Impact of Reducing Waiting Time in Solar Water Heating Systems by Installing Instantaneous Water Heaters in Commercial Premises

Abstract

The use of solar water heating systems (SWHSs) has grown as an alternative source of energy to heat water. In Kenya, commercial premises are required to install these systems to conserve energy and the environment; however, after the SWHS has been designed and installed according to the relevant standard, post-installation factors significantly influence its performance. In this study, the impact of user behavior and waiting time for hot water on the performance of SWHS is investigated using experimental tests and analysis. In the operations of SWHS, water that cools off in the piping system during idle time must be flushed before hot water is supplied, and generally, the cold water goes to waste. This wastage increases the water demand, the amount of liquid waste for disposal, the cost of recycling, and the energy demand for pumping the water. The proposed system involves installing instantaneous water heaters controlled by a fuzzy logic controller in an SWHS to heat water during waiting time and reduce energy and water wastage associated with waiting time and user behavior. The study was carried out in 15 hotels in Kenya. It was observed that installing instantaneous water heaters in an SWHS reduces the waiting time for hot water by 96.90%, saving 14.4 liters of cold water while the user behavior losses were reduced resulting in a saving of 54.6 liters of hot water. The energy savings associated with pumping water was 0.025 kWh per hotel room on average. From these savings, the running cost was reduced by 80.6%. With this hybrid system, an additional 0.117 kWh of energy was consumed by the 4.8 kW instantaneous heater to heat water during waiting time. From these findings, it’s feasible to effectively reduce waiting time, reduce water wastage, and mitigate user behavior losses in hotels by incorporating instantaneous water heaters in SWHS.

1. Introduction

Solar water heating system (SWHS) is recognized as an effective and environmentally friendly method of providing hot water to households [1]. In residential and commercial premises, solar water heating systems provide hot water for showers and other uses [2]. Renewable energy technology is an essential way to mitigate environmental problems such as global warming and carbon neutrality currently facing the world [3]. The applications of solar energy include mainly photovoltaic, photochemical, and photothermal technologies [4]. Photothermal technology has been used in building heating systems, hot water systems, and in drying agricultural products [5]. In a study by Dunia, the energy demands of six hotels were compared, and it was observed that the food and beverage department had the highest energy demand (more than 50%), followed by the hot water system with an energy demand above 40% [6]. Using SWHS can reduce this high energy demand, and an efficient and well-maintained solar hot water system can provide 50% to 80% of the hot water needs in domestic and commercial buildings [7]. Solar thermal collectors include the concentrator type, the flat plate type, and the vacuum tube type [8]. However, SWHS always has delays in the supply of hot water, water held in the piping system during idle time cools off, this cold water must be flushed before hot water is supplied, and this cold water normally goes to waste and the user has to wait. This results in cold water wastage, a concern that is urgent because Kenya has limited water resources as reported by the Water Management Ministry. In Kenya, Nairobi alone has a deficit of 260 million liters a day [9].

An estimated 41% of Kenyans don’t have access to clean water [10], so it is necessary to save water. During the waiting period, 5–10 liters of cold water run into the waste before hot water is provided per household [11]. The waiting time for hot water in SWHS depends on the flow rate, diameter of the pipe, and distance from the shower head to the hot water reservoir [12]. Most hotels have adopted SWHS as an energy-saving solution to heat water. However, the amount of water wasted while waiting for hot water is significant when the user turns on the shower and leaves the cold water to run while waiting for hot water to get to the point of use from SWHS. As cold water runs the client engages in other cores [12]. Vieira investigated the performance of SWHS using multiparametric sensitivity analysis; site-specific conditions, technical specifications, and human behavior parameters to analyze their influence on performance indicators. The study concluded that user behavior must be factored in the SWHS performance analysis, as it plays a significant role in the overall performance of the system [13].

