Effects of Filled Nano-Al2O3 and Its Contents on Friction and Wear Properties of Hydrogenated Nitrile Butadiene Rubber

Abstract

A new hydrogenated nitrile butadiene rubber (HNBR) material filled with silane-modified nano-Al2O3 is developed in this work. Influence of the nano-Al2O3 and its contents on friction and wear performances of the HNBR materials is investigated. The nano-Al2O3 particles with different contents are added into the HNBR composites. Then, friction and wear tests are conducted using a pin-on-disk tribometer. Scanning electron microscope (SEM) is used to observe wear topography of the HNBR composite surfaces. Attenuated total reflection–Fourier transform infrared (ATR–FTIR) spectroscopy is used to investigate mechanism of nano-Al2O3 reinforcing HNBR. Results show that the filled nano-Al2O3 and its contents significantly affect friction and wear performances. Presence of the nano-Al2O3 obviously decreases friction coefficient and volume wear rate. Friction coefficient and volume wear rate of the composites reduce initially with the increase of nano-Al2O3 content and then increase with further increasing the nano-Al2O3 content. The HNBR material filled by the nano-Al2O3 with the content of 15 phr shows better antifriction and wear performances. SEM results indicate that the HNBR material filled by the nano-Al2O3 of 15 phr presents the best topography of wear surface compared with the HNBR materials filled by other nano-Al2O3 contents in this study. ATR–FTIR results show that mechanism of the nano-Al2O3 reinforcing HNBR for wear resistance is due to the graft reaction between the modified nano-Al2O3 and HNBR to form cross-linking networks around the Al2O3 nanoparticles, and self-polymerization of unsaturated groups on the surface of the nano-Al2O3 to form interpenetrating polymer networks with the HNBR molecular main chains.

1. Introduction

Hydrogenated nitrile butadiene rubber (HNBR) has extensively attracted attention in petrochemical, oilfield, automotive, aerospace, and medical industries because of its advantages of oil-resistance, anticorrosion for chemical medium, antiaging, good wear resistance, and high temperature tolerance [1, 2, 3, 4, 5, 6]. However, during long-term operation, the HNBR may degrade and lose its fundamentality (e.g., sealing failure) because of friction and wear. Wear is one of the most important factors that affect the sealing failure, resulting in safety concern [4, 6, 7]. Therefore, decreasing friction coefficient and special wear rate of HNBR is crucial to improve its friction and wear performances.

It is well-known that filler, as reinforcing agent, is added into rubber matrix to improve mechanical properties of the HNBR material, including friction and wear performances. Thus, in open literature, there are many reports regarding the effects of addition of fillers on the HNBR performance. For example, Wang et al. [8] added carbon black and silicon carbide into HNBR and studied the effect of addition of carbon black (CB) and silicon carbide on wear performances of the HNBR composite. Their results indicated that the antiwear performances increased for HNBR material reinforced by CB and silicon carbide. Felhös et al. [9] studied the effect of multiwalled carbon nanotubes (MWCNTs) and its contents on friction and wear performances of HNBR composites. Their results showed that the performance of wear resistance was enhanced for HNBR material reinforced by the filler, and the performance was improved when the MWCNT contents were increased. Li et al. [10] also investigated the influence of MWCNTs and contents on the aging performance of the HNBR material reinforced by MWCNTs, and the results indicated that the addition of MWCNTs enhanced the mechanical and antiaging properties of the HNBR material. Zirnstein et al. [11] reported the influence of multilayer graphene (MLG) on mechanical and flame retardancy performances of HNBR materials reinforced by MLG and found that the addition of MLG in low loadings improved mechanical and flame retardancy performances of HNBR materials. Zhang et al. [12] also studied effects of graphite and contents on vulcanization, mechanical, thermal conductivity, and dynamic mechanical performances of HNBR materials. Their conclusions showed that curing, mechanical, thermal conductivity, and dynamic mechanical performances were obviously improved for HNBR materials filled by the graphite (e.g., tensile strength was increased by 47% when nanographite content of 15 phr was added). Based on self-assembled carbon nanofibers–silica (CNFs–SiO2) nanocomposites as a reinforcing filler, Wang et al. [13] studied performances of CNFs–SiO2 composites and CNFs–SiO2/HNBR materials. They found that CNFs–SiO2 increased HNBR mechanical properties. Wang et al. [14] also added polyaniline–silica (PANI–SiO2) nanocomposite (as filler) into HNBR and investigated influences of the PANI–SiO2 and contents on mechanical properties of the HNBR composite, and results indicated that the PANI-SiO2 nanocomposite increased physical properties of HNBR material. Li et al. [15] investigated physical performance, oil resistance as well as friction and wear performances of a HNBR/polyamide six composite, and found that the addition of the polyamide six improved the mechanical properties, oil resistance as well as the friction and wear performances of the HNBR composite. Zhou et al. [16] studied influences of four fillers (i.e., UHMWPE, NG, NM, and GF) on friction and wear behaviors of HNBR composites. Their results showed that the tribological performances changed for HNBR composites filled with different fillers under different speed conditions.

