Utilizing Additive Manufacturing for Fabricating Energy Storage Components From Graphene-Reinforced Thermoplastic Composites

Abstract

The quest for efficient and sustainable energy storage solutions has prompted exploration into advanced materials that meet stringent mechanical and thermal requirements. This study investigates graphene-reinforced thermoplastic polymers specifically polyether ether ketone (PEEK), polyethylene terephthalate glycol (PETG), and polylactic acid (PLA) fabricated through additive manufacturing techniques. Traditional materials often suffer from limitations in structural integrity, flexibility, and thermal stability, presenting challenges for their application in energy storage. This research aims to evaluate the mechanical properties of these graphene-reinforced polymers to assess their suitability for energy storage components. Using additive manufacturing, test samples were fabricated, and mechanical testing was conducted to evaluate tensile, flexural, and compression strengths. The results indicate that graphene-reinforced PEEK (G-PEEK) exhibits superior mechanical performance, with an ultimate tensile strength of 120 MPa, Young’s modulus of 1700 MPa, ultimate flexural strength of 160 MPa, and ultimate compression strength of 200 MPa, making it an ideal candidate for applications requiring high structural integrity. Graphene-reinforced PETG (G-PETG) offers a balance of strength and flexibility, with an ultimate tensile strength of 55 MPa, while graphene-reinforced PLA (G-PLA) serves as a cost-effective option, despite lower mechanical properties (ultimate tensile strength of 45 MPa).

1. Introduction

Additive manufacturing, commonly referred to as 3D printing, has undergone remarkable progress over recent decades, capturing considerable interest in the manufacturing industry. Its standout feature is the ability to produce customized items directly from digital models through a sequential layering process. Among various additive manufacturing techniques, fused deposition modeling (FDM) is particularly notable for its affordability, adaptability, and capacity to fabricate end-use products from a diverse range of thermoplastic polymers. In FDM, a thermoplastic filament is extruded through a heated nozzle, and the final product is built up layer by layer according to the specified digital design. This method is renowned for its efficiency and flexibility in producing intricate shapes and customized components [1–3]. The FDM process is recognized for its ability to produce complex geometries with high precision and minimal material waste, making it suitable for various industries including automotive, biomedical, aerospace, and electronics. In recent years, there has been a growing interest in applying FDM technology within the energy storage sector [4–6]. Effective energy storage systems are crucial for optimizing renewable energy utilization and stabilizing power sources. Among the different energy storage solutions, batteries and supercapacitors play a significant role. The performance and durability of these systems depend heavily on their components, such as separators, electrodes, and casings. Traditionally, these components are made from ceramics and metals; however, advanced polymer composites are increasingly favored due to their lightweight nature, resistance to corrosion, and customizable properties [7, 8]. Recent research highlights the potential of additive manufacturing, particularly with polymer matrix composites, to enhance energy storage applications.

Wang et al. [9] provided an extensive review of polymer matrix composites used in 3D printing, highlighting their mechanical properties and potential applications in energy storage. Their review underscores the advantages of utilizing polymer matrix materials for energy storage components, including enhanced performance characteristics. Nguyen-Tri et al. [10] discussed the significance of smart and composite materials in his book chapter. This research emphasizes that polymers can be employed to create materials that are both cost-effective and resistant to corrosion, making them suitable for various energy storage applications. Zhang, Demir, and Gu [11] reviewed advancements in 4D printing and smart materials, highlighting how innovative approaches and lightweight smart materials in additive manufacturing could significantly impact energy storage applications in the future. Khan, Momin, and Mariatti [12] discussed the advancements in polymer composites incorporating carbon nanofillers. Their review emphasized that enhanced mechanical properties can be achieved using 3D printing of carbon-reinforced polymer composites, particularly beneficial for energy and electronics applications.

