Optimization Design of a Cost-Effective Surface-Mounted Permanent Magnet Generator Using Hybrid Ferrite and Rare-Earth Halbach Arrays

Abstract

Surface-mounted permanent magnet (SPM) machines are highly capable for wind power generation due to their high output power, simple structural design, and effective thermal management. However, their heavy reliance on rare-earth magnets significantly increases the cost per unit power, limiting large-scale deployment. To address these challenges, this study proposes a cost-effective SPM wind generator featuring a hybrid NdFeB-ferrite Halbach PM array and flux barriers. The structural parameters are optimized using a genetic algorithm (GA) with sensitivity-based constraints. Finite element analysis (FEA) demonstrates that the proposed design reduces material cost by 18.2% and weight by 14% compared to conventional SPM generators, while delivering higher output power. Furthermore, cogging torque and torque ripple are reduced by 54% and 79%, respectively, enhancing its suitability for low-speed wind applications and ensuring smoother operation. Improved loss characteristics and efficiency further highlight the generator’s superior performance. These results position the proposed design as a cost-effective and practical solution for wind power generation.

1. Introduction

Wind power generation has gained considerable attention in recent years as the global demand for renewable energy continues to rise. Permanent magnet synchronous generators (PMSGs) have emerged as a preferred choice for high-power wind turbines due to their superior power density, high efficiency, and low maintenance requirements compared to brushed and induction generators [1–5]. Surface-mounted permanent magnet (SPM) generators, where permanent magnets (PMs) are affixed to the rotor surface, are widely adopted in wind power systems. Their advantages, including high output power, reduced cogging torque, a relatively simple structural design, and effective thermal management, make them particularly suitable for such applications [6–8]. However, the primary drawback of SPM generators is their high cost per unit power, largely driven by the significant use of rare-earth PMs.

To address this challenge, extensive research has focused on enhancing the electromagnetic performance of SPM generators while exploring strategies to reduce material and manufacturing costs. For instance, the use of ferrite magnets as a low-cost alternative to rare-earth magnets was investigated, showing substantial cost reductions without compromising output power [9]. A ferrite-based PMSG design achieved approximately 50% lower active material costs compared to conventional rare-earth–based models [10]. Further advancements have been achieved through the optimization of magnet shapes and configurations. Fang et al. [11] proposed a nonuniform magnet pole arc angle, improving output power without increasing material costs. Similarly, a hybrid-flux PMSG design optimized the reluctance network and core material, resulting in a 9.4-fold improvement in power density and a significant reduction in cost per unit power [12]. Jabbari et al. [13] demonstrated that modifying the magnet pole shape from uniform to nonuniform enhanced back-electromotive force (EMF) and reduced cogging torque. Hybrid designs incorporating NdFeB and Alnico magnets, with optimized pole arc angles, achieved a 37.9% reduction in magnet cost compared to models using only NdFeB magnets [14]. Chen et al. [15] introduced an eccentric pole shape in SPM machines, enhancing magnet utilization and electromagnetic performance. Moreover, auxiliary tooth structures have been proposed to mitigate cogging torque and torque ripple, which remain significant challenges in SPM generators [16]. These advancements highlight the ongoing efforts to improve the cost-effectiveness and performance of SPM generators, ensuring their continued viability in wind power applications.

Segmentation of PMs is a widely recognized technique for enhancing the output power of PMSGs while maintaining or reducing manufacturing costs. This method involves dividing a single magnet into smaller segments while retaining its overall magnetic properties [17–20]. Among various segmentation techniques, the Halbach PM array has proven particularly effective. By optimizing the magnetization direction of the segments, the Halbach array enhances flux focusing and minimizes flux leakage, leading to improved PM utilization, higher power density, and increased efficiency. Several studies have demonstrated the effectiveness of the Halbach PM array technique in improving the performance of PMSGs. For instance, in 2016, a five-segment Halbach array was applied to a SPM generator designed for a 3 MW wind turbine [21]. The results highlighted substantial cost savings without compromising efficiency, making the design highly suitable for large scale wind energy systems. In 2020, Ni et al. [22] optimized SPM machines with Halbach arrays, achieving notable improvements in torque density. Similarly, Duan et al. [23] conducted a comparative analysis of three Halbach configurations: traditional Halbach array, uneven Halbach array, and soft magnetic Halbach array in a four pole PM machine. The study revealed that the traditional Halbach array enhanced the air gap flux density, while the soft magnetic and uneven Halbach arrays provided improved torque performance.

