Numerical Investigation on the Performance Enhancement of InGaN/GaN Light-Emitting Diodes with a Novel p-i-n Electron-Blocking Layer

Abstract

In this study, we propose a novel p-i-n AlGaN electron-blocking layer for GaN-based LEDs. The aim is to enhance the confinement of electrons and improve the efficiency of hole injection, ultimately resulting in a significant enhancement in LED performance. Detailed simulations and analysis were conducted to compare the performances of GaN-based LEDs with a conventional EBL and our proposed EBL. It was observed that our newly proposed p-i-n AlGaN EBL significantly outperforms the conventional EBL in terms of output power and efficiency across a wide range of injecting currents. These improvements can be attributed to the strong reverse electrostatic field induced by our proposed p-i-n AlGaN EBL, which not only enhances electron confinement but also improves hole injection efficiency.

1. Introduction

In recent times, there has been a growing interest in GaN-based light-emitting diodes (LEDs) due to their compact size and low power consumption [1–4]. However, one common issue faced by these LEDs is the easy injection of electrons into the p-GaN region. This hampers carrier recombination in the active regions because of the high mobility and light effective mass of electrons. Consequently, device performance is significantly limited. To address this problem, researchers have introduced an AlGaN electron-blocking layer (EBL) with a wide band gap between the active regions and the p-GaN region [5–9]. Unfortunately, this method does not effectively prevent electron injection into the p-GaN region and also inhibits hole injection from the p-GaN region to the active regions. A subtle alteration in the EBL configuration, such as a moderate increase in the aluminum (Al) content within the EBL, can markedly enhance the EBL efficacy by capitalizing on a more substantial band offset between the EBL and the last quantum barrier (LQB) [10]. Nonetheless, an incremental rise in the Al composition within the EBL layer impedes hole injection, attributable to an elevated potential barrier at the valence band offset interface between the EBL and the p-type injection layer [11, 12]. Additionally, in an aluminum-enriched EBL structure, the downward bending of the conduction band is significantly exacerbated due to the accumulation of polarization charges at the interface between the LQB and EBL heterojunction, which, in turn, further impairs the device’s performance. As a result, GaN-based LEDs with traditional EBLs suffer from both high electron leakage and deteriorated hole injection at higher current levels. Several approaches such as p-doped barriers, AlInGaN EBLs, graded EBLs, and quantum barrier devices have been proposed to enhance hole injection efficiency from the p-GaN region to the active regions [13–20]. However, all these methods require additional heteroepitaxy which poses challenges due to lattice mismatch during growth. In a previous study, we reported high performance green LEDs employing an n-i-p type LQB [21, 22]. Nevertheless, although the introduction of an n-i-p structure in LQB can partially mitigate the reduction of hole barrier and enhance electron-blocking barrier caused by polarization effects, the direction of the built-in electric field formed by the n-i-p structure opposes that of hole injection. This impedes hole injection and impacts its efficiency. The situation contrasts significantly when a p-i-n structure is incorporated into the EBL layer. Due to polarization effects, the valence band bends downward in opposition to epitaxial growth, hindering hole injection. By inserting a p-i-n structure in the EBL layer, a built-in electric field opposite to the polarizing electric field can be obtained. Moreover, this built-in electric field aligns with the direction of hole injection into the active region, accelerating hole movement and facilitating hole injection into the active region. Another crucial aspect is to utilize high Al content AlGaN material as the EBL, which can result in a wider bandgap and thus generate a larger beneficial built-in electric field.

In our study presented here, we propose a novel p-i-n AlGaN EBL for GaN-based LEDs that not only enhances hole injection efficiency but also improves hole concentration within the active regions. Through simulations conducted in our research work, we demonstrate improvements in electron confinement and hole injection efficiency when using our newly designed p-i-n AlGaN EBL compared to traditional EBLs. Our findings indicate that both optical and electrical performances are greatly enhanced in LEDs incorporating a p-i-n AlGaN EBL compared to those utilizing traditional EBLs.

