An Investigation on Characteristics of Spray Combustion Under GCI Engine Conditions Using Gasoline–Biodiesel Blends

Abstract

In this study, mixtures of high-octane gasoline–biodiesel (GB) rating from 0% to 20%, denoted as GB00-GB10-GB20, were chosen to be experimented under simulated gasoline compression ignition (GCI) engine inside a constant volume combustion chamber (CVCC) before making comparisons about spray and combustion characteristics. While typical data of the nonvaporization spray characteristics: spray penetration length, spray cone angle, and spray evolution were collected by varying 40–90 MPa of injection pressure at 15 kg/m3 ambient gas density, data representing combustion characteristics, namely the ignition delay, flame development, and heat release rate (HRR) were illustrated under 90 MPa injection pressure, same ambient gas density, and temperature variation of 900–1000 K. Although the fuel mixture spray development trends followed a similar pattern, GB10 and GB20 had an averagely 6.25%–7.7% faster impingement velocity than that of GB00 except for the lowest considered injection pressure. Additionally, the ignition delay reductions were recognized for both GB10 and GB20, with the duration dropping from 1.09 to 1.06 ms and 0.96 to 0.79 ms, respectively. The results for spray and combustion characteristics under GCI engine condition-like showed a close relationship, offering valuable insights for simulation, spray, combustion, and ANN modeling, thereby supporting the development and application of GCI engines.

1. Introduction

The gasoline compression ignition (GCI) engine is a promising and widely applicable technology, allowing operation without throttle and having similar performance to diesel engines. Studies have demonstrated that GCI engines can run directly on gasoline with an octane rating of 60–85. The advantage of gasoline over diesel is its long combustion delay period, which provides the air–fuel mixture time to combine properly. The combustion process becomes more efficient, resulting in low nitrogen oxide (NOx) and soot concentrations. This is particularly relevant in the current context of global air quality concerns, with emission reduction measures being rigorously applied.

Numerous studies have demonstrated that low-temperature combustion (LTC) conditions can be achieved in GCI engines with high octane and high vaporization fuels [1–4]. Therefore, research into capacity, emissions, and injection strategies in different operating modes has provided interesting results. In a study of strategic control of valve opening and closing at low load [5], the early exhaust valve opening (EEVO) strategy increased the intake and exhaust gas temperatures by 130 and 180 K, respectively. Meanwhile, the exhaust gas regeneration strategy (ExReb) resulted in 11%–18% lower brake-specific fuel consumption (BSFC) compared to EEVO under the same engine operating conditions at 1375 rpm with gasoline fuel of octane 93. Zhang et al. [6] also published a study on combustion and emissions in GCI engines using gasoline-hydrogenated catalytic biodiesel (HCB) blends. The results showed increased ignition efficiency, maximum combustion pressure, and combustion stability with increasing HCB composition in the fuel following the controlled combustion phase. Emissions of NOx, carbon monoxide (CO), and unburnt hydrocarbon (UHC) also decreased significantly with increasing HCB content. In another study, GCI multicylinder engines with 98-octane fuels [7] were tested to study combustion and emissions characteristics. The results showed that emission characteristics tended to differ with EGR level. The soot emission signal of GCI combustion is strong at late injection and stronger at low EGR. The soot/temperature profile is indicative of only high-temperature combustion, while the heat release rate (HRR) based on cylinder pressure indicates two-stage combustion. The effect of injector spray angle on gasoline–diesel mixture fuel was observed under low-load GCI engine operating conditions [8]. The narrower injector spray angle resulted in improved local mix strength and self-ignition with gasoline without the need for turbocharging or preheating the intake air. In addition, emissions of soot and NOx showed a downward trend, while HC and CO emissions were high due to gasoline combustion. Putrasari and Lim [9, 10] have several studies on the control of injection strategy to evaluate the combustion process and emissions of GCI engines using mixed gasoline–biodiesel (GB) fuel. The injection strategy varied from 75° before top dead center (BTDC) to 18° BTDC, with injection timing and injection duration adjusted accordingly. The combustion chamber temperature in LTC mode can reach nearly 1800 K. However, NOx emissions tend to increase slightly while THC and CO decrease in cases where the injection strategy is adjusted several times before the piston reaches TDC.

In a different approach, some studies on spray and combustion characteristics have used a constant volume combustion chamber (CVCC) to test varying experimental conditions for GCI engines. These studies can control the desired conditions of LTC combustion and obtain visual images. The objective of applying mixed fuel gasoline/HCB in GCI engines is achieved by evaluating spray liquid length, ignition delay, and lift-off length [11]. Experimental results showed that ignition delay and liquid length decreased with increasing HCB ratio. The study also showed that the chemical ignition delay plays an important role in the total ignition delay and that the variation between cycles decreases with an increasing proportion of HCB in the mixture. In another study, Du et al. [12] analyzed the liquid and vapor penetration of gasoline fuel using multihole injectors and reported that liquid penetration tends to be greater in a higher molecular weight gas composition. However, vapor penetration showed negligible effect under different gas compositions. The pressure difference did affect the vapor penetration length, while its effect on the steady-state penetration length of the liquid phase at high ambient gas temperatures was negligible. In addition, 77-octane gasoline fuels have been investigated for properties such as penetration lengths under vaporizing and nonvaporizing conditions and ignition delay under reactive conditions [13]. Most published studies conclude that the use of gasoline in diesel engines is feasible and produces positive results [14–17]. However, further research is needed to address the limitations of GCI engine operation at high loads. Specifically, there is a lack of comprehensive studies on spray and combustion characteristics under GCI engine conditions using high-octane fuels.