The challenges of waiting time and human behavior have been addressed by [14] using an on-demand circulator system that allows users in distant locations, such as kitchens or bathrooms, to activate a small pump using a button under the sink. The pump draws hot water from the water heater using either the cold water line or a separate piping return, depending on the type of installation. Although on-demand circulators reduce waiting time and wasted water, there is still a delay in getting hot water from central heating to the desired service point. The method increased the system’s energy demand, an additional installation cost, and no insight into the running and maintenance costs was investigated [14]. Another study on a continuous circulation system solved the problem of waiting for hot water in commercial settings. It involves the installation of a recirculation loop that is set up as a loop within the plumbing system. The loop allows hot water to circulate continuously throughout the system by connecting the hot water outlet of the water heater to all hot water demand points and then looping back to the cold water heater intake [15]. A circulation pump is installed to circulate hot water within the recirculation loop. The pump is controlled by a timer or thermostat, allowing it to operate at specific intervals or continuously, depending on the desired level of circulation temperature. This system provided hot water without waiting [16]. Although this method effectively reduces waiting time and no water is wasted [17], it increases the energy demand of the system depending on the capacity of the facility [17]. This study did not investigate thermal losses hydraulic corrosion and techno-economic analysis of the system. In another study, proper insulation of distribution pipes and solar collectors was investigated results showed that the technique reduced waiting times. Insulation helps minimize heat loss from the system and facilitates hot water delivery to the shower. Studies have shown adequate insulation can substantially reduce waiting times and improve system efficiency [18]. A comparison of the performance of different insulation materials under varying conditions to determine their effectiveness was not investigated in this study. Additionally, a cost-benefit analysis considering installation costs and maintenance costs could provide insight for consumers and policymakers. The size and design of the plumbing system also play a significant role in reducing waiting time, in new homes minimizing plumbing operations by placing the kitchen and bathroom nearby can also help to reduce waiting time [19, 20]. This method was limited to only new buildings and the study didn’t quantify the energy and water savings.

The current study has demonstrated its effectiveness in addressing the research gaps found in previous studies. In a recirculation system, the pipework experiences hydraulic corrosion due to the continuous flow of hot water under high pressure [21]. This issue is mitigated by heating the water at the point of demand by the instantaneous water heater, thus minimizing the continuous exposure of the pipes to hot water and high pressure. Thermal and energy losses in recirculation systems amount to 550 kWh per annum [22]. These losses are significantly reduced since water is only heated at the point of use, reducing the pumping energy required to keep water hot in a recirculation loop. The instantaneous water heaters which can easily be replaced also have lower energy consumption, resulting in reduced operational and maintenance costs. It was noted that recirculation systems installed without detailed modeling tend to use oversized pumps, which also wastes energy [23]. In contrast, the instantaneous water heaters proposed are sized in the design resulting in reduced possibility of over-sizing and hence more energy efficient.

Instantaneous water heaters offer numerous advantages, including energy efficiency, endless hot water supply, and space-saving design [24]. Unlike tank-based systems, instantaneous water heaters supply water on demand, eliminating the need for a bulky storage tank and standby heat loss. This results in savings of between 1465 kWh and 2344 kWh per year [25]. Electrocution death casualties while using an instantaneous electric water heater or a storage water heater have been reported [26]. The main factors that may lead to electrocution in this system are human error and improper installation, including grounding the wiring systems and equipment faults [26]. The addition of the Earth Leakage Circuit Breaker improves the safety aspect while protecting the user from electric shock better than the circuit breaker [26]. The fuzzy logic controller has emerged as a tool for solving imprecise, uncertain, or qualitative problems. The controllers combine intelligent and conventional techniques to control complex dynamic systems with embedded automation. Fuzzy systems have been successfully used in consumer products and commercial systems to describe the relationship between input information and output action without using complex mathematical equations [27].

