Optimal Selection of Earthquake Resisting Schemes for Jakarta-Bandung High-Speed Railway

Abstract

The Jakarta-Bandung high-speed railway is the first overseas project involving China’s high-speed railway. Owing to the high seismic intensity in this area, the optimal selection of earthquake resisting schemes is critical for short-span bridges, and such schemes are related to the safety and cost-effectiveness of the entire line. This study compares the safety and cost-effectiveness of four earthquake resisting schemes: (i) prestressed concrete (PC) simply-supported box beams using common spherical steel bearings; (ii) PC simply-supported box beams using seismic isolation bearings; (iii) steel-concrete (SC) composite simply-supported beams using seismic isolation bearings; (iv) reinforced concrete (RC) rigid frames. The results indicate that PC beams using more expensive seismic isolation bearings reduce the cost of the substructure, making it more cost-effective. In contrast, the scheme of SC composite beams is the most expensive one, and the associated maintenance costs are also the highest. Although the scheme of RC rigid frames is the cheapest among the evaluated schemes, it is only suitable for relatively stiff sites with low pier heights. Overall, PC beams with isolation bearings exhibit good seismic performance and are suitable for prefabricated construction; therefore, this scheme can be applied in various soil conditions with relatively low costs, and it is recommended for use throughout the entire Jakarta-Bandung high-speed railway.

1. Introduction

High-speed railway construction has entered a rapid development period all over the world. To reduce land coverage, the rule of “substituting a bridge for subgrade” is often adopted in the design and construction of high-speed railways. Bridges account for up to 70%–80% of the entire rail line in terms of length, and most are short-span bridges [1–6]. Therefore, selecting the optimal earthquake resisting scheme for short-span bridges is crucial to maximizing the safety, serviceability, and economy of high-speed railways in high seismic intensity regions. Such schemes are influenced by various factors, including the natural climatic conditions, the traffic requirements, and the local site-specific conditions. The beam must be sufficiently stiff to allow the trains to run smoothly enough to meet the high standards required for a high-speed railway. Meanwhile, the weight of the superstructure should be reduced to minimize the seismic response. Prestressed concrete (PC) simply-supported box beams are generally implemented for short-span bridges in China’s high-speed railways [1–6], whereas reinforced concrete (RC) rigid frame bridges are adopted for Japanese Shinkansen railways on a large scale [7, 8], and steel-concrete composite (SC) beams are often used in France [1].

For high-speed railway bridges in strong earthquake conditions, both ductility seismic and isolation seismic systems have been introduced by designers [9–25]. Kang et al.[9] evaluated the seismic damage to high-speed railway bridge components under various earthquake excitation intensities. Chen et al. [10] studied the seismic response of a high-speed railway simply-supported girder bridge. Wei et al. [11] investigated the seismic vulnerabilities of a high-speed railway bridge by considering track-bridge interactions. Li et al. [12, 13] studied the effects of seismic isolation on the seismic response of a high-speed rail prototype bridge in California. Xia et al. [14] investigated the seismic damage and seismic performance of various bridge types. Bai [15] compared structural form selections for small and medium-sized bridges along the Beijing-Shanghai high-speed railway in China. Xie et al. [16] systematically identify and quantify the damage states, repair actions, repair costs, and travel delay losses for China’s high-speed railway multi-span simply-supported bridge system. Cui et al. [17] conducted the seismic fragility and risk assessment of a typical high-speed continuous girder bridge. Guo et al. [18] investigated the seismic damage features of high-speed railway simply-supported bridges under near-fault earthquakes. Shan et al. [19] proposed a novel fragility analysis method for irregular bridges in high-speed railways. Meng et al. [20] assessed the design and seismic mitigation performance of shock absorbers for a railway bridge with a simply-supported beam. Zheng et al. [21, 22] studied the application of seismic devices, including friction pendulum bearings and E-shaped metallic dampers. Xia et al. [23] evaluated the seismic performance of friction pendulum bearings. Jiang et al.[24] studied the effects of friction-based fixed bearings on seismic performance of high-speed railway simply-supported bridge. Guo et al. [25] proposed an improved equivalent energy-based design procedure for seismic isolation system of simply-supported bridges in China’s high-speed railways. Other related research works include train-track-bridge interaction of high-speed railway bridges, seismic design method research of bridge bents, and so on. Guo et al. [26] studied the train-track-bridge interaction in high-speed railways and proposed a real-time hybrid simulation method using the moving load convolution integral method. Shi et al. [27] proposed a toggle BRB system for the seismic retrofit of bridge bents and the corresponding design method. Mitoulis et al. [28] conducted a cost-effective analysis related to the earthquake-resisting system of multi-span motorway bridges. However, limited studies are comparing the economy and safety of common earthquake resisting schemes applied to bridges on high-speed railways.

Indonesia’s Jakarta-Bandung high-speed railway represents a successful application and major breakthrough concerning the “going out” policy of China’s high-speed railway. It provides an important demonstration that supports the brand of “China’s high-speed railway” throughout the world. This study takes the short-span bridge of the Jakarta-Bandung high-speed railway as an example and compares the following bridge earthquake resisting schemes: (i) PC simply-supported box beams using common spherical steel bearings, (ii) PC simply-supported box beams using seismic isolation bearings, (iii) SC composite simply-supported beams using seismic isolation bearings, and (iv) RC rigid frames. The safety and cost-effectiveness of these four schemes are evaluated and compared in detail. The results provide a useful basis for the selection of the earthquake resisting systems throughout the entire line and offer a reference for similar high-speed railway projects in high seismic intensity regions.

2. Description of the Project and Earthquake Input

The total length of Indonesia’s Jakarta-Bandung high-speed railway is 142.3 km. The project is part of the high-speed railway line that connects Jakarta to Surabaya, which has a total length of approximately 800 km. The designed running speed is 350 km/h. After completing the railway, the traveling time from Jakarta to Bandung will be reduced from the current 3 hours to only 40 minutes. The high-speed railway will adopt a cooperation mode involving joint venture construction and management by China and Indonesia enterprises.