In addition, the usage of alternative fuels was investigated in this study. According to recent research trends, the implications of biofuels are still of great interests [18, 19]. A great many of generations of biodiesel fuel have been developed up to now [20–22]. Besides, alcohol-based fuels have also been receiving more attention when applied to diesel engines [23–25]. Nevertheless, the commercialization of biofuels has not yet fulfilled the market demands because these alternatives confront numerous hurdles and begin at a relatively low level. That implies facing rapid and limitless progress in the realm of transportation powered by internal combustion engines [26]. The goal of using biofuels is to progressively replace and lessen reliance on traditional fuels without requiring excessive structural changes to the engine. Their advantages will improve emissions that have detrimental impacts on air quality and greenhouse gas emissions. A quadratic equation was established with 95% confidence for predicting various output parameters (BSFC, BTE, CO, HC, and NOx) in a study on fuel combinations of alcohol–diesel–biodiesel applied to diesel engines [27]. The properties of biodiesel are also studied when trying to bring the fuel mixture to a neutral carbon level. The addition of extra alcohol components to biodiesel and diesel blends boosts the capability of biodiesel mixing at higher percentages. The results revealed that such mixtures improve NOx and CO emissions while having a higher HC concentration [28]. In another study, it was reported that soybean biodiesel is effective when applied in engine fuel mixtures, having the potential to be blended into quaternary fuel blends, thereby reducing the reliance on fossil fuels. The quaternary fuel mixture offered the greatest improvement, with NOx concentration reduced by up to 11.9% [29]. With practicality proven by numerous prior publications, this study also employs a fuel mixture consisting of high-octane gasoline and soybean biodiesel to assure sustainability and improve biofuels’ progressive replacement potentials. Furthermore, the injector operates at high pressure with low-viscosity gasoline fuel; the inclusion of biodiesel will promote injector stability.

In this work, experiments were carried out to evaluate the characteristics of the spray and combustion processes in order to prove their correlation with each other. Furthermore, the results were assessed while modifying injection pressure values in small increments, as well as the ability to use high-octane gasoline fuel under GCI engine operating conditions. The fuel mixtures used in this study are GB blends with biodiesel concentrations ranging from 0% to 10% and 20% by volume. The nonvaporization spraying process was investigated by setting injection pressure from 40 to 90 MPa with a step of 10 MPa and the ambient gas density from 10 to 15 kg/m3. Spray development, spray penetration length, and spray cone angle results are presented for a more in-depth study of spray properties. Meanwhile, the combustion process is reflected through the findings of HRR, pressure trace, ignition delay, and flame development with combustion temperatures ranging from 900 to 1000 K, injection pressure settings of 90 MPa, and ambient gas density of 15 kg/m3. The study complements the necessary parameters with previous studies based on the aforementioned results to generate a thorough assessment. Furthermore, these data are capable of being used as a database as well as validation to develop simulation models, spray models, combustion models, and ANN model applications to enhance the development and application of GCI engines.

2. Methodology

2.1. Experiment Apparatus

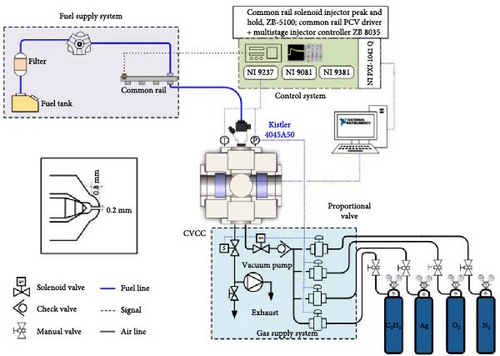

This experimental study, including the spray and combustion process, is carried out in a CVCC, as shown in Figure 1. For the combustion process, a premix-combustion is performed before injection timing to create a diesel engine-like environment. The gases charged into the chamber were C2H2, Ar, O2, and N2. The control system is completely automatic from the chamber cleaning process, controlling everything from the intake air composition to the exhaust process. The gases are loaded into the chamber based on the density calculation condition set for each test process through the solenoid valve (Burkert 8605), compatible with the self-configured LabVIEW software. The intake and exhaust systems are executed by two electromagnetically controlled pneumatic valves. The combustion chamber is designed for a maximum pressure of 100 bar. After charging, the static pressure sensor will compare the instantaneous pressure value with that set by the software. If the difference exceeds 2%, the system will automatically deactivate prior to premix combustion activation. A high-frequency pressure transducer (Kistler 6061B) is connected to a charge amplifier (Kistler 5018) to record the full pressure of the premix combustion and main combustion process after the injectors are activated. The injection pressure is controlled via a common-rail system with a Zenobalti (ZB)-5100 controller and a signal sync driver with a ZB-8035. The fuel system can increase the pressure to 1600 bar and maintain the fuel pressure at a stable injection value.