The study′s objective was to determine the waiting time for hot water in SWHS in hotels, quantify the water and energy wastage during the waiting time, and user behavior time. Further, the study aims to determine the energy required by a 4.8 kW instantaneous water heater to heat cold water before SWHS provides hot water at a desirable temperature of 40°C. Finally, it compared the performance of SWHS incorporated with instantaneous water heaters with conventional SWHS among 15 hotels. The novelty of this study lies in adopting a hybrid system that incorporates instantaneous water heaters into SWHS to reduce waiting time for hot water in hotels using solar water heaters. This approach aims to reduce wastage of cold water and energy in pumping make-up water, while also improving user experience when having a shower.

2. Materials/Methods

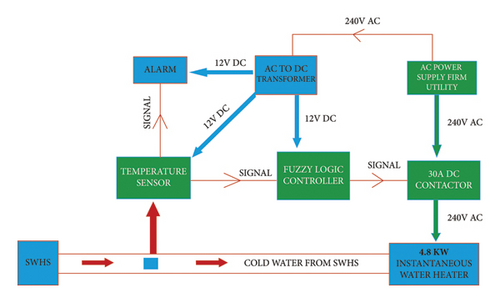

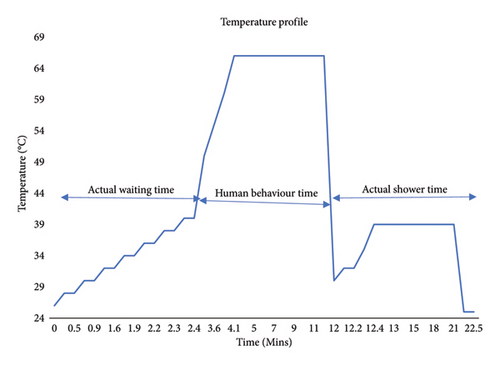

This study involved the incorporation of an instantaneous water heater in the SWHS shower head to heat cold water to 40°C (during waiting time) until the SWHS supplies hot water at 40°C. The fuzzy logic controller receives signals from the temperature sensor mounted on the shower head and uses it to energize or de-energize the contactor that powers the heater. When the SWHS supplies water at above 40°C, the fuzzy controller automatically de-energies the contactor. The alarm goes on at the end of the waiting time. Utility power used to energize the instantaneous heater is shown in Figure 1.

2.1. Experimental Materials and Methods

The study used Slovin’s formula to determine a sample size from a known population of 15 hotels with installed solar water heating systems in Kenya. The system consisted of a 4.8 kW instantaneous water heater, solar water heaters, 1.5 kW water pumps, and water tanks. The instantaneous heater was used to heat water to 40°C during the waiting time while an evacuated tube solar collector was used to heat water during the day and store it for later use. The water pump was used to pump water from the ground tank reserve to the elevated tank. A flow control valve was used to control the flow rate.

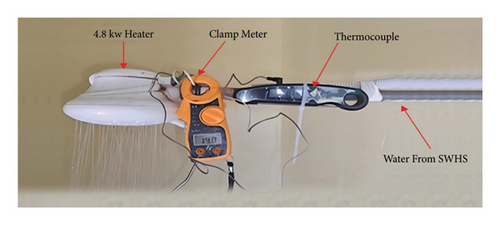

In Figure 2, the experiment mainly measured the waiting time, current drawn by the instantaneous heater, human behavior time, and water temperature during the start and end of the waiting time.

In the experimental test, the PM2028B clamp meter was used to measure the current, and the data were recorded. The smart TUYA Q2YA thermocouple was used to obtain the temperature profile (hot water profile). It has an operating range which can be used to determine the waiting time and water temperature before hot water is delivered by SWHS (when connected to a smartphone or a laptop it provides a graph of temperature vs time). Table 1 shows the specification and accuracy of parameters of equipment used in the research including those for the smart TUYA Q2YA.

| No | Equipment | Accuracy |

|---|---|---|

| 1 | PM2028B clamp meter | ± (2.0% + 5) |

| 2 | Smart TUYAQ2YA thermocouple | ±1°C |

| 3 | Ultrasound flowmeter (TYZ 456–341) | ±0.7% |

| 4 | UT33D multimeter | ± (2.0% + 5) |

| 5 | DTS6619 energy meter | ±1% |

An ultrasound flowmeter (TYZ 456–341) was used to measure the water flow rate from the solar collector. The UT33D Multimeter was used to measure the voltage of the utility supply, and the DTS6619 Energy Meter was used to measure the energy consumption of the water pump and the instantaneous heater. Earth Leak Circuit Breaker ELCB (DPN VIGI 32A–30 mA Schneider) was used to prevent users from electric shock.