As the first “going out” project of China’s high-speed railway, the Jakarta-Bandung high-speed railway will apply the technical standards, surveys, designs, facilities, engineering construction, management, and operation of China’s high-speed railways, and it will promote China’s “one belt and one road” policy.

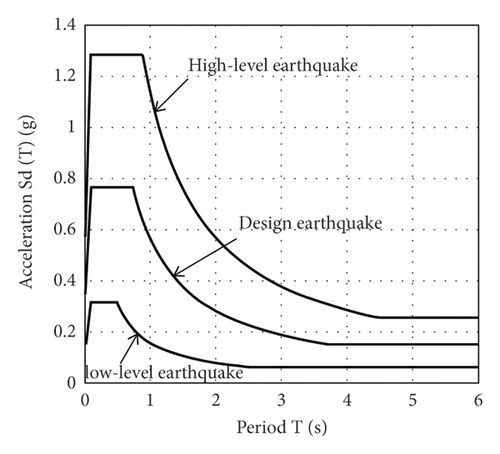

According to the seismic ground motion parameters zoning map developed based on the Indonesian code for seismic design of bridges [29], the peak acceleration along the Jakarta-Bandung high-speed railway line is equal to that of a site with a seismic intensity of 8 or 9 in China [30]. Therefore, the seismic response of bridges is a decisive parameter for selecting the resisting scheme. Moreover, comparative results depend on the geological conditions and seismic parameters of the site. The standard technical parameters are as follows: design speed = 350 km/h; track type = ballastless track; mainline design = double track; design load = Chinese ZK live load. The design parameters influencing the ground motion are as follows: site soil type = Type II (moderately firm soil where the interval range of the shear wave velocity is between 250 and 500 m/s). The peak acceleration and characteristic period are 0.14 g and 0.5 s, respectively, for low-level earthquakes (i.e., earthquake recurrence interval ≈50 years); the peak acceleration and characteristic period are 0.34 g and 0.74 s, respectively, for design earthquakes (i.e., earthquake recurrence interval ≈ 475 years); peak acceleration and characteristic period are 0.57 g and 0.89 s for high-level earthquakes (i.e., earthquake recurrence interval ≈ 2475 years). Figure 1 presents the design response spectra for these three earthquake levels. Time history analyses have been conducted by matching the seismic time curves against the spectra given in the code governing the seismic design of railway engineering in China (China Railway Code, an abbreviation for the code) [30].

3. Seismic Calculation Principles

The Eurocode for the earthquake resistance of bridge structures [31] dictates that in regions of moderate to high seismicity, it is generally preferable (for economic and safety reasons) to design a bridge with ductile behavior, i.e., to provide reliable means to dissipate a significant amount of the input energy under severe earthquake conditions. This is accomplished via an intended configuration of flexural plastic hinges or by using isolating devices.

In seismic bridge design specifications for the United States [32], for Seismic Design Category (SDC) C or D, all bridges and their foundations must have a clearly identifiable earthquake resisting system that satisfies the life safety criteria. Moreover, the design should be based on one of three earthquake resisting systems: (1) a ductile substructure with an essentially elastic superstructure (e.g., for conventional concrete bridges), where seismic energy can be dissipated through the plastic hinges in piers and bents; (2) an essentially elastic substructure with a ductile superstructure (e.g., only for steel superstructures), where ductility is derived from ductile elements in the pier cross-frames; (3) an elastic superstructure and a substructure with a fusion mechanism between the two (e.g., for seismically isolated structures and structures with supplemental energy dissipation devices, such as dampers, to control inertial forces transferred between the superstructure and substructure).

In China Railway Code [30], bridges in regions with seismic intensities >7 should undergo ductile checks of the RC piers under rare earthquake conditions. Additional mitigation and isolation design strategies can be applied for bridges in areas with higher seismic intensities.

Considering the codes or specifications of various countries, the two most applicable earthquake resisting systems are ductility seismic and isolation seismic systems. In this study, the first and fourth schemes involve ductility seismic systems, whereas the second and third schemes use isolation seismic systems.

The Jakarta-Bandung high-speed railway is the first overseas project of China’s high-speed railway, and therefore, the seismic design of bridges should be completed according to China Railway Code [30]. The three levels of seismic fortification goals are as follows: (1) low-level earthquakes (63% probability exceedance in 50 years) cause the bridges to sustain negligible or slight damage, and they can still work elastically; (2) design earthquakes (10% probability exceedance in 50 years) cause damage, but bridges can be readily inspected and repaired; (3) high-level earthquakes (2% probability exceedance in 50 years) may induce significant damage to the bridges, but they would not collapse.

For the seismic design of the isolation system, pier reinforcement should be monitored under low-level earthquake conditions in the same way. In a rare earthquake scenario, piers should remain elastic and may sustain slight damage owing to the protection of isolation devices. Moreover, the working conditions of the isolation devices should be checked regularly to ensure proper functioning under rare earthquake conditions.

4. Prestressed Concrete Simply-Supported Box Beams with Common Bearings

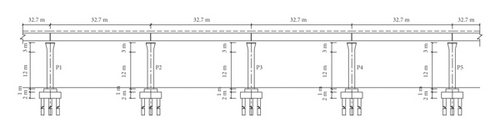

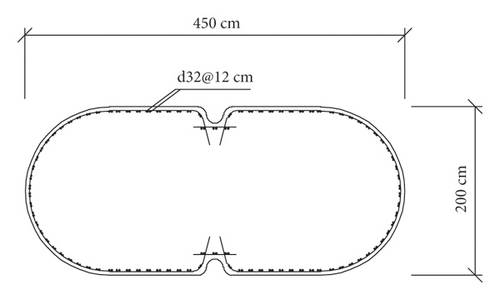

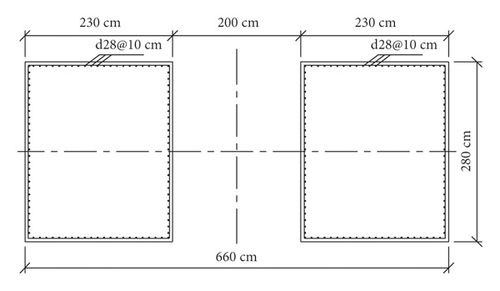

PC simply-supported box beams are generally implemented for short-span bridges along China’s high-speed railway. This structure has various advantages, including high stiffness, simple working mechanism, and beautiful appearance. Moreover, PC beams can be constructed quickly using a prefabricated construction method. The most extensively used beams have a span of 32 m. The calculated length of the beam is 31.5 m, and the total length is 32.6 m. Since the gap between the adjacent beams is 0.1 m, the standard span of the beam is 32.7 m as shown in Figure 2.