2. Device Structure and Parameters

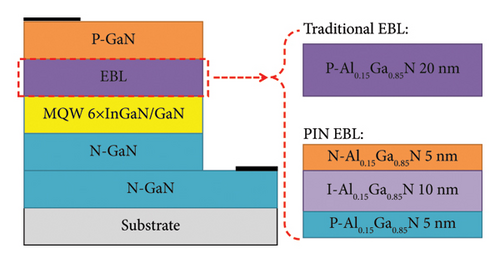

In this investigation, a reference blue InGaN/GaN MQW LED with a conventional EBL was utilized. The schematic cross-sectional view of the device is depicted in Figure 1. Starting from the bottom, the device structure comprises a sapphire substrate, an n-type GaN: Si layer (4 μm thick and doped at 5 × 1018 cm−3), six periods of In0.15Ga0.85N (2 nm, undoped)/GaN (13 nm, undoped) MQW active regions, followed by an p-type Al0.15Ga0.85N: Mg EBL (20 nm thick and doped at 3 × 1017 cm−3), and finally topped with a p-type GaN: Mg cap layer (0.2 μm thick and doped at 3 × 1017 cm−3). The LED has a square geometry measuring 60 μm × 60 μm. By substituting the Al0.15Ga0.85N layer with our proposed p (doped at 3 × 1018 cm−3)-Al0.15Ga0.85N-i-Al0.15Ga0.85N-n (doped at 3 × 1018 cm−3)-Al0.15Ga0.85N EBL (each layer having thicknesses of 5 nm, 10 nm, and 5 nm, respectively), we form an LED as shown in Figure 1. The only structural distinction between these two types of LEDs lies in their respective EBLs.

In order to examine the impact of the p-i-n AlGaN EBL on device performance, simulations were conducted using Silvaco ATLAS software to construct models for both types of LEDs. These simulations encompassed band diagram analysis, carrier concentration evaluation, light output power assessment, I–V curve characterization, and electroluminescence spectra investigation. The SRH lifetime within the QWs was estimated at 1 ns during calculations. Auger recombination coefficient was set at 1.0 × 10–34 cm6·s−1. Interface charges resulting from spontaneous and piezoelectric polarization were determined using Fiorentini et al.’s methods [23], with compensation by fixed defects and other interface charges considered as 50% of theoretical values. Band structure parameters were derived through k.p model calculation, while all computations were performed under room temperature conditions (T = 300 K). Furthermore, we adopted Xia et al.’s approach [24] to analyze the correlation between carrier transport and band structure.

3. Results and Discussion

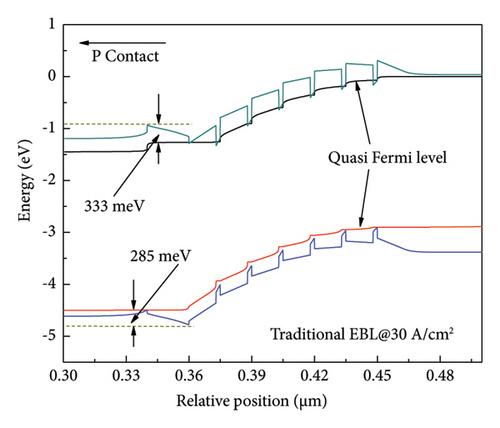

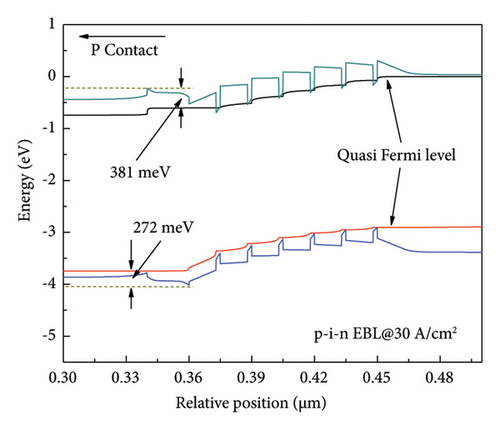

In order to investigate the transport characteristics of carriers in LEDs, simulations were performed to analyze the band diagram. Figure 2 shows the calculated band diagrams of two types of LEDs: one with a conventional EBL and another with a p-i-n AlGaN EBL, both are injected with a current of 30 A/cm2. It can be observed that for the traditional EBL, there is an effective barrier height in the valence band for holes measuring 285 meV (Figure 2(a)). On the other hand, for the p-i-n AlGaN EBL, this effective barrier height decreases to 272 meV (Figure 2(b)). Therefore, it can be inferred that when using a traditional EBL, holes face a higher barrier compared to when using a p-i-n AlGaN EBL. Consequently, employing a p-i-n AlGaN EBL facilitates easier transportation of holes into the active regions and enhances hole injection efficiency. Additionally, it is important to note that utilizing a p-i-n AlGaN EBL also results in a remarkable increase in effective potential barrier height for electrons in the conduction band. This increased electron barrier effectively reduces electron leakage. In summary, adopting a p-i-n AlGaN EBL significantly improves carrier transport not only during hole injection but also by enhancing electron confinement.