Reducing machine costs can be achieved not only by minimizing magnet costs but also by decreasing the use of core materials. One effective approach for this purpose is the incorporation of flux barriers, which has been widely employed to enhance the performance of PM machines while simultaneously reducing core material usage [24–26]. Flux barriers utilize air barriers to optimize and control the flux circulation within the machine structure, improving performance without increasing material requirements. The application of flux barriers in SPM machines has been investigated in a few studies. Qu et al. [27] proposed a flux barrier design for SPM generator, incorporating notched auxiliary slots between magnetic poles. Their findings indicate improvements in flux-weakening capability, significant reduction in cogging torque, and increased output torque. Chen et al. [28] introduced a flux gap modular stator design for a 12-slot/13-pole SPM motor, demonstrating enhanced electromagnetic performance through flux gap modulation. Their approach improved back-EMF and average torque by 21.6% and 7.1%, respectively. Zhou and Gerling [29] proposed a design technique that slightly widens the stator teeth and incorporates 10 half-circle flux barriers on the inner rotor surface at the q-axis position to enhance flux-weakening capability. This design significantly improved power delivery while reducing torque ripple.

Previous studies have highlighted that cost-effectiveness is a critical consideration in the design of SPM generators, particularly for wind power applications. To address this requirement, this study proposes an enhanced SPM generator design that integrates a hybrid Halbach PM array, combining NdFeB and ferrite materials, with flux barrier techniques. To the best of our knowledge, this combination of methods has not been explored in prior studies. Its implementation is expected to enhance the cost-effectiveness of SPM generators while maintaining competitive performance. The proposed design optimizes the hybrid NdFeB-ferrite Halbach PM array, flux barrier geometry, and key structural parameters to minimize material costs while maintaining power output. A genetic algorithm (GA) is employed to achieve optimal design parameters, ensuring a balance between performance and cost efficiency.

The rest of this paper is organized follows: Section 2 describes the topology of SPM generators. Section 3 presents the process of design optimization, employing a multiobjective GA. Section 4 evaluates the electromagnetic performance of the proposed designs using 2D finite element analysis (FEA). Finally, Section 5 provides the conclusions drawn from this study.

