Evaluation of Two-Wheel Tractor Fuel Consumption Rates During Direct Seeding of Sorghum and Pearl Millet in Sandy and Clayey Soils

Abstract

Knowledge on the fuel consumption of agricultural tractors helps in the management and planning of farm operations. Fuel consumption data are also important in calculating the cost of using machinery to carry out operations and to estimate the contribution of agricultural machinery to greenhouse gas emissions. Various factors, including operating speed, soil type and tractor load affect the fuel consumption rate. Promotion of two-wheel tractors (2WTs) as an appropriate power-source for smallholder farmers has been on the rise in Zimbabwe. However, the fuel consumption performance of these tractors for some operations has not been established. Our study focused on evaluating the fuel consumption performance of a 2WT–based direct seeding system for sorghum and pearl millet crops in clayey and sandy soils at varying speeds of operation. Results showed that crop type, soil type and speed of operation affect fuel consumption rate. Increasing the operating speed resulted in a decrease in fuel consumption rate. For the same soil type, the fuel consumption rates for pearl millet seeding were higher than those of planting sorghum. At the recommended planting speeds, the fuel consumption rates when planting sorghum were 6.42 L/ha and 7.34 L/ha for clayey and sandy soils, respectively. For pearl millet planting, the fuel consumption rates were 10.93 L/ha and 11.90 L/ha for clayey and sandy soils, respectively. This information on fuel consumption rate can be used by farmers and other operators of 2WTs for planning the fuel quantity and budgetary requirements.

Summary

- •

Increasing operating speed results in a reduction in fuel consumption rate per unit area worked.

- •

The fuel consumption rate varies with crop type for direct seeding operations.

- •

Crops with relatively smaller inter-row spacing have higher fuel consumption rates.

1. Introduction

There is advocacy to promote the mechanisation of sorghum and pearl millet field production operations to enhance input utilisation efficiency, improve productivity levels and reduce the effort required to produce these grains [1]. These efforts are aimed at improving the economic viability and promoting wide-spread production of these grains for provision of food and nutrition security in the face of climate change. However, information on the performance of recommended mechanisation systems in sub-Saharan Africa is limited.

One of the most important performance parameters of agricultural tractors is fuel consumption and awareness of fuel consumption information for a certain machine helps in proper management of production costs and fuel resources [2]. Fuel consumption data are important in preparing budgets for agricultural operations [3]. More so, energy-saving initiatives in agriculture have created a demand for information on the extent of energy consumption for single operations and for total fuel consumed at farm level [4]. Because of rising fuel prices, fuel consumption has become an important factor in agricultural production economics [5]. Appropriate decisions need to be made to reduce fuel consumption of agricultural machinery to reduce the contribution of agriculture to environmental pollution [6].

The fuel consumption rate of agricultural machinery is generally known, but operating conditions influence fuel consumption, hence, the need to acquire more precise figures [4]. There also exists large variations between the generally known figures, for example, the fuel consumption figures for ploughing vary from 14 L/ha to 52 L/ha [4]. The variation is as a result of the effect of various factors that include: soil type, working depth and width, operating or working speed and tillage depth as well as soil moisture content [4, 5]. Performing fuel consumption tests for agricultural tractors generates data that can be used for the estimation of the quantity and cost of fuel required to perform a certain agricultural specialised operation [5].

Efficient operation of farm tractors include maximising the fuel efficiency of the engine and mechanical efficiency of the drive train, as well as selecting an optimal travelling speed for a given tractor-implement system [3]. The use of agricultural machinery that multitasks, for example, direct seeding planters, can reduce energy consumption per unit of the crop produced, resulting in lower production costs [7]. Whilst vast quantities of fuel are required to perform conventional tillage operations [2], reduced tillage systems can result in 55% reduction in fuel consumption compared to conventional tillage systems [7].