2.2. Determining Cold Water Wasted during Waiting Time

Waiting time is the period when water that had cooled off in the piping system of SWHS has to be flashed before the user starts receiving hot water from SWHS this happens when the system idles.

To determine the waiting time, a smart thermocouple was mounted on the shower head, its measurement tip was positioned to contact the SWHS running water, with a set point of 40°C. Once the temperature is achieved, an alarm goes on to signal the end of the waiting time.

The thermocouple provided the temperature profile of the water supplied by SWHS and from the profile the waiting time was determined.

2.3. Determining Water Lost during User Behavior Time

User behavior element was observed when the waiting time for hot water had elapsed, and SWHS was providing hot water above 40°C but the user was not available to shower due to overestimation of the waiting time or was involved with other activities. This resulted in the wastage of hot water.

2.4. Determining Instantaneous Power Rating

For easy reference, the specifications of the instantaneous water heater are shown in Table 2.

| Parameter | Range |

|---|---|

| Heater model | Lorenzetti Ducha |

| Rated max power (Pmax) (kW) | 4.8–6 |

| Volumetric flow rate (L/s) | 0.05–0.12 |

| Voltage (V) | 240 |

| Current (A) | 20–25 |

| Heater efficiency (%) | 96 |

| Working pressure (bars) | 4 |

| Maximum system temperature (°C) | 40 |

| Recommended wire size (mm) | 6.0 |

2.5. Determining Pumping Energy Losses during Waiting Time and User Behavioral Losses

2.6. Determining Energy Demand for an Instantaneous Heater during the Waiting Time

2.7. Setting up Fuzzy Logic Controller

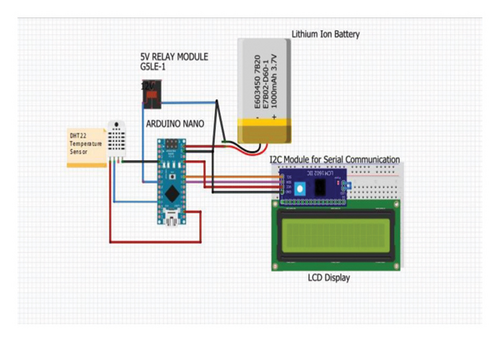

The C programming language was used to program the fuzzy logic controller and implanted it in the Arduino. The Arduino code provided was designed to control the heating system using a DHT22 temperature sensor and a relay as shown in Figure 3.

The code regulates to ensure the temperature setpoint is below 40°C. If it is, the relay is turned on (HIGH), energizing the contactor to activate the heating element to heat the water.

Once the temperature exceeds 40°C, the relay is turned off (LOW) to de-energize the contactor, and the heating stops.

2.8. Defuzzification (Center-of-Area Method)

3. Results and Discussion

3.1. Waiting Time in SWHS

The findings demonstrated the users experienced an average waiting time of 2.35 minutes before SWHS could provide hot water at 40°C from an initial temperature of 25°C, as illustrated in Figure 4. However, when an instantaneous water heater was integrated into the SWHS, the hot water was available on demand and hence the waiting time was reduced substantially. It was noted that proximity to the hot water reservoir and flow rate significantly influenced waiting time. It is also observed that hotel rooms closer to the hot water reservoir exhibited shorter waiting times by 31%. The research also demonstrated that higher water flow rates have an impact on the waiting time and reduce it by 44%.

During the actual waiting time, SWHS flashes cold water which goes to waste before hot water is supplied, human behavior time; at this point, SWHS has already provided hot water but the user isn’t available; thus, wasting hot water and actual shower time is time spent by the user to shower.