Nano-Al2O3 exhibits good compatibility with rubber matrix, and it also presents favorable physical and mechanical properties, such as thermal stability and high strength and wear resistance [17, 18]. Therefore, nano-Al2O3, as a potential polymer filler, can be added into rubber to improve the rubber composite performances, such as friction and wear performances. Busse et al. [19] added different contents of Al2O3 particles into nitrile butadiene rubber (NBR) and studied the physical performances, surface topography, and tribological properties of NBR composites. Their results presented that Al2O3 and its contents significantly impacted mechanical, surface topography, and tribological performances of the NBR composites. In another study, the mechanical, chemical, anti-aging, and tribological performances of NBR and natural rubber (NR) materials filled by nano-Al2O3 were also studied by Fu et al. [20, 21]. Their results were similar to the report by Busse et al. [19], i.e., the presence of nano-Al2O3 significantly increased mechanical and tribological properties of the NR material. Ouyang et al. [22] introduced Al2O3 nanoparticles into silicon rubber (SR) and studied the effect of nano-Al2O3 on the mechanical properties of the SR composite. Their results indicated that nano-Al2O3 displayed good compatibility with SR matrix, and the addition of nano-Al2O3 increased thermal stability and mechanical performances of the SR composite. He et al. [23] studied the physical performance and tribological behaviors of Fluorine rubber (FKM) composite materials reinforced by nano-Al2O3 under different temperatures. Their results showed that nano-Al2O3 (as filler) improved the mechanical, friction, and wear performances of FKM composites. Yang et al. [24] studied the influences of Al2O3 nanoparticle and their average diameter on vulcanization, mechanical, friction, and wear performances of HNBR composite materials. Their conclusions indicated that the presence of nano-Al2O3 with different sizes enhanced vulcanizing, mechanical, friction, and wear performances of HNBR composite materials, and these properties were enhanced with reduction of particle sizes of nano-Al2O3.

Although there has been a lot of literature regarding effects of addition of various fillers into rubber composites on mechanical, chemical, antiaging, and friction and wear properties, few results have been reported regarding the influences of nano-Al2O3 and its contents on friction and wear properties of HNBR composite. In this paper, a new HNBR material reinforced by silane-modified nano-Al2O3 was developed. Influences of the nano-Al2O3 and its contents on friction and wear properties of HNBR composite materials were investigated experimentally. The objective of this research is to develop a new HNBR composite reinforced with nano-Al2O3 for wear resistance and to explore the mechanism of the nano-Al2O3 reinforcing HNBR composite for wear resistance. The nano-Al2O3 particles with different contents of 5, 10, 15, and 20 phrs were added into HNBR materials in the work, respectively. Then, friction and wear tests of the rubber materials without and reinforced by the Al2O3 nanoparticles with various contents were conducted using a pin-on-disk tribometer. Wear topography of HNBR composite surfaces was observed using a scanning electron microscope (SEM). Attenuated total reflection–Fourier transform infrared (ATR–FTIR) spectroscopy was used to investigate the antiwear mechanism of HNBR materials reinforced with the nano-Al2O3. The research results can provide useful information for industrial applications.

2. Experimental

2.1. Materials and Methods

HNBR composite materials filled with nano-Al2O3 particles were used and studied in this work. The raw HNBR (C3446) consisted of 34% acrylonitrile monomer, which was produced by Germany Lanxess Company. CB (N330), as a common filler, was manufactured by Anhui Lixin Rubber Technology Company (China). Al2O3 nanoparticle (i.e., α-Al2O3, nearly nanospherical) with the average particle size of 200 nm, as a reinforcing filler, was manufactured by Shanghai Chaowei Nanotechnology Company (China). In order to investigate the effects of nano-Al2O3 contents on friction and wear performances of HNBR composite materials, the nano-Al2O3 particles with contents (0, 5, 10, 15, and 20 phr) were used in the study. γ-Methacryloxypropyl trimethoxy silane (KH570) was also provided from Shanghai Chaowei Nanotechnology Company (China). Sulfur (S) at full powder was selected as curing agent and was provided by Jinghua Chemical Plant Company (China). Stearic acid (SA), zinc oxide (ZnO) as inorganic vulcanization accelerating agent, tetramethylthiuramdisulfide (TMTD), and 2,2-dibenzothiazoledisulfde (DM) as organic vulcanization accelerating agents, Antioxidant 4010 and Antioxidant RD were bought from Jinghua Chemical Plant Company (China). Formulations of the HNBR composites in the study are shown in Table 1. In Table 1, A0 represents the formula of HNBR material without nano-Al2O3, A1 represents the formula of HNBR material filled by the nano-Al2O3 with content of 5 phr. Similarly, A2, A3, and A4 represent the formulas of HNBR composites filled with nano-Al2O3 with the contents of 10, 15, and 20 phr, respectively.

