Study on the Effect of Foundation Pit Excavation on the Deformation of Adjacent Shield Tunnel

Abstract

With the construction of a large number of urban infrastructures, there will be new engineering loading and unloading behavior around the urban metro built-up area, and the deformation characteristics of the new tunnel will be more significantly affected by the external environment. In this paper, the damage to shield tunnel structure caused by pit excavation in similar engineering is analyzed. The finite element model, based on the different distances between the foundation pit and the tunnel and the different thicknesses of tunnel segment, is established. The displacement field and the convergent and longitudinal deformation of the shield tunnel segment with different thicknesses are analyzed. The following conclusions are drawn: (1) the excavation of adjacent foundation pit will cause excessive displacement, settlement, and structural convergent deformation of shield tunnel, causing structural damage such as increasing of faulting, water leakage, and seeping. (2) With the decrease of the distance between the tunnel and the foundation pit, the convergent deformation of the tunnel increases continuously, and when the distance is less than 30 m, the increase of segment thickness greatly improves the convergent deformation of the structure. (3) The increase of segment thickness has no obvious effect on the resistance to longitudinal deformation. When the distance between tunnel and foundation pit is less than 50 m, additional protective measures should be taken to reduce the longitudinal deformation of tunnel.

1. Introduction

Due to the continuous progress of construction technology and improvement of construction mechanization, the underground structure has undergone a transformation from open-excavated structure and underground-excavated structure to the shield tunnel structure widely used at present [1]. However, the early structural design of urban metro engineering mainly considered the surrounding soil and water load and partial overload. With the construction of a large number of urban infrastructures, there will be new engineering loading and unloading behaviors around the urban metro built-up area [2], such as surrounding loading and unloading construction and construction of new adjacent tunnel crossing construction. The change of urban environment leads to the problem of insufficient designed stiffness of shield tunnel according to the traditional theory, which leads to various diseases, such as excessive deformation. It also increases the operational risk and maintenance cost in the later period and affects the durability of shield tunnel. Therefore, in the structural design of urban metro engineering, various influencing factors caused by environmental changes should be considered [3].

At present, many scholars have studied the influence of foundation pit excavation on adjacent metro structures from three aspects: engineering monitoring, model test, and numerical simulation. Ding et al. [4] and Jiang and Hou [5] analyzed the monitoring data of the foundation pit adjacent metro tunnel in operation. The relationship between the lateral displacement of deep soil and the deformation of adjacent Metro tunnel during the whole construction stage of foundation pit excavation is studied. Guo et al. [6], Wei et al. [7], and Kong et al. [8] summarized the tunnel deformation caused by the excavation of foundation pit and analyzed the relationship between the longitudinal maximum uplift deformation of tunnel and various influencing factors. In terms of model tests, Ng et al. [9], Kuwahara [10], and Huang et al. [11] studied the transverse and longitudinal deformation of the existing tunnel structure caused by new shield tunneling and foundation pit excavation by two-dimensional and three-dimensional centrifuge tests. In addition, Byun et al. [12] measured the stress on the lining segment of the existing tunnel caused by the newly built foundation pit and the uplift deformation of the existing tunnel caused by the newly built tunnel through the scale model test simulation. Kojima and Yashiro [13] conducted indoor model test on existing tunnel deformation under the ground loading and unloading and found that the nonlinear deformation characteristics of tunnel caused by unloading in sandy soil were obvious. In terms of numerical research, Gao et al. [14] proposed that excavation of one-side foundation pit of adjacent Metro tunnel can cause asymmetric deformation of tunnel structure based on numerical simulation. Lo and Ramsay [15] used the finite element method to simulate the excavation of the foundation pit above a tunnel in silty clay strata in Toronto and predicted the additional displacement of the tunnel. Marta [16] proposed a two-dimensional finite element method for numerical analysis of the whole construction process of the foundation pit above the tunnel in hard strata, and the analysis results obtained were basically consistent with the field measured data. Sharma et al. [17] reported the influence of foundation pit construction on the Xiqiao tunnel in Singapore. In this study, the deformation characteristics of the tunnel were studied through numerical simulation, and the conclusion that the tunnel with large structural stiffness would bear large additional bending moment was proposed. At present, in the process of foundation pit excavation, measures such as block excavation and partition wall are often adopted to protect the tunnel [18–20]. Considering the influence of lateral platform on the boundary of newly built Metro lines, the inner diameter of the tunnel in China shows a trend of expansion. Now, the deformation characteristics of the tunnel structure under the influence of external environment after diameter expansion are not clear. Meanwhile, after diameter of tunnel changing, the thickness of tunnel segment should be added to match the expanded diameter. However, most current studies were not involved in determining relationship between the thickness and capacity of bearing deformation.