For the nonvaporizing spray process, the CVCC system only charges the chamber with N2 gas, yielding densities ranging from 10 to 15 kg/m3. The heater system of the chamber is only activated for combustion with the controlled chamber temperature fluctuating around 100°C.

2.2. Optical Setup

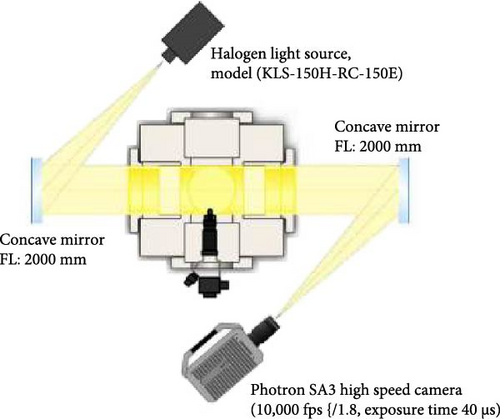

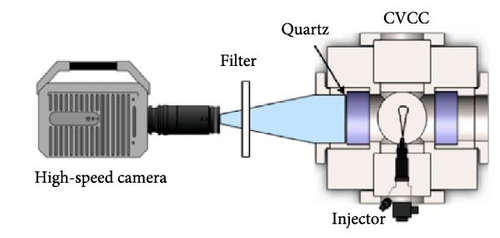

Figure 2 presents the experimental setup for macroscopic spray and combustion analysis with the optical setup is based on the Schlieren approach with a Z-type configuration. Halogen lamps, high-speed cameras, and concave spherical mirrors (diameter 150 mm, focal length 2000 mm) collect spray images from the combustion chamber. A halogen light source is shone at the first concave spherical mirror with a diverging light source to capture spray movement. This diverging light source is then transformed into a parallel light source and shone at the second concave mirror into the converging source and directly at the camera. Using a Photron SA3 high-speed camera, the photos were captured at 10,000 frames per second with a resolution of 512 × 256 pixels.

2.3. Fuel Properties and Experimental Conditions

The objective of the study is to apply high-octane gasoline fuel to experimental cases of GCI engine conditions. In addition, biodiesel is added to the fuel mixture to increase the usability of biofuel as well as to ensure the stable viscosity of the fuel. The three fuel mixes used in this study were GB00, GB10, and GB20, with volumes of soybean biodiesel of 0%, 10%, and 20% by volume, respectively. The properties of the fuels are shown in Table 1.

| Property | Unit | Test method | GB00 | GB10 | GB20 | B100 |

|---|---|---|---|---|---|---|

| Density at 15°C | kg/m3 |

|

712.7 | 732.2 | 757.1 | 882.3 |

| Lubricity | μm |

|

548 | 282 | 236 | 189 |

|

15°C |

|

−57 | −32 | −16 | 3 |

| Pour point | °C |

|

<−57 | <−57 | <−57 | <1 |

| Kinematic viscosity at 40°C | mm2/s |

|

|

1.0844 [33] |

|

4.229 |

| Heating value | MJ/kg |

|

45.86 | 44.92 | 43.6 | 39.79 |

|

mN/m |

|

|

|

|

|

| Stoichiometric air–fuel ratio | — | 14.7 | 14.7 | 14.488 | 14.276 | 12.58 |

| Blend ratio | — | 1.0 | 1.0 | 0.90 | 0.80 | — |

- Abbreviation: GB, gasoline–biodiesel.

Spray and combustion are separated into two sets of experiments with the different ambient temperatures and oxygen concentrations. The mixed fuels GB00, GB10, GB20, and 0.2 mm single-hole injectors were used in both experimental processes. To distinguish the spray morphology, the selected pressures vary from 40 to 90 MPa for nonvaporizing conditions. For combustion, an injection pressure of 90 MPa and ambient gas density of 15 kg/m3 were chosen as representative with a temperature change from 900 to 1000 K to determine the differences in combustion characteristics and the relationship to the spraying process. Table 2 presents the experimental conditions as well as the parameter settings for the high-speed camera to obtain the results.

| Parameters | Spray | Combustion |

|---|---|---|

| Fuel type | GB00-GB10-GB20 | GB00-GB10-GB20 |

| Injector type | Single hole—0.2 mm | Single hole—0.2 mm |

| Injection duration (µs) | 1500 | 1500 |

| Fuel temperature (K) | 308 | 308 |

| Injection pressure (MPa) | 40–90 (step 10 MPa) | 90 |

| Ambient gas density (kg/m3) | 10–15 | 15 |

| Chamber body temperature (K) | 298 | 398 |

| Oxygen concentration (%) | 0 | 15 |

| Ambient temperature (K) | 298 | 900−1000 |

| Frame rate (frames/s) | 10,000 | 10,000 |

| Exposure time (µs) | 20 | 40 |

| Image resolution (pixels) | 512 × 256 | 512 × 256 |

- Abbreviation: GB, gasoline–biodiesel.