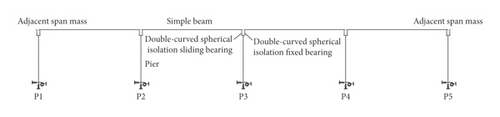

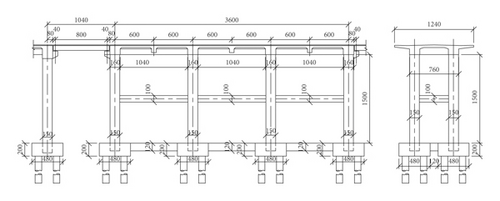

Therefore, PC simply-supported box beams with a span of 32 m were used in this study. According to the Jakarta-Bandung high-speed railway statistics, the average height of the piers is approximately 15 m. A multi-span simply-supported beam with a height of 15 m is depicted in Figure 2.

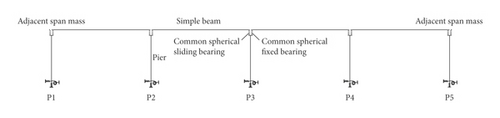

In order to eliminate the boundary effect, the four-span 32-m beam was taken as an example. Common spherical steel bearings were used on the pier top. There were two fixed bearings and two longitudinal sliding bearings. Soil springs under the bottom of the piers were modeled to simulate the interactions between the foundation and the structures. The overall computed seismic beam model is shown in Figure 3x, y and z axes represent the longitudinal, transverse, and vertical axis of the bridge, respectively.

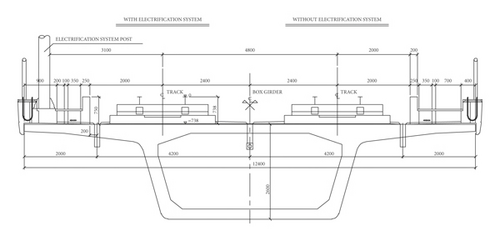

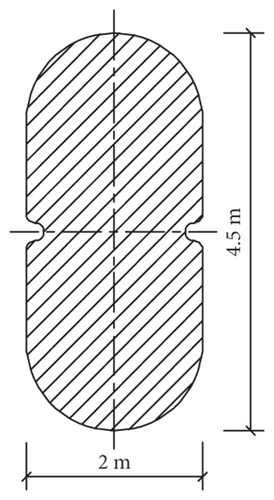

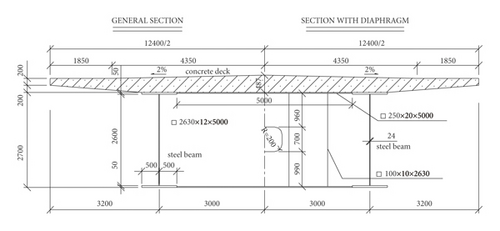

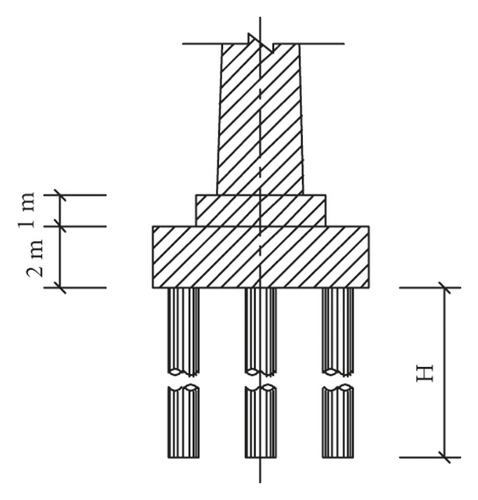

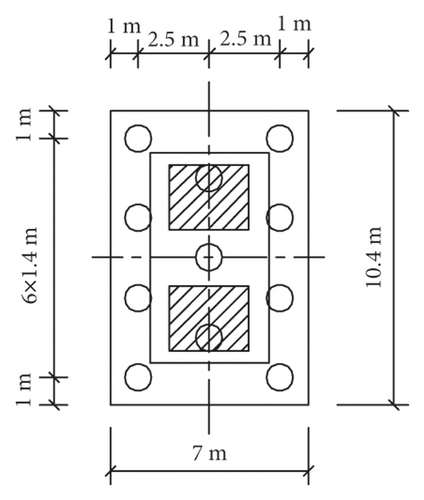

The cross-section of the deck is a box-girder with a total width of 12.4 m (Figure 4). The bridge deck arrangement for a double ballastless track is also shown in Figure 4. The piers are wall-like columns (Figure 5), and their cross-sections are rounded. The bridge piers are founded on Type II ground, as defined by China Railway Code [30], via 11 pile groups, each with a diameter of 1.0 m. Concrete C50 and C40 and steel rebar HRB400 (Hot-rolled Ribbed Bar) as defined in Chinese code for the design of concrete structures of the railway bridge and culvert [33] were used in the scheme. The mechanical properties of concrete and steel rebar are shown in Tables 1 and 2, respectively. The concrete of the beam is C50, and the concrete of the piers, pile caps and piles is all C40. The primary load-bearing steel rebar used in the piers is HRB400. The longitudinal cross-section of the common steel fixed bearings is shown in Figure 6.