The fuel consumption rate of agricultural tractors can be measured as fuel consumed per tilled area, that is, litres per hectare (L/ha) [2, 4]. In some instances, the fuel consumption rate is measured as the amount of fuel consumed per working time, that is, litres per hour (L/h) [2, 5]. However, fuel consumption per unit time does not reflect the consumption rate per unit tilled area which is an important parameter, especially for operations in agricultural production [8]. The fuel consumption per hectare compensates for different working widths for different machines used to perform various operations in agriculture [8]. It is also necessary to test the fuel consumption of using a specific implement or attachment when performing specific agricultural operations and conditions [2]. Our work focused on evaluating the fuel consumption of performing direct seeding operations using a two-wheel tractor (2WT) and a no-till seeder for small-scale sorghum and pearl millet production systems.

Various methods can be used to measure fuel consumption [4]. One of the simplest ways is manually recording the total fuel consumed and the work done [4]. To do this, the fuel tank is filled to the brim and refilled after the operation [5, 9]. The amount of fuel used to refill equals the amount of fuel used during the operation. The variation of voltage signal from the machine’s own fuel level sensor can be used to measure fuel consumption [4]. A voltage data logger can be used to record the voltage signal, whilst a global positioning system (GPS) tracker can be used to record machine movement. Combining the fuel measurement system with GPS information enables an effortless recording of the velocity of the machine, the area covered and the extent of fuel consumption during an operation [4]. The use of GPS in our local fields is, however, limited due to poor signal coverage. The system also requires to be calibrated to obtain the voltage signal values at different fuel levels [4], which requires advanced skills and equipment. Additionally, the measuring period needs to be long to obtain reliable results [4], hence, the time required for data collection is increased.

The most common way to measure fuel consumption has been the use of flow metres [4, 6]. This method can provide accurate results and can be used in a wide range of applications. However, additional work other than the measurement of fuel consumption is required, for example, measuring the fuel flow rate and the temperature of fuel flowing in the return line, as well as providing cooling to the return line [4].

In modern machines, fuel consumption data can be retrieved from the CAN-bus (controller area network) of the machine. Suitable analyser hardware and software are required to collect information from the bus data traffic [4]. No additional sensors are required in this method.

2. Materials and Methods

2.1. Site Description

The experiments were carried out at Gwebi Agricultural College (17° 40’ 54” S; 30° 51’ 24” E) and in Nyabira in the Zvimba District of Zimbabwe (17° 40’ 59” S; 30° 47’ 37” E). The two sites are located in agro-ecological zone IIa which receives an average annual rainfall of 700–1000 mm and has a mean annual temperature range of 18–27°C. Gwebi Agricultural College is characterised by red clayey soil, whilst Nyabira is characterised by sandy soil.

2.2. Data Collection and Analysis

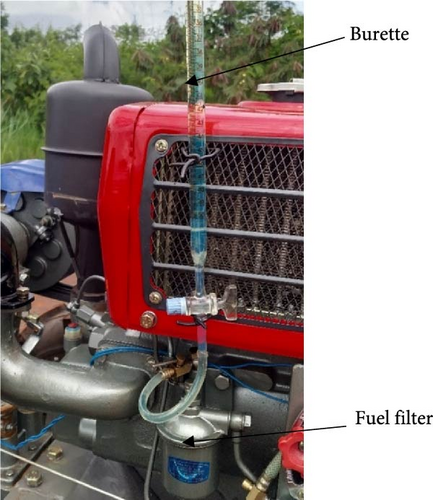

A system consisting of a 2WT, a tool-bar and a direct seeder (Figure 1) was used. A Yancheng Benniu tractor (Model ZS1110NL), a University of Zimbabwe (UZ) developed tool-bar and a UZ-developed traditional grains conservation agriculture (CA)–based direct seeder were coupled together to create the planting system. In all experiments, the direct seeder was set to plant the seeds at a depth of 2 cm.

Planter performance was evaluated at four different forward speeds corresponding to the gear level of the 2WT transmission gear box; from one low to one high for sorghum and from one low to three low for pearl millet. During the tests, a gear level was selected and the throttle was set to maximum. Four replications were done for each gear level. To evaluate the fuel consumption of the system, a burette was installed onto the receiving end of the 2WT engine’s fuel filter (Figure 2). The fuel level reading on the burette before starting the tractor and after completing a replicate and turning was measured and recorded for every replication at all gear levels. To simplify data reading, the tractor was started at the beginning of a run, complete the run, turn and switched off. The total time taken to complete a run and turn was recorded. The soil moisture content during the tests was determined using the oven method. Sandy soils had a moisture content of 12.60%, whilst the moisture content in clayey soils was 16.57%.