2. Topology of SPM Generators

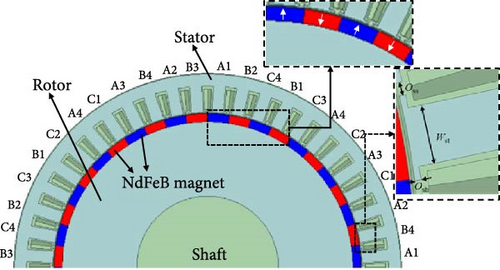

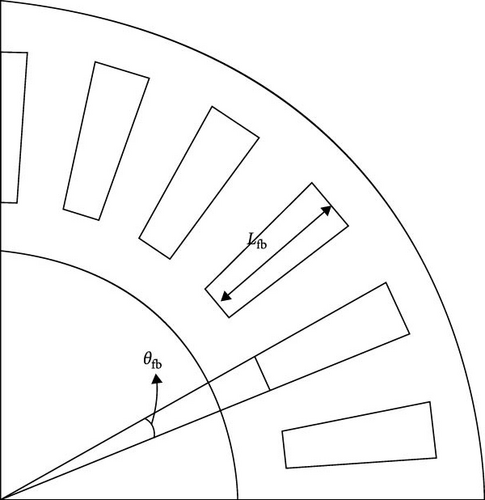

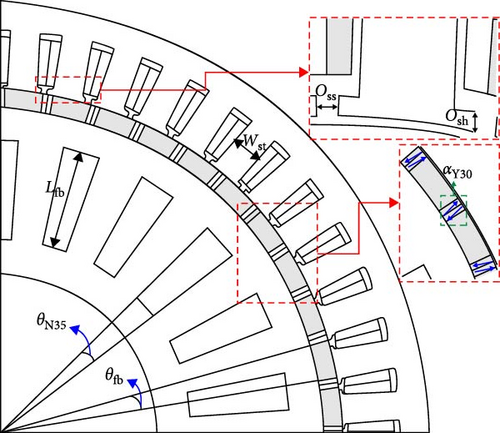

Figure 1a shows the optimal structure of 12-phase, 48-slot/22-pole-pair SPM generator used as the benchmark in this study [30]. It was selected due to its superior power generation capability among low-speed PM generators for wind power applications. Figure 1b illustrates the proposed SPM generator incorporating a hybrid ferrite-NdFeB Halbach PM array with flux barrier, developed to address the identified limitations of the benchmark design. Both configurations employ concentrated armature windings with PMs mounted on the rotor surface in an alternating polarity arrangement. The key specifications of both generators are summarized in Table 1.

| Items | Unit | Conventional structure | Proposed structure |

|---|---|---|---|

| Stator outer radius | mm | 163.5 | |

| Stator inner radius | mm | 130.8 | |

| Stator yoke radius | mm | 153.2 | |

| Stator tooth base height, Osh | mm | 1 | |

| Stator slot opening, Oss | mm | 2.28 | |

| Stator tooth width, Wst | mm | 10.27 | |

| Air gap length | mm | 1 | |

| Rotor outer radius | mm | 129.8 | |

| Rotor inner radius | mm | 60 | |

| Rotor yoke radius | mm | 123.1 | |

| Rotor cut length, Lfb | mm | — | 38.5 |

| Angle of flux barriers, θfb | ° | — | 7.45 |

| Rotor to upper barrier length, Lrb | mm | — | 11.35 |

| Rotor to shaft length, Lrs | mm | — | 12.75 |

| Upper separation length barrier, Lus | mm | — | 17.3 |

| Lower separation length barrier, Lls | mm | — | 11.3 |

| PM height | mm | 6.7 | |

| N35 arc angle, θN35 | ° | 8.182 | 6.53 |

| Y30 arc angle, θY30 | ° | — | 0.826 |

| Stack length | mm | 185 | |

| Current density | A/mm2 | 2.4 | 2.7 |

| Total slot area | mm2 | 8664 | 7593.6 |

| Number of turns per coil | turn | 40 | |

| Slot filling factor | — | 0.58 | 0.67 |

| Number of parallel branches | — | 1 | |

| Steel type | — | DW465-50 | |

| Winding diameter | mm | 0.912 (AWG-19) | |

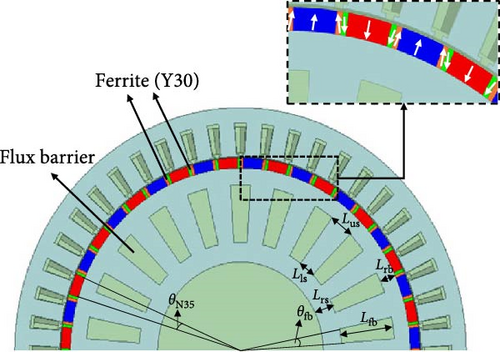

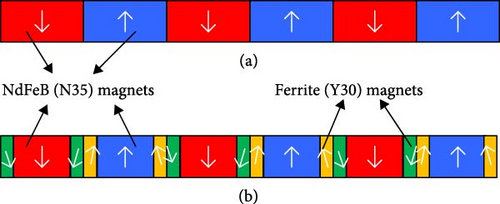

In PM machines, the total cost is heavily influenced by the cost of the PMs. To improve the cost-effectiveness of the conventional SPM generator, the original homogeneous NdFeB magnets (N35 type) as shown in Figure 2a were reconfigured into a hybrid Halbach PM array, as depicted in Figure 2b. In this proposed configuration, ferrite magnets (Y30), which are approximately seven times more cost-effective than NdFeB, are used as side magnets, as indicated in Figure 2, with white arrows representing the magnetization direction. The adjacent ferrite magnets are magnetized in varying directions to enhance flux focusing, while the central NdFeB magnet retains the same magnetization direction as in the conventional structure. The magnetization direction of the adjacent ferrite magnets will be optimized to maximize flux focusing, while the central NdFeB magnet retains the same magnetization direction as in the conventional structure. The characteristics of the NdFeB magnets and ferrite magnets used in the models are listed in Table 2. The central NdFeB segment retains the same magnetization direction as in the conventional design, while the magnetization of side magnets is optimized to enhance flux focusing along the primary magnetic circuit. This modification hypothesizes to increase the magnetic flux concentration into the main circulation and minimizes flux leakage, thereby improving the generator’s performance. Importantly, the rotor pole arc angle remains unchanged during this transformation.