Based on the excavation scheme of adjacent foundation pit of Shaoxing Metro line 1, the main objective of the article is to predict the tunnel deformation after pit excavation and whether the thickness of tunnel segment could increase its resistance to pit disturbance. This paper analyzes the field measured data of the effect of foundation pit excavation on tunnel structure of similar existing projects and discusses the deformation and damage of shield tunnel structure. Then, the finite element model of the interaction between the foundation pit and the tunnel is established based on the background of the 5.9-m large inner diameter shield tunnel of Shaoxing Metro Line 1. The longitudinal deformation of tunnel structure during foundation pit excavation is simulated. On this basis, the antideformation ability of shield tunnel structure with different distance between foundation pit and tunnel and different segment thickness is studied, which can be used as a basis for structural design of shield tunnel with large inner diameter in metro.

2. Project Overview

2.1. Project Design Scheme

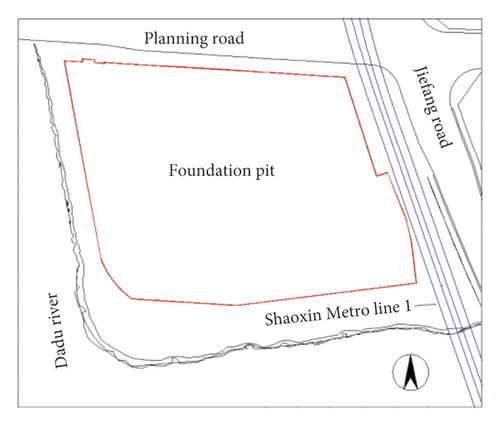

The research object is the tunnel interval between Jinghu Station and Fenglin Road Station of Shaoxing Metro Line 1. The starting and ending distance of the left line is left K31 + 523.250—left K32 + 561.290, while that of the right line is right K31 + 523.250—right K32 + 561.290. The total lengths of left line and right line are 1033.097 m and 1038.040 m, respectively. The tunnel section is a round tunnel with single hole and line, which is constructed by shield construction. The minimum flat curve radius is 450 m, and the line spacing ranges from 13.4 to 17.0 m. The maximum longitudinal slope of the tunnel is 25.326‰, and the buried depth at the top is 9.2–17.32 m. Within the excavation area, the buried depth of the tunnel is about 13.8–17.2 m, the outer diameter of the tunnel is 6.7 m, and the thickness of the shield segment is 0.4 m. The left and right lines of the metro shield tunnel are parallel, and the distance between the center lines of the dual lines is about 12.0 m. The tunnel is mainly located in (4)1 silty clay layer, and the top part of the tunnel is located in (3)12 silty clay layers. Before the pit begins excavating, construction of two tunnel lines has been completed.

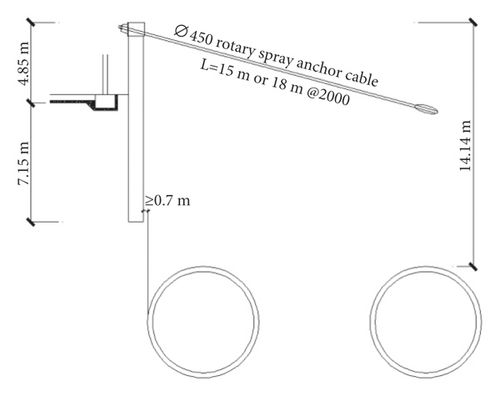

The area of the foundation pit is about 46,000 m2. The distance between the top of the metro tunnel structure and the bottom of the foundation pit is about 9.29 m, and the nearest horizontal distance is about 0.7 m. The buried depth of the roof is about 1.8 m, and the excavation depth of the foundation pit is about 4.85 m. The foundation pit is constructed by the open excavation method, using SMWφ 850@600 construction method plies bracing and adding ∅450 rotary spray anchor cable on the top of the pile near tunnel structure, L = 15 m or 18 m @2000. The position relationship between foundation pit and tunnel is shown in Figure 1.