Research by Ma et al. [13] and Ning et al. [14] focused on optimizing the mechanical properties of carbon fiber-reinforced polymers. Their findings indicate that selecting appropriate process parameters is crucial for achieving superior mechanical performance. Vijay Kumar et al. [15] and Reddy Dumpa, Bandari, and Repka [16] reviewed the benefits of advanced composite polymers in energy storage applications, noting advantages such as resistance to corrosion, reduced weight, and balanced mechanical and electrical properties. In recent studies, researchers have focused on enhancing the mechanical properties of recycled polymers for FDM. Kumar et al. [17] demonstrated that reinforcing HDPE and LDPE waste polymers with iron (Fe) powder significantly improved the polymers’ hardness and mechanical strength. Their findings revealed that Fe powder, added via single-screw extrusion, increased the melt flow index (MFI) and enhanced properties like peak strength and Shore D hardness (SDH), suggesting this approach offers a sustainable and high-performance solution for additive manufacturing applications. Ramesh et al. [18] in their review described the advancement and development of polymer composites in energy storage applications. They highlighted that while polymer materials offer significant potential for energy storage, challenges remain in achieving superior mechanical properties, as well as maintaining efficiency and stability under operational conditions. Kumar et al. [19] explored the properties of four different filaments, including virgin polylactic acid (PLA) and PLA reinforced with polyvinyl chloride (PVC), wood powder, and Fe3O4, prepared using twin-screw extrusion for potential multimaterial 3D printing. Their study revealed that the melt flow rate increased with reinforcements, except for wood powder, which showed a negative trend. While mechanical properties decreased with loading, the addition of Fe3O4 improved them. Additionally, thermal analysis indicated stable samples, though reinforced composites displayed reduced integral energy in successive cycles and magnetic properties varied with Fe3O4 content. Despite numerous reviews acknowledging the promise of polymer and polymer composite materials for energy storage, current studies are still limited. Consequently, this research focuses on evaluating graphene-reinforced composite polymers such as PLA, polyethylene terephthalate glycol (PETG), and polyether ether ketone (PEEK) as suitable materials for fabricating energy storage components.

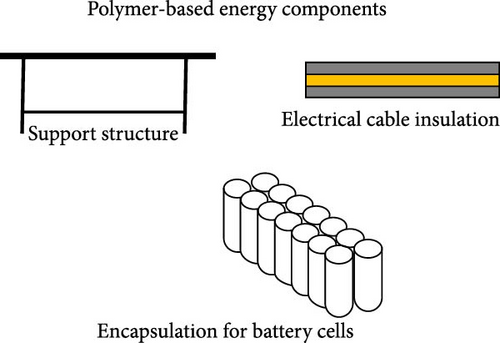

Figure 1 depicts the proposed energy storage components using polymer composites. Stiffness and strength are increased when graphene is reinforced with pure polymers. Graphene-reinforced polymer composites are expected to enhance the mechanical performance of energy storage components, making them more reliable and durable. The primary aim of this study is to explore the potential of graphene-reinforced thermoplastic composites for energy storage applications, with a particular focus on battery encapsulation and electrical cable insulation. Although energy storage systems are typically evaluated for their electrical and thermal properties, the mechanical properties of the materials used are equally important. This is because components such as battery casings and cable insulation must withstand mechanical stresses, pressure fluctuations, and environmental conditions without compromising their structural integrity. In this work, we specifically tested the mechanical properties of our composites tensile, flexural, and compressive strength because these attributes directly impact the reliability and durability of energy storage components. For instance, battery enclosures must resist both inward and outward pressures during charging and discharging cycles, which is critical to ensure safe and prolonged operation. Similarly, electrical cables require insulation materials that are not only effective at preventing electrical breakdown but also capable of withstanding mechanical loads and physical deformation during installation and operation. By focusing on structural properties, we aim to demonstrate that the graphene-reinforced thermoplastic composites can meet the mechanical demands of energy storage systems. The microstructural analysis further supports this by showing how the uniform dispersion of graphene within the polymer matrix enhances material stability and mechanical performance, which are key factors in their application. Additionally, this study explores the environmental and mechanical stress tolerance of these advanced materials in energy storage applications. As a result of this research, the polymer with the best flexibility, strength, and structural integrity among the selected materials is identified. The following sections outline the study’s objectives and methodologies: Materials and Methods, Results and Discussion, and Conclusion.

2. Materials and Methods

Selecting the appropriate material can reduce the overall cost of the final product and decrease the need for additional fillers, whether mineral, natural, or synthetic. Proper fillers enhance the electrical, mechanical, and thermal properties of the composite. Fillers significantly influence the properties of the polymer matrix, aiming to improve mechanical characteristics such as tensile strength, Young’s modulus, toughness, impact resistance, abrasion resistance, compression strength, flexural strength, and hardness [18–20]. Fillers also enhance the thermomechanical behavior and thermal properties of the polymer matrix, such as heat deflection/softening temperature, storage modulus, glass transition temperature, and damping factor. They reduce the warping effect and heat expansion coefficient that are common in polymer matrices and improve properties like dielectric constant and conductivity [21]. Moreover, fillers modify gas permeability, barrier properties, and flammability of the polymer matrix, and they influence melt rheology. Surface properties such as hydrophobicity, roughness, weathering resistance, and UV stability are also improved with fillers. Fillers can add opacity and color to the composite materials [22].