| Characteristics | Unit | Rare-earth (N35) | Ferrite (Y30) |

|---|---|---|---|

| Remanent flux density | T | 1.17–1.22 | 0.37–0.4 |

| Coercivity | kA/m | 860–955 | 175–210 |

| Relative permeability | N/A2 | 1.05 | 1.035 |

| BH max | kJ/m3 | 33–36 | 26–30 |

| Curie temperature | °C | 80 | 450 |

An air magnetic flux barrier was incorporated into the rotor design to enhance cost-effectiveness and improve generator performance, as illustrated in Figure 3. This modification hypothesizes to reduce core material usage, minimizes noncirculating magnetic flux, and increases output power. The number of flux barriers was set equal to the rotor pole pairs. It is important to note that specific geometric constraints were applied to ensure the rotor design’s robustness while adhering to the limitations of the conventional structure. This was achieved by maintaining the rotor segment length above permissible thresholds. The geometric parameters of the Halbach PM array, magnetic flux barriers, and stator configuration were systematically optimized to achieve a cost-effective and efficient design, as described in Section 3.

3. Design Optimization

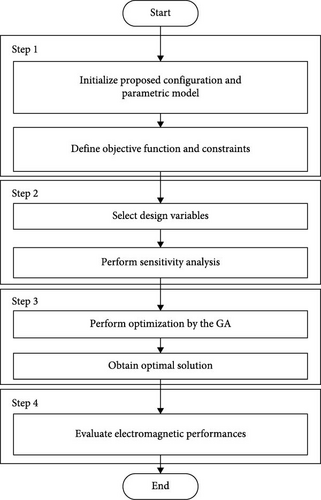

The proposed SPM generator, incorporating a Halbach PM array and magnetic flux barriers, was optimized using GA. The design process, outlined in the flowchart shown in Figure 4, consists of four main steps:

-

Step 1: Define the objective functions and design constraints.

-

Step 2: Identify the design variables and perform sensitivity analysis to determine their impact on the objective functions.

-

Step 3: Optimize the design variables using GA.

-

Step 4: Evaluate the performance of the optimized machine.

3.1. Objective Function and Constraints

- 1.

The output power of the proposed structure must not be less than that of the conventional structure.

- 2.

The proposed generator utilizes identical number of turn per coil, rated voltage, and rated resistive load as the conventional design.

- 3.

Minimum thickness values around the flux barriers are required to ensure the structural robustness of the proposed machine.

- 4.

The optimization process is performed under identical speed of 500 rpm.

- 5.

The proposed machine retains the same outer and inner stator diameters, outer and inner rotor diameters, stack length, and shaft dimensions as the conventional structure.

- 6.

All components of the proposed machine are constructed from the same materials as the benchmark, with the addition of ferrite magnets.