| Formulas | HNBR (C3446) | Silane-modified nano-Al2O3 | CB (N330) | Sulfur | TMTD | DM | ZnO | SA | Antioxidant RD | Antioxidant 4010 |

|---|---|---|---|---|---|---|---|---|---|---|

| A0 | 100 | 0 | 50 | 0.5 | 1.5 | 1.5 | 5 | 1 | 1.5 | 1.5 |

| A1 | 100 | 5 | 50 | 0.5 | 1.5 | 1.5 | 5 | 1 | 1.5 | 1.5 |

| A2 | 100 | 10 | 50 | 0.5 | 1.5 | 1.5 | 5 | 1 | 1.5 | 1.5 |

| A3 | 100 | 15 | 50 | 0.5 | 1.5 | 1.5 | 5 | 1 | 1.5 | 1.5 |

| A4 | 100 | 20 | 50 | 0.5 | 1.5 | 1.5 | 5 | 1 | 1.5 | 1.5 |

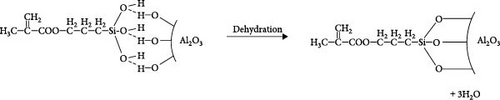

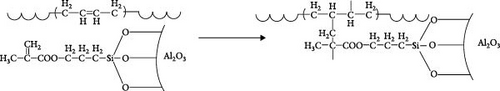

In order to make nano-Al2O3 good dispersibility in the HNBR and effectively reinforcing effect with the HNBR, the nano-Al2O3 was organically modified through γ-methacryloxypropyl trimethoxy silane (KH570) to obtain the silane-modified nano-Al2O3. The surface-treated method of Al2O3 nanoparticles is the similar to the reports in literature [24]. First, nano-Al2O3 particles were dried in vacuum environment at temperature of 110°C for 24 hr. The nano-Al2O3 particles of 100 g and the silane of 2 g were added into 500 mL 50% ethanol solution. Second, the mixed solution was treated using ultrasonic oscillation for 30 min and then stirred for 24 hr to obtain suspension. Third, the suspension was centrifuged and dried to get silane-treated nano-Al2O3 particle. Interaction mechanism between the silane-coupling agent (KH570) and Al2O3 nanoparticles is shown in Scheme 1. The actions between the silane-coupling agent (KH570) and nano-Al2O3 particles consisted of three steps. In the first step, the alkoxy groups in the silane-coupling agent were hydrolytic to form silanol (see Scheme 1(a)). In the second step, interaction between the silanol and hydroxyl groups of surface of nano-Al2O3 particles through chemical adsorption produced hydrogen bonds (see in Scheme 1(b)). In the third step, strong chemical bonds were produced through reactions of dehydration and condensation (see Scheme 1(c)).

2.2. Preparation for HNBR Composites

Fabrication of the HNBR composites included two processes, i.e., mixing and vulcanizing. In the mixing stage, an open two-roller mixing machine (Model: MZ-3010, Mingzhu Testing Co., Ltd., China) was used to mix the materials on the basis of each formula in Table 1. The distance between the two rollers was adjusted to 1 mm for the test. In order to prepare the HNBR compounds, the amount of the HNBR (i.e., 100 phr) is at the base. For example, in formula A1, the HNBR amount of 100 phr was the basis of the CB amount of 50 phr and the nano-Al2O3 amount of 5 phr for HNBR composite. After all the additives were added into the plasticated HNBR, the compound was blended several times to let fillers uniform dispersion in HNBR material. Then, the distance between two rollers was adjusted to 3 mm, and the compound was taken out from the mixing mill. After the compound was left 24 hr, it was remixed for 3–5 min. Finally, the HNBR compound was obtained. In the vulcanization stage, the plate vulcanization machine (Model: MZ-3012, Mingzhu Testing Co., Ltd., China) was employed to vulcanize the HNBR compound. The curing temperature was set as 150°C and curing pressure was 12 MPa. The normal vulcanization time of HNBR compounds can be obtained by the rotorless vulcanizer (Model: MZ-4010, Mingzhu Testing Co., Ltd., China). Then, the HNBR composites were obtained in our labs for tests.

2.3. Cross-Linking Density

2.4. Friction and Wear Tests

2.5. Scanning Electron Microscope

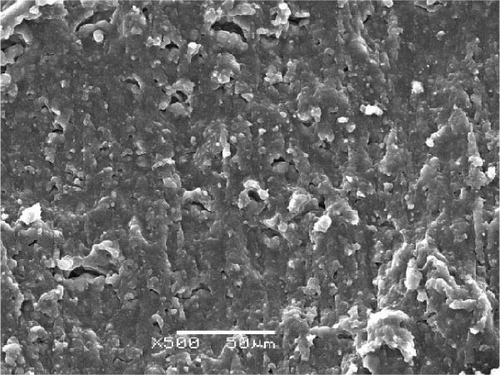

To further study influences of nano-Al2O3 and contents on friction and wear performances of the rubber materials, SEM (Model: JSM-6360, Nidec Corporation, Japan) was employed to examine wear topography of the rubber composite sample. The rubber composite samples were sputtered with a thin layer of gold before the SEM tests, then tests were carried out at the accelerating voltage of 20 kV.

