Design and Performance Evaluation of a Novel Portable Pedestal Fan With Cooling Effects by Peltier Modules

Abstract

An experiment was conducted to explore the impact of cooling air in a portable bladeless pedestal fan using Peltier modules. Traditional cooling methods face challenges of high energy consumption, motivating the need for innovative solutions. This study hypothesized that integrating Peltier modules into a pedestal fan could significantly enhance cooling efficiency while conserving energy. Investigating the shift from traditional to renewable energy systems for air conditioning (A/C) and ventilation is crucial for achieving sustainability and energy conservation. To meet the comfort standards set by ASHRAE, a study was carried out to design, construct, and assess the cooling efficiency of a bladeless pedestal fan employing Peltier modules. This study also examined how Peltier modules influence the efficiency of a conventional pedestal cooling fan. The experimental study was held in a 4 × 4 m room using two, four, six, and eight Peltier modules at external temperatures ranging from 43°C to 45°C, with indoor starting temperatures of 37°C. Each setup was tested three times and each experimental condition was tested for 60 min, with data recorded at 10-min intervals. The Peltier effect was utilized to cool water, which in turn cooled the air. The comfort zone was subsequently created using this cooled air. A regression analysis was employed to validate the results, with the cooling performance evaluated using standard error and confidence intervals. The energy savings were estimated by comparing the power consumption of the Peltier module-based fan to that of conventional pedestal fans and A/C units. The temperature reduction achieved was 4%, 12%, 18%, and 22% with the use of two, four, six, and eight Peltier modules, respectively. The energy analysis indicated significant savings, suggesting that the proposed Peltier-based bladeless pedestal cooling fan could potentially save over 2000 MW of energy nationwide if it replaced traditional pedestal fans.

1. Introduction

The impact of high temperatures and humidity on human productivity has been well documented, with reductions in both observed under such conditions. In Pakistan, temperatures can reach up to 50°C during the summer, which lasts from May to September, and humidity levels can reach as high as 80% in August and September [1]. While this study focuses on addressing extreme heat in Pakistan, the findings and proposed design are applicable globally, especially in regions striving for energy sustainability.

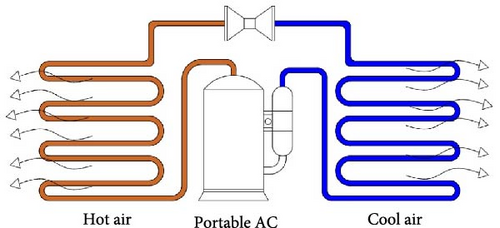

Air conditioning (A/C) systems are commonly used to combat these extreme temperatures, including central A/C, split A/C, window A/C units, and water air cooler systems. The process of removing heat and humidity from an occupied room to enhance occupant comfort is known as A/C [2]. This process is employed in both domestic and commercial settings to achieve a more comfortable environment for humans and animals alike. The conditioned air with the desired temperature and humidity is ted into the required space using an electric fan [3]. A/C systems range in size from small 1-ton units to large central air handling units for airports, shopping malls, and hospitals. The ultimate cooling process cycle is shown in Figure 1. In central A/C systems, the air is conditioned at a location separate from the comfort zone and distributed using ducts and fans. The two main components of split A/C systems are the outside unit, which houses the compressor and condensing units and the indoor unit, which houses the thermostatic sensors, blower, and evaporation system [4]. Finally, the evaporation, condensation, and compression devices in a packed central cooling system are all contained in a single cabinet that is usually placed on a concrete block or roof outside the conditioned zone.

Peltier modules offer a small, dependable, and effective substitute for conventional cooling systems by utilizing the thermoelectric (TE) effect. Peltier-based systems function without moving parts, lowering maintenance and their environmental effect in contrast to air conditioners (ACs), which need compressors and refrigerants. They are also perfect for off-grid and renewable energy applications because of their scalability and low power consumption. The inherent benefits of a bladeless fan over traditional fans influenced its design. Comfort is increased with bladeless designs, which provide consistent airflow with less noise and turbulence. Furthermore, the lack of external blades reduces safety risks, especially in homes with kids, and provides a contemporary look that appeals to modern users.