The main soil layers in the excavation area of the block foundation pit are miscellaneous filling soil layer, silty clay layer and mucky silty clay. Among them, mucky silty soft soil is a kind of highly compressible soil, and the settlement caused by the reconsolidation of construction disturbance will affect the settlement and deformation of shield tunnel, causing safety problems. Physical and mechanical parameters of soils as shown in Table 1.

| Soil layer number | Soil classification | Unit weight (kN/m3) | Cohesion (kPa) | Friction angle (°) | Elastic modulus (MPa) |

|---|---|---|---|---|---|

| (1) | Miscellaneous fill | 18 | 8 | 12 | 15 |

| (2)1 | Silty clay | 18.5 | 25 | 12 | 13.5 |

| (3) | Mucky silty clay | 19.2 | 9 | 9 | 9.6 |

| (4)1 | Silty clay layer | 18.7 | 13 | 13 | 17 |

2.2. Monitoring Analysis of Tunnel Damage in Similar Engineering

The safety reliability of unimplemented projects can be evaluated through the implementation of similar projects. This section takes the shield tunnel interval between Haiyan North Road Station and Fuqing North Road Station of Ningbo Metro Line 1 Phase I project as an example, and the deformation of shield tunnel caused by foundation pit excavation is analyzed. The outer diameter and inner diameter of the tunnel are 6200 mm and 5500 mm, respectively. The width and thickness of the segment are 1200 mm and 350 mm, respectively. The line spacing in this section is 13–15 m, the maximum longitudinal slope of the tunnel is 25‰, the buried depth at the top of the tunnel is about 11–17 m, and the minimum plane curve radius is 600 m. The tunnel in this section mainly passes through (2)2-1 layers of grey silt, (2)2-2 layers of grey silt clay, (3)1 layer of silt sand, and (3)2 layers of grey silt clay with silt sand.

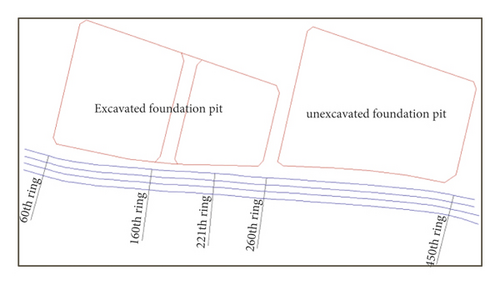

Within the 60–260 ring range of the north side of the left line tunnel in Hai-Fu interval, there is the foundation pit in the eastern new town, which is about 7–13 m away from the outer edge of the left line tunnel. The plane position relationship between the Hai-Fu interval tunnel and the foundation pit in Eastern New Town is shown in Figure 2. The foundation pit in the Eastern New Town is supported by bored piles, water-stopping curtains, and two vertical reinforced concrete supports, with a depth of about 11.3 m.

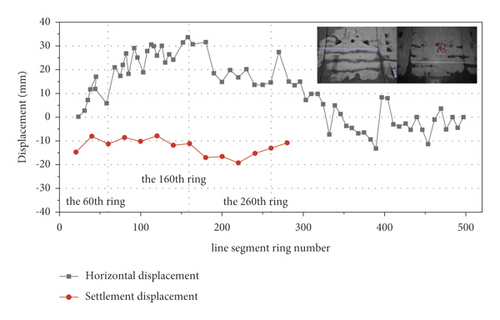

When excavating the foundation pit under the second support, the project group found the leakage phenomenon at the bottom of the shield tunnel in the left line of Hai-Fu section during the daily inspection. A week later, longitudinal cracks and water seepage appeared at the bottom of the shield tunnel in the Hai-Fu section. Influenced by the construction of the large foundation pit in the adjacent East New Town plot, the 40∼414 rings of the interval tunnel were damaged to varying degrees, including increasing of faulting, water leakage, and segment cracking.

