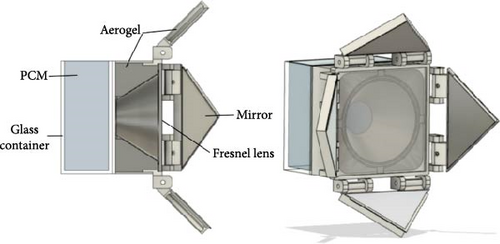

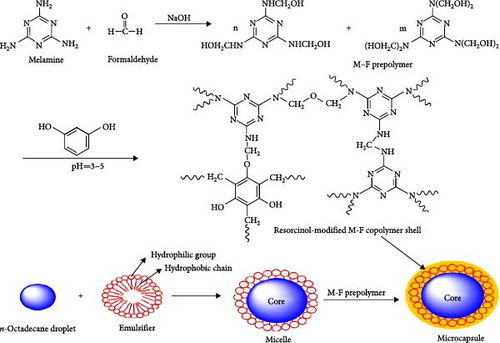

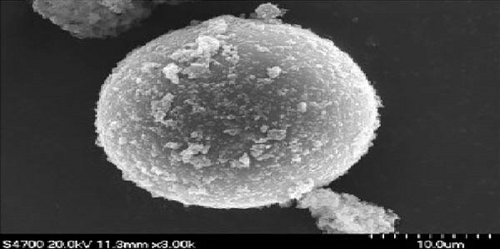

The device enhances the number of cycles and extends the lifespan of the PCESM [93, 94]. A numerical model was successfully used to develop a mathematical model for phase transition materials. The heat exchanger with PCES exhibited superior heat transfer properties [95, 96]. Figure 7 depicts the schematic representation for the MPCMs, which are composed of an octadecane core and a modified MF–based shell. Additionally, SEM images of the microcapsules with different weight ratios of core/shell materials are shown: (a) and (b) 65/35, (c) 75/25 using SMA as a surfactant, and (d) and (e) 70/30 and (f) 75/25 using SDS as a surfactant [97].

Utilizing PCESMs on a large-scale grid can potentially result in environmental consequences. The impacts encompass the substantial utilization of electricity and heat in the manufacturing process of the system’s raw materials, including the SC, PCESMs, PCESMs tank, and heat exchanger [5]. In a comparison with other energy storage technologies, the PCESMs system has a stronger environmental impact in 11 out of 18 areas, including global warming potential [98]. Nevertheless, a sensitivity analysis demonstrates that extending the system’s lifespan to 40 years leads to a substantial reduction in environmental impacts. Furthermore, a 40-year phase shift energy storage system exhibits a lower global warming potential than natural gas, as indicated by Rahman and Habib [75].