1.1. Background of the Study

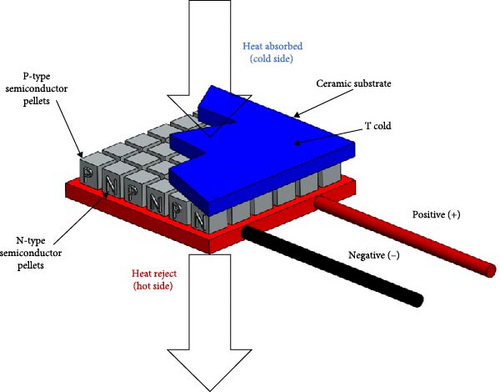

Because of the temperature-induced energy difference, electrons move from the hot to the cold side of a temperature gradient between two distinct conductive or semiconductive materials, causing the Seebeck effect. The Seebeck effect is a type of TE phenomenon that involves the conversion of temperature differences into electrical energy [5]. On the other hand, the Peltier effect is the opposite, where heat is absorbed on one side and released on the other when an electric current flows across a junction of two different materials. These effects are used for cooling in a Peltier module. Heat is received at the cold junction and released at the hot junction as current passes through the module. As electrons move energy through the TE material, heat transfer takes place. A heat sink is connected to the hot side to efficiently disperse heat and a cooling effect is produced when the cooled surface comes into contact with the target medium, such as water in our case, to guarantee successful operation. The discovery of the Seebeck effect by Thomas Johann Seebeck in 1821 opened up a new field of research and development of TE materials and devices. The Seebeck effect is widely used in various applications, such as power generation, temperature sensing, and refrigeration. Figure 2 shows the working of a Peltier module. It has found applications in diverse fields, including the automotive, aerospace, medical, and electronics industries. In recent years, there has been a renewed interest in TE materials and devices due to their potential for waste heat recovery and renewable energy generation. Researchers are working on developing high-performance TE materials and devices that can convert waste heat into useful electricity [6]. The development of efficient and cost-effective TE devices could significantly contribute to the reduction of greenhouse gas emissions and the sustainable use of energy resources.

The combination of photovoltaic (PV) and TE systems for energy-efficient buildings demonstrates how versatile TE technology is in lowering energy use and improving sustainability across a range of applications. The performance of a test room with a TE-air duct (TE-AD) system and a PV wall is investigated by Irshad et al. [7]. To achieve considerable cooling efficiency and user satisfaction under a variety of operating situations, it highlights the integration of PV and TE technologies to improve indoor thermal comfort, while lowering energy consumption in tropical regions. An inventive combination of PV wall and TE-AD systems for building cooling in tropical regions is presented by Irshad et al. [8]. The findings demonstrate that, in comparison to traditional systems, the PV-TE-AD system provides greater energy efficiency, notable CO2 emission reductions, and long-term financial advantages. This effort advances cooling technologies powered by renewable energy. To minimize thermal loads, increase energy efficiency, and save operating costs, a previous study investigates the integration of a TE-AD system with a PV wall for tropical climates [9]. The outcomes show that this integrated system offers both financial and environmental advantages while achieving notable improvements in cooling performance. The performance of a TE-AD system for energy-efficient buildings is also assessed by Irshad et al. [10]. According to simulation and experimental results, the TE-AD system achieves energy savings of 38.83% when compared to traditional A/C, while lowering room temperature by 1.2–5.3°C and humidity by 5%–31%. Additionally, it reduces CO2 emissions by 38.81%, offering cooling applications a dependable and refrigerant-free substitute. The performance of a TE-AD system for thermal comfort in tropical regions is also examined by Irshad et al. [11]. Comparing the system to traditional air conditioning, the results show that it reduces energy consumption and operating costs, while achieving adequate cooling and dehumidification at 6 A input, meeting ASHRAE standards for acceptability. For building space conditioning, this eco-friendly, freon-free option provides a dependable substitute.

TE materials are composed of PbS, ZnSb, CoAs, and chalcogenide minerals, and they have been tested for their Seebeck effect [12]. The Seebeck effect refers to the conversion of temperature differences into electrical voltage and vice versa. Werner Haken characterized the Seebeck coefficient and electrical conductivity of various TE materials, and Peltier presented the reverse process of the Seebeck effect, which is known as the Peltier effect [13]. TE modules are electronic devices that are composed of two different semiconducting materials. These modules are suitable for heating and cooling applications. Mostly used TE materials include lead telluride (PbTe), silicon germanium (SiGe), and bismuth telluride (Bi2Te3) [14]. Hendy, El-Attar, and Ezzat [15] created a thermoelectricity system consisting of memory-dependent derivative technology in 2019 and looked at how different parameters affected the system. Huang et al. [16] used TE materials as TE generators for heat recovery systems in exhaust gases. Additionally, Xu et al. [17] developed microelectromechanical system-based sensors in 2018. Overall, the passage provides an overview of the history, development, and potential applications of TE materials.

Gong, et al. [18] conducted a study where they utilized a modeling package to create a model of a nanoscale TE device. The objective of this study was to investigate the TE and thermal effects of the device. In 2018, Benallou et al. [19] utilized a first-principles-based density functional theory to explore the TE possessions of ZrIrAs, ZrIrBi, and ZrIrSb. Their results showed that ZrIrAs demonstrated the best TE properties at temperatures of 300, 600, and 800 K. Benmalem et al. [20] studied the TE characteristics of CuNMn3 using first-principles calculations. Their findings demonstrated that the highest thermal conductivity was obtained at a temperature of 900 K. Overall, these studies provide valuable insights into the TE and thermal properties of different materials, which can be applied to the development of more efficient TE devices. The following excerpt pertains to the investigation and application of TE cooling in various studies. Lee, Kwon, and Lee [21] utilized a practical approach to examine a rapid heating and cooling device with a maximum thermal conductivity value of 0.38 W/mK. Shi et al. [22] employed the TE cooling effect in tandem gas metal arc welding to regulate extreme temperatures that result in metal overflow and melting. Additionally, Kim, Lee, and Park [23] conducted experiments to evaluate the heat transfer and pressure characteristics of a TE heat sink. In a separate study, Lee et al. [24] studied the parametric optimization of TE appliances for comfort seats in vehicles through both experimental and simulated methods.