2.4. Image Processing

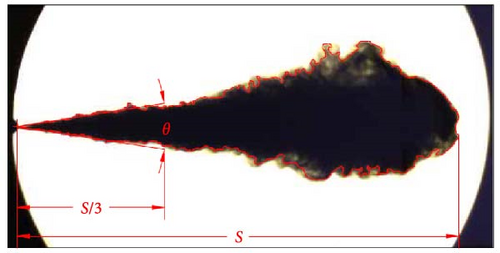

Spray characteristics such as spray penetration length and spray cone angle are determined based on the image processing collected from the high-speed camera during the experiment. The image processing algorithm was built using MATLAB with references from previous studies [37–39]. During the image processing steps, the color is converted to grayscale and then to binary. The origin is defined as the nozzle tip. The spray penetration length is determined by the distance from the nozzle tip to the furthest point of the spray. The spray cone angle is the opening angle of the jet, measured from the nozzle tip to the position of one-third of the spray penetration length. The scale of the image is 1 pixel/0.2 mm. Figure 3 illustrates the spray characteristics.

2.5. Ignition Delay and HRR

The ignition delay of GCI injection combustion is another important parameter for engine optimization when applying different fuels. Ignition delay includes both chemical kinetic effects and physical delays, such as injector hydrodynamic delay and fuel–air mixing delay. The accumulated heat release is a criterion to measure the ignition delay.

3. Results and Discussion

3.1. Spray Characteristics

3.1.1. Spray Evolution

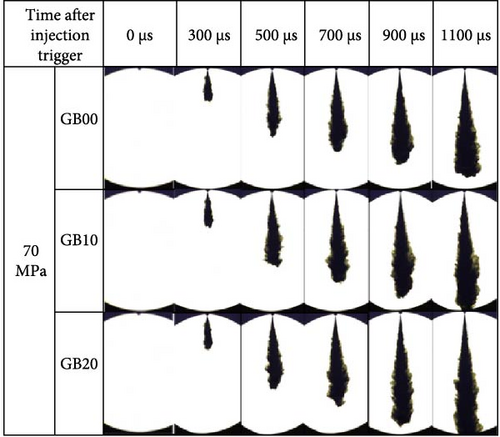

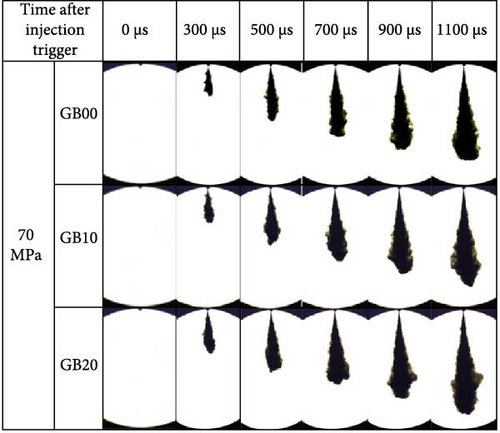

The spray evolution of GB00, GB10, and GB20 at 70 MPa and ambient gas densities of 10 and 15 kg/m3 are shown in Figures 4 and 5. The spray beam shape develops differently depending on the proportion of biodiesel in the fuel mixture. This proves that the addition of biodiesel has an effect on spray characteristics [31]. In terms of fuel properties, an increase in biodiesel content means an increased fuel viscosity and a similar trend in the density of the fuel mixture. Notice that the spray beam of GB00 tends to go slower than the rest of the fuels due to its high vaporization characteristics. GCI studies have also demonstrated that gasoline fuels have the shortest liquid length under vaporization conditions compared with diesel-based fuels [41, 42]. In addition, increasing the density of the gas in the chamber increases the resistance of the spray formation process, making the spray have a slower time to the wall at high density. The spray angle is reflected clearly in the presented images. It can be seen very intuitively with the spray angle covering the entire spray at two different density levels that the spray angle in the case of 15 kg/m3 always tends to be larger and more complete. Combustion theories also predict that a well-formed fuel–air mixture will result in highly efficient combustion [43]. The definition is perfectly appropriate when the engine has a large compression ratio, resulting in high density and higher efficiency. The spray-forming tendency at 10 and 15 kg/m3 is consistent. In addition, an increase in the gas density in the chamber does not mean that the spray growth follows the linear law of that density value.

