Improved Cluster Intelligent and Complex Optimization Algorithm for Power Equipment CAD-Assisted Intelligent Operation and Maintenance

Abstract

By using the data collected by the cluster intelligent and complex optimization of the power system equipment, the cluster intelligent and complex optimization algorithms are introduced into the CAD-aided intelligent operation and maintenance of power system equipment (CAD-IOMPSE). Based on this, the CAD-aided intelligent operation and maintenance graph of power system equipment is used to apply the cluster intelligent complex data contained in the quality inspection of the different types of data obtained to restrict the relationship between different entities for the value of knowledge contained in the collected power data in the operation process and control stage of the power system. According to the types of equipment with problems in the operation of power system, the defects and problems are quickly diagnosed to quickly locate the problems and give solutions. Finally, the results of example analysis show that compared with the traditional naming entity recognition algorithm, BiLSTM-softmax and Seq2Seq-Attention model, the algorithm in this study is better than the traditional algorithm in the three evaluation index values of accuracy, recall, and F1 value.

1. Introduction

In the CAD-aided intelligent operation and maintenance of power system equipment, a lot of data analysis that can reflect the operation of power system equipment has been accumulated [1, 2]. This data can show the historical problems and the corresponding solutions of power system equipment. For a long time, the analysis of data has not been used effectively and is usually stored in the data system [3, 4]. In addition, due to the defects of the power system equipment functions, the relative complexity of operating conditions, the professional knowledge, and the long-term accumulated experience of maintenance personnel are needed in the process of dealing with power system equipment problems to a certain extent [5, 6]. If the historical failures can be processed and used using the cluster intelligent and complex optimization algorithms and the processing case analysis results are stored in the data platform, the power system equipment maintenance case processing database can be constructed, which is convenient for maintenance personnel in different areas, real-time query, learning, and experience reference to better exchange and share experiences with each other, and then can quickly deal with faults. The historical cases are analyzed that can be used for reference, which will help new maintenance personnel quickly mastering the operation and maintenance of power system equipment and quickly improving the maintenance level of maintenance personnel, which is of great significance for the effective diagnosis of power system equipment in the later period [7–9].

According to the above analysis, in order to effectively solve the problems in the CAD-aided intelligent operation and maintenance process of power system equipment, combined with data mining algorithms, the CAD-aided intelligent operation and maintenance of power system equipment is performed effectively in combination with the two-way long and short time network and random conditions. Through constructing the knowledge graph ontology model of electrical power system, AD-aided intelligent operation and maintenance processing technology is used in power system equipment failures, and finally, the feasibility and effectiveness of the algorithm are verified in this study through an example analysis.

2. CAD-Aided Intelligent Operation and Maintenance of Power System Equipment

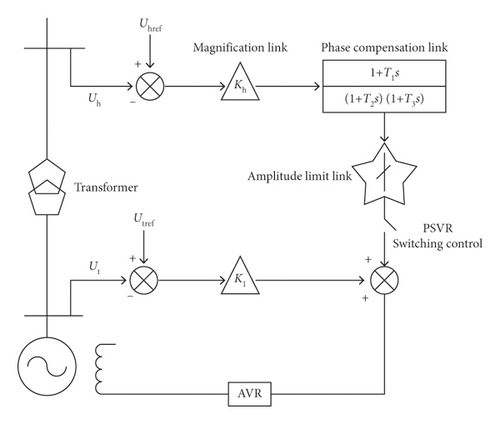

According to equation (8), it can be seen that the additional difference adjustment generated by the power system has the effect of negative difference adjustment. The additional adjustment coefficient produced by the power system is positively correlated with the magnification factor Kh of power system. The greater Kh, the greater the absolute value of the additional difference adjustment coefficient, but it will not be greater than the reactance of the transformer.