Common fillers in polymer matrices include carbon fibers, metal powders, ceramics, glass fibers, and renewable fillers like flax, jute, hemp, cellulose, coconut, and bamboo. Mineral fillers such as mica, titanium dioxide (TiO2), graphite, chalk, talc, and diatomaceous earth are also used. These fillers provide properties like thermal, chemical, and UV resistance. Biofillers such as wood flour and coffee grounds are used in certain applications [23]. The fillers can be used in polymer matrices based on their source, chemical composition, shape, size, aspect ratio, purpose, and cost. Fillers are typically classified as either synthetic or natural depending on their origin [24]. Common procedures for extracting environmental materials and fibers for natural fillers include washing, milling, sieving, and drying. Examples of such fillers are montmorillonite, bentonite, and various types of clay. Biofillers are typically obtained from renewable sources through microorganisms or bioprocesses. Examples of inorganic biofillers include biosilica and elements like diatomaceous earth. Organic biofillers include plant-based fibers such as ramie and kenaf, as well as animal-derived fibers like silk and cotton.

Synthetic fillers are derived from either synthetic materials or through intensive chemical processing of raw materials, such as metal ores or biomaterials. Examples include materials like calcium carbonate, precipitated silica, and TiO2. Regarding composition, fillers can be classified into two types: organic and inorganic. Inorganic fillers include TiO2, hydroxides (Mg(OH)2), salts (CaCO3 and BaSO4), metals (boron and steel), and silicates (mica and talc). Organic fillers consist of natural polymers like cellulose, ramie, and silk-based fibrillar structures, as well as synthetic polymers such as polyamide and polyester. These fillers are used to produce fibers and sheets for fabricating fiber-reinforced thermoplastic or laminated objectives [25]. Silicone resins are a type of organic filler known to enhance the dynamic mechanical properties of the polymer matrix when used. Organic polymers, including those reinforced with carbon fibers, have shown to possess mechanical properties comparable to inorganic carbon materials in various applications. Wypych [26] conducted a study on filler distribution size, presenting significant findings. Their research indicated the importance of selecting an appropriate size range for practical filler types rather than relying on single fillers. They discovered that when choosing fillers in this manner, the size distribution remains consistent across material samples.

A common practice involves using a filler diameter ratio where d15 and the size of other fillers are less than 50% of the median particle size. Similarly, d90 and d10 represent 90% and 10% reductions in the cumulative polymer matrix mass, respectively. The shape of the filler varies based on its inherent characteristics. Natural fillers like plant fibers or talc often require milling/deagglomeration and purification processes to achieve the desired properties. Synthetic fillers such as TiO2 nanoparticles or fumed silica are formulated using significant methods like the chloride process or sulfate process. Alternative fillers, such as cellulose or nanoclays, undergo nanoengineering or chemical treatments to achieve the desired aspect ratio, particle size, or surface chemistry properties. Diatoms, a type of natural filler, are single-celled eukaryotic algae with unique, hard silica shells that cannot be replicated by conventional engineering methods. Diatoms possess high porosity, nonflammability, low thermal conductivity, poor odor absorption, moisture absorption, and acid resistance. Early research has explored the use of diatoms in FDM printing. For example, Aggarwal et al. [27] used diatoms as a filler with a PLA matrix and found that while the mechanical properties slightly decreased, the usage of PLA material was reduced by ~10%. This reduction in raw material usage, despite the slight decrease in mechanical properties, represents a minor setback. When diatoms are incorporated in FDM technology, they enhance the antiviral and antibacterial properties due to their immobilization and surface functionality. Therefore, diatom fillers are considered ideal for biomedical applications. Han et al. [28] investigated poly(DL-lactide-co-glycolide) composites with diatom fillers for tissue engineering applications. Their research concluded that the compression strength and material durability were enhanced, while thermal decomposition and biodegradation were reduced. They highlighted that diatom fillers are suitable for 3D printing applications such as biomedical devices and bone regeneration scaffolds.

While various fillers are available, graphene fillers are considered optimal for producing polymer matrix products suitable for external environments [29–34]. In this research, graphene fillers are added to selected biodegradable and nonbiodegradable polymers such as PEEK, PETG, and PLA. The focus is on developing suitable thermoplastic composites using FDM technology to fabricate energy storage components with superior mechanical properties. The first polymer examined is graphene-reinforced PEEK (G-PEEK). Figure 2 illustrates the experimental procedure followed in this research.