| Concrete grade | C50 | C40 |

|---|---|---|

| Elastic modulus E(MPa) | 35500 | 34000 |

| Shear modulus G(MPa) | 15265 | 14620 |

| Poisson’s ratio μ | 0.2 | 0.2 |

| Axial compression strength of concrete fc(MPa) | 33.5 | 27 |

| Axial tensile strength of concrete fct(MPa) | 3.1 | 2.7 |

| Coefficient of linear expansion | 0.00001 | 0.00001 |

| Steel rebar Grade | HRB400 |

|---|---|

| Standard tensile strength fsk(MPa) | 400 |

| Elastic modulus Es(MPa) | 2.0 × 105 |

The total flexibility of the foundations was taken into account by implementing linear soil spring elements. The translational and rotational stiffness values of the springs are given in Table 3. These values adopted were determined by the geotechnical in situ tests conducted for the bridge.

| K x | (kN/m) | 5.53·106 |

| K y | (kN/m) | 6.09·106 |

| K z | (kN/m) | 6.07·107 |

| K rx | (kN m/rad) | 7.84·108 |

| K ry | (kN m/rad) | 5.29·108 |

| K rz | (kN m/rad) | 1.00·1012 |

The seismic design was prepared in accordance with China Railway Code [30]. Pier reinforcement should be checked under low-level earthquake conditions. The strength of the connection between the superstructure and substructure should be monitored under the design earthquake scenario, and ductility calculations should be performed to prevent collapse under high-level earthquake conditions.

4.1. Low-Level Earthquake

A low-level earthquake controls the reinforcement ratio of the piers. The peak ground acceleration of the low-level earthquake is 0.14 g, which is equal to a seismic intensity of 9 in the China Railway Code [30]. Table 4 gives the pier bottom internal forces of the P3 pier following longitudinal and transverse earthquakes. The HRB400 reinforcement bar with a diameter of 32 m was used, and the reinforcement ratio was 1.63%, as shown in Figure 7. For the longitudinal earthquake, the largest stress of the concrete and steel rebar is 13.5 MPa and 300.0 MPa, respectively. For the transverse earthquake, the largest stress of the concrete and steel rebar is 15.9 MPa and 308.9 MPa, respectively.

| Pier bottom internal force | Longitudinal earthquake | Transverse earthquake |

|---|---|---|

| Axial force, Fx(kN) | 16270 | 16270 |

| Longitudinal shear force, Fy(kN) | 4476 | 0 |

| Transverse shear force, Fz(kN) | 0 | 5551 |

| Longitudinal moment, My(kN·m) | 64709 | 0 |

| Transverse moment, Mz(kN·m) | 0 | 94126 |

4.2. Design Earthquake

The longitudinal force of the bearing should be checked under the design earthquake scenario. The ratio between the longitudinal force and the vertical capacity can then be calculated. The longitudinal force of the bearing is approximately 5605 kN, which is 1.25 times the vertical bearing capacity of 4500 kN. Generally, along with the increasing of the horizontal force of the bearing, the difficulty of manufacturing is also increasing. Thus, the cost of the bearing would increase significantly.

4.3. High-Level Earthquake

Under high-level earthquake conditions, ductility analysis of the pier bottom must be conducted to determine whether the bridge pier is damaged. If ductile damage has occurred, the nonlinear displacement ductility ratio is calculated. According to provision 7.3.3 of the China Railway Code [30], the allowable displacement ratio is 4.8. For the studied bridge, the displacement at the yielding moment is 9.5 cm, and the ultimate displacement is 22.59 cm. Thus, the calculated ductility ratio is 2.38, which is smaller than the allowable ratio of 4.8, and the performance level required for “no-collapse” under rare earthquake conditions is satisfied.

According to capacity protection theory, the piles should work elastically before the piers suffer from plastic damage. Therefore, the pile length and reinforcement area should be increased. Table 5 presents the corresponding pile length and reinforcement area under low-level and high-level earthquake conditions.

| Item | Low-level earthquake | High-level earthquake | Difference |

|---|---|---|---|

| Reinforcement area(cm2) | 102.1 | 204.0 | 101.9 |

| Pile length(m) | 48 | 56 | 8 |

| Number of piles | 11 | 11 | 0 |

| Rebar(t) | 42.3 | 98.7 | 56.4 |

| Concrete(m3) | 414.7 | 483.8 | 69.1 |

According to Table 5, following a low-level earthquake, the calculated pile length is 48 m, and the reinforcement area is 102.1 cm2. Following a high-level earthquake, capacity protection theory indicates that the pile length should increase to 56 m, while the reinforcement area should increase to 204.0 cm2. The concrete volume increases to 483.8 m3, and the rebar weight increases to 98.7 t. The integrated unit price of rebar is RMB 4342.9, and the integrated unit price of concrete is RMB 1368.7. Thus, the total cost increases by approximately 339k RMB.

5. Prestressed Concrete Simply-Supported Box Beams with Isolation Bearings

The piers of bridges with common spherical steel bearings in high-intensity seismic regions may suffer significant damage, which is difficult and costly to repair. Moreover, the bearings themselves may also be damaged, and the longitudinal and transverse restrainers would likely be broken. The fixed bearings would become movable bearings and, in consequence, the entire structural system would be a pure sliding friction system. Although such a system (with no restoring ability) is beneficial for the substructures, the superstructures cannot be restored to their original state.

Bridges with isolation bearings exhibit better seismic performance. Under rare earthquake conditions, the shear key of the bearings would be broken (as designed), and the upper and bottom bearing plates would slide. This mitigation effect sufficiently protects the substructure, including the piers and piles. Moreover, this structural system has self-restoring abilities. After a rare earthquake, the bearings can readily be repaired. Therefore, a PC simple beam with isolation devices is included in the comparison.