2.6. Attenuated Total Reflection–Fourier Transform Infrared

To understand the mechanism of nano-Al2O3 reinforcing HNBR composites, specimens nonreinforced and reinforced with the nan-Al2O3 with different contents were characterized using the ATR–FTIR spectrometer (Model: IRAFFINITY-1S, SHIMADZU Instrument, Japan) and run at a scanning frequency of 128 with a resolution of 4 cm−1.

3. Results and Discussion

3.1. Vulcanizing Characteristics

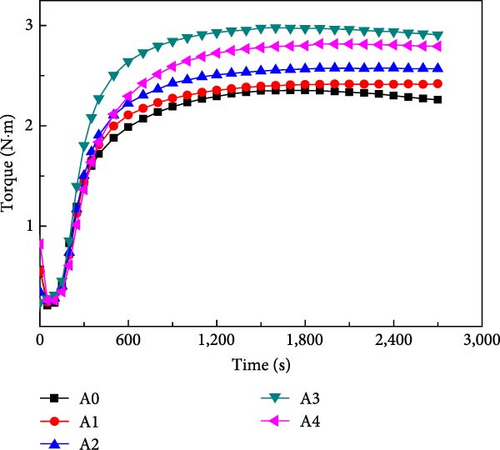

Figure 2 presents vulcanization curves for the rubber composite materials without and with nano-Al2O3 particles with different contents at the vulcanizing temperatures of 150°C and under the vulcanizing pressure of 12 MPa. In Figure 2, A0 represents the formulation of the HNBR composite unfilled by the nano-Al2O3 particles. A1 represents formulation of the HNBR material filled by the nano-Al2O3 particles with the content of 5 phr. Similarly, A2, A3, and A4 represent the formulations of the HNBR materials filled by nano-Al2O3 particles with the contents of 10, 15, and 20 phr, respectively. It can be noted from Figure 2 that the nano-Al2O3 and its contents significantly affected the curing process. During curing process, the torque for the HNBR material filled by the nano-Al2O3 particles was greater than that for the rubber material without the nano-Al2O3 particles. In addition, the torque increased initially with increase of the nano-Al2O3 contents from 5 to 15 phr, and then decreased with further increasing the nano-Al2O3 contents from 15 to 20 phr. It is found that the torque had the maximum value when the nano-Al2O3 content was 15 phr (i.e., formulation A3).

Table 2 presents the vulcanizing characteristics of the rubber composite materials without and with nano-Al2O3 particles with different contents at the vulcanizing temperatures of 150°C under the vulcanizing pressure of 12 MPa. All the HNBR materials were vulcanized at the vulcanizing temperature of 150°C under vulcanizing pressure of 12 MPa. In Table 2, t10 and t90 represent scorch time and normal vulcanizing time, respectively. ML and MH represent minimum and maximum torques, respectively. The cure rate indexes (CRIs, CRI = 100/(t90−t10)) of the vulcanizates are also shown in Table 2. From Table 2, the nano-Al2O3 and its contents importantly affected curing characteristics of the HNBR materials. Normal vulcanizing time (i.e., t90) initially decreased with the increase of the nano-Al2O3 contents from 0 to 15 phr, then raised when nano-Al2O3 contents were further increased from 15 to 20 phr. In addition, during the curing process, the torque difference (MH−ML) initially raised as the nano-Al2O3 contents were increased from 0 to 15 phr, then reduced with further increasing the nano-Al2O3 content from 15 to 20 phr, and the cure rate indexes (CRIs) had similar trends, indicating that nano-Al2O3 could increase cure rate of the HNBR composite materials and save curing time. In addition, it is found that the t90 had the shortest time, and CRI had the largest value when the nano-Al2O3 content in the HNBR composite materials was 15 phr, and the torque difference (MH−ML) shows similar results. These results demonstrate that it existed an optimal content of the nano-Al2O3 for the HNBR composites in terms of the vulcanization characteristics, which was 15 phr.