PEEK is distinguished by its remarkable mechanical and thermal properties, including excellent temperature resistance, high stiffness, structural strength, and durability, making it suitable for rigorous applications. Its chemical resistance further enhances its functionality. In this study, we use G-PEEK filament, which integrates graphene to boost its performance. This filament, with specific graphene content, is selected to achieve optimal dispersion and mechanical properties during the printing process. Graphene-reinforced PLA (G-PLA) and graphene-reinforced PETG (G-PETG) filaments are also evaluated to compare their performance. Table 1 details the FDM process parameters used for the sample fabrication.

| FDM process parameters | Values |

|---|---|

| Shell count | 2 |

| Infill pattern | Line |

| Printing temperature | For PEEK-CF −440°C |

| For PETG-CF −240°C | |

| For PLA-CF −230°C | |

| Print speed | 60 mm/s |

| Infill percent | 80% |

| Platform temperature | 70°C |

- Abbreviations: FDM, fused deposition modeling; PEEK, polyether ether ketone; PETG, polyethylene terephthalate glycol; PLA, polylactic acid.

The second polymer investigated in this research is PETG, which is reinforced with graphene and sourced from the same supplier as the other materials. PETG is known for its ease of use in the FDM process, with good layer adhesion, low shrinkage, and suitability for complex geometries. G-PETG filament provides enhanced mechanical properties compared to standard PETG filaments. This filament has been confirmed to meet the quality and performance requirements necessary for energy storage applications. Additionally, PLA, a biodegradable polymer reinforced with graphene, is used in this study. G-PLA is relatively easy to print using the FDM method, requiring lower temperatures compared to other materials. It is recognized for its environmental compatibility and sustainability benefits. The graphene reinforcement improves the mechanical properties of PLA, making it more suitable for lightweight applications and durable components. G-PLA has been employed to ensure reliable printability and enhanced mechanical performance for energy storage applications, sourced from the previously mentioned supplier. This research focuses on evaluating polymer matrix materials for various applications, including battery encapsulation, cable insulation, and structural supports. The study investigates the mechanical properties of selected graphene-reinforced polymer materials, including Young’s modulus, tensile strength, flexural strength, compression strength, and microstructure. In the fabrication process, graphene (11%) is blended with PLA, PETG, and PEEK granules for 10 min. The mixture is then processed into 1.75 mm filaments using a twin-screw extruder (model 226 W, Deccan Manufacture) to ensure consistent quality and performance of the final spools.

The optimal ratio for graphene reinforcement in filaments was determined through iterative testing. Extrusion parameters were precisely controlled to ensure uniform dispersion of graphene and a consistent filament diameter. The filament’s diameter and roundness were measured using a laser micrometer (LDMD090 INSIZE) with a precision of 0.01 mm to ensure the mechanical properties of the filament were consistent.

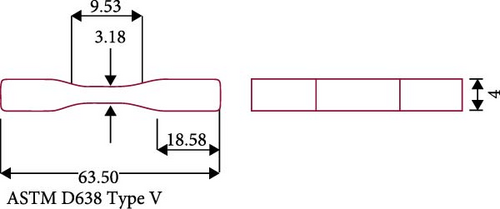

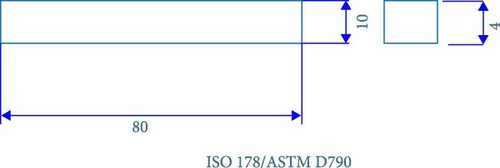

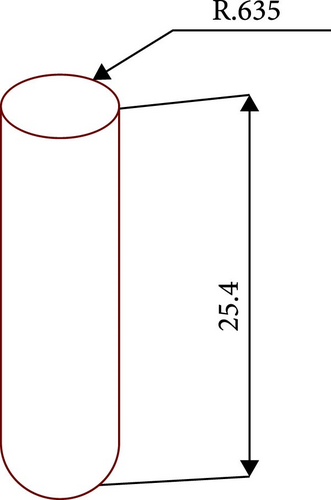

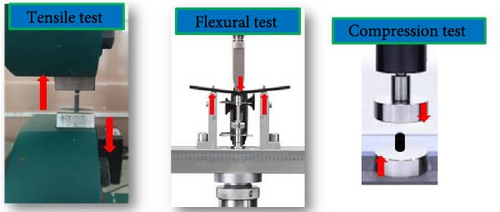

The study focused on key mechanical properties, tensile strength, flexural strength, and compressive strength, evaluated using ASTM D638 Type V for tensile tests, ASTM D790 for flexural tests, and ASTM D695 for compressive tests. Figure 3 shows the geometries of the printed samples conforming to these ASTM standards, and Figure 4 depicts the mechanical characterization of tensile test, flexural test, and compression test. A total of nine samples were printed for each material, with three replicates for each test. The Zortrax Endureal 3D printer from Olsztyn, Poland, was used for the printing process. Key FDM parameters such as shell count, platform temperature, and printing speed were adjusted during printing. Previous studies have indicated that carbon fiber reinforcement improves mechanical properties, and similar expectations hold for graphene reinforcement. The printed samples were tested using a Tinius Olsen Hk10 universal testing machine (UTM) at a strain rate of 1 mm/min and a 10 kg Newton load cell. Postprocessing involved annealing the samples at 60°C for 45 min to relieve internal stresses and enhance mechanical strength. Results and discussions on the experimental observations will follow. Additionally, microstructure analysis was performed on 1 cm × 1 cm samples, which were gold sputter-coated before examination. The printing temperatures used were 440°C for PEEK, 230°C for PETG, and 220°C for PLA, corresponding to the optimal fused states of each material.