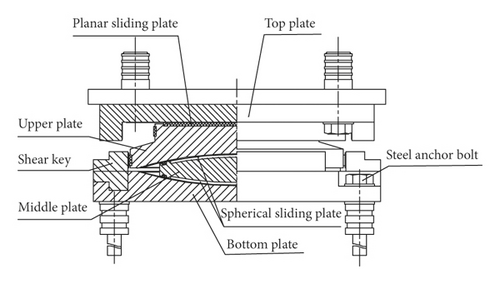

The most common isolation devices include lead rubber bearings, high damping laminated rubber bearings, elastoplastic steel damping bearings, and double-curved spherical seismic isolation bearings, among others. The vertical loading capacity and durability are limited for the lead rubber bearings and high damping laminated rubber bearings. The design life of a rubber bearing is approximately 30 years. Therefore, during the 100-year design life of the bridge, several bearing replacements are required. It is very costly and difficult to replace the numerous bridge bearings along the entire high-speed railway line, which is fully closed. However, the design life of a steel bearing can reach 100 years with normal maintenance and rehabilitation procedures. In the case of elastoplastic steel damping bearings, the affordable bending times of the damping components are limited, and permanent yielding deformation would occur after a rare earthquake. It is costly to replace the elastoplastic components, and therefore, they are not recommended. Double-curved spherical isolation bearings, which have a large loading capacity, good durability, and self-restoring capacity, are suitable for the seismic design of high-speed and general-speed railway bridges.

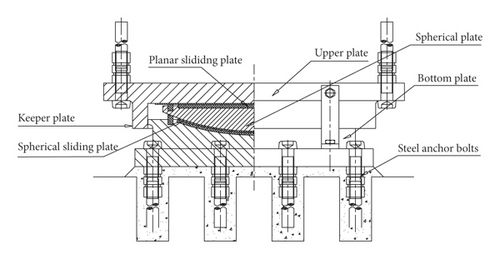

When using common double-curved spherical isolation bearings, the beam will rise slightly when moving because of the influence of the double sphere. This slight rise is tolerable for common highway bridges, while it is intolerable for high-speed railway bridges. Therefore, specific double-curved spherical seismic isolation bearings were designed and developed for railway bridges. Considering the features of common double-curved spherical isolation bearings, a planar sliding plate was added to the bearings to prevent the rise during operation. The railway double-curved spherical seismic isolation bearings have been applied in several national projects in China, including the Sutong Yangtze River Bridge, Hongkong-Zhuhai-Macao Major Bridge, and bridges along the Fuzhou-Xiamen Railway.

Thus, the railway double-curved spherical seismic isolation bearings were adopted in this study, and the corresponding overall seismic computational model is shown in Figure 8. The beam and pier sizes and the materials adopted are as same as the scheme (i).

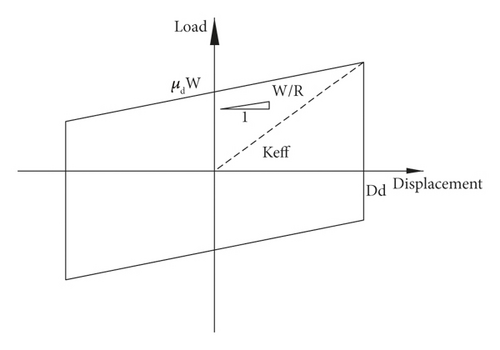

The curved surface radius of the double-curved spherical seismic bearings is 2.3 m, and the friction coefficient under earthquake is 0.06. The vertical loading capacity of the bearings is 4500 kN. The longitudinal cross-section of railway double-curved spherical seismic isolation bearings is shown in Figure 9. The hysteresis curve of bearings is given in Figure 10:

Where W is the vertical force of the bearings under dead load; R is the curved surface radius of the bearing; Dd is the design horizontal displacement of the bearings; μd is the sliding frictional coefficient of the bearings.

The two-stage seismic design was carried out using the railway's double-curved spherical seismic bearings according to China Railway Code [30].

5.1. Low-Level Earthquake

Under low-level earthquake conditions, the isolation devices of the simple beam would not function. Therefore, the mechanical performance of the bridges is the same with the simple beam as it was with common spherical bearings. The reinforcement ratio is also the same. The HRB400 reinforcement bar with a diameter of 32 m was used, and the reinforcement ratio was 1.63%.

5.2. High-Level Earthquake

With the isolation devices, the performance level of the bridges can be enhanced. In general, after a rare earthquake, the bridges work elastically or sustain little damage. Table 6 presents the pier bottom internal forces of the middle pier (P3) after a rare earthquake.

| Pier bottom internal force | Longitudinal earthquake | Transverse earthquake |

|---|---|---|

| Axial force, Fx(kN) | 16002 | 16002 |

| Longitudinal shear force, Fy(kN) | 4012 | 0 |

| Transverse shear force, Fz(kN) | 0 | 3970 |

| Longitudinal moment, My(kN·m) | 55921 | 0 |

| Transverse moment, Mz(kN·m) | 0 | 62175 |

| Mitigation rates | 78.9% | 83.8% |

According to Table 6, the mitigation rates for longitudinal and transverse earthquakes reach 78.9% and 83.8%, respectively. The pier bottom internal forces following the high-level earthquake are lower than the corresponding forces of the low-level earthquake when the isolation devices are operating. The reinforcement can be calculated based on the internal forces of the low-level earthquake, and therefore, the piers remain elastic after a rare earthquake.

Owing to the favorable seismic effect, the seismic response to the rare earthquake does not dictate the design, and capacity protection design is not needed. With the isolation devices, the pile length and reinforcement under low-level earthquake conditions are adopted directly. Table 7 provides the mechanical status of various components under different loading cases.

| Load case | Piers | Piles | Bearings |

|---|---|---|---|

| Normal operating condition | Elastic | Elastic | Normal |

| Low-level earthquake | Elastic | Elastic | Normal |

| 1.1 times low-level earthquake | Elastic | Elastic | Broken |

| Design earthquake | Elastic | Elastic | Broken |

| High-level earthquake | Elastic | Elastic | Broken |

It is clear that the piers and piles of the bridges with the isolation bearings all remain elastic. Only the shear keys of the bearings are broken, and these are easily repaired. Thus, the bridges have a higher seismic performance.