3.2. Design Variables and Sensitivity Analysis

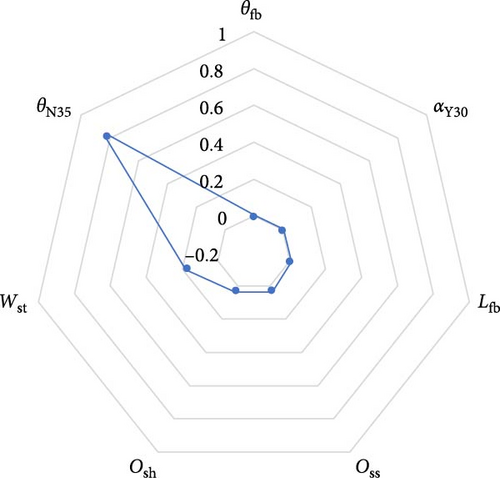

The design variables of the proposed generator are defined in Figure 5, including the stator tooth width, Wst; stator slot opening, Oss; stator tooth base height, Osh; PM arc of N35 magnets, PMarc; magnetization angle of Y30 magnets, αY30; length of flux barrier, Lfb; arc angle of flux barriers, θfb. The variation range of these parameters is determined and prioritized based on their sensitivity analysis results. Figure 6 illustrates the sensitivity of each design variable to the objective function, highlighting that PMarc, Wst, and Lfb have significantly higher sensitivity compared to the other variables. The variation range for each design variable is presented in Table 3.

| Design variables | Minimum | Maximum |

|---|---|---|

| Wst | 7.189 | 11.5 |

| Osh | 0.8 | 1.2 |

| Oss | 1.824 | 2.736 |

| θN35 | 2.45 | 6.54 |

| αY30 | 45 | 90 |

| θFb | 5.96 | 8.94 |

| Lfb | 30.8 | 39 |

3.3. Optimization Using GA

The design variables of the proposed SPM generator are optimized using GA. The GA parameters are set as follows: a population size of 100, a mutation probability of 0.85, and a crossover probability of 0.02. The optimization process spans 600 generations, with convergence to the optimal solution stabilizing after approximately 324 iterations. Table 4 summarizes the design parameters and generator performance indicators before and after optimization. The results confirm that the design objectives and constraints were successfully met. Compared to the initial design, the optimized structure achieves an 18.2% reduction in material cost while delivering slightly higher output power.

| Design variables | Initial value | Optimal value |

|---|---|---|

| Wst | 10.27 | 11.32 |

| Osh | 1 | 1.2 |

| Oss | 2.28 | 2.63 |

| θN35 | 6.54 | 6.54 |

| αY30 | 60 | 83.3 |

| θFb | 7.45 | 8.94 |

| Lfb | 38.5 | 39 |

| Cost (USD) | 1091.6 | 892.5 |

| Output power (kW) | 18.7 | 18.8 |

4. Evaluation of Generator Characteristics and Performance

This section analyzes the characteristics and performance of the optimized SPM generator in comparison with the conventional design, with both evaluated at a rated speed of 500 rpm. The simulations are conducted using 2D FEA, focusing on cost, as well as no-load and on-load performance characteristics for both generator designs.

4.1. Comparison of Material Cost

To evaluate the cost-effective design objectives of the SPM generators, a comparison of cost and weight between the conventional and optimized SPM generators is presented in Table 5. The costs of active materials are $1 per kilogram for steel, $7 per kilogram for copper, $126.6 per kilogram for N35 magnets, and $18.46 per kilogram for Y30 magnets, as referenced in [31, 32]. The results show that the weight of the proposed SPM generator is reduced by 14% compared to the conventional design, primarily due to the implementation of rotor flux barriers. Additionally, the proposed generator achieves an 18% reduction in material cost, mainly resulting from the decreased use of NdFeB magnets. This cost reduction surpasses that achieved in previous studies that explored ferrite magnet replacements for NdFeB magnets as a cost-saving approach [33–35]. These findings confirm that the optimization process successfully meets the intended design goals. It is noted that the additional manufacturing costs associated with the proposed structure should be considered, though they are expected to be minimal in large-scale production.

| Items | Material | Cost/kg ($/kg) | Weight (kg) | Cost ($) | ||||

|---|---|---|---|---|---|---|---|---|

| Conventional structure | Proposed structure | Conventional structure | Proposed structure | Conventional structure | Proposed structure | Conventional structure | Proposed structure | |