| Formulas | t10 (s) | t90 (s) | ML (N·m) | MH (N·m) | MH−ML (N·m) | CRI (s−1) |

|---|---|---|---|---|---|---|

| A0 | 151 | 819 | 0.202 | 2.361 | 2.159 | 0.150 |

| A1 | 167 | 743 | 0.238 | 2.423 | 2.185 | 0.174 |

| A2 | 167 | 747 | 0.252 | 2.581 | 2.329 | 0.172 |

| A3 | 166 | 674 | 0.277 | 2.983 | 2.706 | 0.197 |

| A4 | 185 | 868 | 0.246 | 2.826 | 2.580 | 0.146 |

3.2. Cross-Linking Density of HNBR Composites

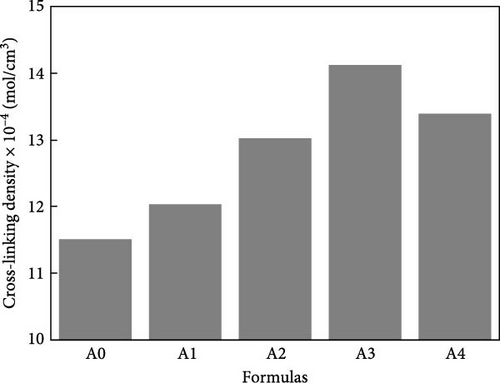

Figure 3 presents cross-linking density result obtained experimentally on the basis of swelling equilibrium method for HNBR materials filled by nano-Al2O3 with various contents. The test result of cross-linking density for the rubber material without nano-Al2O3 is also presented in Figure 3 for comparison. It can be observed from Figure 3 that the nano-Al2O3 and its content obviously affected the cross-linking density of the HNBR composites. The cross-linking density for the HNBR material without nano-Al2O3 particles was smaller than that for the HNBR materials filled by nano-Al2O3 particles, indicating that the addition of nano-Al2O3 increased the cross-linking density of the HNBR composites. In addition, the cross-linking density increased gradually with the increase of the nano-Al2O3 contents from 5 to 15 phr. However, when the nano-Al2O3 content further increased from 15 to 20 phr, the cross-linking density of the HNBR material decreased. It existed an optimal nano-Al2O3 content in terms of maximum cross-linking density, which was 15 phr. The reason is that when the amount of silane-modified nano-Al2O3 particles in the HNBR composite increased, the silane-modified nano-Al2O3 particles were combined with rubber molecular chain to form more rubber macromolecular network structure and to increase cross-linking density of the material. However, when amount of the silane-modified Al2O3 nanoparticles in the HNBR composite was too much (i.e., content of 20 phr), it may affect continuity of the rubber matrix and then affect the cross-linking of rubber molecular chain, resulting in the reduction of cross-linking density.

3.3. Friction and Wear Performances

Figure 4 presents test results of friction coefficient versus time curves for the rubber materials reinforced by the nano-Al2O3 with the contents of 5, 10, 15, and 20 phr which corresponded to formulas A1, A2, A3, and A4. Test results of friction coefficient versus time curve for the rubber material without the nano-Al2O3 (i.e., corresponding to formula A0) are also presented in Figure 4 for comparison. From Figure 4, friction coefficients initially decreased sharply, then increased gradually and finally kept relatively stable. The initially sharp decrease of the friction coefficients was due to that friction process transformed from static to dynamic. Moreover, the friction coefficient–time curves presented periodic fluctuation for the HNBR composites with nano-Al2O3. The periodic fluctuation of the friction coefficient was attributed to the generation of surface breakage and small pits during the friction process. It can be seen from Figure 4 that the nano-Al2O3 and its content significantly affected the friction and wear performance of the HNBR materials. Friction coefficient of HNBR material unfilled by the Al2O3 nanoparticle was greater than that of the rubber composite materials reinforced by the nano-Al2O3 particles, indicating that presence of the nano-Al2O3 improved tribological performance. This reason may be that after nano-Al2O3 particles were added into HNBR material, the nano-Al2O3 particles on the sample surface decreased the contact between metal pin and the HNBR, and decreased adhesive friction, then reduced friction coefficient. In addition, friction coefficient reduced gradually as the nano-Al2O3 contents increased from 5 to 15 phr and then increased with further increasing the nano-Al2O3 contents from 15 to 20 phr, showing that the nano-Al2O3 content had an important impact on the friction and wear performance of HNBR material. This possible reason may be as follows. With increasing amount of the nano-Al2O3 particles, the nano-Al2O3 particles on sample surface decreased contact between metal pin and the HNBR, and further decreased the adhesive friction, thus reduced the friction coefficient. However, when amount of the nano-Al2O3 particles added to the HNBR material was too much (i.e., 20 phr), it may result in reduction of continuity of rubber matrix, thus the friction coefficient was increased. It is found that the rubber composite material reinforced by the nano-Al2O3 with the content of 15 phr had the lowest friction coefficient, showing that the rubber material reinforced by the nano-Al2O3 content of 15 phr had the best friction and wear performance in the study.

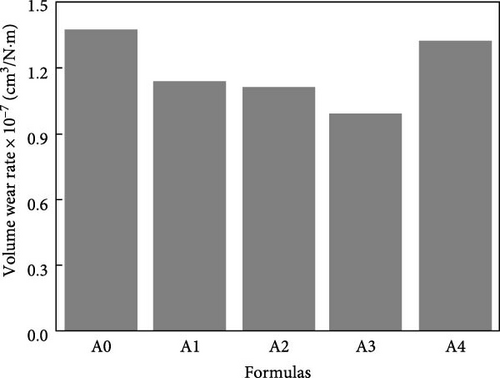

Figure 5 presents volume wear rates of tested samples without and reinforced by nano-Al2O3 with various contents. From Figure 5, volume wear rates of the rubber samples filled by nano-Al2O3 particles were smaller than that of the specimen unfilled with nano-Al2O3. In addition, wear rate decreased when nano-Al2O3 contents increased from 5 to 15 phr, and then increased with further increasing the nano-Al2O3 contents from 15 to 20 phr, indicating that the nano-Al2O3 content had an important impact on the friction and wear performance of the HNBR material. It is found that the rubber composite material reinforced by the nano-Al2O3 with the content of 15 phr had the lowest wear rate, showing that the HNBR material filled with the nano-Al2O3 content of 15 phr had the best friction and wear performance in the study. These results were similar to those of friction coefficients for the rubber materials filled by Al2O3 nanoparticles (Figure 4).