A study by Ilmiawan et al. [25] investigates the impact of desk fan configurations and wind directions on personal thermal comfort (PTC) and energy efficiency in air-conditioned office spaces within hot–humid climates. Results demonstrate that desk fans effectively reduce skin temperature, improve occupant comfort by up to 53%, and achieve 8%–20% energy savings compared to conventional low-setpoint A/C setups. Another study by Aqilah et al. [26] provides insights into electricity consumption patterns and indoor thermal environments in residential buildings in Malaysia. Results indicate significant disparities in electricity use based on income groups, with A/C predominantly used during sleeping hours. The findings underline the need for tailored energy efficiency standards in hot–humid climates, particularly addressing cooling demands and occupant behaviors. A study by Sena et al. [27] identifies key determinants of electricity consumption in Malaysian households, emphasizing the significant impact of appliance characteristics and occupant behavior. Appliances such as ACs and fluorescent lamps, along with usage patterns, emerged as primary contributors to electricity usage. These findings support targeted electricity-saving strategies to reduce energy consumption in tropical climates. The weather department has reported on the extreme heat experienced in Pakistan during June and July, with temperatures reaching as high as 52.2°C. Enduring such intense heat without A/C is considered nearly impossible [28]. In South Asian countries, A/C and domestic air coolers are the primary means to create a comfortable environment. However, due to the related costs, the use of traditional ventilation and A/C techniques is limited, including electricity costs [29]. Therefore, this research presents an effort to design, fabricate, and investigate the impact of the Peltier modules on cooling as a potential alternative to conventional methods.

1.2. Novelty of the Current Study

The use of Peltier modules in a bladeless pedestal fan for home cooling applications is being pioneered by this study. This work explores a novel use case, that is, adapting Peltier modules to improve fan-based cooling for tiny office spaces, in contrast to traditional TE research that concentrated on material attributes or automotive cooling applications [3, 16]. Previous research has examined solar-powered home air coolers with TE plates [13], and Kim, Lee, and Park [23] assessed heat transmission in TE heat sinks. However, these designs ignore the energy-saving potential of bladeless fans in conjunction with TE effects, instead relying on conventional evaporative cooling processes.

The present research fills this gap by introducing a cost-effective and energy-efficient bladeless pedestal fan, specifically designed to meet ASHRAE comfort standards in hot climates. Experimental results demonstrate significant energy savings compared to standard pedestal fans and A/C units, thus addressing the need for sustainable cooling technologies in energy-deficient regions.

2. Materials and Methods

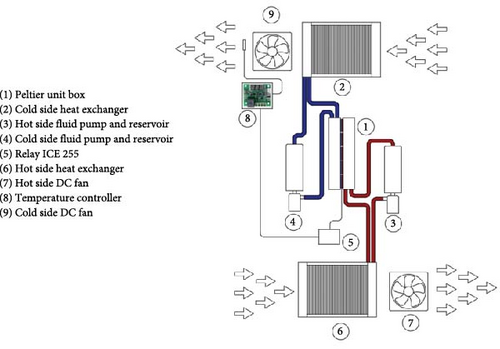

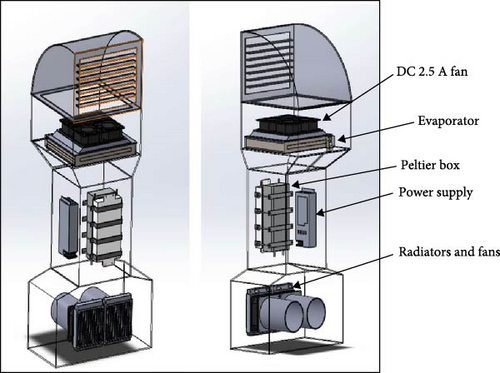

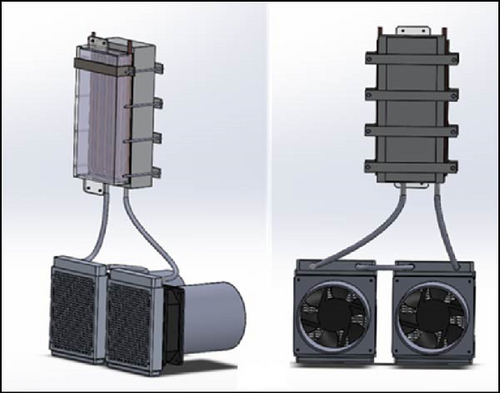

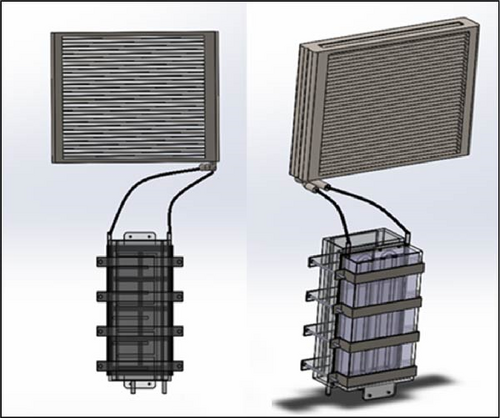

This research aimed to develop a household pedestal fan that does not rely on traditional evaporation cooling techniques or components like cooling radiators, pumps, motors, or fans. Instead, Peltier modules were utilized as the cooling agents. The schematic diagram of the current experimental study is shown in Figure 3. The design of the pedestal fan with Peltier modules is shown in Figure 4.