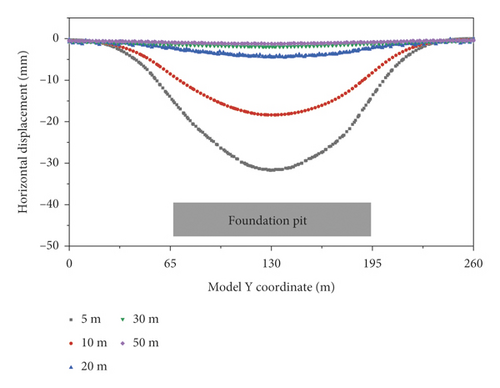

The excavation scope of the foundation pit is the location between the 60th ring and the 260th ring of the shield tunnel. As can be seen from Figure 3, during the excavation of the foundation pit, the tunnel had obvious lateral displacement and settlement displacement. The lateral displacement tended to be larger in the middle and smaller on both sides, and the maximum horizontal displacement was 34 mm. The overall settlement of the tunnel was obvious, with the maximum settlement of 20 mm. After all construction is completed, the cumulative settlement of the tunnel is 33.26 mm, and the vertical and horizontal convergent deformations are −23 mm and 28 mm, respectively. The tunnel settlement, vertical convergent deformation, and horizontal convergent deformation caused by foundation pit excavation accounted for 40%, 47.8%, and 42.9% of the final value, respectively (Table 2).

| Monitoring item | Final cumulative value (mm) | Cumulative maximum before pit bracing (mm) |

|---|---|---|

| Settlement | 160th ring: −33.36 | 251th ring: −13.4 |

| Vertical convergent deformation | 241th ring: −23 | 221th ring: −11 |

| Horizontal convergent deformation | 241th ring: −28 | 231th ring: −12 |

3. Numerical Model and Excavation Schemes

3.1. Numerical Model and Parameters

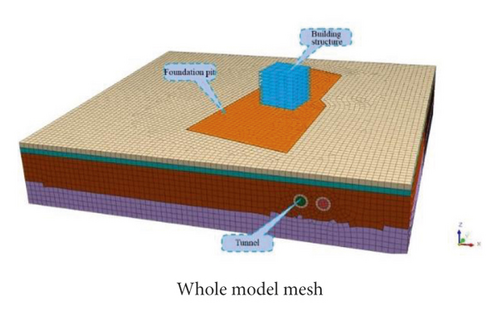

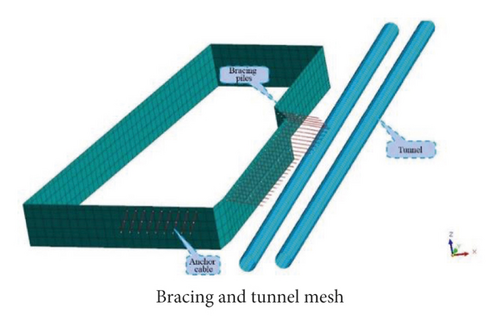

MIDAS-GTS is three-dimensional finite element analysis software for soil and tunnel. It includes almost all the analysis functions required for stress analysis and permeability analysis in the construction stage and can conduct visual and intuitive modeling for complex geometric models. The size of the calculation model was selected as 260 m × 220 m × 40 m (length × width × height), and the calculation model mesh is shown in Figure 4(a). The surface was taken as a free boundary, and the other five surfaces were all constrained in its normal deformation. The model was divided into 76,512 elements with 13,576 nodes. The inside structure position relationship in the model is shown in Figure 4(b). The modified Mole Coulomb failure criterion was used for the constitutive model of soil. Soil mechanical parameters are shown in Table 1. Other components of the model were simulated by the following methods: (1) solid elements were used in the soil around the model; (2) the shield segment and block structure were simulated by plate element; (3) the foundation pit retaining pile was converted to plate element simulation using equivalent stiffness principle; (4) steel bracing and concrete bracing were simulated using beam element; (5) the bolt adopted implantable beam element. At the same time, the excavation process of soil and the function of retaining structure were considered, and the variable load of 20 kN/m2 was considered.

3.2. Simulated Excavation Process

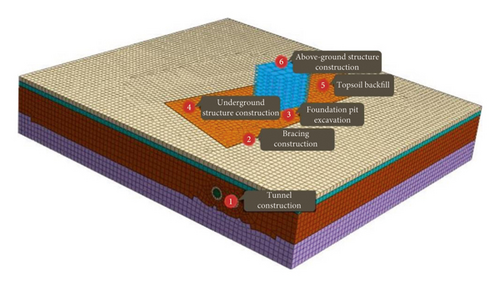

In order to simulate the influence of the whole plot development process on the tunnel, the construction steps were divided into six steps, including bracing construction, tunnel construction, foundation pit excavation, underground structure construction, basement backfill, and above-ground structure construction, as shown in Figure 5. Among them, since the design side did not provide a detailed construction organization plan, the model calculation was carried out in accordance with the most adverse working conditions when the excavation is completed at one time.