3. Results and Discussion

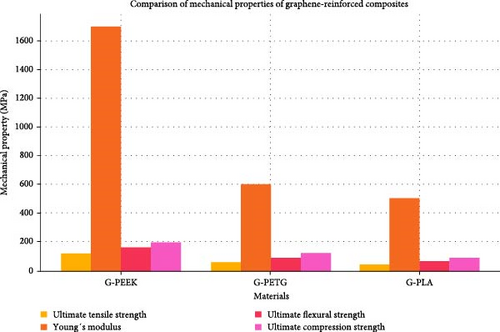

G-PETG has proven to be a robust material for applications requiring impact resistance and durability, demonstrating significant resilience under flexural loading. Its mechanical properties make it suitable for various applications, including as an insulating material due to its nonconductive nature. The mechanical properties of graphene-reinforced composites PEEK, PETG, and PLA were evaluated through tensile, flexural, and compression tests. G-PEEK demonstrated the highest performance with an average tensile strength of ~120 MPa, indicating superior strength, flexibility, and stiffness. It also showed an exceptional Young’s modulus of around 1700 MPa, reflecting its rigidity and structural stability. In terms of flexural strength, PEEK outperformed the other materials with an average of 160 MPa, and it exhibited the highest compression strength at 200 MPa, showcasing its excellent resistance to compressive forces. G-PETG displayed a balanced profile with an average tensile strength of 55 MPa and a Young’s modulus of 600 MPa, providing a good combination of strength and flexibility. Its flexural strength averaged 90 MPa, and its compression strength was moderate at 120 MPa. G-PLA, while having the lowest tensile strength at ~45 MPa and a Young’s modulus of 500 MPa, still offers reasonable mechanical properties with an average flexural strength of 60 MPa and a compression strength of 85 MPa. Although PLA’s mechanical properties are lower compared to PEEK and PETG, it remains a viable option for applications requiring sustainability and cost-efficiency. Table 2 summarizes these experimental observations, highlighting the mechanical performance of the graphene-reinforced materials.

| Materials/mechanical property | Ultimate tensile strength | Young’s modulus | Ultimate flexural strength | Ultimate compression strength |

|---|---|---|---|---|

| Average (MPa) | ||||

| G-PEEK | 120 | 1700 | 160 | 200 |

| G-PETG | 55 | 600 | 90 | 120 |

| G-PLA | 45 | 500 | 60 | 85 |

In contrast, G-PLA, despite its biodegradable nature, shows a tensile strength of ~44 MPa. This strength is adequate for specific components like small battery head caps, which are used in battery storage. G-PEEK, with its superior strength, is well-suited for applications such as mini solar panel casings and battery encapsulation cells. While PEEK exhibits the highest mechanical strength among the tested materials, PETG offers moderate performance, and PLA shows comparatively lower strength across all tests.