5. Thermal Energy Storage in Buildings

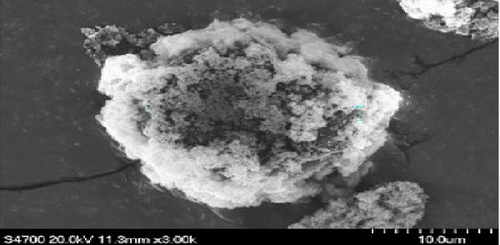

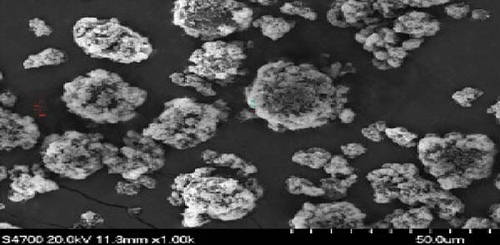

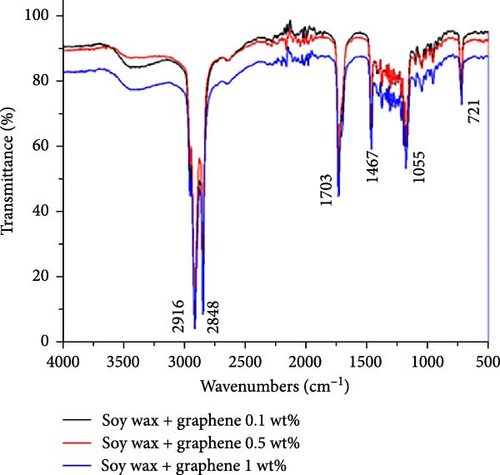

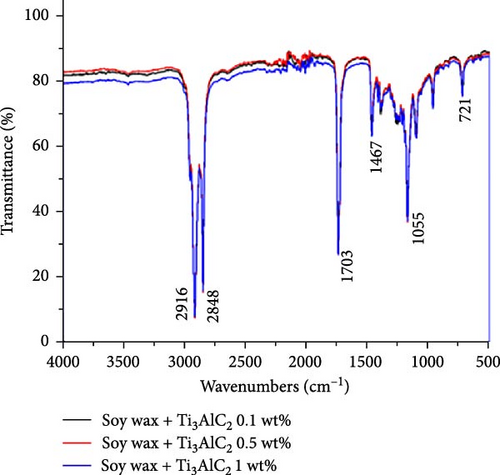

PCESMs can be used to store thermal energy in buildings [4, 26, 99–101]. PCESMs are materials that can absorb or release a sizable amount of energy during a phase change, as from a solid to a liquid. Thermal comfort, energy consumption, and energy efficiency can all be increased by integrating PCESMs into building applications. PCESMs can store thermal energy and lower cooling/heating loads in building envelopes, such as roofs and external walls. Buildings that employ PCESMs can see significant energy savings and improved thermal comfort. Numerous techniques and strategies have been looked into to maximize the application of PCESMs in structures. Research has been done on encapsulation technology as a potential solution to pure PCESM problems such limited heat conductivity and leakage. Recent years have seen encouraging advancements in the development and use of PCESMs–based thermal storage technology in the building industry [101]. The FTIR spectra of soy wax with graphene (a) and soy wax with Ti3AlC2 (b) are displayed in Figure 8 [100].

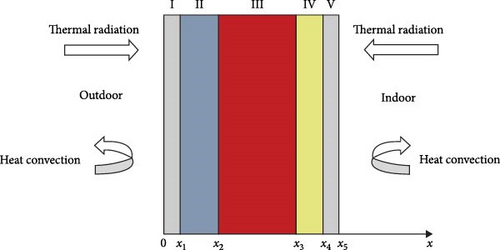

PCESMs used in TES in buildings can improve building performance and energy efficiency. Buildings can attain thermal comfort, lower cooling and heating loads, and boost energy efficiency by adding PCESMs to the building envelope [26, 72]. According to studies, installing PCESMs in the building envelope can become lower interior air temperature and increase heat storage, which can save a significant amount of energy [102]. Furthermore, by increasing the heat transfer surface area, TES systems can perform even better when their designs are optimized with PCESMs [102, 103]. The local climate, PCM thickness, and building location are some of the parameters that affect how successful the PCESM application is. PCESMs can improve building performance, energy efficiency, and thermal comfort when used for TES in buildings. There may be advantages and disadvantages for the environment when PCES is used in buildings for TES. Positively, PCESMs can lessen the need for fossil fuels to meet heating and cooling needs, which lowers carbon emissions and promotes more sustainable energy use [26, 99]. Additionally, PCESMs can enhance a building’s insulating efficiency, which can reduce energy use and boost thermal comfort [104, 105]. But there are a few issues to take into account. Due to their high heat conductivity, PCESMs may not be as useful in buildings [51, 106]. Furthermore, PCESMs could have low heat conductivity and leakage concerns; however, PCM nanocomposites can solve these issues [4, 107–109]. All things considered, PCES in buildings has the potential to improve environmental sustainability and energy efficiency. However, in order to maximize its benefits and mitigate any negative effects, particular materials and technologies must be carefully considered. The PCM wall’s heat transmission diagram is displayed in Figure 9 [103].

TES in buildings is becoming more and more interested in PCESMs. PCESM combinations, also known as EPCMs, offer better stability and a wider phase change temperature range for TES applications [30]. One way to offset variations in solar energy availability is to provide the building envelope with additional functions, including acting as a TES system [72]. Pure PCESM drawbacks such as low heat conductivity and leakage are being addressed by encapsulation technology [101]. PCESM integration has demonstrated promise in reducing building energy consumption in materials like mortars, concrete, and solar thermal systems [4]. Future prospects include the development of materials for heat storage with better thermal characteristics and microencapsulated PCESM optimization techniques. Table 4 presents current research on TES in buildings.

| SL | Year | Findings | Reference |

|---|---|---|---|

| 1 | 2023 | Salt hydrate phase change material (PCM) gives a 22% boost to energy performance. In energy stocks, PCM lessens induced stresses and strains. | [110] |

| 2 | 2022 | MXene-based phase transition materials are interesting for solar TES applications because they greatly improve thermal conductivity, heat storage capacity, and thermal stability. | [111] |

| 3 | 2022 | PCMs have been created to improve energy storage systems, especially in applications like photovoltaic systems, solar absorption chillers, and buildings. | [112] |

| 4 | 2024 | Techniques for maximizing the TES potential of sugar alcohols. Applications for solar cookers, waste heat recovery, and electricity production. | [113] |

6. Transportation Sector

PCESMs have opportunities that go beyond stationary applications and into the transportation industry. These materials have a high energy density, which makes them promising for use in sophisticated TES systems in electric cars, which will boost performance and range. The PCM layer adding process is depicted in Figure 10 [114].