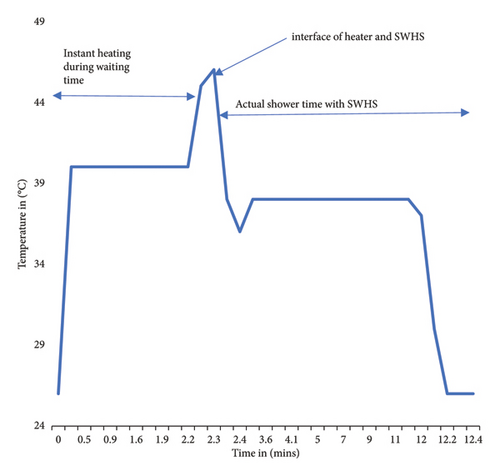

At the interface of SWHS heater instantaneous and the temperature rise was noticed, at this point, SWHS had started to provide hot water above 40°C the user had to mix to achieve desirable shower water temperature.

3.2. User Behavior Time

User behavior time was observed between the end of waiting time and the start of actual shower time as shown in Figure 4. It happened when SWHS had provided hot water above 40°C, but the user was not available to use it as may have overestimated waiting time and left the bathroom and engaged in other activities. During this time, hot water is wasted. The sudden drop in temperature marked the end of user behavior time as at this point the user returns to the bathroom and finds SWHS providing water above 65°C which is too hot for showering. The user mixes it with cold water and hence the sudden drop in temperature as seen in Figure 4

When an instantaneous water heater was incorporated in SWHS, the user behavior time was eliminated as shown in Figure 5 since hot water was readily available on demand. The temperature change was noticed when the heater was automatically turned off and SWHS started providing water above 40°C and the user had to mix hot water from SWHS to their desired shower temperature. It was noted that hotels that provided internet connectivity to their guest experienced more user behavior time increase by 69.8%. With the integration of the instantaneous water heater to the SWHS, the clients were advised to expect hot water immediately as shown in Figure 5, and hence start taking the bath without having to wait. With or without the elimination of the behavior time, the shower time remained the same at an average of 9.4 minutes as shown in Figures 4 and 5.

3.3. Impact of Waiting Time on Floor Elevations in SWHS

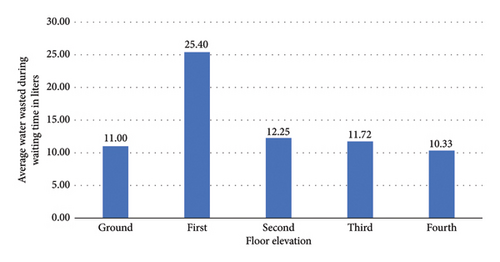

When investigating different floor elevations, the average waiting time of 2.34 minutes was obtained. The difference depends on the proximity of rooms from the hot water reservoir, so rooms closer to the hot water reservoir had a shorter waiting time by 46%. However, the ground floor rooms which were expected to have the longest waiting time did not because of the constant need for hot water due to the amenities around them such as the kitchen, and hence had experienced shorter waiting time as demonstrated in Figure 6.

3.4. The Water Wasted during Waiting Time

The amount of water flushed before hot water is provided by the SWHS was determined to be 14.14 liters per hotel room per floor elevation on average as shown in Figure 7. The amount of water lost varied per elevation mainly due to proximity to the hot water reservoir. The rooms closer to SWHS reservoir lost less water by 43%. The diameter size of the installed hot water pipe of more than 25 mm has more water losses by 53% compared with hotels that have installed smaller diameter pipe. This was due to the difference in volume per unit length of the pipe.