6. Steel-Concrete Composite Beams with Isolation Bearings

The SC composite beams are lighter than concrete beams, and therefore, they exhibit smaller seismic responses. Compared with pure steel beams, SC beams save steel materials, emit less noise, and exhibit better fatigue performance. SC beams are effective for the construction of high-speed railway bridges, especially in conditions involving limited clearance or where they are used as adjustable span beams.

The potential applicability of this type of beam in the high-intensity seismic region of the Jakarta-Bandung high-speed railway was studied. The weight of the superstructures can be reduced to a certain degree, and therefore, the seismic forces of the substructures can also be decreased.

The calculated span of the SC composite bridge is 31.5 m, and the total length of the beam is 32.6 m. According to the train-bridge coupling vibration results, the height of the steel beam is 2.7 m, and the steel parts adopt a double-I-shaped section. The thicknesses of the top and bottom steel plates are each 50 mm, and the thickness of the web plate is 24 mm, with a stiffening rib thickness of 20 mm. The concrete bridge deck is cast-in-situ. The overall seismic computational model is the same as scheme (ii) (PC simply-supported box beams using seismic isolation bearings), as shown in Figure 8.

Q370qE steel as defined in Chinese code for the design on steel structure of railway bridge [34] was used in the scheme. The mechanical properties of steel plates are shown in Table 8. The SC beam comprises a Q370qE steel beam and C50 concrete deck. The concrete of the piers, pile caps, and piles is all C40. The primary load-bearing steel rebar used in the piers is also HRB400.

| Steel plate grade | Q370qE |

|---|---|

| Elastic modulus Es(MPa) | 2.1 × 105 |

| Shear modulus G(MPa) | 8.1 × 104 |

| Poisson’s ratio μ | 0.3 |

| Coefficient of linear expansion | 0.000012 |

| Axial allowable strength [σ](MPa) | 210 |

| Bending allowable strength[σ](MPa) | 220 |

| Allowable shear strength [τ](MPa) | 120 |

The cross-section of the SC composite beam is shown in Figure 11.

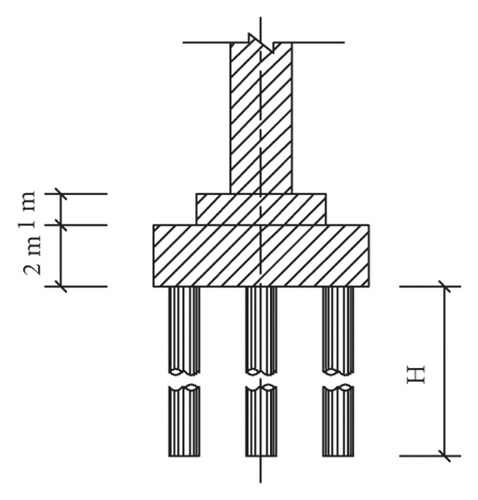

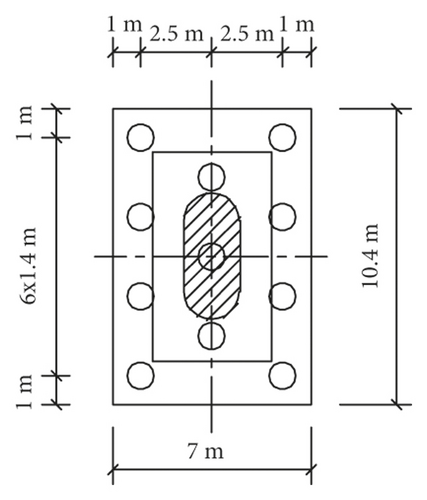

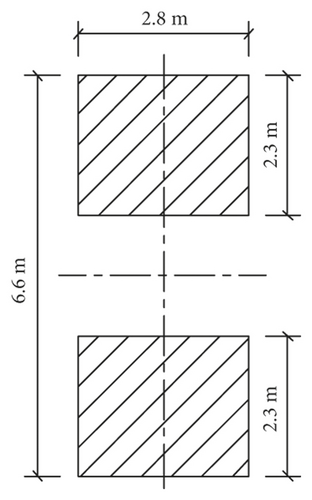

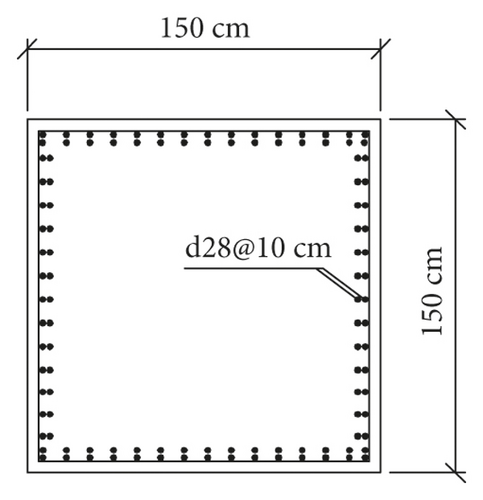

The piers are double-column piers (height = 15 m), and the cross-section of the piers and foundation pile plan are shown in Figure 12.

Considering the inherent defects of common spherical steel bearings, the double curved spherical seismic isolation bearings were used in this scheme. Although the no-collapse performance after a rare earthquake can be reached through rational reinforcement, significant damage cannot be avoided for SC composite beams with common spherical steel bearings. According to the calculated results of scheme (ii) (P.C. simply-supported box beams using seismic isolation bearings), although the isolation devices are more expensive than common bearings, the total cost is lower because of the action of isolation devices. Two-stage seismic design can therefore be conducted according to China Railway Code [30].