| Stator | DW465-50 | 1 | 31.3 | 32.8 | 31.3 | 32.8 | ||

| Rotor | DW465-50 | 1 | 52.7 | 38 | 52.7 | 38 | ||

| Copper | Copper AWG-19 | 7 | 8.3 | 8.3 | 58.1 | 58.1 | ||

| N35 | N35 neodymium magnet | 126.6 | 7.5 | 5.9 | 949.5 | 747 | ||

| Y30 | Y30 ferrite magnet | — | 18.46 | — | 0.9 | — | 16.6 | |

| Total | — | — | 99.8 | 85.9 | 1091.6 | 892.5 | ||

4.2. No-Load Performance

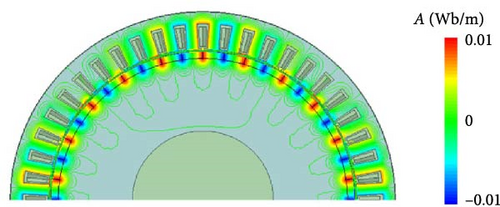

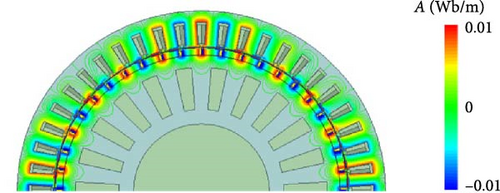

The no-load characteristics of the proposed SPM generator, including the EMF with total harmonic distortion (THD), cogging torque, and magnetic field distribution, were evaluated. The magnetic field distribution is a critical parameter for assessing magnet utilization in PM machines. Figure 7a,b presents the magnetic flux distribution for both the conventional and proposed structures, respectively. The results indicate that the primary magnetic flux circulation in the rotor of the proposed design is positioned closer to the air gap with magnetic flux leakage reduced, which can be attributed to the integration of the Halbach PM array and flux barrier techniques. This adjustment enhances the effective utilization of PMs. Furthermore, the intensity of the magnetic flux at the air gap is reduced due to the inclusion of ferrite magnets, which could contribute to the reduction of cogging torque and torque ripple. These findings highlight the effectiveness of the proposed design in improving magnet utilization while mitigating key performance limitations in SPM generators.

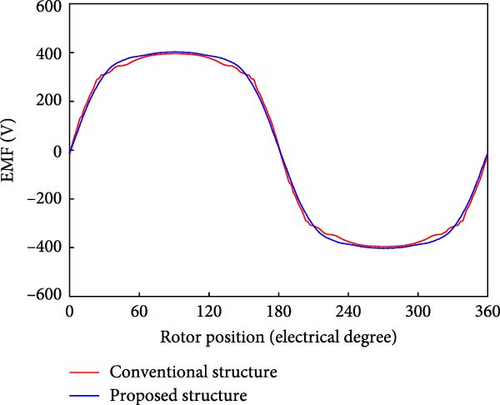

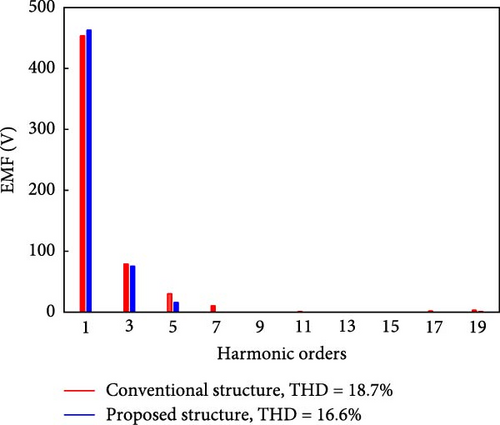

Figure 8 compares the EMF profile of the proposed SPM generator against the conventional design, presenting the EMF waveforms and harmonic spectra in Figure 8a,b, respectively. The proposed generator exhibits an improved sinusoidal EMF profile, demonstrating a 2.1% increase in fundamental EMF magnitude from 320.7 to 327.1 Vrms, accompanied by a 1.8% reduction in THD. These enhancements reflect improved waveform quality, contributing to smoother operation and an increased potential for enhanced power generation.