3. CAD-Aided Intelligent Operation and Maintenance Platform for Equipment Deficiency

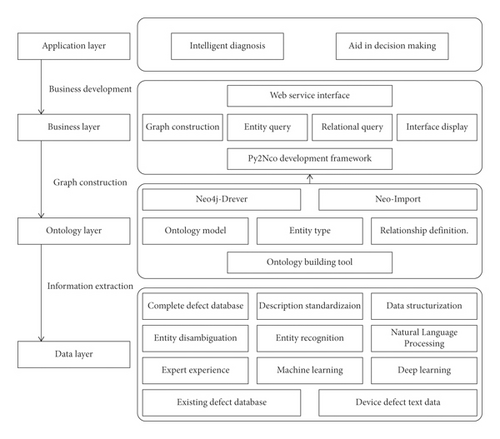

Aiming at the mining and application of CAD-aided intelligent operation and maintenance of power system equipment, a CAD-aided intelligent operation and maintenance platform for equipment functional defects is constructed based on the CAD-aided intelligent operation and maintenance model and knowledge graph of power system equipment [10–13]. Its architecture is shown in Figure 2, including data layer, ontology layer, business layer, and application layer. Among them, the data layer is based on the historical CAD-aided intelligent operation and maintenance data of the equipment, and the named entity recognition NER (Named Entity Recognition) model is introduced to complete the information extraction, thereby providing data support for the next step of building the knowledge graph; the establishment of the relationship between entities is performed by the ontology layer based on the Protege ontology l construction tool, to establish the equipment CAD-aided intelligent operation and maintenance graph ontology model; the business layer is based on the ontology model constructed by the ontology layer and the data provided by the data layer and provides information query and knowledge reasoning services for functional defects of equipment to support the intelligent diagnosis and decision-making functions of the application layer.

3.1. NER

When dealing with CAD-aided intelligent operation and maintenance data such as “causes and processing conditions” in the data layer, the CAD-IOMPSE algorithm is introduced in NER in this study. NER is an important task in information extraction and information retrieval, to locate the boundaries of named entities in the text and classify them into predefined sets [14, 15]. At present, NER methods are mainly divided into two categories: methods based on rules, dictionaries, and online knowledge bases and methods based on intelligent algorithms. In recent years, deep learning technology has been widely used in various natural language processing tasks. Compared with the traditional NER model, the NER method based on deep learning does not require manual design of rules or features and can be used to extract easily implicit semantic features from the original input text.

“Defect phenomenon” is taken as an example in this study. Although some phrases that characterize “defect phenomenon” are not a noun or nominal phrase and do not conform to the conventional entity definition, in terms of the task concerned for instance and in the text data of the “running light is off, it works normally after restarting,” the “running light is off” is extracted, which conforms to the basic input/output characteristics of the NER model, and in the obtained CAD-aided intelligent operation and maintenance data, the “defect phenomenon” can be a generalized with certain subsequence in the original text (or multiple subsequences, which can be regarded as multiple entities). Therefore, the extraction of “defect phenomenon” information from CAD-aided intelligent operation and maintenance can be regarded as a NER task, and the CAD-IOMPSE algorithmic model used for the NER model in the deep learning in accordance with the “defect phenomenon,” and the information is extracted.

3.2. Knowledge Graph

The knowledge graph is a knowledge base established by Google to support its semantic search, including entities, concepts, and complex semantic relationships between them. After completing the data alignment work, rich semantic relationships are contained in various types of data. For example, “defect” is a component of “defective equipment” and “defect phenomenon” is a specific manifestation of defects in “defective equipment”. The traditional way of data storage and management is to store data in a database in the form of tables so that the semantic relationship between the data is easily lost, and the application of data knowledge and value is hindered. Taking into account the technical advantages of knowledge graphs, the CAD-aided intelligent operation and maintenance graph of power system equipment is constructed in this study.

At present, knowledge graphs are mainly divided into two categories: (1) general domain knowledge graphs for the general public, such as the NELL (Never-Ending Language Learner) system built by Carnegie Mellon University and CN_DBPedia developed by Fudan University and (2) vertical industry-oriented knowledge graph of professional fields, such as “Baidu Medical Brain” in the medical field and “JD Brain” in the e-commerce field.

However, there is still a lack of relevant research and discussion on knowledge graphs oriented at power system equipment. An industry-type knowledge graph is established for power system equipment, which can integrate the rich cluster intelligence and complex information between various types of data into the relationship constraints between various entities in the knowledge graph and can set specific path constraint conditions to in-depth mine and apply the data in various application scenarios. The established knowledge graph is applied to two specific business scenarios of equipment functional defects’ CAD-aided intelligent operation and maintenance in this study.