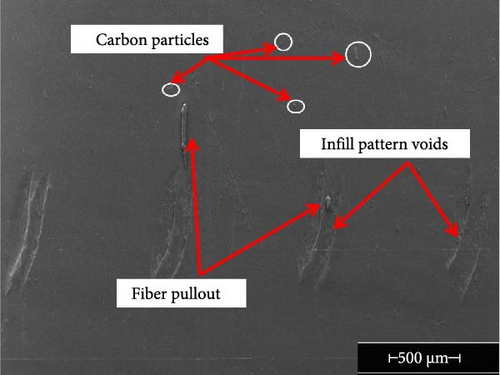

Figure 5 presents a comparative analysis of key mechanical properties ultimate tensile strength, Young’s modulus, ultimate flexural strength, and ultimate compression strength for the graphene-reinforced composites (G-PEEK, G-PETG, G-PLA). These properties demonstrate the superior mechanical performance of G-PEEK, making it suitable for high-stress applications such as battery casings and structural support in energy storage systems. G-PETG and G-PLA, while having lower mechanical properties, are lightweight alternatives that can still provide adequate strength for specific components, such as cable insulation. The experimental observations illustrate that G-PEEK is the most robust, followed by PETG and PLA in terms of mechanical strength. It is important to note that the optimized process parameters employed in this study such as layer height, infill density, printing temperature, and printing speed play a crucial role in enhancing the final product’s mechanical properties. For future research, exploring various optimization tools and parameters could further improve the strength of polymer composites. Additionally, experimenting with alternative fillers beyond carbon fiber may yield improvements in properties like thermal conductivity and stability, crucial for energy storage applications. While PEEK can endure temperatures above 400°C, demonstrating excellent thermal stability, G-PLA, though slightly less temperature resistant, remains a sustainable and biodegradable option. Figure 6 also highlights the microstructure of the graphene particles, printed infill patterns, and fiber pullout observed in PEEK at a magnification of 500 μm.

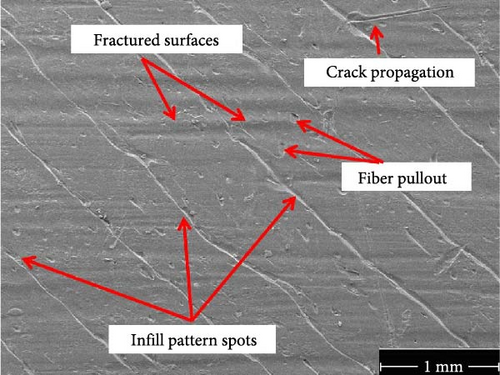

Microstructure analysis provides insights into the interface bonding of the graphene-reinforced materials and their impact on mechanical performance. The analysis reveals that graphene is uniformly dispersed within the polymer matrix, enhancing both the mechanical properties and structural integrity of the composites. For instance, the microstructure of G-PETG, as shown in Figure 7, displays effective bonding of graphene to the polymer matrix, with minimal integration stress and improved load transfer mechanisms. The observed features include filler pullout, crack propagation, mild surface fractures, and distinct infill patterns at a 1-mm magnification.

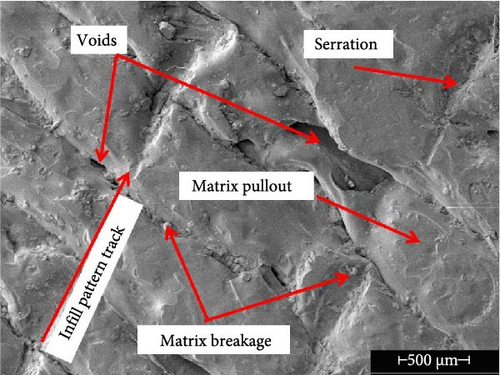

In G-PEEK, the microstructure indicates robust interface adhesion and optimal fiber orientation, contributing to its superior mechanical strength and stiffness compared to other materials. This is illustrated by the absence of significant defects and the strong bonding of graphene to the polymer matrix. Conversely, Figure 8 depicts the microstructure of G-PLA, revealing matrix pullout, voids, serration, infill pattern tracks, and matrix breakage at a 500-μm magnification.

Field emission scanning electron microscopy (FESEM) was employed to conduct these microstructure analyses. Comparative studies reveal that pure PLA exhibits a mechanical strength of around 50 MPa, PETG shows 70 MPa, and PEEK achieves ~80 MPa [32]. These findings underscore that G-PEEK offers superior mechanical properties and is particularly suitable for external environmental components in energy storage applications using the FDM process, a polymer fabrication technique in additive manufacturing. G-PETG, while demonstrating moderate thermal stability, is suitable for applications like support frames and caps in energy storage systems. The integration of graphene into the polymer matrix enhances the strength and stiffness of all tested polymers, underscoring the benefits and sustainability of using graphene-reinforced composites in additive manufacturing. The standard mechanical properties of the materials used in this study, PLA, PETG, and PEEK, show significant variation. PLA typically has a tensile strength of 50–70 MPa and a Young’s modulus of 2.7–3.6 GPa, making it relatively stiff but brittle. PETG, on the other hand, offers more flexibility with tensile strength ranging from 40 to 55 MPa and a Young’s modulus between 2.0 and 2.3 GPa. PEEK is the strongest of the three, with tensile strength around 90–100 MPa and a Young’s modulus of 3.6–4.0 GPa, providing superior mechanical performance. In comparison, the current results for graphene-reinforced composites show enhanced mechanical properties across all three materials, especially in tensile and flexural strength, due to the reinforcement with 11% graphene. This improvement in mechanical properties highlights the effectiveness of graphene as a reinforcing agent, leading to better performance in energy storage applications where high strength and durability are essential.