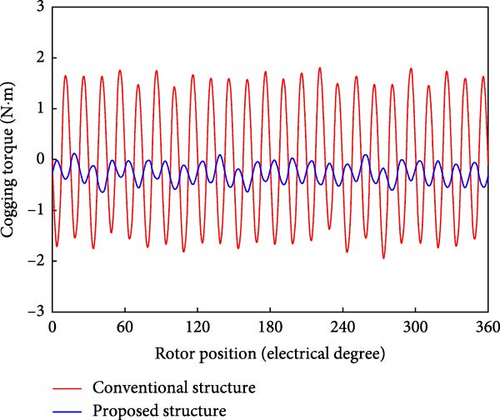

Cogging torque is typically a significant performance parameter for PM generators, particularly those designed for low-speed operation, as it directly affects the generator’s ability to start and operate efficiently at low rotational speeds. In this study, cogging torque is therefore considered one of the key performance indicators. Figure 9 presents a comparison of the cogging torque between the proposed SPM generator and the conventional design. The results show a 79.2% reduction in the peak-to-peak cogging torque of the proposed generator, from 3.70 N·mp-p to 0.77 N·mp-p, demonstrating improved performance in starting and low-speed operation. This significant reduction is attributed to the replacement of certain NdFeB magnet sections with a hybrid Halbach ferrite magnet array, where the magnetization direction was optimized. This configuration effectively reduces both the magnitude and harmonic content of the air gap flux, leading to improved cogging torque performance.

4.3. On-Load Performance

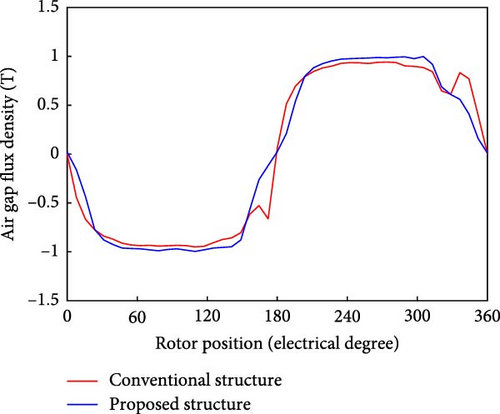

The performance of the proposed and conventional SPM generators was evaluated under on load conditions at a rated speed of 500 rpm, using a 12-phase external resistive load of 58 Ω. Figure 10 compares the on-load air gap flux density profiles of the conventional and proposed SPM generators. The proposed generator maintains the overall waveform profile of the conventional design while exhibiting a slightly higher air-gap magnetic field in certain regions due to reduced magnetic flux leakage, consistent with the results in Figure 7.