4. Extraction of Information Based on CAD-Aided Intelligent Operation and Maintenance Model of Power System Equipment

Intelligent and complex optimization algorithms for power system equipment clusters are filled in by first-line operation and maintenance personnel. It is inevitable that professional terminology is expressed with colloquialism and does not conform to conventional grammar, which increases the complexity of text data and the difficulty of mining its potential knowledge and value. The main task of the data layer is to extract and standardize the above data, so as to provide a data foundation for the construction of the subsequent knowledge graph. Among them, as described in Section 1, the three types of data “defective equipment,” “defect,” and “defect cause” are relatively regular nominal phrases, which can be used as input data for subsequent construction of the knowledge graph model after simple processing. Regarding the two types of defect information, “defect phenomenon” and “solution measures,” it is stored in the power system in the form of short text data, such as “error in circuit breaker failure protection device (LFP-923A) self-inspection; OP light goes out. After the maintenance personnel went to the site to check and the power plug-in is replaced, the protection device returned to normal.” These text data include the defect phenomenon after a specific defect occurred and the corresponding solutions, but because it is unstructured text data, it needs to be based on natural language processing technology for extraction of information in order to obtain a relatively short, standardized description.

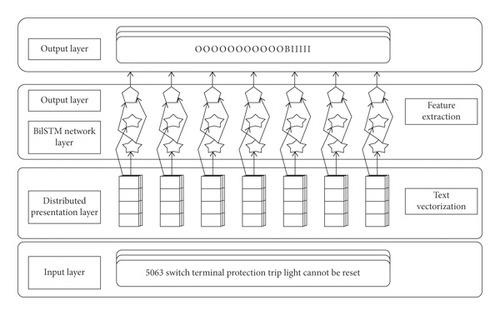

Therefore, the “defect phenomena” will be extracted from CAD-aided intelligent operation and maintenance as NER tasks, and the CAD-IOMPSE algorithm (the “solution measures” can be dealt with in the same way, so I would not say more than is needed) will be introduced. First, the BIO (Begin-Inside-Outside) annotation method is used for data labeling, where B represents the beginning of the “defect phenomenon” sequence, 1 represents the character belongs to the “defect phenomenon” sequence, and 0 represents the character does not belong to the “defect phenomenon” sequence. Then, the model is trained and tested based on the CAD-IOMPSE algorithm, and the “defect phenomenon” information is extracted from the CAD-aided intelligent operation and maintenance.

The CAD-IOMPSE-based NER model is currently a widely used algorithm model in the NER field. The CAD-aided intelligent operation and maintenance model of power system equipment can be used for performing tasks through combination with the bidirectional long-short term memory (BiLSTM) network to extract text features and the advantages of CRF processing sequence labeling tasks.

A two-way architecture is used by the BiLSTM network model based on the LSTM network model, making the model be in two-way coding sequences more flexibly. Such a model architecture is more suitable for natural language features, and context feature learning can be performed, thereby improving the performance of natural language processing tasks.

The CRF model is used to predict the conditional distribution P(Y | X) of output random variable Y = {Y1, Y2, ⋯, Yn}, on the premises of solving the problem of the given input random variable X = {X1, X2, ⋯, Xn}. The linear chain CRF is mainly used for sequence labeling tasks. The model considers the constraint relationship of the label Yi corresponding to Xi and the context label and has achieved good results.

The CAD-aided intelligent operation and maintenance model architecture of power system equipment is shown in Figure 3. It is mainly composed of input layer, distributed presentation layer, BiLSTM network layer (encoder), CRF layer (decoder), and output layer. In the distributed presentation layer, since the deep learning model cannot accept nonnumerical data as input, the input sentence needs to be expressed as a set of vectors. In the BiLSTM network layer and CRF layer, the feature extraction of the original data is completed, and the target sequence is finally obtained by output.