The cooling requirements for the investigational zone, that is, a 4 × 4 m office with two seats at the Swedish College of Engineering and Technology in Rahim Yar Khan, Punjab, Pakistan, were calculated. Figure 5 shows the physical experimental rig used in the current study. To meet comfort standards (60% humidity, 25°C), a DC motor, 12 V DC fans, and Peltier modules were selected. The appropriate heat sinks and the body of the pedestal fan were then determined to meet these comfort requirements. The system is powered by electricity. This electric energy partially powers four DC fans. The remaining electricity is supplied to the Peltier modules. These modules release heat from their lower side, which is then dispersed by aluminum sinks, and cool their upper side due to the Peltier effect. Through this technique, heat may be immediately transmitted from the water to the Peltier modules’ chilled side, which cools the water. The interaction between the airflow and the cooling and radiator systems contributes to creating conditions that may improve thermal comfort. However, the level of comfort achieved is influenced by the operating parameters and environmental factors, and further research may be required to fully optimize the system for various conditions.

A sigma temperature and humidity meter were used to collect the temperature and humidity data. The water temperature at the Peltier module’s interface and the air entering and leaving the fan were among the several locations within the experimental zone, where measurements were made. Throughout the 60-min duration for each operating state, the readings were taken six times at 10-min intervals to reduce measurement errors. To guarantee data consistency and evaluate the thermal behavior of the modules under various operating situations, variations in the Peltier modules’ temperature were also regularly tracked and contrasted with the surrounding environment.

2.1. Limitations of the Present Study

This study was conducted in a controlled experimental environment with a 4 × 4 m room under specific ambient conditions. The performance of the Peltier module-based cooling system may vary in larger spaces or different environmental conditions, such as higher humidity or varying external temperatures. Additionally, the system’s efficiency and cost-effectiveness were analyzed using a specific set of parameters, which may need further validation in diverse real-world scenarios. Future studies could investigate scaling the system for larger areas, integrating renewable energy sources, and optimizing module placement for enhanced cooling efficiency.

3. Heat Transfer Modeling

The cooling process and system efficiency of the Peltier module-based bladeless pedestal fan are described by heat transfer modeling. The Peltier modules’ hot side uses an aluminum heat sink with forced convection from DC fans to dissipate heat, while the cold side cools the water by absorbing heat from flowing water. Figure 6 illustrates the heat transfer mechanism for both hot and cold sides. As the cooled water absorbs heat from the surrounding air, the cooling effect is produced. The specific heat capacity of the water, the convective dissipation of the heat sink, and the temperature gradients in the system are used to model the rates of heat transfer. The cooling power to electrical input ratio is used to measure system efficiency. These models connect theory to data and direct system optimization by faithfully simulating the experimental situation.

- •

m˙:Mass flow rate of water(kg/s).

- •

Cp : Specific heat capacity of water(J/kg · K).

- •

ΔT : Temperature change of water(K).

- •

h : Convective heat transfer coefficient(W/m2 · K).

- •

A : Surface area of the heat sink(m2).

- •

ΔT : Temperature difference between the heat sink surface and ambient air(K).

- •

Qcooled : Cooling power provided by the system (W).

- •

Pinput : Electrical power input the Peltier module (W).

4. Cooling Load

Throughout the summer, several factors can influence a building’s interior air temperature. To maintain a comfortable humidity and temperature, the heat must be turned off. The amount of heat that needs to be removed is known as the cooling load. Determining the cooling load is essential for selecting the appropriate size of distribution systems and A/C equipment. Cooling load analysis is also a way to assess energy use and conservation. It is difficult to determine the space’s real-time cooling load with accuracy since the quantity of heat the space absorbs from different sources varies with time. The working area is not directly exposed to all of the sun’s radiation. Most of the radiation is absorbed by the building’s roof, windows, and walls, which then release heat into the interior [30].

Various techniques have been developed to estimate the cooling load for a specific area. Common methods include the transfer function method, cooling load factor (CLF) method, cooling load temperature difference (CLTD) method, and total equivalent temperature difference method. In this investigation, the cooling load in a designated area, where comfort is required, was calculated using the CLTD method. This method was chosen for its simplicity and ease of use, whether performed manually or with the aid of a computer [13].