A field efficiency value of 75% was used during the fuel consumption calculations. The effective field capacity was determined using the time taken to complete a run and turn at headland. Gear levels on the tractor’s gearbox were used to change speed, whilst engine throttle was set at maximum for all runs. The average speed and the recommended inter-row spacing for sorghum and pearl millet, respectively, were used to calculate effective field capacity.

To analyse the fuel consumption rate per unit area data, one-way ANOVA was performed in R statistical software to infer the fuel consumption performance of the planting system at different operating speeds. Where significant differences existed at 95% confidence interval in the means of the fuel consumption rates at different operating speeds, Fisher’s protected least significant difference (LSD) was used for mean separation.

3. Results

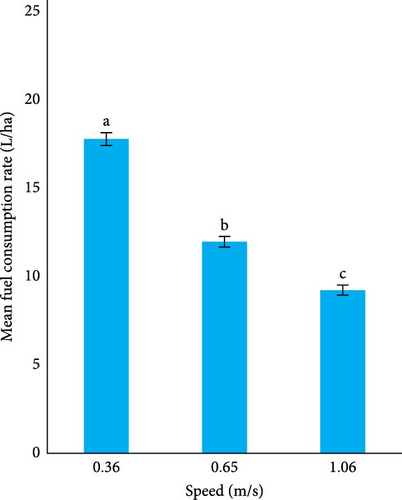

The resultant forward speeds for gear levels one low, two low, three low and one high were 0.38 m/s, 0.72 m/s, 1.12 m/s and 1.49 m/s, respectively, in clayey soil. In sandy soil, the resultant forward speeds were 0.36 m/s, 0.65 m/s, 1.06 m/s and 1.41 m/s for gear levels one low, two low, three low and one high, respectively.

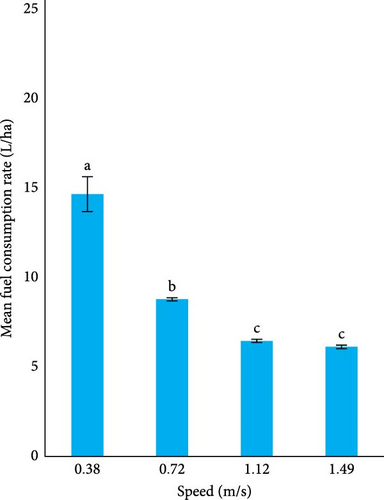

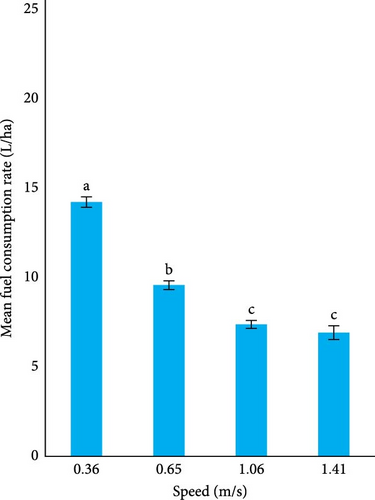

The mean rate of fuel consumption rate generally decreased with increased forward speed in both clayey and sandy soils for both sorghum and pearl millet (Figures 3 and 4). When planting sorghum in clayey soils, the least fuel consumption rate of 6.09 L/ha was obtained at a forward speed of 1.49 m/s, whilst the maximum mean fuel consumption rate of 14.58 L/ha was obtained at a forward speed of 0.38 m/s. In sandy soils, the least fuel consumption rate of 6.88 L/ha was obtained at forward speeds of 1.41 m/s, whilst the maximum mean fuel consumption rate of 14.14 L/ha was obtained at forward speeds of 0.36 m/s when planting sorghum. For both soil types when planting sorghum, there was a significant difference between the fuel consumption rates obtained at the three first speed levels. However, no significant difference between the mean fuel consumption rates was obtained for the last two speed levels (Figure 3).