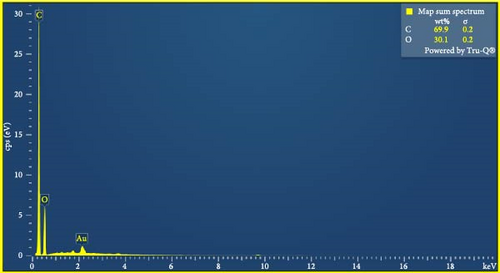

The energy-dispersive X-ray spectroscopy (EDS) analysis presented above reveals the elemental composition of the 3D-printed G-PEEK thermoplastic polymer. The spectrum displays peaks corresponding to the major constituent elements of the composite material, primarily carbon and oxygen, with trace amounts of gold. Figure 9 illustrates EDS spectrum of 3D-printed G-PEEK thermoplastic polymer. The predominant peak observed at 0.277 keV is attributed to carbon, which makes up 69.9 wt% of the material. This high carbon content is characteristic of both the PEEK polymer matrix and the graphene reinforcement. The carbon peak’s prominence aligns with expectations for a graphene-reinforced polymer, as graphene itself is a carbon-based material with a strong sp2 bonding structure, contributing to the material’s overall mechanical strength and thermal stability. The oxygen peak, appearing at 0.525 keV, accounts for 30.1 wt% of the sample. Oxygen is likely present due to the PEEK polymer, which contains oxygen atoms in its molecular structure. The oxygen content is expected in a polymer composite of this nature, as PEEK’s chemical structure comprises repeating ether and ketone groups. Additionally, the presence of oxygen may also result from any surface oxidation that occurred during the 3D printing process, particularly under elevated temperatures. A small peak for gold is observed at around 2.1 keV, though it is not a significant component of the sample. This trace amount of gold is likely a result of the sample preparation process, where gold coating may have been applied to improve the sample’s conductivity for more accurate EDS analysis.

The high carbon content, contributed by both the PEEK matrix and the graphene reinforcement, suggests that the composite is well-suited for applications requiring strong mechanical properties, such as high tensile strength, thermal conductivity, and resistance to chemical degradation. The graphene’s inclusion is crucial in enhancing the overall structural integrity and stiffness of the composite material, as graphene exhibits excellent mechanical and electrical properties.

The oxygen presence, primarily from the PEEK matrix, ensures that the polymer maintains its well-known characteristics, such as high thermal stability, chemical resistance, and low flammability. These properties make the G-PEEK polymer ideal for demanding engineering applications, such as aerospace, automotive, and electronics industries.

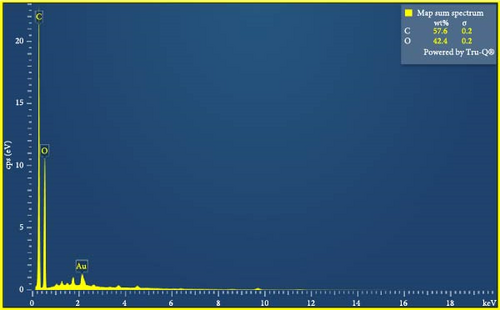

Figure 10 presented the EDS analysis insight into the elemental composition of the 3D-printed G-PLA composite. The spectrum shows two dominant peaks for carbon (57.6 wt%) and oxygen (42.4 wt%), corresponding to the primary elements in the PLA polymer and the graphene reinforcement. The substantial carbon content (57.6 wt%) indicates the presence of graphene, a carbon-based nanomaterial, which has been successfully integrated into the PLA matrix. Graphene, known for its high tensile strength and thermal conductivity, enhances the mechanical and electrical properties of the composite material. Oxygen, contributing 42.4 wt%, is primarily attributed to the PLA polymer’s ester functional groups. PLA is a biodegradable polymer made from renewable resources, and the oxygen content confirms the structural integrity of the PLA backbone. The trace presence of gold is detected due to the coating applied to the sample during scanning electron microscopy (SEM) preparation. Gold is often used to enhance conductivity for clearer imaging during EDS analysis.

This elemental breakdown confirms the successful fabrication of a G-PLA composite, with graphene potentially contributing to improved strength and conductivity while maintaining the biodegradable nature of PLA. The relative proportions of carbon and oxygen suggest a balanced composite, suitable for applications requiring ecofriendly and enhanced performance materials.