5. Construction and Knowledge Application of CAD-Aided Intelligent Operation and Maintenance Graph of Power System Equipment

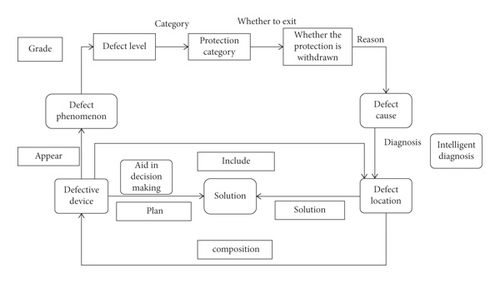

Based on the general construction process of the current knowledge graph, combined with the needs of actual applications, the CAD-aided intelligent operation and maintenance graphs are constructed and applied in the ontology layer, business layer, and application layer, as shown in Figure 4.

5.1. Ontology Layer

Ontology is the abstract concept of knowledge graph database. Protege ontology construction tool is used to build the ontology model of equipment knowledge graph, as shown in Figure 4.

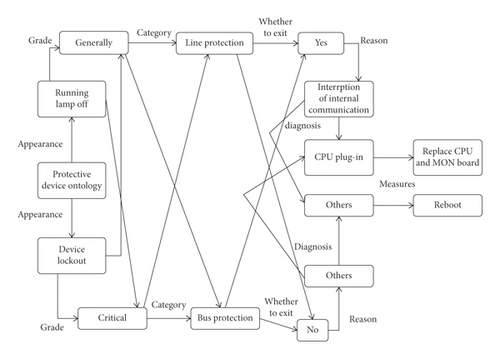

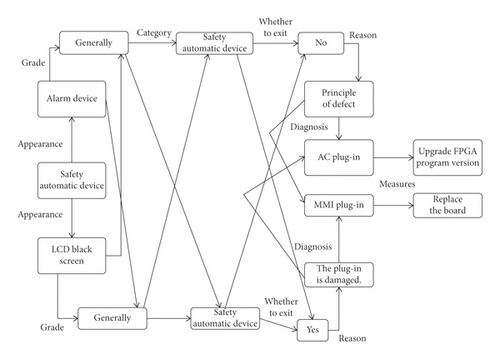

According to the regular data and application requirements of the data layer, it can be determined that the entity category includes 5 core entities of defective equipment, defect phenomenon, defect cause, and defect location solution measures, as well as 3 related entities of defect degree, protection withdrawal, and protection category. Furthermore, the relationship between defining entities is composed of appearance, reason, diagnosis, measure, level, whether to withdraw, and category.

5.2. Business Layer

Based on the ontology model constructed by the ontology layer, combined with the regular data of the data layer, the business layer fills in specific entities, attributes, and relationships. Based on the ontology model shown in Figure 3, combined with the regular CAD-aided intelligent operation and maintenance data in Section 3, the ontology model is instantiated. The knowledge subgraphs of the protection device ontology and the safety automatic device are shown in Figures 2 and 3, respectively. Among them, in view of the differences and independence between different devices when dealing with device defects, a relatively independent subgraph is established for each device in this study; otherwise, the many-many complex mapping relation will exist between defect phenomenon, defect location, and other entities and attributes, which will lead to the recommendation of the defect location, defect cause, and solution for a certain device to another device as the result of CAD-aided intelligent operation and maintenance. Subgraphs are established for various types of equipment, which greatly reduces the structural complexity of the knowledge graph and improves the retrieval and reasoning capabilities of the model in the implementation of subsequent business functions. In addition, the dotted lines between the entities in Figures 2 and 3 mean the possible corresponding relationships between the two types of entities, which need to be determined based on actual data.