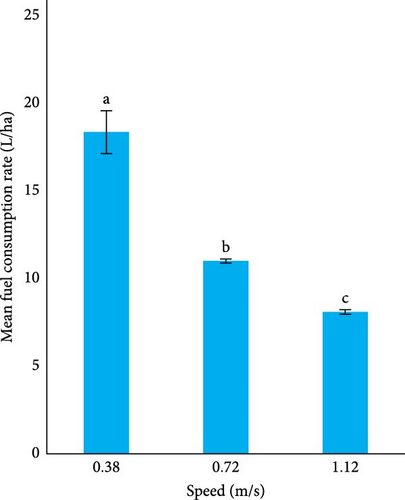

The mean fuel consumption rates decreased with an increase in forward speed when planting pearl millet in both clayey and sandy soils. When planting pearl millet in clayey soils, the least fuel consumption rate of 8.03 L/ha was obtained at forward speed of 1.12 m/s, whilst the maximum mean fuel consumption rate of 18.23 L/ha was obtained at forward speed of 0.38 m/s.

In sandy soils, the least fuel consumption rate of 6.88 L/ha was obtained at forward speeds of 1.06 m/s, whilst the maximum mean fuel consumption rate of 17.67 L/ha was obtained at forward speeds of 0.36 m/s when planting sorghum. There were significant differences between the fuel consumption rates obtained at the three forward speed levels at 95% level of significance (Figure 4).

The mean fuel consumption rate (L/h) generally increased with increasing operating speed (Table 1). The lowest fuel consumption rate was observed at gear one low, 0.38 m/s in clayey soil and 0.36 m/s in sandy soil; whilst the highest fuel consumption rate was observed at gear one high, 1.49 m/s in clayey soil and 1.41 m/s in sandy soil. For both soil types, the fuel consumption rates observed were significantly different from each other at all levels of operating speeds.

| Soil type | Gear level | |||

|---|---|---|---|---|

| One low | Two low | Three low | One high | |

| Clayey soil | 1.12 ± 0.074a | 1.27 ± 0.012b | 1.43 ± 0.022c | 1.84 ± 0.031d |

| Sandy soil | 1.02 ± 0.021a | 1.25 ± 0.031b | 1.47 ± 0.045c | 1.82 ± 0.100d |

- Note: Means with different letters across the same soil type are significantly different (p < 0.05, Fisher’s protected LSD).

Increasing operating speed resulted in increasing field capacity for sorghum and pearl millet in both soil types (Tables 2 and 3). The maximum field capacity achieved when planting sorghum in clayey and sandy soils were 0.29 and 0.27 ha/h, respectively. When planting pearl millet, maximum field capacity levels of 0.18 and 0.16 ha/h were achieved for clayey and sandy soils, respectively. The field capacities obtained when planting both sorghum and pearl millet at varying operating speeds in each soil type were all significantly different.

| Soil type | Gear level | |||

|---|---|---|---|---|

| One low | Two low | Three low | One high | |

| Clayey soil | 0.08 ± 0.0024a | 0.15 ± 0.0019b | 0.23 ± 0.0025c | 0.29 ± 0.0032d |

| Sandy soil | 0.07 ± 0.0008a | 0.13 ± 0.0022b | 0.20 ± 0.0049c | 0.27 ± 0.0016d |

- Note: Means with different letters across the same soil type are significantly different (p < 0.05, Fisher’s Protected LSD).

| Soil type | Gear level | ||

|---|---|---|---|

| One low | Two low | Three low | |

| Clayey soil | 0.06 ± 0.0019a | 0.12 ± 0.0016b | 0.18 ± 0.0026c |

| Sandy soil | 0.06 ± 0.0007a | 0.10 ± 0.0018b | 0.16 ± 0.0039c |

- Note: Means with different letters across the same soil type are significantly different (p < 0.05, Fisher’s Protected LSD).

4. Discussion

The fuel consumption rate, measured in L/h, for both clayey and sandy soil operations tended to increase with increasing operating speed. Modi et al. [10] and Ali et al. [11] found similar results when evaluating the tractor-operated seeder for sowing mat-type paddy nursery and the wheat straw combine, respectively. This can be attributed to wheel slippage which causes energy losses in the system and implement draft requirement which increases with increasing speed. Both fuel consumption rate and wheel slippage are affected by speed of operation and tend to increase with increasing speed [5, 8, 12–14]. Slippage results in power loss in tractors [12], which means that more fuel has to be burnt to generate more tractor power and compensate for the lost power, as well as to maintain operating speed. Wheel slippage can be reduced by increasing the weight supported by the wheels through wheel ballasting. However, the fuel consumption rate is increased by the same [15]. Tractors with more power exhibited less slippage [12] and this can be attributed to the larger weight of more powerful tractors which generates more traction at the same value of coefficient of friction.