4.1. Heat Transfer From Walls and Roof

The calculation of the CLTD is performed in accordance with ASHRAE standards, with the computation time set at 2:00 PM. Table 1 provides a summary of the CLTD and the adjusted CLTDC values.

| Walls | Q (Btu/h) | CLTDC | A (SFT) | U (Btu/h-ft2-°F) | Ta (°F) | TR (°F) | LM | CLTD |

|---|---|---|---|---|---|---|---|---|

| Exposed roof | 1852.3 | 34.8 | 196 | 0.37 | 109.6 | 96.8 | 0 | 29 |

| West wall | 751.4 | 27.2 | 196 | 0.2789 | 109.6 | 96.8 | 0 | 22 |

| North wall | 751.4 | 27.2 | 196 | 0.2789 | 109.6 | 96.8 | 0 | 22 |

4.2. Heat Gain for Floor

4.3. Cooling Load From Glazed Windows

4.4. Lighting Load

4.5. Human Load

4.6. Filtration and Ventilation Load

5. Fabrication of Pedestal Fan With Peltier Modules

The cooling load calculation for a 16 m2 experimental zone with a capacity for two people served as the basis for the design of the domestic pedestal fan. The Peltier modules, which are described in Table 2, are the main parts of the pedestal fan. By imparting heat to water that comes into contact with their cold plate surfaces, these modules transform electrical power into cooling. To ensure comfort, this cold water then absorbs heat in the air entering the experimental zone. To facilitate ventilation and maintain comfort in the zone, four fans powered by 2.5 A DC motors were selected.

| Parameter | Specifications |

|---|---|

| Internal resistance | 1.99 Ω ±5% |

| Type | Cool cell |

| Dimensions | 35 mm × 35 mm × 3.2 mm |

| Qmax (W) | 72 W |

| Imax (A) | 6 A |

| Voltage | 12 V |

| Vmax (V) | 12 V |

| Model number | TEC1-12706 |

6. Experimental Methodology

In the experimental setup, the water cooled by the Peltier modules was circulated using a closed-loop system with a pump, and a heat exchanger was integrated to enhance heat transfer efficiency. The environmental conditions were carefully controlled, with humidity maintained at 60%–63% and the initial room temperature standardized at 37°C. These measures ensured consistent and reliable results across all experimental trials. We looked into how Peltier modules affected the functionality of a traditional pedestal fan in this experiment. A domestic pedestal fan with Peltier modules was created especially for this use. When air came into contact with cooled water through the evaporator, the Peltier effect caused the water’s temperature to drop, which in turn caused the air’s temperature to drop indirectly. This process created a comfort zone with the cooled air. To ensure comfort in an office environment that complies with ASHRAE standards of 25–27°C and 60% relative humidity [31], a Peltier module pedestal fan was constructed. The experiments were conducted during the last week of August under the prevailing environmental conditions of that period.

The external temperature ranges from 43 to 45°C, while inside the workplace, it is 37°C. The water circulating in the evaporator is at 31.50°C. The relative humidity is between 60% and 63%. The domestic pedestal fan had a 60-min runtime configured, and during this time, a sigma temperature and humidity meter recorded the relevant temperatures and humidity levels. By using the mentioned humidity and temperature meter, measurements were taken for both the baseline and the modified pedestal fan equipped with eight Peltier modules, respectively. The temperatures of the water, the air entering the fan, and the air exiting the fan were recorded. The fan was operated for 60 min, and during this period, the experimental zone’s temperatures were documented six times at 10-min intervals for each operating condition.

7. Experimental Results

After analyzing the experimental data, various visualizations such as column charts, contour plots, and residual plots are employed to illustrate the reduction in temperature within the experimental zone relative to the initial temperature of the zone. Each figure is accompanied by explanations based on the principles of thermodynamics and heat transfer to support the findings.

7.1. Regression Analysis

The experimental findings on the temperature of the test zone were subjected to a regression analysis. A multivariate linear regression model was applied to analyze the relationship between the number of Peltier modules and the resulting temperature reduction. The statistical analysis showed the model’s predictive accuracy, yielding an R2 value of 76.92%, as shown in Table 3. This enhancement confirms a significant correlation between the experimental variables, strengthening the reliability of the proposed cooling system’s performance assessment. Tables 3 and 4 display the standard deviation, standard error, and regression coefficients for predicting the temperature in the experimental zone. The following regression equation can be used to determine the temperature of the investigational zone:

| Rsq (pred) | Rsq (adj) | Rsq | S |

|---|---|---|---|

| 76.92% | 79.58% | 82.67% | 1.05637 |

| Source | p-Value | F-Value | Adj MS | Adj SS | DF |

|---|---|---|---|---|---|

| Regression | 0.0001 | 29.08 | 22.1927 | 47.6149 | 2 |

| Number of modules | 0.0016 | 20.27 | 25.5154 | 21.7629 | 1 |

| TAmb of zone | 0.0482 | 0.76 | 0.3864 | 0.4894 | 1 |

The statistical significance of the regression model’s predictors, that is, the ambient temperature and the number of Peltier modules, is assessed by the ANOVA analysis, which is shown in Table 4. The ANOVA analysis was conducted using Minitab 21.0 software, which provided the necessary statistical insights into the relationship between the number of Peltier modules and the cooling performance. By taking this step, it is ensured that random mistakes are not the cause of the observed fluctuations in the experimental zone temperature. The correlation between these predictors and temperature is measured using the regression equation that was produced from this investigation. Statistical indicators like R2, adjusted R2, and standard error are used in Table 3 to summarize the model’s accuracy and predictive power. The efficiency of the predictors in predicting the experimental setup’s cooling performance is confirmed by this integrated analysis.