PCMs are useful for energy storage in the transportation industry. PCMs have the ability to regulate food temperature while in transit, save energy, and reduce emissions of pollutants [115–117]. PCMs improve food safety, preserve temperature stability, and reduce energy consumption in the refrigerated transportation of perishable commodities such as fruits and vegetables, increasing the effectiveness of cold chain logistics [114]. Furthermore, PCMs have been investigated for use in the transportation of crude oil through pipelines in an effort to lower energy usage and pollution levels in the environment. The results have shown promise in terms of improving oil viscosity and transmission efficiency [118]. All things considered, the use of PCMs in the transportation industry has the potential to increase energy efficiency, lower emissions, and improve the security and quality of items being moved. PCMs containing nanoparticles are being used in the transportation industry to improve thermal qualities, according to current trends and breakthroughs in PCM energy storage materials [77, 119]. Furthermore, in order to address leakage concerns, mineral-based form-stable PCMs are being investigated; minerals with low cost and chemical inertness, such as graphite, diatomite, and perlite, show promise in this regard [120]. Research is also concentrating on adopting sophisticated manufacturing techniques to increase the energy and power density of PCMs. The goal is to maximize device geometry and material properties while cutting down on waste and production time [79]. These developments aim to improve transportation energy systems and eventually contribute to sustainable energy solutions in the industry through time shifting or lowering peak thermal loads. In transportation applications, PCMs have a number of advantages over conventional energy storage techniques. When PCMs are installed inside car walls, daily refrigeration loads can be as low as 34.4%, which results in significant energy savings [26]. Furthermore, PCMs exhibit excellent cost-effectiveness and have payback times of less than 3 years, which makes them a feasible option for long-term usage in automobiles [30]. Moreover, including PCMs in automobiles can cut greenhouse gas emissions by roughly 2700 kg CO2/year, demonstrating their beneficial effects on the environment [121]. PCMs, on the other hand, offer environmental benefits and increased efficiency over existing energy storage systems in transportation applications. The integration of PCMs into the transportation industry has both potential and obstacles. Among the difficulties are the necessity to develop efficient insulation models for pipelines [122], enhance PCM thermal conductivity for effective energy storage [22], and remove material-related obstacles for stable PCM operation [4]. Possibilities include improving the characteristics of PCM by adding nanoparticles, foam structures, and external fields [123, 124]; maximizing composite energy storage pipelines for safe shutdowns [35, 125, 126]; and creating novel uses for PCM in solar thermal systems and building materials. To enhance PCM integration in the transportation industry, research and development endeavors have to concentrate on enhancing thermal conductivity mechanisms, optimizing insulation models, and tackling material obstacles.

7. High Latent Heat

Energy storage via PCMs have a high latent heat storage capacity, which helps boost energy storage density. This is especially true of materials that use PCMs. These materials are appropriate for high-temperature applications because they can supply a heat source with a high density and steady temperature [127]. With a working temperature range of −20 to 200°C, PCMs are suitable for a variety of uses, including air-conditioning, refrigeration, solar heating, and high-temperature processes including waste power generation and heat recovery [128]. By adding nanoparticles, PCMs become even more efficient during cycles of charging and discharging, greatly increasing heat transfer rates [46]. Furthermore, choosing particular PCMs—like Mg84Cu16—can result in higher loading rates and thermal conductivity, which makes them attractive for use in thermal storage applications [129]. All things considered, PCMs are a competitive alternative to other energy storage technologies because of their high latent heat and adaptability. Figure 11 depicts the triplex tube heat exchanger (TTHE) with internal fins in both (a) its physical configuration and (b) its reduced computational domain [129].