Increasing working speed increases the power consumption, and consequently, the fuel consumption rate (L/ha) when using tillage equipment [16]. This can be attributed to the fact that the draft forces on soil engaging implements increase with increasing speed [12], hence, more power needs to be generated to overcome these forces, resulting in increased fuel consumption. Various researchers have investigated the effect of increasing operating speed on the draft requirement of tillage implements [12]. The researchers concluded that the draft force requirement increases significantly with increasing operating speed [12]. As the draft force requirement of the implement was increased, wheel slippage and fuel consumption increased, whilst the speed of operation decreased [12].

Fuel consumption rate varies with engine speed for the same operating speed depending on gear selection, with the fuel consumption rate increasing with increasing engine speed [5]. Given that the fuel consumption results were obtained at maximum engine speed, selecting an optimal gear and engine speed combination to achieve the recommended planting speeds could reduce the current fuel consumption levels.

Even though fuel consumption rates as measured in L/h tend to increase with an increase in forward speed, fuel consumption rates as measured in L/ha tend to decrease. This is because increasing the forward operating speed will reduce operational time per hectare, which in-turn more than compensates for the increase in fuel consumption rate per hour. Precision planters that operate optimally at high speeds are beneficial. This is because they minimise fuel consumption rates per unit area covered, which reduces the operating costs resulting in increased profits. Further, quicker planters reduce the levels of greenhouse gas emissions which is a climate mitigation measure.

The effective field capacity of the planting system increased with increasing operating speed. These findings are similar to observations by other researchers [17, 18]. The field capacity of agricultural equipment is influenced by operating width and operating speed. Assuming that there are no stoppages, speed variation whilst keeping operating width constant results in field capacity variation.

The maximum achieved field capacities of 0.29 and 0.18 ha/h for sorghum and pearl millet, respectively, are low and need to be improved. However, the current study showed that operating the planting system beyond 1.49 and 1.41 m/s, that is, gear level one high at full throttle in clayey and sandy soils, respectively, is unsafe for the operator, hence, further increasing the speed is not recommended. In this regard, effective field capacity can be improved by increasing the number of planting units per system, thereby increasing the operating width.

5. Conclusion

The operating speed affects the tractor’s mean fuel consumption rate. Operating the 2WT tractor at high speeds results in decreasing fuel consumption rates per unit area, as opposed to the increasing fuel consumption rates per unit time. It can be concluded that the reduction in time required to complete a task per unit area more than compensates for the increase in fuel consumption rate, thus, making systems that operate at higher speeds more fuel-efficient. At the recommended planting speeds, the fuel consumption rates when planting sorghum are 6.42 and 7.34 L/ha for clayey and sandy soils, respectively. For pearl millet planting, the fuel consumption rates were observed as 10.93 and 11.90 L/ha for clayey and sandy soils, respectively.

Disclosure

The funders had no role in the design of the study; in the collection, analyses or interpretation of the data; in the writing of the manuscript or in the decision to publish the results.

Conflicts of Interest

The authors declare no conflicts of interest.

Funding

Financial support for this research was provided by the Ministry of Higher and Tertiary Education, Innovation, Science and Technology Development of the Government of Zimbabwe, through the University of Zimbabwe Vice Chancellor’s Challenge Research Fund.

Acknowledgments

We would like to acknowledge administrative support from the University of Zimbabwe Innovation Hub and the Future Grains for Africa Programme and technical assistance from the Department of Agricultural and Biosystems Engineering. We are grateful to the following institutions in the Ministry of Lands, Agriculture, Fisheries, Water and Rural Development of Government of Zimbabwe for providing technical support; Gwebi Agricultural College in the Department of Agricultural Education and the Institute of Agricultural Engineering in the Department of Agricultural Engineering, Mechanisation and Farm Infrastructure Development.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.