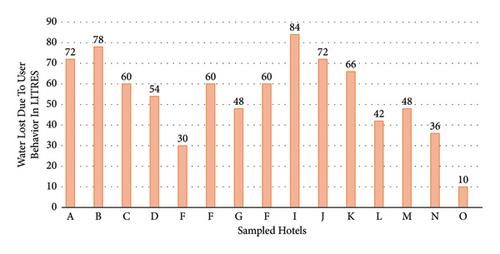

3.5. Water Loss Due To User Behavior Time

The research established that the average amount of hot water wasted due to user behavior is 54.6 liters per hotel room. It was observed that each hotel experiences a different wastage associated with user behavior due to the size of pipes used in plumbing, hotel capacity, and internet connectivity. The hotels with pipe diameters of 25 mm and more had more wastage compared to those with 20 mm pipes by 57%. Hotels with larger room capacity also had more wastage by 45% while internet connectivity in hotel rooms contributed to 69.8% more in water wastage. It was noted that 93% of the hotels sampled had losses related to user behavior. Information to clients on the waiting period of hot water can be important in regulating human behavior as noted in Hotel O in Figure 8 where a notice on the bathrooms to the users substantially reduced the water loss.

3.6. Pumping Energy Demand Due Human Behavior and Waiting Time

The research established the average energy demand of 0.017 kWh per hotel room due to waiting time. The energy is used to pump water attributed to user behavior. With the introduction of an instantaneous heater, the waiting and human behavior time were reduced since hot water was available immediately. It was established a 4.8 kW instantaneous heater consumed an average of 0.117 kWh per hotel room to heat cold water to 40°C. The energy consumed varies depending on the elevation of the hotel rooms and the waiting time. Rooms with longer waiting times consumed more energy as shown in Figure 9.

3.7. Comparing SWHS Incorporated with Instantaneous Water Heater and Conventional SWHS

The analysis of the two systems was carried out for 30 days when hotel occupancy was 60%. The parameters for comparison included waiting time, human behavior time, energy and water demand, and the total running costs. The results in Table 3 show that the SWHS incorporated with instantaneous heater and a SWHS alone. The running costs of the combined system are USD100 less than that of conventional SWHS alone.

| No | SWHS type | Waiting time in (minutes) | Human behavior time (minutes) | Energy demand kWh | Water demand in (liters) | Running cost in USD |

|---|---|---|---|---|---|---|

| 1 | Conventional | 2.30 | 9.8 | 18.36 | 78775.2 | 130 |

| 2 | Incorporated with a 4.8 kW instantaneous heater | 0.184 | 0 | 126.36 | 0 | 30 |

4. Conclusions

This study demonstrated the benefits of reducing waiting time in SWHS by incorporating instantaneous water heaters controlled by a fuzzy logic controller. The study sampled 15 hotels in Kenya with existing SWHS installed and were experiencing water and energy wastage associated with waiting time for hot water. By incorporating an instantaneous water heater, the operating cost was reduced by 80.6% while waiting time for hot water was almost eliminated by approximately 97%. Apart from energy savings, water saving of 14.4 liters per hotel room was achieved. The water saving due to user behavioral change was 54.6 liters of hot water per hotel room. The cumulative energy savings amounted to 0.025 kWh per hotel room. The research also established that a 4.8 kW instantaneous heater found in the market consumes an average of 0.117 kWh per hotel room to heat water from 25°C to the desired shower temperature of 40°C during the waiting time. This energy is significantly low compared to the water and energy wasted during waiting time for a SWHS without an instantaneous heater. From these findings, it is scientifically feasible to effectively reduce waiting times for hot water, minimize water and energy wastage, and mitigate user behavior losses in hotels by incorporating instantaneous heaters in SWHS. The study also demonstrated the impact of information on the availability of instantaneous heaters in hotel rooms can also significantly assists in regulating the human behavior costs and losses.

Conflicts of Interest

The authors declare that there are no conflicts of interest regarding the publication of this article.

Acknowledgments

The authors would like to thank the staff of the Department of Electrical Engineering and Physics of the Multimedia University of Kenya and the Kisumu Hotel Owners Association.

Open Research

Data Availability

The data used to support the findings of this study are included in the article.