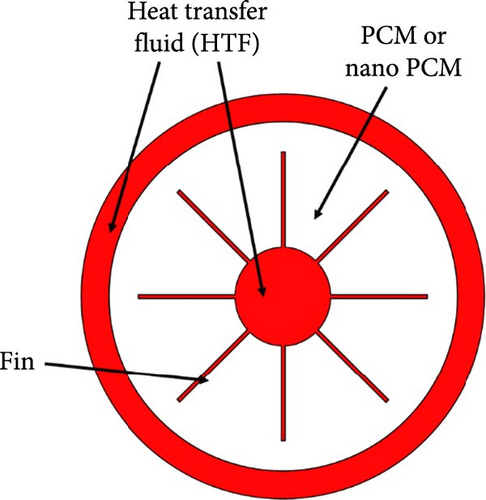

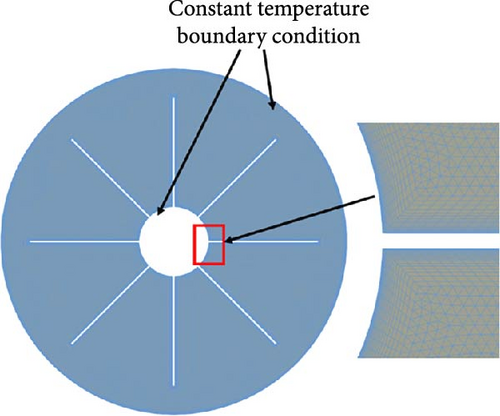

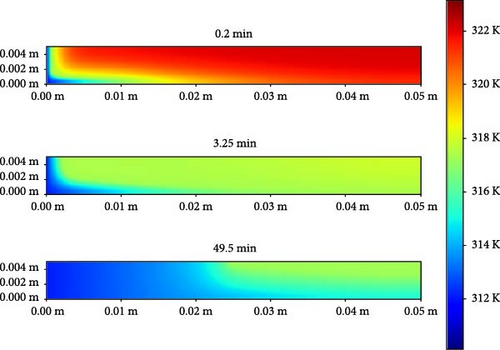

The temperature differential between the PCM and the heat transfer fluid (HTF), the PCM’s type and configuration, the addition of nanoparticles to increase the PCM’s effectiveness, and the system’s geometry are the factors that affect the high latent heat of PCESMs. Latent heat TES (LHTES) devices are highly affected by temperature differentials [130, 131]. The melting behavior and heat absorption rates are influenced by various PCMs and configurations, with natural convection being a key factor in the process [131]. A homogenous distribution is essential for optimal performance when adding nanoparticles to PCMs, which might increase heat transfer rates during cycles of charging and discharging [132]. Furthermore, the discharge temperature of the secondary fluid, fin geometries, and PCM thermal conductivity all affect the stored energy, heat flow, and stored exergy in PCMs [129]. Energy storage via phase change high-latent heat materials provide several benefits for TES applications. The temperature distributions (TDs) for the reference system with continuous fin, 0.3 W/(m·K), and Tsf = 312.15 K are shown in Figure 12 at 0.2, 3.25, and 49.5 min [133].

These substances, which include microencapsulated PCMs and the colloidal PCM-in-liquid metal system, offer high-density heat storage at steady temperatures, improving thermal management effectiveness [133, 134]. Furthermore, high-latent heat PCMs have great thermal conductivity and storage volume, which makes them economical and thermally practical for CSP applications. Examples of these PCMs are those chosen for high-temperature TES in CSP facilities [73, 127]. Moreover, compared to traditional salt-based PCMs, ultrahigh-temperature PCMs like silicon exhibit better energy storage density and rate, highlighting their potential for effective energy conversion and storage in CSP systems [73, 135]. To sum up, for a variety of energy storage applications, high-latent heat PCM materials provide better thermal performance, durability, and energy storage capabilities. Table 5 presents the state-of-the art studies on high latent heat.

| SL | Year | Findings | Reference |

|---|---|---|---|

| 1 | 2022 | Li2CO3 + K2CO3 (25:72) and Na2CO3 + Li2CO3 (56:44) were chosen as the optimal materials. Thermal energy storage (TES) development at high temperatures at a reasonable cost for concentrated solar power (CSP) systems. | [ 73] |

| 2 | 2023 | High latent heat is exhibited by phase change energy storage materials (PCESMs), which store heat isothermally during phase transitions. The temperature range of different materials is extensive, ranging from −20 to 180°C. | [46] |

| 3 | 2022 | Enhancing thermal properties using additives and encapsulation. | [136] |

| 4 | 2021 | Phase change materials (PCMs) such as silicon, which have high latent heat, are intriguing for high-temperature latent heat storage devices because they offer a better energy storage density and rate than salt-based PCM. | [135] |

| 5 | 2021 | PCMs, such as nano-encapsulated PCMs (NEPCMs), use latent heat to store thermal energy from heat emitted or absorbed during phase transitions, improving the efficiency of heat transfer. | [93] |

| 6 | 2022 | PCM and NEPCM heat storage capacity comparison. Examined both systems’ charging and discharging cycle performance. | [119] |