3.1.2. Spray Penetration Length

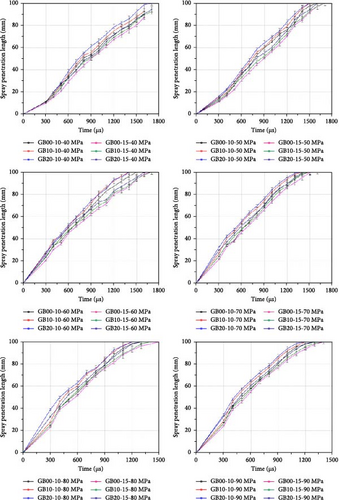

Figure 6 presents the results of spray penetration length under injection pressures of 40–90 MPa and ambient gas densities of 10–15 kg/m3 for the three fuel types GB00, GB10, and GB20 with injection duration of 1500 µs. The spray penetration length is defined as the distance from the nozzle tip to the furthest point of the spray. The limit of the spray is set at the contact position as the endpoint of the analysis. The time axis step was chosen to be 300 µs due to the exclusion of near-spray measurements. Conditions are consistently supervised throughout the experiment to ensure that errors are kept to a minimum. Each test case was repeated three times, and the error did not exceed 5% in almost all experimental values. The variations in spray morphology and spray penetration length among the fuels tested in this study are relatively minor. Similar patterns have been noted in earlier research. However, previous studies did not thoroughly examine the effects of slight differences in injection pressure. Therefore, the injection pressure conditions were carefully selected, ranging from 40 to 90 MPa with 10 MPa increments in this study. Test cases of GB20 fuel have been validated with previous results, following the same patterns with previous research [38]. The spray impingement velocity of GB20 at a pressure of 40 MPa and an ambient density of 10 kg/m3 was recorded as 57.2 m/s, while the previous study had a value of 58.82 m/s. The study also recorded that the difference in the results of spray penetration rate between the levels of 40 and 50 MPa is acceptable. This also happens for adjacent pressure levels between 60 and 70 MPa or 80 and 90 MPa. The average spray impingement velocity was also recorded to be 10 m/s higher when comparing pressure levels of 90 and 70 MPa at most fuel and ambient density levels.

As the ambient density increases, the spray penetration length tends to decrease across all types of fuel. The change in injection pressure significantly influences the kinetic energy of the spray, resulting in the delivery of greater energy being in the same injection duration. Despite the increase in injection pressure based on a linear model, the results between 40 and 90 MPa exhibit nonlinear trends. Specifically, at an injection pressure of 40 MPa, needle closing is observed before fuel impingement on the wall. When compared among GB00, GB20, and GB10 fuels, the difference in impingement time is reduced by an average of 6.25%–7.7% for injection pressures of 50–90 MPa. However, GB20 has a reduction of about 5.8%–7.1% compared to GB00 at a density of 15 kg/m3. Meanwhile, GB10 gives an average result of about 6.25%–6.6%. This clearly highlights the difference in fuel properties that affect the overall results with conservative boundary conditions, which has also been proven in previous studies when evaluating the viscosity difference of fuel mixtures [13, 37, 38]. In addition, it can be verified that the phenomenon of spray breakage before the spray impingement on the wall does not occur for pressure levels from 50 to 90 MPa. This can be explained by the increased axial injection momentum due to a larger amount of fuel being supplied during the spray process [12]. The phenomenon of spray breakage or determining the time of spray impingement can also provide an intuitive value about the spray formation. It is considered under the condition that normal diffusion occurs in the combustion process. At that time, determining the ignition delay will be decisive, and these results will complement each other.

Across nearly all experimental conditions, the spray development of GB20 fuel outperforms the others. The superiority observed in the spray development can be attributed to the higher biodiesel content in the fuel. This elevated biodiesel content leads to greater fuel density, resulting in enhanced kinematic development. The increased density and biodiesel content likely influence the fuel behavior during injection, contributing to the improved spray characteristics observed in the study.

3.1.3. Spray Cone Angle

Figure 7 presents the results of the spray cone angle under the influence of varying biodiesel composition in the fuel. The experimental process is combined with changing conditions, including fuel injection pressure and ambient gas density. Experimental results are collected in image form and analyzed using self-executed MATLAB code to improve accuracy and shorten the time in the process of analyzing results. The general trend of the spray cone angle when increasing the biodiesel content in the fuel or increasing the injection pressure is gradually decreasing until it enters a stable period. In a stable spray pattern, the spray cone angle tends to decrease slightly until the value remains almost unchanged or has a very small change in the range of less than 2°. However, the difference between the spray cone angle value when the spray is newly formed compared to the stable phase is very different. This can be explained by the impact of axial velocity, radial momentum, and drag effects from the density of the environment inside the chamber. The spray cone angle reaches its maximum value in the early stages when the spray has just been formed, especially recorded at the time interval of 300 µs. The maximum values recorded were 42°, 39.6°, and 38° for fuels GB00, GB10, and GB20, respectively. The average value of the spray cone angle over the entire spray process is also recorded and calculated. Based on the comparison results of spray cone angle reduction when increasing injection pressure from 40 to 90 MPa, the values are 8.8%, 15.8%, and 17%, respectively, for fuels GB00, GB10, and GB20 at 15 kg/m3 ambient gas density. However, the values recorded under the condition of the ambient gas density of 10 kg/m3 are 16.6%, 18.6%, and 11.49% for GB00, GB10, and GB20, respectively. The results show that the decrease is not linear under any conditions of pressure or environmental density. This can be explained that in the atomization regime, there is no theory to explain the disintegration of liquids at high velocities [44], but the shock wave development and amplitude increase, as well as instability, is the main cause leading to the above phenomenon. Indeed, the process of liquid decomposition is influenced by various factors, including velocity, nozzle diameter, and the properties of both liquid and gas. These parameters play a crucial role in determining how the liquid fuel breaks down and atomizes into small droplets during the spraying process. Velocity affects the kinetic energy of the liquid, while the nozzle diameter determines the size of the orifice through which the liquid passes. Additionally, the properties of the liquid, such as viscosity and surface tension, as well as the properties of the surrounding gas, impact the breakup and atomization of the liquid into a spray [45–49]. Certainly, the influence of numerous boundary conditions can lead to instability and turbulence in the spray during the spraying process. As the spray enters a stable phase, these fluctuations tend to diminish, and the resulting values stabilize within a narrow boundary. Understanding and controlling these boundary conditions are crucial in achieving consistent and predictable spray behavior in various applications.