6.1. Low-Level Earthquake

Low-level earthquakes control the reinforcement ratio of the piers. The peak ground acceleration of a low-level earthquake is 0.14 g. Table 9 shows the pier bottom internal forces of the P3 pier under longitudinal and transverse earthquake conditions. The HRB 400 reinforcement bar with a diameter of 28 mm was used, and the reinforcement ratio was 0.98%, as shown in Figure 13. For the longitudinal earthquake, the largest stress of the concrete and steel rebar is 13.3 MPa and 297.8 MPa, respectively. For the transverse earthquake, the largest stress of the concrete and steel rebar is 9.0 MPa and 163.4 MPa, respectively.

| Pier bottom internal force | Longitudinal earthquake | Transverse earthquake |

|---|---|---|

| Axial force, Fx(kN) | 7393 | 7393 |

| Longitudinal shear force, Fy(kN) | 2302 | 0 |

| Transverse shear force, Fz(kN) | 0 | 2673 |

| Longitudinal moment, My(kN·m) | 27260 | 0 |

| Transverse moment, Mz(kN·m) | 0 | 13918 |

6.2. High-Level Earthquake

With the isolation devices, the seismic performance of the bridges increases. In general, after a rare earthquake, the bridges work elastically or sustain little damage. Table 10 presents the pier bottom internal forces of the middle pier (P3) after a rare earthquake. The mitigation rates for longitudinal and transverse earthquakes reach 88% and 87%, respectively. The pier bottom internal forces of the high-level earthquake are less than those of low-level earthquakes when the isolation devices are operating. The reinforcements are monitored according to the internal forces of a low-level earthquake, and therefore, the piers remain elastic after a rare earthquake.

| Pier bottom internal force | Longitudinal earthquake | Transverse earthquake |

|---|---|---|

| Axial force, Fx(kN) | 7270 | 7270 |

| Longitudinal shear force, Fy(kN) | 2125 | 0 |

| Transverse shear force, Fz(kN) | 0 | 1877 |

| Longitudinal moment, My(kN·m) | 21349 | 0 |

| Transverse moment, Mz(kN·m) | 0 | 8796 |

| Mitigation rates | 88.0% | 87.0% |

7. Reinforced Concrete Rigid Frames

The RC rigid frame scheme is economical and has a simple structure, good mechanical performance, good integrity, and facile construction. As a result, this structural system is widely used in various countries, especially in Japan’s Shinkansen. In China, many RC rigid frame bridges have been used, e.g., in the Beijing-Shanghai high-speed railway and Datong-Xi’an passenger dedicated line.

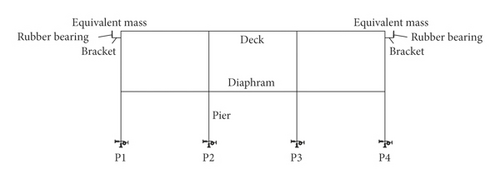

The RC rigid frame scheme was evaluated in the context of the Jakarta-Bandung high-speed railway. One unit of RC rigid frame bridge comprises a 3 × 12 m rigid frame and an 8-m simple plate. The total length of the structure is 46.4 m, and the double-column piers have a transverse distance of 6 m between columns. The width of the deck is 12.4 m, and the height of the rigid frame is 15 m. The heights of the cross beams at the two ends and in the middle are 1.48 m and 1.1 m, respectively. The elevation and cross-section of the RC rigid frame are depicted in Figure 14.

A finite element analysis model was built using the Midas Civil software program as shown in Figure 15. Space beam elements were used to model the piers and beams. The secondary dead loads were transferred to mass. Soil springs were modeled under the bottom of the piers to simulate the interactions between the foundation and the structures. The RC rigid frame comprises C40 concrete and an HRB400 steel rebar.

7.1. Low-Level Earthquake

Low-level earthquakes control the reinforcement ratio of the piers. Taking P2 piers (see Figure 15) as an example, Table 11 presents the pier bottom internal forces under longitudinal and transverse low-level earthquakes. The HRB 400 rebar with a diameter of 28 mm was used, and the reinforcement ratio was 3.06%, as shown in Figure 16. For the longitudinal earthquake, the largest stress of the concrete and steel rebar are 11.8 MPa and 206.0 MPa, respectively. For the transverse earthquake, the largest stress of the concrete and steel rebar are 8.7 MPa and 166.1 MPa, respectively.

| Pier bottom internal force | Longitudinal earthquake | Transverse earthquake |

|---|---|---|

| Axial force, Fx(kN) | 1179 | 210 |

| Longitudinal shear force, Fy(kN) | 1100 | 0 |

| Transverse shear force, Fz(kN) | 0 | 1300 |

| Longitudinal moment, My(kN·m) | 7653 | 0 |

| Transverse moment, Mz(kN·m) | 0 | 5804 |

7.2. High-Level Earthquake

The no-collapse performance under rare earthquake conditions should be satisfied. According to China Railway Code [30], when the outermost steel rebar begins to yield, the displacement at this moment is defined as the yielding displacement of the piers. Taking the P2 piers as an example, under a longitudinal earthquake, the displacement at the yielding moment is 8.56 cm, while the ultimate displacement is 12.42 cm. Thus, the calculated ductility ratio is 1.45, which is smaller than the allowable ratio of 4.8. Under a transverse earthquake, the displacement at the yielding moment is 7.42 cm, and the ultimate displacement is 11.68 cm. Thus, the calculated ductility ratio is 1.57, which is also smaller than the allowable ratio of 4.8. The no-collapse performance under rare earthquake conditions is therefore satisfied. For an RC rigid frame bridge under a high-intensity earthquake, the piers will yield at the pier bottom, and ductility hinges are formed to dissipate the seismic energy.

8. Technical and Economic Comparison

For the 32-m simply-supported box beam, a prefabricated erection method was adopted. The overall cost of the bridges considers the cost of the prefabricated yards and the temporary roads. For a simply-supported bridge, the erection cost of a simple beam is approximately 220k RMB. For the RC rigid frame bridge, full framing is used for the construction, and the cost for one unit of the frame is approximately 593k RMB.