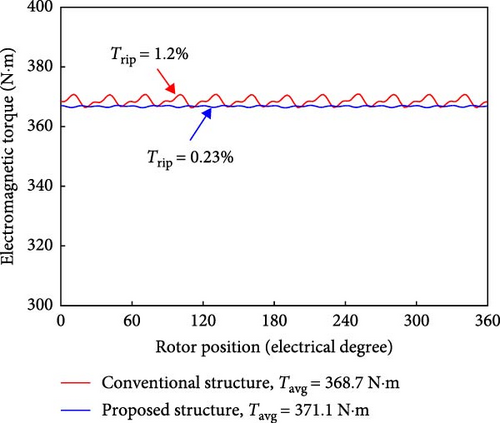

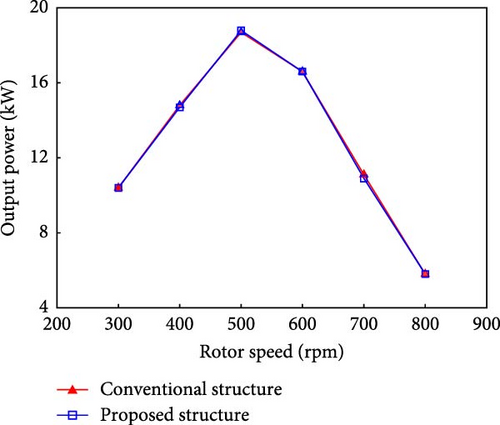

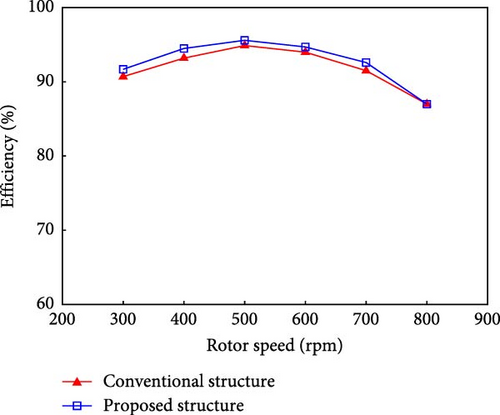

Figure 11 compares the torque characteristics of both designs. Although the proposed SPM generator exhibits a slightly lower torque magnitude compared to the conventional design, it achieves a significant 5.2 times reduction in torque ripple. The improvement in torque ripple is primarily attributed to the implementation of the hybrid ferrite-NdFeB Halbach PM array with optimized magnetization direction. The on-load performance characteristics of both SPM generators are summarized in Table 6. The proposed SPM generator demonstrates not only the ability to maintain its initial output power but also a slight improvement in power generation. Additionally, the use of ferrite magnets, which have lower magnetic flux density and higher electrical resistivity compared to NdFeB magnets, leads to a reduction in PM losses. The insertion of flux barriers not only reduces core losses by decreasing the use of core material but also lowers the rotor inertia by 23.7%, contributing to improved dynamic performance. As a result, the proposed design demonstrates a significant reduction in total losses and achieves higher efficiency compared to the conventional structure. Moreover, the proposed SPM generator achieves a 17.6% improvement in output power per cost, reaching 21.1 W/$, surpassing state-of-the-art designs [31, 32] and demonstrating enhanced cost-effectiveness. In particular, the proposed generator maintains power generation capability across a wide speed range, as shown in Figure 12a. Figure 12b further demonstrates the improved efficiency of the proposed generator across the entire speed range. This efficiency enhancement is primarily attributed to the reduction in PM losses achieved through the use of ferrite magnets and the implementation of a Halbach PM configuration, which minimizes induced currents within the magnets. Additionally, the incorporation of magnetic flux barriers lowers iron losses by reducing the iron core material. These results confirm that the proposed generator successfully meets the design objective of reducing material costs while delivering higher output power, making it a promising and efficient solution for wind power generation applications. For experimental validation, challenges include precise magnetization alignment of ferrite magnet and potential structural weakening from flux barrier insertion, requiring careful positioning and reinforcement. Further refinements in these aspects should be considered to enhance the proposed structure.

| Items | Unit | Conventional structure | Proposed structure |

|---|---|---|---|

| EMF | Vrms | 320.7 | 327.1 |

| THD | % | 18.7 | 16.6 |

| Peak to peak cogging torque | N·mp-p | 3.7 | 0.77 |

| Rated voltage | Vrms | 301 | |

| Rated current | Arms | 5.18 | 5.2 |

| Output power | kW | 18.7 | 18.8 |

| Average torque | N·m | 371.1 | 368.7 |

| Torque ripple | % | 1.2 | 0.23 |

| Copper loss | W | 482.1 | 417.5 |

| Iron loss | W | 323.1 | 279.3 |

| PM eddy current loss | W | 167 | 139.6 |

| Power/cost | W/$ | 17.1 | 21.1 |

| Power density | kW/m3 | 1203.1 | 1209.6 |

| Rotor inertia | kg/m2 | 0.570 | 0.435 |

| Efficiency | % | 95 | 95.7 |

5. Conclusion

This study proposed a cost-effective 12-phase SPM wind generator with 48 stator slots and 22 pole pairs, addressing the high cost per unit power of conventional SPM machines. By integrating hybrid NdFeB-ferrite Halbach PM arrays with flux barrier techniques and optimizing the design using a GA, significant performance improvements were achieved. The proposed design reduced material cost by 18.2% and weight by 14% compared to the conventional structure while delivering slightly higher output power. The generator demonstrated an enhanced EMF magnitude with reduced THD, a 54% reduction in cogging torque, and a 79% reduction in torque ripple, ensuring smoother operation and improved suitability for low-speed wind power generation. Additionally, reductions in copper loss, core loss, and PM eddy current loss contributed to improved overall efficiency. The rotor inertia was also reduced by 23%. These results validate the proposed design as a cost effective and efficient solution for wind power generation, offering substantial potential for advancing sustainable energy systems.

Conflicts of Interest

The authors declare no conflicts of interest.

Funding

This work was funded by the Fundamental Fund of Khon Kaen University from the National Science, Research and Innovation Fund or NSRF, Thailand.

Open Research

Data Availability Statement

Data sharing is not applicable to this article as no datasets were generated or analyzed during the current study.