3.2. Combustion Characteristics

3.2.1. Pressure and HRR

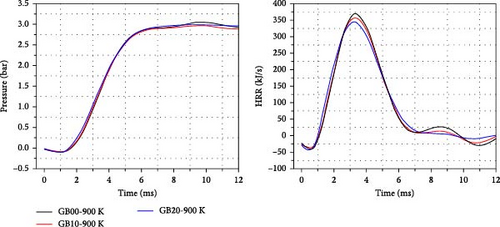

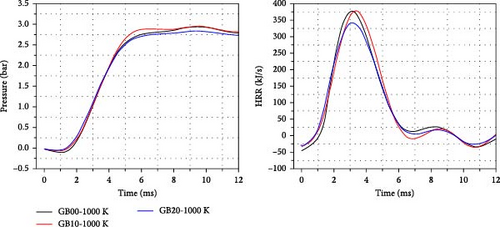

Figure 8 shows the pressure development and HRR of GB fuels with different ratios under typical conditions. Pressure is calculated by the difference in pressure after injection timing compared with the value of pressure at the injection timing signal appears. These measurements were conducted within a temperature range of 900–1000 K, utilizing an injection pressure of 90 MPa and an ambient gas density of 15 kg/m³. The study specifically investigated combustion mixture control under conditions of 15% oxygen. A slight decrease in pressure was recorded due to heat loss caused by cold fuel in the injection area, where no reaction occurred [39]. This phenomenon can be clearly demonstrated through the appearance of a negative HRR after the fuel injection timing. The pressure tends to decrease while the biodiesel concentration increases due to the lower calorific value for blended fuels with a higher percentage of biodiesel. The reduction in energy input results in a reduction in the total amount of heat released, thereby reducing the maximum total pressure. Trends indicate that most fuels exhibit single-stage ignition due to the predominance of gasoline as the main chemical composition. The chemical reaction occurs rapidly over a wide temperature range, leading to an increase in temperature and a peak in pressure. In the case of GB00, pure gasoline has a slow combustion process and causes the longest ignition delay. That shows more clearly the nature of longer ignition delay compared to high cetane fuels. The results also showed that fuel mixtures with a lower biodiesel ratio had shorter combustion duration under all test conditions. It implies that the combustion characteristics become more similar to the Otto cycle, thus preserving higher engine performance according to the principles of engine combustion.

The increase in biodiesel content even slows down the combustion process in the cases of 900 and 1000 K. The evidence is that the HRR decreased in the two ambient temperature cases. Furthermore, gasoline has a maximum peak HRR level due to the prolonged mixing process that results in a larger volume of air and fuel being prepared before combustion. This is consistent with the characteristics of the fuel mixture, suggesting that a larger biodiesel content increases the fuel cetane number and reduces the combustion delay. Additionally, the HRR decreased as the ambient temperature increased from 900 to 1000 K in most of the three fuels tested in the experiment. The combination of higher ambient temperature and the volatile nature of the fuel mixture results in earlier mixture formation and, thus, increased heat loss through conduction into the chamber walls and the diffusion flame. These findings highlight the complex relationship between fuel composition, ignition characteristics, and ambient conditions, providing valuable insights for optimizing combustion.