8. Challenges and Future Directions

Even with a bright future, issues including cost-effectiveness, material compatibility, and thermal conductivity still need to be resolved. To overcome these obstacles, research is still being conducted, with a particular focus on investigating novel materials and cutting-edge production processes. PCESMs are difficult to create because of issues such as limited heat conductivity, volume expansion, and leakage [6]. Composite PCMs (ss-PCMs), which encase PCMs in porous materials to improve heat transfer and stop leakage, have been offered as a solution to these problems [35]. Solid–solid PCMs are becoming more and more popular as a viable substitute for solid–liquid PCMs because of benefits like long cycle life and solid state processing [125]. Future work will focus on structure-property linkages and their uses, while also creating high-performance solid–solid PCMs for sophisticated TES applications [126]. In order to overcome drawbacks like low thermal conductivity, research also highlights the significance of creating form-stable nano-enhanced PCMs, with an emphasis on thermal performance and energy density augmentation [124].

By overcoming obstacles, these developments hope to open the door to effective and long-lasting phase-shift energy storage technologies. The requirement for enhanced thermal characteristics, such as stability, thermal conductivity, and latent heat capacity, is one of the present obstacles in the research and application of PCESMs [34]. To guarantee reliable operation and promote the creation of unique solutions, a deeper comprehension of material science, crystallization kinetics, and heat transfer related to PCMs is also required [4]. In addition, the food industry’s use of PCMs in conjunction with solar dryers presents obstacles in the form of performance assessment, potential applications, and implementation difficulties, underscoring the need for greater investigation and study in this field [137]. In summary, it is imperative to tackle these obstacles via multidisciplinary research endeavors to promote the efficiency and extensive integration of PCESMs across diverse sectors [138]. A viable way to improve the effectiveness and affordability of energy storage technologies is through PCESMs. These substances, like PCMs, are perfect for a variety of applications because they are highly efficient in storing and releasing energy [1, 39, 121]. By storing energy in the form of heat, PCMs have the benefit of reducing intermittency problems with RESs like solar and wind power [79]. Furthermore, it has been demonstrated that adding PCMs to solar thermal collectors significantly improves their thermal performance and energy storage capacity [139].

Even with their promise, issues including phase separation, supercooling, and subcooling must be resolved to improve their overall performance and dependability. By efficiently mitigating leakage concerns, the practical applicability of mineral-based form-stable PCMs can be enhanced. When compared to conventional energy storage technologies, PCESMs show a competitive advantage in terms of efficiency and affordability. Prospective investigations into PCESMs may concentrate on augmenting thermal conductivity, refining microencapsulation methodologies, and investigating innovative strategies such as incorporating nanoparticles and embedded foam structures to enhance PCM characteristics [4, 22, 30]. These developments may result in increased stability and efficiency across a range of applications. Construction is one industry that can benefit from these advancements because PCM can reduce energy consumption in materials like mortar, concrete, and solar thermal systems [140]. Furthermore, the application of microencapsulated PCMs may improve the performance and corrosion resistance of industrial coatings [23]. All things considered, the development of PCM technology has the potential to completely transform energy storage in industries like coatings and construction, as well as maybe other sectors looking for effective and sustainable thermal energy solutions.

9. Conclusion

- •

Overcoming conventional problems like phase separation and limited heat conductivity has been made possible by the development of innovative PCESM composites and encapsulating techniques. PCESMs’ prospective applications have been further increased by advancements in hybrid and nanoenhanced materials, which have improved the thermal stability and characteristics of PCESMs. Furthermore, the investigation of bio-based PCMs offers environmentally suitable substitutes for traditional synthetic materials, reflecting the growing trend toward sustainability.

- •

A recent area of focus for study has been the integration of PCESMs into different energy systems, with applications ranging from solar energy systems to buildings and electronics. PCESMs have been successfully applied to thermal regulation in the building industry, resulting in energy savings and improved occupant comfort. PCESMs have been essential to electronics’ thermal management, lowering overheating and extending device life. PCESMs, on the other hand, have proven their ability to store and release energy effectively in solar energy storage systems, which is in line with the demand for dependable RESs.

- •

The necessity for more effective energy utilization across multiple sectors has propelled the rise of PCESM applications. The novel applications of PCESMs in smart fabrics, electric vehicles, and healthcare (such as temperature-sensitive drug delivery) have been described in this review. These new uses demonstrate the adaptability of PCESMs and their capacity to solve energy-related issues in a range of sectors.

Conflicts of Interest

The authors declare no conflicts of interest.

Funding

No funding was received for this research.

Open Research

Data Availability Statement

The data will be made available on request.