Economic analysis was conducted for the four evaluated schemes, and the costs of the substructures and superstructures are shown in Table 12.

| Item | PC simple beam (common bearing) | PC simple beam (isolation bearing) | SC composite beam (isolation bearing) | RC rigid frame |

|---|---|---|---|---|

| Piles(k RMB) | 1516.7 | 1177.7 | 905 | 1851.3 |

| Piers(k RMB) | 412.3 | 412.3 | 285 | 785.6 |

| Pile caps(k RMB) | 201.4 | 201.4 | 205 | 392.1 |

| Foundation + Piers(k RMB) | 2130.4 | 1791.4 | 1495 | 3029.0 |

| Beams + Bearings (k RMB) | 1789.9 | 1839.9 | 2230 | 1950.3 |

| Total costs(k RMB) | 3920.3 | 3631.3 | 4062 | 4979.2 |

| Cost indicator per meter (k RMB/per meter) | 120.255 | 111.390 | 124.220 | 107.311 |

Overall, the cost of RC rigid frames is the lowest among the four evaluated schemes, whereas the cost of SC composite beams is the highest. The cost of PC simply-supported box beams with isolation bearings is 7.4% cheaper than scheme (i) (PC simple beams with common bearings), whereas the cost of SC composite beams is 3.3% more expensive than scheme (i) and the cost of RC rigid frames is 11.0% cheaper than scheme (i). In conclusion, RC rigid frames are advantageous in terms of costs. Table 13 presents a technical comparison of the four schemes considering parameters besides costs.

| Items | PC simple beam (common bearing) | PC simple beam(isolation bearing) | SC composite beam (isolation bearing) | RC rigid frame |

|---|---|---|---|---|

| Structural system | Static determinate | Static determinate | Static determinate | Static indeterminate |

| Construction method | Precast; fast | Precast; fast | Factory manufacture for steel beams, cast-in-situ for concrete deck; medium | Cast-in-situ; slow |

| Seismic system | Ductility system | Isolation system | Isolation system | Ductility system |

| Low-level earthquake | Elastic | Elastic | Elastic | Elastic |

| High-level earthquake | Piers damaged; difficult to repair | Piers elastic, shear key broken; easy to replace | Piers elastic, shear key broken; easy to replace | Piers damaged; difficult to repair |

According to investigations in Indonesia, SC composite beams are rarely used, and the corresponding design, construction, and maintenance experiences are lacking. Since Indonesia is located in a tropical rainforest zone, there is abundant rain throughout the year, and the air humidity is ∼80%. The railway line traverses a sea climate, which makes maintenance and rehabilitation difficult and costly. Thus, considering the lifetime costs, it is even more expensive. Moreover, the noise of SC composite beams is higher than that of concrete beams, which can increase the damping of the structure, thereby reducing the vibration and noise of the bridge. In contrast, concrete beams have advantages in terms of maintenance and rehabilitation, and have less noise pollution and better durability. Therefore, concrete beams are generally preferred.

Considering the overall structural systems, for a simple beam, advanced isolation devices can be implemented in the seismic design because of the favorable separation between piers and beams, leading to a better seismic performance. The integrity of the RC rigid frame is better because of the rigid pier-beam connection. Therefore, only a ductile design method can be applied (at the price of pier damage). From the perspective of the project timeline, PC beams are faster to build because of their construction method (i.e., prefabricated erection). In contrast, the RC rigid frames are constructed using a full framing method, and the construction period is the longest. The construction period for SC composite beams is between that of PC beams and RC rigid frames. Although the scheme of RC rigid frames has economic advantages, its overall applicability is relatively low. Under high-level earthquake conditions, piers would undergo significant damage, which would be difficult to repair. Earthquakes in Japan have caused massive disruption of RC rigid frame bridges, leading to significant economic losses for the north-eastern Shinkansen [8]. The present study indicates that PC simply-supported beams with double-curved spherical seismic isolation bearings are optimal for the entire railway line. The other schemes can also be applied to some specific bridges.

9. Conclusions

- (1)

PC simply-supported beams are generally constructed using a prefabricated method, and the construction quality can be guaranteed. The construction form and devices can be used repeatedly, and the beams are suitable for large-scale manufacturing. These simple beams have static determinate structures and are suitable for various types of soils.

- (2)

PC simply-supported beams are connected to the piers through bearings, and therefore, advanced isolation bearings or other energy dissipation devices can be applied. The seismic performance of the bridge is thus improved, and the total cost of the project can be minimized. Under high-level earthquake conditions, the shear key can easily be replaced after broken. Although the isolation bearings are more expensive than common spherical steel bearings, the cost of the substructure can be reduced to a larger extent. The total cost is, therefore, smaller for beams with isolation bearings.

- (3)

The SC composite beam is the most expensive, especially when considering the subsequent costs associated with maintenance and rehabilitation. Moreover, SC composite beams exhibit less rigidity and require longer construction processes than concrete beams. The noise from SC composite beams is also relatively larger than from concrete beams.

- (4)

In RC rigid frame bridges, the piers and beams are rigidly connected, and the advanced isolation devices cannot be integrated into this system. Therefore, only a ductile design method can be used (at the price of bridge pier damage). Moreover, RC rigid frame bridges, which are indeterminate structures, are not applied to soft site regions. The cast-in-situ construction method requires a longer period of time and more manpower, and the RC rigid frame bridges show only limited economic advantages.

In conclusion, considering their high seismic performance, convenient construction, and beam type integrity, the PC simply-supported beams with isolation bearings are recommended for use throughout the entire railway line of the Jakarta-Bandung high-speed railway. Considering the economic advantages of RC rigid frame bridges, this bridge type can be employed for certain locations with relatively low pier heights when the bridge girder erection machine and transporting girder vehicle are difficult to run, but the soil conditions are suitable and the site allows for full framing construction.

Conflicts of Interest

The authors declare no conflicts of interest.

Acknowledgments

The authors would like to acknowledge the financial support from the Fundamental Research Funds for the Central Universities, CHD (Grant no. 300102212518), the National Natural Science Foundation of China (Grant No.52068026), the Scientific Research Project of Huangshan University (Grant no. 2020xhwh013), and a Talent Startup Project of Huangshan University (Grant no. 2019xkjq009).

Open Research

Data Availability

The data presented in this study are available on request from the corresponding author.