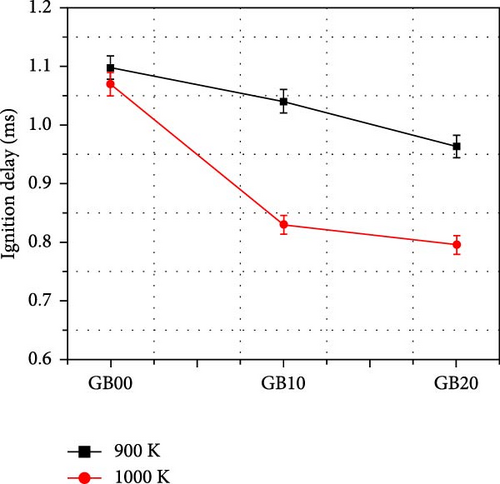

3.2.2. Ignition Delay

In Figure 9, the ignition delay values of three fuels are depicted at two different ambient temperatures, calculated from the HRR results. Notably, the ignition delay has significant changes with increasing biodiesel content in the fuel and ambient temperature. This observed trend is consistent with findings from combustion studies involving GCI engines. In addition, the injection time is fixed at 1500 µs to ensure that the injector needle is completely opened. The lack of comparison with larger injection timings is due to the lack of change in ignition delay when injection timing exceeds 1500 µs [30, 39]. A reduction in ignition delay was observed as the biodiesel composition increased from 0% to 20% and was rationalized through fuel properties. The main component of the mixture is gasoline, which has high ignition delay properties. When adding biodiesel, the cetane index of the fuel increases, leading to a shortened ignition delay time. The evidence is that the ignition delay was recorded as 1.09, 1.04, and 0.96 ms for GB00, GB10, and GB20 fuels at 900 K temperature, respectively. The trend and quantification of the resulting values are completely consistent with previous studies. In addition, the longer ignition delays due to fuel mixtures with lower biodiesel content increase fuel evaporation to produce lean fuel–air combustion, thus reducing soot formation. For these reasons, blending gasoline with moderate biodiesel has great potential to achieve high efficiency and low emissions by maintaining the advantages of gasoline. GB blends with small biodiesel (less than 20%) will significantly extend the engine’s operating range to low load conditions while maintaining high thermal efficiency and low emissions.

Additionally, increased ambient temperature results in reduced ignition delay due to faster fuel evaporation, causing the jet to develop more rapidly at lower ambient temperatures. Therefore, the mixture formed early during combustion under these conditions. The recorded results decreased from 1.09 to 1.06 ms for GB00 and 0.96 ms to 0.79 for GB20. The reason for this difference is the shorter time for atomization, evaporation and mixing with air. In turn, those resulted in a smaller amount of the air and fuel mixture reaching the autoignition temperature. At the same time, such reasons also reduce the expansion rate of the flame. Conversely, longer ignition delays cause higher oxygen concentrations in the fuel-rich combustion zone, increasing the rate of oxidation reactions and increasing combustion speed. It is important to emphasize that although the injection pressure varied from 40 to 90 MPa during the test, the pressure in the common rail system remained stable. Furthermore, fuel temperature is carefully maintained at optimal levels. However, it is important to acknowledge that significant fluctuations in injection pressure can cause system instability, requiring further investigation to fully understand the significance of such fluctuations.

In addition, the difference between the ignition delay determined by combustion pressure always tends to be longer than the luminous ignition delay. This difference has also been mentioned in studies of CI motivation. When the ambient temperature increases, the combustion process develops rapidly. It shortens the time required for the pressure sensor to register a value. Meanwhile, determining luminous ignition delay does not depend on the flame speed. Therefore, this difference can increase or decrease depending on the mixing process as well as the boundary conditions that affect the ignition delay.

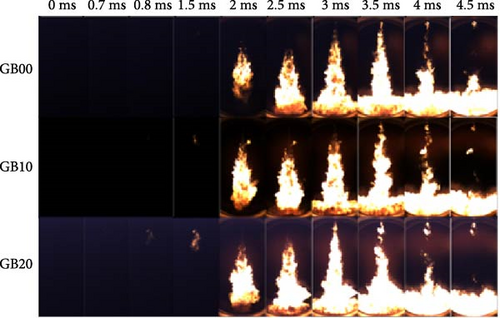

3.2.3. Flame Development

Figures 10 and 11 present images of the combustion process captured at ambient temperatures of 900 and 1000 K. It should be noted that images captured with high-speed cameras only represent broadband light intensities expressed in pixel values and do not provide spectral information. Chemiluminescence and soot luminescence are the main sources of natural brightness. Since the latter is much stronger than the former, it is therefore reasonable to argue that soot luminosity can be well represented by broadband luminosity [50]. However, the use of the two-color method and OH-chemiluminescence was not applied, so the results of soot and oxidative luminescence are not presented in this study. Applying the natural luminosity method to record images of the combustion process is prone to observing the relationship between the injection process and the combustion process as well as comparing the deviation of the ignition delay value. In Figures 10 and 11, each line presents the combustion process of fuel mixtures GB00, GB10, and GB20, respectively, under the same test conditions. In each image of the flame, the nozzle is located above the tip of the flame, and the arc at the corresponding edge represents the chamber wall. In most fuel mixtures, flame onset occurs around 1 ms for 900 K and 0.8 ms for 1000 K. Notably, the earliest flame appearance is consistently recorded for GB20 fuel. The flame, from the moment it appears, gradually diffuses downstream, with multiple areas igniting, particularly those near the wall. It is observed that luminous intensity increases with higher biodiesel content in the fuel, a phenomenon explained by the reduced ignition delay associated with increased biodiesel.

Additionally, it is evident that the brightness threshold rises with escalating ambient temperatures. The higher temperature induces autoignition, altering the flame’s brightness. A common diffuse combustion mode is observed in both temperature cases where autoignition occurs before the end of the injection process and is also in complete agreement with the results of the nonvaporization process. This has also been proven in previous studies on the combustion process of GCI engines [13, 18]. Furthermore, when comparing the ignition delay values between Figures 10 and 11, the values determined through the natural brightness method have similar trends. However, the results measured by the natural luminosity method have a higher value than the values normally calculated through the HRR. Regarding the combustion characteristics of GCI engines, employing high-octane gasoline with added biodiesel to the mixture aids the combustion process and ensures more stable injector operation. This approach enhances the efficiency and reliability of GCI engines during operation.

4. Conclusions

- 1.