4. Result and Discussion

4.1. Tunnel Displacement

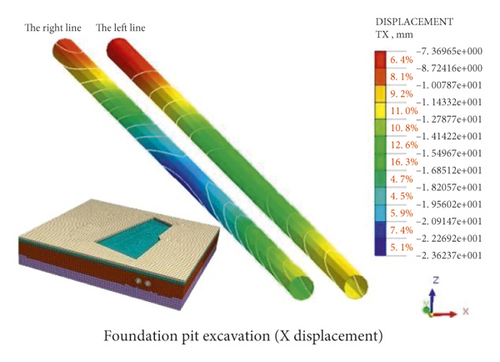

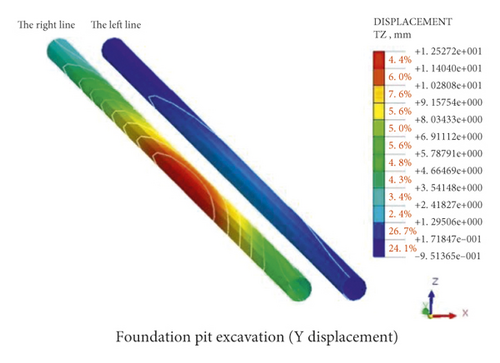

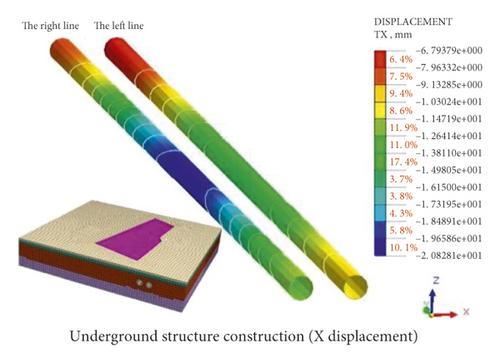

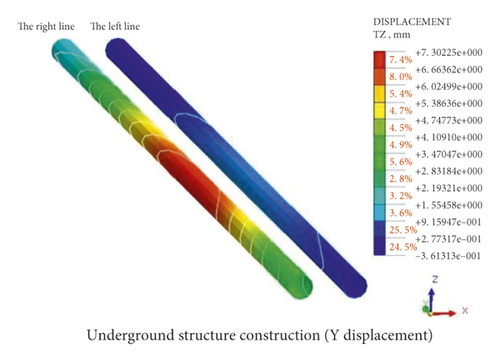

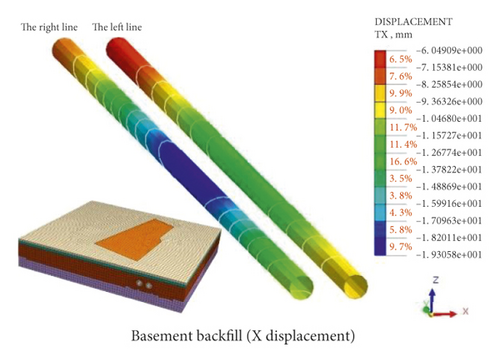

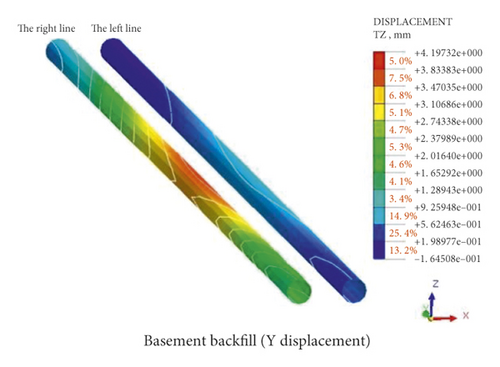

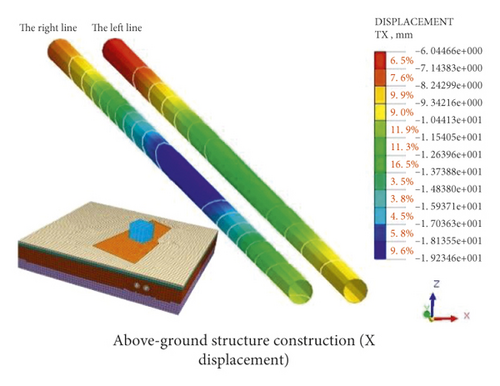

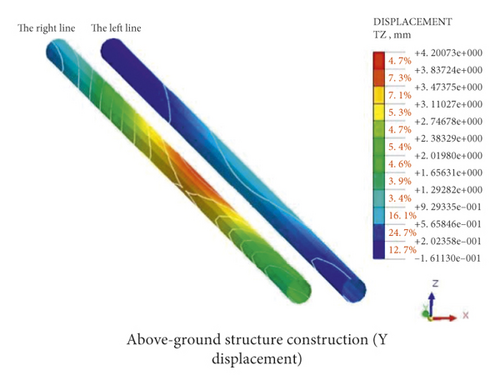

The tunnel completion stage is taken as the initial state, and the tunnel displacement is regarded as zero. Figure 6 shows the simulated tunnel displacement results of the four construction steps, including foundation pit excavation, underground structure construction, basement backfill, and above-ground structure construction. From these results, it can be seen that the horizontal displacement of shield tunnel towards the foundation pit is caused by the excavation of the foundation pit, and the uplift displacement of the tunnel is also produced. The maximum horizontal displacement is 23.6 mm, and the maximum settlement displacement is 4.2 mm. In the following steps, the tunnel displacement gradually rebounds. Among them, the influence of t above-ground structure construction on the tunnel is very small. In the final case, the cumulative horizontal displacement of the tunnel is 19.2 mm, and the cumulative settlement displacement is 4.2 mm. Compared with the field monitoring results in Section 2.2, it can be found that the calculated results can reflect the actual situation of foundation pit construction.

4.2. Sensitivity Analysis of Tunnel Segment Thickness

Due to the requirements of the fire evacuation platform, the inner diameter of the shield tunnel of Shaoxing Metro Line 1 was increased to 5.9 m, which is rare in current metro shield tunnel of China. Therefore, the matching of segment thickness with an inner diameter of 5.9 m is not clear. In this section, by changing the thickness of segments, the antideformation ability of segments with different thickness under foundation pit excavation was studied. Segment thickness was taken every 25 mm and ranges from 350 mm to 425 mm. Moreover, depths of foundation pit were taken as 8 m and 12 m, respectively, and the distances between tunnel and pit were also adjusted between 5 m and 50 m.