There is closely relationship between wear rate and wear mechanism, which can be verified by SEM observation. Nano-Al2O3 particles distributed on the sample surface can effectively decrease contacts between metal pin and HNBR material, then decrease adhesive wear. On the other hand, nano-Al2O3 particles were combined to rubber matrix so that degradation of surface material (e.g., wear scars of rubber material surface) was decreased, thus the wear rate of rubber material was decreased. In addition, wear rate is also related to cross-linking density of the rubber materials. The rubber composite filled by nano-Al2O3 nanoparticle with content of 15 phr could form a denser cross-linking network (Figure 3), indicating that HNBR material filled with the nano-Al2O3 content of 15 phr had better wear performance.

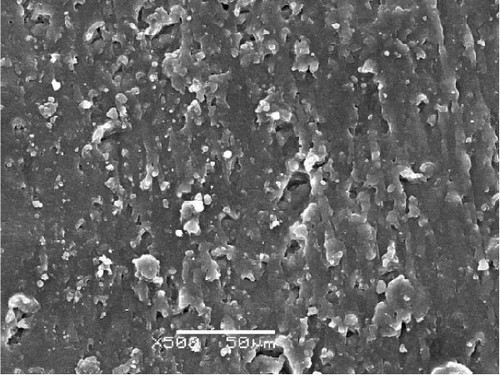

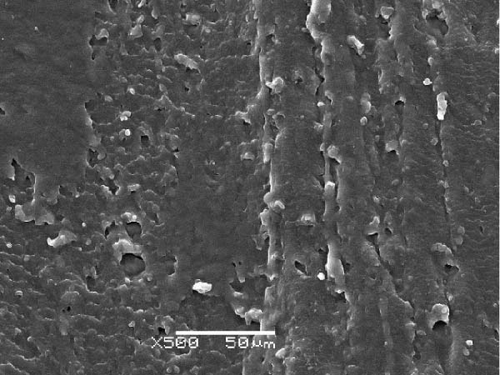

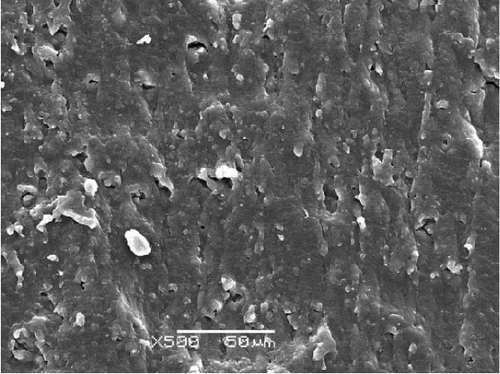

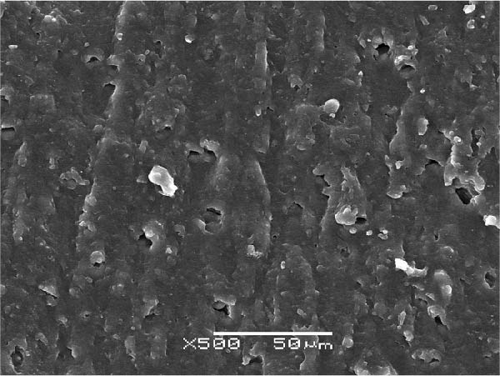

3.4. Scanning Electron Microscope

SEM was employed to observe the morphology of the worn surfaces of the specimens without and with nano-Al2O3 particles. Figure 6 presents the SEM images of the morphology of the worn sample surfaces. Figure 6(a) presents a topography of the wear surfaces of the HNBR samples without the nano-Al2O3. From Figure 6(a), the worn surface was very rough, a lot of curled tongue wear debris were observed and attached to the friction surface for tearing. In addition, many deep holes and microcracks were also observed on sample surface for tear and wear. These results indicate that wear of the sample surface for the rubber composite unfilled by the Al2O3 nanoparticles was very serious. Wear mechanism mainly resulted from fatigue wear.