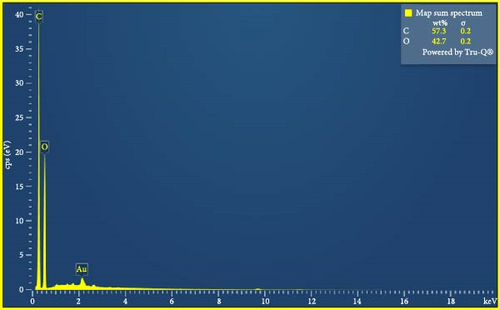

Figure 11 presented the EDS analysis insight into the elemental composition of the 3D-printed G-PETG composite. The spectrum displays two predominant peaks corresponding to carbon (57.3 wt%) and oxygen (42.7 wt%), which are the major constituents of the PETG polymer and graphene additive. The high carbon content (57.3 wt%) signifies the successful incorporation of graphene into the PETG matrix. Graphene, being a carbon-based material, is known for its mechanical reinforcement and electrical conductivity, which are expected to enhance the overall properties of the PETG composite. The increased carbon percentage aligns with the expectations for a graphene-infused material. The oxygen content (42.7 wt%) is typical of PETG, which contains ester functional groups. This high oxygen proportion reflects the structural integrity of the PETG base polymer, contributing to its well-known durability, flexibility, and transparency. The presence of gold is an artifact from the coating used during sample preparation for SEM imaging. Gold is applied to improve the conductivity of the sample surface for more accurate EDS readings.

The elemental analysis suggests that the G-PETG composite has been successfully fabricated with a proper balance between carbon and oxygen, which retains the mechanical robustness and processability of PETG while benefiting from graphene’s enhancement in strength and thermal properties. This composition makes it a promising material for applications requiring improved mechanical performance and electrical conductivity, such as in energy storage devices, automotive components, and lightweight structural parts. In the context of polymer-based energy components, specifically, they highlight the use of G-PETG due to its superior mechanical properties and suitability for various applications. For electrical cable insulation, G-PETG offers an ultimate tensile strength of 55 MPa and a Young’s modulus of 600 MPa, providing excellent dielectric strength that enhances safety and minimizes electrical failure risks. The material can withstand operational pressures up to 70 psi, outperforming traditional insulation materials like PVC, which are heavier and less flexible. In support structures, G-PETG exhibits ultimate compression strength of 120 MPa and is designed to endure pressures of ~80 psi, ensuring robust structural integrity while avoiding corrosion and offering better fatigue resistance than metals. Furthermore, for battery encapsulation, G-PETG provides a strong protective barrier with an ultimate flexural strength of 90 MPa, capable of withstanding internal pressures up to 75 psi, which accommodates battery expansion during operation. The advantages of G-PETG include reduced weight, enhanced flexibility, and improved chemical resistance, establishing its efficacy as a replacement material for existing encapsulation solutions.

4. Conclusion

- •

G-PEEK exhibits exceptional mechanical performance with an ultimate tensile strength of 120 MPa, Young’s modulus of 1700 MPa, ultimate flexural strength of 160 MPa, and ultimate compression strength of 200 MPa. This superior strength and durability position G-PEEK is an ideal candidate for demanding energy storage applications requiring robust structural integrity and resistance to environmental stressors.

- •

G-PETG shows a balanced combination of strength and flexibility, with an ultimate tensile strength of 55 MPa, Young’s modulus of 600 MPa, ultimate flexural strength of 90 MPa, and ultimate compression strength of 120 MPa. This makes G-PETG suitable for applications where moderate thermal stability and mechanical performance are essential.

- •

G-PLA, despite having lower mechanical properties—ultimate tensile strength of 45 MPa, Young’s modulus of 500 MPa, ultimate flexural strength of 60 MPa, and ultimate compression strength of 85 MPa—still provides adequate strength and improved properties, making it a cost-effective and sustainable option for energy storage components.

The microstructure analysis further validated these improvements, revealing that the uniform dispersion of graphene within the polymer matrices contributes to enhanced load transfer, minimized integration stress, and improved overall structural integrity. The findings highlight the significant potential of graphene-reinforced polymers in advancing energy storage solutions and provide a valuable foundation for selecting and optimizing materials in additive manufacturing, underscoring the benefits of incorporating advanced fillers like graphene to achieve superior performance and sustainability in energy storage components.

Conflicts of Interest

The authors declare no conflicts of interest.

Author Contributions

Conceptualization, R.S. and S.Y.; methodology, R.S. and S.Y.; software, R.S.; validation, R.S. and S.Y.; investigation, R.S.; resources, R.S.; data curation, R.S.; writing–original draft, R.S. and S.Y.; writing–review, R.S.; editing, R.S. and S.Y.; visualization, R.S.; supervision, R.S.; funding acquisition, R.S.

Funding

This work is partially funded by the Center for Advanced Multidisciplinary Research and Innovation, Chennai Institute of Technology, India, vide funding number CIT/CAMRI/2024/3DP/001.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.