To validate the experimental results across all cases (two, four, six, and eight modules), the correlation between statistical parameters, such as standard deviation, standard error, and regression coefficients, was examined. The precision of these measurements was shown by the standard error, while the standard deviation measured the dispersion of temperature reduction data. A positive correlation was confirmed by regression coefficients, which shed light on the predictive relationship between the number of modules and temperature reduction. The statistical reliability of the experimental observations was improved by this analysis, which showed steady performance trends.

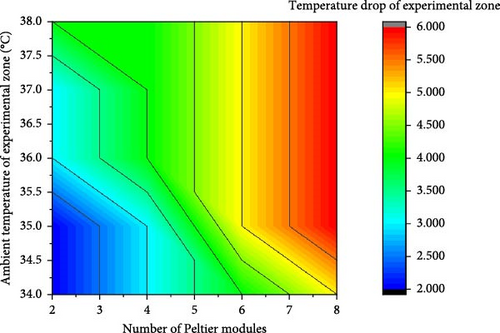

The analysis revealed that the optimal performance of the Peltier module-based pedestal fan was achieved with eight modules under ambient temperatures of 34–38°C. The optimum configuration of eight Peltier modules and the ambient temperature range of 34–38°C were determined through experimental trials and regression analysis. The study systematically tested setups with two, four, six, and eight Peltier modules in a controlled environment, recording temperature reductions at 10-min intervals over 60-min sessions. Although the incorporation of Peltier plates increases the initial project cost, the significant energy savings of up to 1,850 kWh annually justify their use. This reduction in energy consumption could result in substantial long-term cost benefits, particularly in regions with high electricity tariffs.

- •

Texpzone is the temperature of the experimental zone.

- •

N is the number of Peltier modules.

- •

Tamb is the ambient temperature.

- •

a, b, c are regression coefficients.

From the analysis, the model confirmed that an increasing number of Peltier modules led to a greater reduction in temperature, with eight modules yielding a 22% temperature drop, effectively reducing the test zone temperature to ASHRAE comfort levels (26–27°C). However, beyond eight modules, the cooling efficiency showed diminishing returns due to thermal resistance and heat sink limitations.

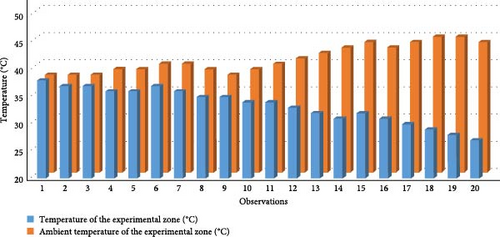

7.2. Temperature Fluctuations in the Test Zone at Varying Ambient Temperatures

The study aimed to evaluate the effectiveness of Peltier modules in cooling under various ambient temperatures. Figure 7 illustrates the temperature decrease patterns in the test zone. Blue columns depict the temperature reduction in the investigational zone due to the Peltier modules’ cooling effect, while orange columns represent the ambient temperature in the test zone during experiments, conducted from 2:00 to 4:00 PM. The results clearly showed that the temperature drop in the investigational zone was minimal at higher ambient temperatures. As indicated on the x-axis of Figure 7, the comfort criteria was more effectively met toward the end of the observation period. The experimental measurements used to assess the cooling capabilities of the portable pedestal fan with Peltier modules are represented by observations 1–20. Variations in operating times, ambient temperature, and the cooling effects produced by the Peltier modules were all factors in these results. When all eight Peltier modules were functional at saturation levels (observations 16, 17, 18, 19, and 20), the cooling capacity at lower ambient temperatures brought the experimental zone’s comfort level closer to the ASHRAE comfort standards. Conversely, with two Peltier modules in operation and ambient temperatures above 35°C (observations 1 through 6), the temperature reduction was negligible. The experimental data suggest that with maximum module operation and lower ambient temperatures, the Peltier module domestic pedestal fan met the ASHRAE comfort criteria of 25°C and 60% humidity.

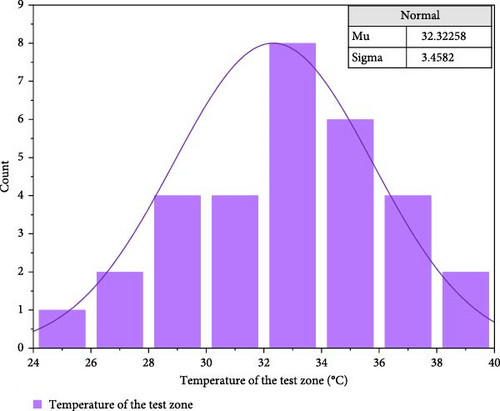

7.3. Gaussian Model Applied to the Temperature of the Experimental Area

The validity of experimental observations can be assessed using various statistical models. Figure 8 shows the histogram of experimental results from repeated cooling temperature tests using two, four, six, and eight Peltier modules at different ambient temperatures (34, 35, 36, 37, and 38°C), conducted between 14:00 and 16:00 PST on August 20, 2023. The results indicated that, for 20 observations under these conditions, the average temperature was 30.56°C with a standard deviation of 1.781. When eight Peltier modules were used, the test zone’s temperature was 27°C, and there was a minimal temperature decrease when two modules were used. At ambient temperatures of 37 and 38°C, most results fell between 29°C and 33°C. The ASHRAE comfort criterion sets the comfort threshold at 26°C. The experimental results were generally consistent with the ASHRAE comfort standards. As the number of modules rose and the ambient temperature declined, the temperature of the investigational zone decreased linearly, as shown by the results’ normal distribution curve.