Figure 6(b) presents a topography of the worn surface for the rubber samples reinforced by the Al2O3 nanoparticles with the content of 5 phr. From Figure 6(b), the wear surface was relatively smooth. The sample surface for the rubber material filled with the nano-Al2O3 particles was not severely worn compared to that of the sample unfilled by the nano-Al2O3 particle, showing that the addition of the nano-Al2O3 particles improved the antiwear performance of the HNBR composite material. From Figure 6(b), it is noticed that HNBR material was teared from the substrate to form voids, and furrows were produced by the move of wear debris, indicating that wear mechanism could be due to adhesive wear accompanied with abrasive wear. Figure 6(c) presents a topography of worn surfaces of the rubber samples reinforced by the nano-Al2O3 with the content of 10 phr. It can be seen from Figure 6(c) that there was slight wear debris, and many furrows appeared on the sample surface due to wear action. However, the amount of wear debris and furrows on the wear surface for the rubber sample reinforced by nano-Al2O3 with the content of 10 phr was less than that for the rubber sample reinforced by nano-Al2O3 with the content of 5 phr. Wear mechanism could be due to adhesive wear for HNBR material filled with the nano-Al2O3 of 10 phr. Figure 6(d) presents a topography of worn surfaces for the HNBR samples reinforced by the nano-Al2O3 with the content of 15 phr. From Figure 6(d), it can be observed that wear surface was shallow and smooth. Wear surface of the rubber material reinforced by the Al2O3 nanoparticles with content of 15 phr was smoother compared to the wear surface of the HNBR material reinforced by the nano-Al2O3 particles with content of 5 or 10 phr. Furthermore, the wear scars and furrows on the wear surface were not observed obviously. These results demonstrate that the rubber composite material filled with nano-Al2O3 particles with content of 15 phr had better wear properties than the rubber material reinforced by the nano-Al2O3 particles with content of 5 or 10 phr. Wear mechanism could result from adhesive wear accompanied with fatigue wear for HNBR material filled with the nano-Al2O3 of 15 phr.

Figure 6(e) presents a topography on worn surfaces of the rubber samples reinforced by the Al2O3 nanoparticles with the content of 20 phr. It can be seen from Figure 6(e) that wear surface was greatly rough and surface degradation was serious, many curled tongue wear debris were observed, which attached to the friction surface for tearing. In addition, many deep holes and microcracks were also observed on sample surface for tear and wear. These results reveal that wear of the rubber material reinforced by the Al2O3 nanoparticles of 20 phr was more serious compared with the rubber composite material filled by the Al2O3 nanoparticles of 15 phr. Wear mechanism mainly resulted from fatigue wear for the rubber material filled by the Al2O3 nanoparticles of 20 phr.

Overall, it concluded that the nano-Al2O3 particles and their contents had an important influence on the topography of the wear surface. Addition of the nano-Al2O3 particles can improve the morphology of the wear surface and, consequently, improve the wear performances of the rubber material. When nano-Al2O3 particle content for the HNBR composites was 15 phr, there was the best topography of the wear surface of the HNBR samples among all the contents of the nano-Al2O3 in this study. SEM results were consistent with the results in Figures 4 and 5.

3.5. ATR–FTIR Analysis and Reinforcement Mechanism

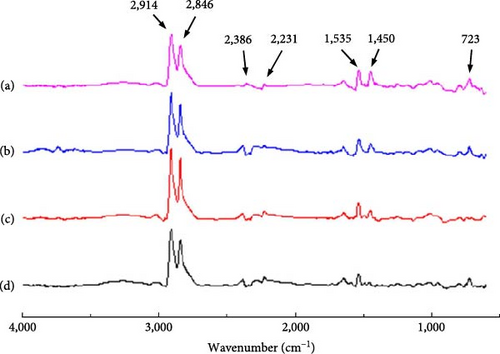

To investigate the mechanism of nano-Al2O3 reinforcing HNBR materials, HNBR composite materials nonreinforced and reinforced by the nano-Al2O3 particles with the contents of 5, 10, and 15 phr were used in this work. Then ATR–FTIR tests were carried out on the HNBR materials without the nano-Al2O3 and filled with the nano-Al2O3 of 5, 10, and 15 phr, respectively.

Figure 7 presents the ATR–FTIR test results for the rubber composites reinforced and nonreinforced by the nano-Al2O3 particles. Figure 7(a) shows the ATR–FTIR result for the rubber composite reinforced by the Al2O3 nanoparticles with the content of 5 phr. Figures 7(b) and 7(c) present ATR–FTIR results for the rubber composites reinforced by the nano-Al2O3 particles with the contents of 10 and 15 phr, respectively. Figure 7(d) presents the ATR–FTIR result for the rubber material without the nano-Al2O3 for comparison. The maximum summit at 2,914 cm−1 resulted from antisymmetric stretching vibration of ─CH2─. The characteristic summit at 2,846 cm−1 corresponded to stretching vibration mode of C─H. The summit at 2,386 cm−1 was assigned to deformation vibration of ─NH2. Peak at 2,231 cm−1 resulted from ─C≡N stretching vibration. The summit at 1,535 cm−1 corresponded to deformation vibration mode of the N─H in the secondary amide (R1─CO─NH─R2). The summit at 1,450 cm−1 was due to stretching vibration of the unsaturated carbon–carbon double bond (C═C) in the silane-coupling agent (KH570). The Summit at 723 cm−1 corresponded to stretching vibration mode of unsaturated carbon–carbon double bond (i.e., ─CH2─CH═CH─CH2─) in the HNBR molecular chain.