It provides essential data concerning the nonvaporizing characteristics of high-octane fuel blends under varying experimental parameters, encompassing injection pressure and ambient gas density. The research quantifies fundamental spray characteristics, such as spray penetration length and spray cone angle. Additionally, it explores spray development to offer comprehensive insight into the spray morphology. The study reveals that the spray penetration length increases with the escalating biodiesel content in the fuel, with the penetration rate experiencing rapid enhancement. Simultaneously, elevating ambient gas density decelerates spray development. Regarding the spray cone angle, the impact of injection pressure becomes evident as the angle gradually diminishes with increasing injection pressure. A similar pattern emerges when the biodiesel content in the fuel increases. These outcomes adhere to the principles of injection laws and align with the kinetic trends evident through environmental density variations and fuel properties.

- 2.

The research delves into the influence of ambient temperature inside the chamber on combustion characteristics. Most fuel blends exhibit single-time ignition, predominantly due to the presence of gasoline in the fuel mix. Across various temperature scenarios, both the HRR and ignition delay decrease with an increase in biodiesel content. A consistent decline in ignition delay is also observed with rising ambient temperature, attributed to the significant promotion of fuel vaporization. High-speed camera images depicting flame development corroborate this decreasing trend in ignition delay. Besides, the ignition delay value determined by combustion pressure always tends to be higher than the luminous ignition delay.

- 3.

The results of the spray process also show the importance in calculating engine design as well as shaping a perfect combustion process. The normal diffusion combustion process is determined through a comparison of the value of ignition delay and the investigation of spray characteristics. It highlights the close relationships between the processes of nonvaporization, vaporization, and combustion.

- 4.

The integration of high-octane gasoline with added biodiesel enhances the combustion process, ensuring more stable injector operation. This strategic approach substantially improves the efficiency and reliability of GCI engines during operation, underscoring its potential significance in advancing engine performance.

In harmony with previous studies, the results have provided the basic data and parameters necessary for the development and application of GCI engines with high-octane fuel. Additionally, further developments include in-depth investigations about the issues of soot formation, NOx and toxic exhaust components for the experimental matrices that have been built throughout the previous studies. Eventually, there will be thorough strategies to control the spray and combustion processes so as to meet the goals of stable operation at medium and high loads of GCI concept. In addition, tribology experiments, as well as durability test cycles, should be available to investigate the engine’s stability when operating with the proposed fuel types. It will help to come to the final conclusions about the applicability of GCI conditions directly from the CI engine without changing the engine structure.

Nomenclature

-

- GCI:

-

- Gasoline compression ignition

-

- CVCC:

-

- Constant volume combustion chamber

-

- GB:

-

- Gasoline–biodiesel

-

- LTC:

-

- Low-temperature combustion

-

- DAQ:

-

- Data acquisition

-

- NI:

-

- National instrument

-

- PID:

-

- Proportional integral derivative

-

- HCB:

-

- Hydrogenated catalytic biodiesel

-

- BTDC:

-

- Before top dead center

-

- ZB:

-

- Zenobalti

-

- BSFC:

-

- Brake-specific fuel consumption

-

- CO:

-

- Carbon monoxide

-

- UHC:

-

- Unburn hydrocarbon

-

- NOx:

-

- Nitrogen oxide

-

- EEVO:

-

- Early exhaust valve opening.

Ethics Statement

The authors have nothing to report.

Disclosure

All individuals who meet the criteria for authorship are duly credited as authors. Each author certifies active participation in the work, taking public responsibility for its content, including contributions to the conception, design, analysis, writing, or critical revision of the manuscript. Furthermore, we confirm that all authors have been involved in drafting the article, revising it for significant intellectual content, and approving the final version.

Conflicts of Interest

The authors declare no conflicts of interest.

Author Contributions

Nguyen Ho Xuan Duy: writing–review and editing, writing–original draft, methodology, investigation, conceptualization. Tran Quang Khai: writing–review and editing, methodology. Ock Taeck Lim: supervision, project administration.

Funding

This work was supported by the ministry collaboration type human resource development program by the Ministry of Trade, Industry and Energy (MOTIE, Korea) (P0025588, Future Automotive Technology Convergence Innovation Human Resources Development Project) and the National Research Foundation Korea (NRF), grant funded by the Korea Government (MSIT) (No. RS-2023-00281590). This result was supported by the “Regional Innovation Strategy (RIS)” through the National Research Foundation of Korea (NRF), funded by the Ministry of Education (MOE) (2021RIS-003).

Acknowledgments

This work was supported by the ministry collaboration type human resource development program by the Ministry of Trade, Industry and Energy (MOTIE, Korea) (P0025588, Future Automotive Technology Convergence Innovation Human Resources Development Project) and the National Research Foundation Korea (NRF), grant funded by the Korea government (MSIT) (No. RS-2023-00281590). This result was supported by the “Regional Innovation Strategy (RIS)” through the National Research Foundation of Korea (NRF), funded by the Ministry of Education (MOE) (2021RIS-003).

Open Research

Data Availability Statement

The data supporting the findings of this study can be obtained from the corresponding author upon reasonable request. Certain limitations may apply due to the proprietary nature of some experimental setups (or other applicable reasons). All essential data, including processed data that support the conclusions, are included in the manuscript.