7.4. Percentage Decrease in Temperature Within the Test Area

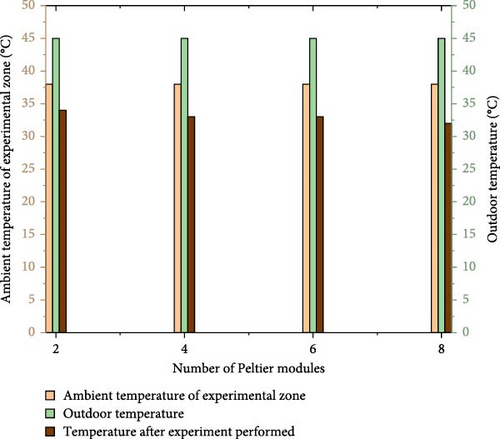

Figure 9 illustrates the temperature reduction percentages within the investigational zone with varying numbers of Peltier modules in operation, alongside the ambient and external temperatures. When four Peltier modules are active, the plot indicates a 12% temperature reduction in the experimental zone. When the number of Peltier modules increased to six, the investigational zone temperature was reduced by 18%. The maximum decrease in temperature was recorded as 22% when eight Peltier modules were used. There was a temperature reduction of 6% to 22% when two, four, six, and eight Peltier modules were used, with the experimental zone’s ambient temperature ranging from 34 to 36°C. Figure 10 shows the comparison of indoor temperature with outdoor air temperature for different numbers of Peltier modules.

The cumulative effect of each Peltier module in lowering the water temperature and boosting air cooling is responsible for the cooling efficiency increase that has been noticed as the number of modules increases. With six modules, the system operates at peak efficiency since cooling capacity and airflow distribution are effectively balanced. However, the performance advantages saturate after eight modules. This restriction results from the system’s thermal resistance and the heat sinks’ limited capacity to dissipate heat, which precludes additional notable temperature drops.

7.5. Validation of Current Experimental Study

To validate our experimental results, we compared our findings with those reported by Abbas et al. [13], who examined the performance of a solar-powered domestic air cooler using Peltier modules. Their study demonstrated a temperature drop of up to 20% under similar conditions. Our experimental results showed a comparable cooling performance, achieving a maximum temperature reduction of 22% with eight Peltier modules. This consistency between the studies strengthens the validity of our experimental outcomes and further confirms the potential of Peltier modules as an effective solution for energy-efficient cooling applications.

8. Cost Analysis

Every creative idea must be financially viable to succeed in the market. Here, we assess the practical cost of a domestic pedestal fan using Peltier modules, without an in-depth economic analysis. The components that are directly powered include the DC fan motor and the Peltier modules. Four 2.5-A DC fans, commonly utilized in computer systems, were utilized in the test setup. The specifics of the Peltier modules utilized in the experimental study are outlined in Table 2. The operational expenses and energy savings related to the usage of Peltier modules in the suggested cooling system are the main subjects of the cost analysis provided in this study. Although this offers a preliminary assessment of the system’s financial advantages, it ignores the Peltier modules’ production, upkeep, and disposal expenses. One important aspect affecting the system’s overall viability is the cost of manufacturing Peltier modules, which comprise materials like SiGe and Bi2Te3 as well as related production techniques. A thorough life-cycle cost analysis should be incorporated into future studies to assess the suggested system’s long-term effects on the economy and environment more comprehensively.

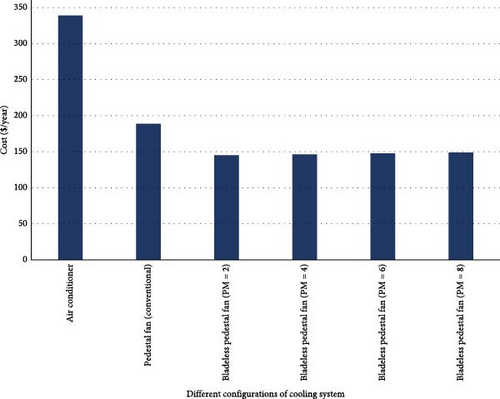

The cost of electricity in Pakistan is 0.087 USD/kWh. So, if the fan is run for 8 h daily, the cost of 1 day will be 0.41 USD. The cost of electricity for 1 year will be 148.76 USD.

8.1. The Annual Cost of a Standard Pedestal Fan and a 1-Ton AC

If the fan operates for 8 h every day, it will amount to 0.52 USD/day in electricity expenses. Over a year, this translates to a total of 188.58 USD in electricity costs. Similarly, the following method can be used to determine the annual cost of operating a 1-ton split AC with a thermostat set to 26°C in a 36°C environment: The current state of power usage is about 1.340 kW. The amount of power used for 8 h of operation would be 8 multiplied by 1.43, or 10.72 kWh. With power costing 0.087 USD per unit, the annual outlay comes to 338.73 USD. Figure 11 shows the cost comparison of a bladeless pedestal fan with Peltier modules to an AC and a conventional pedestal fan.