From Figure 7, the summit intensity at 723 cm−1 decreased for HNBR material filled with the silane-modified nano-Al2O3 compared to that for the rubber material without the nano-Al2O3, demonstrating that the double bond (i.e., C═C) in the rubber molecular main chain reduced for addition of the silane-modified nano-Al2O3 particles. The summit intensity at 1,450 cm−1 also reduced for HNBR material filled with the silane-modified nano-Al2O3, implying that the double bond (i.e., C═C) in the silane coupling agent (KH570) on the surface of Al2O3 nanoparticles decreased with addition of the nano-Al2O3 particles. Meanwhile, it was found that the summit intensity at 2,846 cm−1 raised when Al2O3 nanoparticles were added into the rubber composites, and summit intensity increased gradually with the increase of nano-Al2O3 contents. The possible reason is as follows. Combination of the unsaturated carbon–carbon double bond in the rubber molecular chain and the unsaturated carbon–carbon double bond on the surface of the nano-Al2O3 formed ─CH─ for grafting reaction, demonstrating that the silane-modified nano-Al2O3 particles successfully cross-linked to HNBR molecules, which improved friction and wear performances of the rubber composite materials. Furthermore, the more the Al2O3 nanoparticle contents were, the silane-modified Al2O3 nanoparticles grafted more HNBR molecular chains (Figure 7(c)). These results were in agreement with results of the cross-linking density. The grafting reaction process of the rubber molecular chain with the silane-modified Al2O3 nanoparticles is shown in Scheme 2.

In addition, self-polymerization of unsaturated groups (i.e., carbon–carbon double bond) on surface of the silane-modified Al2O3 nanoparticles could be conducted to form interpenetrating polymer networks with the HNBR molecular main chains, resulting in enhancement of friction and wear performances of the HNBR composite materials. Reaction mechanism of self-polymerization of unsaturated groups on surface of Al2O3 nanoparticles is shown in Scheme 3.

Thus, it can be obtained that mechanism of the silane-modified nano-Al2O3 reinforcing HNBR for wear resistance is due to the graft reaction between the silane-modified nano-Al2O3 and HNBR to form the cross-linking networks around the Al2O3 nanoparticles, and self-polymerization of unsaturated groups on surface of silane-modified Al2O3 nanoparticles to form interpenetrating polymer networks with the HNBR molecular main chains.

4. Conclusions

- (1)

Results of vulcanization tests reveal that the nano-Al2O3 and its contents had a significant effect on the vulcanization characteristics of the HNBR composite materials. The presence of the Al2O3 nanoparticles accelerated curing process and saved the vulcanization time. It is found that it existed the optimal content of the nano-Al2O3 for the HNBR composites in terms of the vulcanizing characteristics, which was 15 phr. The cross-linking density tests had similar results, i.e., the addition of nano-Al2O3 increased the cross-linking density of the rubber composite materials. Cross-linking density raised initially as nano-Al2O3 contents increased, and then decreased with further increasing the nano-Al2O3 contents. It existed an optimal nano-Al2O3 content in terms of maximum cross-linking density, which was 15 phr.

- (2)

Results of friction and wear tests indicate that friction and wear properties of the rubber composite materials reinforced by the Al2O3 nanoparticles were markedly enhanced compared with the rubber material without nano-Al2O3. The friction coefficients and volume wear rates reduced gradually with the increase of the nano-Al2O3 contents, then increased with the further increasing the nano-Al2O3 contents. It is found that the rubber material reinforced by nano-Al2O3 of 15 phr had better friction and wear performances.

- (3)

SEM observation shows that the nano-Al2O3 and its contents had a significant effect on morphology of the wear surface of the rubber materials. Addition of the nano-Al2O3 particles can improve morphology of the wear surface and, consequently, improve the wear performance of the rubber composite materials. When nano-Al2O3 content for HNBR composites was 15 phr, there was the best topography of wear surface on the HNBR samples in this study. The SEM results were consistent with those of friction and wear tests.

- (4)

The mechanism of the nano-Al2O3 reinforcing HNBR for wear resistance is due to the graft reaction between the silane-modified nano-Al2O3 and HNBR to form the cross-linking networks around the Al2O3 nanoparticles, and self-polymerization of unsaturated groups on the surface of Al2O3 nanoparticles to form interpenetrating polymer networks with the HNBR molecular main chains.

Disclosure

Present address of Xinyang Tan: Shanghai Jiao Tong University, 800 Dongchuan RD., Shanghai 200240, China.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work is sponsored by the Shanghai Sailing Program (22YF1420800), the Chenguang Program of Shanghai Education Development Foundation and Shanghai Municipal Education Commission (21CGA74), and the Interdisciplinary Program of Shanghai Jiao Tong University (YG2023QNB19, YG2024QNB08).

Open Research

Data Availability

The data used to support the findings of this study are available from the corresponding author upon request.