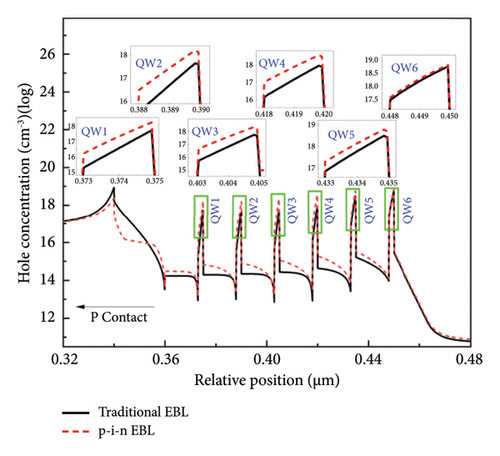

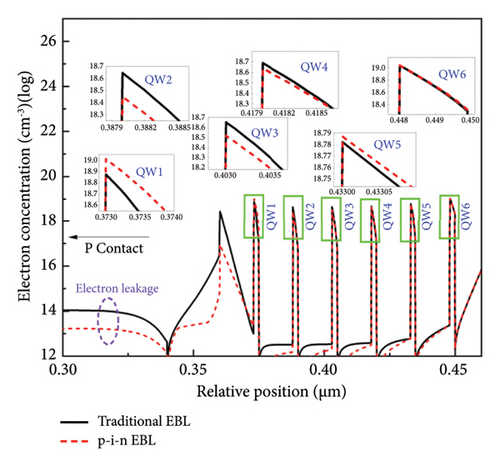

Based on the analysis of the band diagram provided above, it can be inferred that the utilization of a p-i-n AlGaN EBL leads to an enhancement in hole injection. In order to validate this claim, we conducted a study on carrier concentrations within the active regions and compared the distributions of holes and electrons under DC bias. Figure 3 illustrates the calculated distributions of holes and electrons in six QWs for both types of LEDs at an injection current density of 30 A/cm2. The reference point for relative position is set at the interface between the EBL and MQWs, pointing vertically towards MQWs. As anticipated, it is evident that in all six QWs, LED with a p-i-n AlGaN EBL exhibits significantly higher hole concentration compared to its counterpart with traditional EBL. Specifically, when employing a p-i-n AlGaN EBL, peak hole concentration reaches up to 1.6 × 1018 cm−3, 1.33 × 1018 cm−3, 2.2 × 1018 cm−3, 3.55 × 1018 cm−3, 5.75 × 1018, and 6.76 × 1018 cm−3, in QW1, QW2, QW3, QW4, QW5, and QW6, respectively, whereas with traditional EBL, peak hole concentration only amounts to 5.0 × 1017 cm−3, 4.4 × 1017 cm−3, 5.5 × 1017 cm−3, 8.7 × 1017 cm−3, 3.0 × 1018 cm−3, and 5.8 × 1018 cm−3 in QW1, QW2, QW3, QW4, QW5, and QW6, respectively (as depicted in Figure 3(a)). The hole concentrations in QW1, QW2, QW3, QW4, QW5, and QW6 of the newly structured LED have exhibited significant enhancements of 220%, 202%, 300%, 308%, 48%, and 17%, respectively, when compared to the conventional architecture. It is worth noting that when utilizing p-i-n AlGaN EBL, only enhancements in electron concentration were observed in QW1 and QW5. This phenomenon can be attributed to the lower voltage needed by the new structure at the same current density (as depicted in Figure 4). As shown in Figure 3(b), under identical injection current density conditions, the novel structured device exhibits reduced electron leakage current. These findings further confirm that the implementation of p-i-n AlGaN EBL enhances hole injection efficiency while minimizing electron leakage, resulting in increased concentrations of both holes and electrons within active regions.