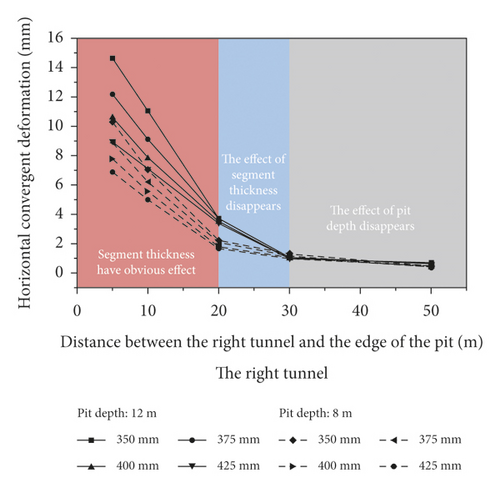

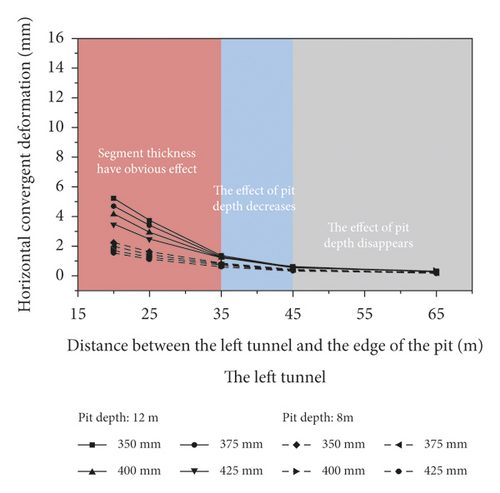

Under the influence of the excavation of the foundation pit, the soil outside the tunnel moves towards the inside of the foundation pit. However, the convergent deformation of the tunnel increases as the displacement of tunnel near the foundation pit is greater than that of tunnel far away from the foundation pit. The horizontal convergent deformation of the right tunnel with different distances from the foundation pit is shown in Figure 7(a). With the increase of the distance, the horizontal convergent deformation of the tunnel decreases continuously. When the distance is between 5 m and 20 m, the convergent deformation decreases linearly, and the thickening of segment could reduce the convergent deformation by 20%∼50%. At the same time, the thickening of segment could obviously reduce the convergence deformation value for deeper foundation pit. When the distance was between 20 m and 30 m, the effect of segment thickness decreased, and the increase of thickness could not significantly reduce the tunnel convergent deformation. When the distance was greater than 30 m, the convergent deformation tended to be stable, and the deformation of segments with different thickness was basically the same. In this case, the influence of the depth of foundation pit on the convergent deformation of tunnel no longer changed. The horizontal convergent deformation of the left line is shown in Figure 7(b), which is similar to that of the right line. The difference is that due to the distance from the foundation pit, the overall convergent deformation of the tunnel was small, and the effect of segment thickness reduced.

| Segment thickness (mm) | The distance between right tunnel and foundation pit (m) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pit depth: 8 m | Pit depth: 12 m | |||||||||

| 5 | 10 | 20 | 30 | 50 | 5 | 10 | 20 | 30 | 50 | |

| 350 | 87 | 194 | 867 | 1297 | 3570 | 55 | 97 | 382 | 1294 | 3555 |

| 375 | 91 | 197 | 876 | 1307 | 3578 | 60 | 102 | 396 | 1302 | 3521 |

| 400 | 94 | 199 | 884 | 1316 | 3600 | 63 | 109 | 403 | 1312 | 3646 |

| 425 | 96 | 204 | 890 | 1326 | 3611 | 69 | 114 | 412 | 1333 | 3655 |

As can be seen from the table, with the small distance between the tunnel and the foundation pit, the minimum relative curvature decreased continuously for the same excavation depth. When the distance was between 30 m and 50 m, the minimum relative curvature exceeded the standard value required by the standard, and protective measures should be taken. The minimum relative curvature of tunnel structures with different segment thicknesses was basically the same at the same distance, indicating that the increase of segment thicknesses had no obvious effect on the resistance to longitudinal deformation.

5. Conclusions

- (1)

According to the monitoring results of similar projects, the excavation of adjacent foundation pit will cause excessive overall deviation, settlement, and structural convergent deformation of shield tunnel, causing structure damage such as increasing of faulting, water leakage, and segment cracking. Among them, the absolute value of tunnel deformation caused by foundation pit excavation accounts for the largest proportion, more than 40%.

- (2)

The numerical simulation results of the adjacent foundation pit excavation of Shaoxing Metro show that the excavation of foundation pit causes excessive horizontal deformation and settlement deformation of tunnel structure and the deformation of the tunnel structure rebounded in the subsequent construction. The consistency between the numerical results and the monitoring results of type projects indicates that the model presented in this paper is correct and can be used to predict the construction process of adjacent foundation pit of Shaoxing Metro Line 1.

- (3)

The analysis of segment thickness and the distance between tunnel and foundation pit shows that the convergence deformation of tunnel increases with the decrease of the distance between tunnel and foundation pit, and the thickening of segment can significantly reduce the convergence deformation. With the increase of the distance, the thickening effect of the segment decreases. When the distance is greater than 30 m, the convergent deformation tends to be stable, and different thickness segments and foundation pit depth have little effect on the tunnel deformation. In addition, the increase of segment thickness has no significant effect on the resistance to longitudinal deformation. When the tunnel is less than 50 m from the foundation pit, additional protective measures should be taken to reduce the longitudinal deformation of the tunnel.

Conflicts of Interest

The authors declare that there are no conflicts of interest regarding the publication of this paper.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 51988101). Shaoxing Metro Group Co. Ltd. is greatly appreciated for providing financial support for this research.

Open Research

Data Availability

The data used to support the findings of this study are included within the article.