8.2. Capital and Power Saved

Based on the aforementioned analysis, swapping out a traditional pedestal fan with one using Peltier modules can conserve 1850 kWh of energy. Additionally, by employing a domestic pedestal fan utilizing Peltier modules instead of a standard A/C unit, 3850 kWh of energy can be conserved and available for alternative applications. If the proposed Peltier-based pedestal fan is adopted nationwide, replacing 2 million conventional pedestal fans, an energy saving of approximately 2000 MW can be achieved. It could even save 3700 MW of energy if it is replaced with existing A/C systems, approximately matching the current national energy shortfall.

8.3. Assumptions in Energy Savings Estimate

- •

The estimated number of pedestal fans in use across the country is approximately 2 million units.

- •

During the hottest summer months, each fan runs for an average of 8 h each day.

- •

Traditional pedestal fans with blades use an average of 90 W of power per unit.

- •

The suggested Peltier-based pedestal fan uses about 84.5 W of electricity per unit, but it offers cooling advantages comparable to those of traditional air conditioning.

Field research, fan usage market data, and the experimental results presented in this study were the sources of these hypotheses. The resulting savings demonstrate the substantial possibility of switching to this cutting-edge technology and are in line with the predicted national energy shortfall.

9. Conclusions

There is an urgent need to switch from conventional A/C and ventilation techniques to renewable energy sources to guarantee the sustainability of our energy systems. To comply with ASHRAE comfort criteria, we attempted to evaluate the influence of Peltier modules on the cooling efficiency of a portable pedestal fan in this study. Two, four, six, and eight Peltier modules were used in our studies, which were carried out in a 4 × 4 m space at different ambient temperatures. The choice of configurations with 2, 4, 6, and 8 Peltier modules was made to systematically evaluate the cooling performance and scalability of the system. The electrical power input was not kept constant; instead, it increased proportionally with the number of modules used, as each module operated independently and required additional power. Three replications of each experimental condition were conducted. The application of Peltier modules resulted in a 4%, 12%, 18%, and 22% drop in temperature within the experimental zone using two, four, six, and eight Peltier modules, respectively. In addition, the setup evaluated in this study can be employed in the agriculture and livestock sectors, where it is not required to maintain a low temperature to produce comfort. On a larger scale, up to 2000 MW of energy may be saved if Peltier modules, as suggested and demonstrated in this study, were used in place of all traditional pedestal fans. Moreover, more than 3700 MW of energy might be saved if 1-ton capacity ACs were replaced nationwide.

Nomenclature

-

- A:

-

- Area

-

- AC:

-

- Air conditioner

-

- ANOVA:

-

- Analysis of variance

-

- BF:

-

- Ballast factor

-

- Btu:

-

- British thermal unit

-

- CFM:

-

- Cubic feet meter

-

- CLF:

-

- Cooling load factor

-

- CLTD:

-

- Cooling load temperature difference

-

- °C:

-

- Degree centigrade

-

- DC:

-

- Direct current

-

- DR:

-

- Daily temperature range

-

- Ft:

-

- Foot

-

- ℉:

-

- Degree Fahrenheit

-

- Hp:

-

- Horsepower

-

- Hr:

-

- Hour

-

- HVAC:

-

- Heating, ventilation, and air conditioning

-

- kW:

-

- Kilo Watt

-

- kWh:

-

- Kilowatt-hour

-

- LM:

-

- Latitude and month correction

-

- MD:

-

- Memory-dependent derivative

-

- m:

-

- Meter

-

- mm:

-

- Millimeter

-

- MW:

-

- Megawatt

-

- PKR:

-

- Pakistani rupees

-

- PST:

-

- Pakistan Standard time

-

- PVC:

-

- Photovoltaic cell

-

- Q:

-

- Heat

-

- qs:

-

- Latent and sensible heat gain

-

- RPM:

-

- Revolution per minute

-

- SC:

-

- Shading coefficient

-

- SHGF:

-

- Solar heat gain factor

-

- Ta:

-

- The average temperature of the surrounding

-

- To:

-

- Outside design dry bulb temperature

-

- Tr:

-

- Room temperature

-

- µ (eV):

-

- Micro electron volt

-

- USD:

-

- United State Dollar

-

- V:

-

- Volt

-

- W:

-

- Watt.

Conflicts of Interest

The authors declare no conflicts of interest.

Author Contributions

Muhammad Sarfraz Ali: conceptualization; methodology; software; formal analysis; writing–original draft. Sadia Saleem: software; resources; writing–review and editing. Asad Naeem Shah: supervision; writing–review and editing. Shanawar Hamid: supervision; validation; writing–review and editing. Zeeshan Ali: investigation; resources; data curation. Hafiz Asad Ur Rehman: investigation; validation; writing–review and editing. Muhammad Saifullah: validation; investigation. Eustache Hakizimana: supervision; writing–review and editing. Sadia Saleem contributed equally to this work and should be listed as co-first author.

Funding

No funding was received for this research.

Acknowledgments

The authors express gratitude to the administration of the Swedish College of Engineering and Technology, Rahim Yar Khan, for their backing of this research endeavor.

Open Research

Data Availability Statement

The research data supporting the findings of this study are not shared.