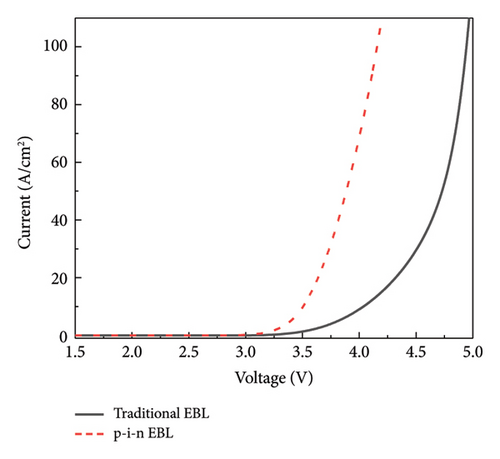

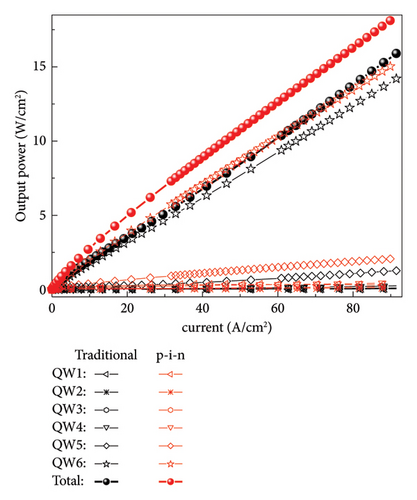

The light output power performances of the two types of LEDs were compared after calculating, as depicted in Figure 5. It is evident that incorporating a p-i-n AlGaNEBL significantly enhances the LED’s light output power at all levels of injecting current. By utilizing a p-i-n AlGaN EBL, the LED’s output power density can increase by approximately 41% in contrast with traditional one at an injection current density of 30 A/cm2. In order to further quantify the significance of each quantum well (QW) and evaluate the impact of the proposed electron-blocking layer (EBL), we conducted calculations to determine the relative contribution of each QW to the overall light output of the LED. This analysis confirms that QW6 emerges as the most prominent contributor, and introducing a p-i-n EBL amplifies the optical power output from QW6, as illustrated in Figure 5. The I–V curves for both types of LEDs are illustrated in Figure 4, revealing that the LED with a p-i-n AlGaN EBL exhibits a lower turn-on voltage, indicating improved carrier transport. These findings align with the analysis conducted on the band diagram.

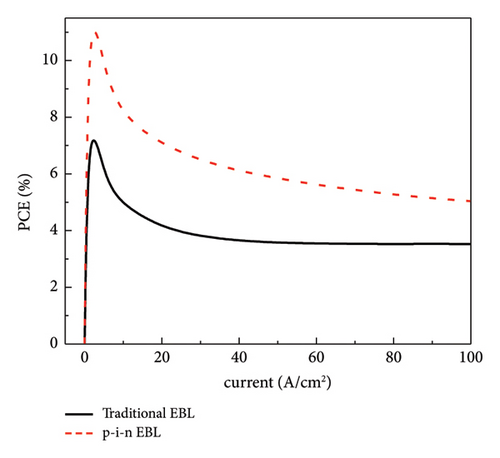

Figure 7 illustrates the simulation results, which present a comparison of the PCE between the proposed LED structure and the conventional structure.

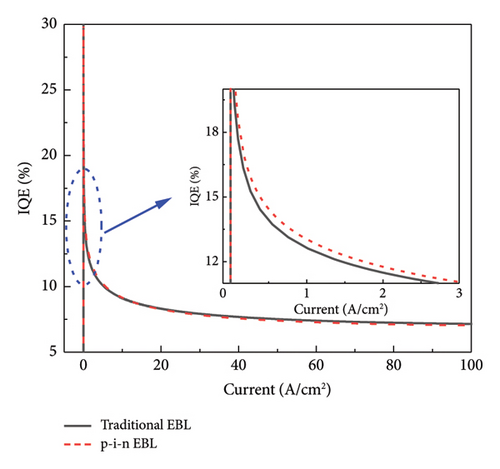

Based on the data presented in Figures 6 and 7, it can be observed that both the proposed structure and traditional structure LEDs exhibit a drop in IQE and PCE as the injection current increases. From the comparison results, it can be seen that our proposed new structure does not significantly enhance the IQE of GaN-based MQW LED. The PCE of our LED with a p-i-n structure, as depicted in Figure 7, exhibits a significant enhancement compared to traditional structure LEDs, showcasing an impressive 71% increase at an injection current of 30 A/cm2. The observed enhancements can be attributed to the band changes induced by our proposed p-i-n AlGaN EBL, which not only augments electron confinement capability but also enhances hole injection efficiency (refer to Figure 3). It should be noted that, throughout the entire injection current range, the percentage increase in PCE of the proposed PIN structure, relative to the traditional structure, is significantly greater than the increase rate of the light output power. The primary enhancement can be attributed to the fact that, at a constant injection current density, the novel architecture necessitates a reduced voltage (As shown in Figure 4), thereby significantly enhancing the conversion efficiency of the device.

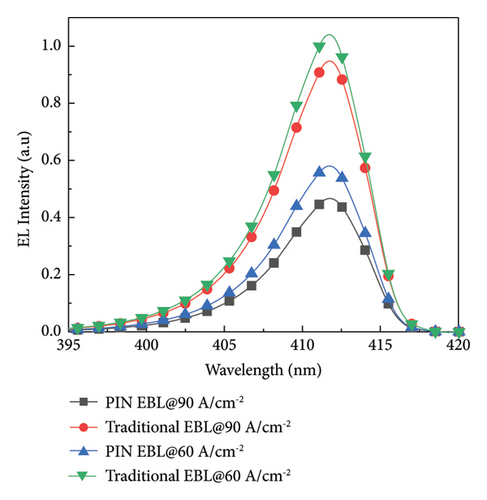

Figure 8 illustrates the simulated electroluminescence (EL) spectra of these two types of LEDs at an injection current density of 60 A/cm2and 90 A/cm2, respectively. Both under the given injection current, it is evident that the LED with a p-i-n AlGaN EBL exhibits a higher EL intensity compared to the LED with a traditional EBL. This enhanced EL intensity can be attributed to the improved carrier transport facilitated by the introduction of a p-i-n AlGaN EBL. In conclusion, these findings suggest that incorporating a p-i-n AlGaN EBL can significantly enhance the performance of GaN-based LEDs.

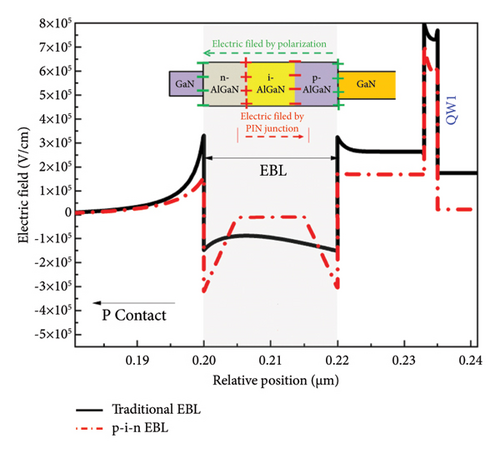

In order to comprehend the enhanced device performance resulting from the proposed structure, it is imperative to analyze the electrostatic field in AlGaN EBL. Figure 9 illustrates the amplified distribution of the electric field at 30 A/cm2 for both p-i-n EBL and traditional LED structures. In the conventional LED, polarization effects cause a downward bending of the energy band in AlGaN EBL due to a strong electric field. Consequently, this leads to an increase in effective barrier height for hole injection and electron leakage. However, by introducing a p-i-n structure, the degree of downward bending of the energy band is significantly reduced as it generates an opposing electric field. It becomes evident that this reduction decreases barrier height experienced by holes while increasing it for electrons (Refer to Figure 2), thereby enhancing hole injection efficiency and suppressing electron leakage. To conclude, these results demonstrate that incorporating an n-i-p EBL structure can substantially improve GaN LED performance.

Based on the aforementioned discussion, it is apparent that our proposed innovative structural device effectively enhances the light emission efficiency of LEDs. In contrast to recent developments in EBLs [13, 15, 16, 18, 19], which primarily focus on improving IQE, our proposed architecture uniquely optimizes LED performance by substantially augmenting PCE. Importantly, these contemporary advancements often require complex heteroepitaxial growth methods that introduce challenges arising from lattice mismatch and pose substantial growth complications. In stark contrast, our approach circumvents these limitations by solely leveraging doping strategies, thereby offering unparalleled practicality and ease of implementation for enhancing LED performance.

4. Conclusions

In summary, a comprehensive analysis and comparison were conducted on the performances of two types of GaN-based LEDs. One type features a conventional EBL, while the other incorporates our innovative p-i-n AlGaN EBL. Our investigation reveals three key advantages associated with the utilization of a p-i-n AlGaN EBL. Firstly, it effectively curbs electron run-off from the active regions. Secondly, it enhances hole injection efficiency from the p-GaN region into the active regions. Lastly, it improves carrier confinement within the active regions. Consequently, our newly designed EBL significantly enhances LED performance by increasing light output power, reducing turn-on voltage, and strengthening EL emission intensity.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Acknowledgments

This work was supported in part by the Anhui Provincial Natural Science Foundation (No. 2108085MF228) and Hefei Municipal Natural Science Foundation (No. 2021002).

Open Research

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.