5.3. Application Layer

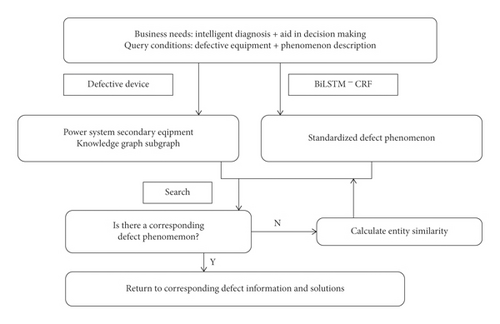

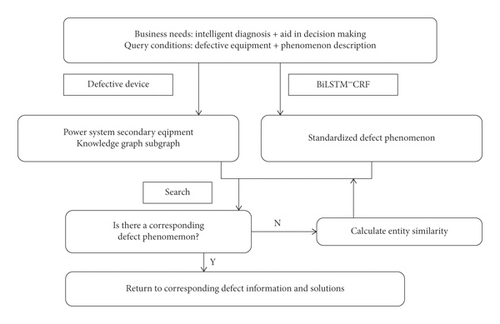

In the application layer, the open source web application framework Django is chosen as the front-end page development framework in this study, integrating the CAD-aided intelligent operation and maintenance model of trained power system equipment and the established knowledge graph in the framework, to build the CAD-aided intelligence operation and maintenance platform of equipment functional defects. The platform reasoning process is shown in Figure 5. Based on this platform, when a new defect occurs, the defect equipment + phenomenon description are entered, to first enter CAD-aided intelligent operation and maintenance model of the power system equipment to complete the defect phenomenon information extraction and then return to the defect location corresponding to the same defect phenomenon and the defect cause corresponding to the same defect phenomenon occurred to equipment in the historical data through knowledge reasoning in combination with knowledge graph, to complete intelligent diagnostic function; furthermore, based on historical data, reasonable solutions are recommended to complete the auxiliary decision-making function. During practical applications, the 5 most frequently occurring diagnosis and decision options will be returned to in historical data for operation and maintenance personnel to choose.

- (1)

After entering the description of the phenomenon, the corresponding case cannot be found in the defect phenomenon obtained through entity recognition in combination with defect equipment, such as “monitoring notification, xx changed xx line rcs-931bm protection to send out the channel interrupt signal and then revert voluntarily at xx: Xx. After resetting, measurement protection backboard and the photoelectric conversion device’s transceiver level are both within the qualified range.” The result obtained through entity identification is “channel interruption signal” and the “channel interruption” in the case library. In this case, the vectorized expression of each entity is completed based on word2vec technology, and the cosine similarity between the phenomenon and each entity is computed to find the most similar defect phenomenon and recommend the defect cause, defect location, and solution corresponding to the phenomenon. For example, by calculating the cosine similarity between the “channel interruption signal” and each entity, the most similar phenomenon, “channel interruption,” is obtained; the corresponding defect reason and rejected region and solution are recommended when the channel interruption occurs to protective device.

- (2)

In actual situations, the abnormalities may exist in several parts of the equipment, that is, there may be multiple entities that need to be identified in the description of the phenomenon mentioned in Section 2. The specific data are shown. In this case, when performing CAD-aided intelligent operation and maintenance, the corresponding information will be recommended based on “Defective Equipment” and “Defect Phenomenon 1” and “Defective Equipment” and “Defect Phenomenon 2,” respectively.

6. Example Analysis

Based on the functional defect processing text accumulated by the power company in many provinces in the operation and maintenance of equipment in the past ten years, after data cleaning, 7200 historical data are obtained, and the information extraction model of defect phenomenon of power system equipment based on the CAD-aided intelligent operation and maintenance model of power system equipment is built. The above data are divided into the training set and the test set at a ratio of 8 : 2 to perform model training and testing, respectively; based on the above data, a CAD-aided intelligent operation and maintenance graph of power system equipment is constructed to establish a power system based equipment CAD-aided intelligent operation and maintenance model and knowledge graph of power system equipment functional defects’ CAD-aided intelligent operation and maintenance platform.

In order to extract defect phenomenon information in the intelligent and complex optimization algorithm of equipment clusters, an information extraction model based on CAD-IOMPSE is constructed in this study. The related hyperparameter settings of the CAD-aided intelligent operation and maintenance model of power system equipment and the control group are shown in Table 1. In Table 1, λ is the L2 regularization coefficient, Optimizer is the model-solving optimizer (Adam is the adaptive moment estimation algorithm and SGD is the stochastic gradient descent algorithm), NHidden_dim is the number of hidden layer units of the BiLSTM network, NEpoch is the number of training rounds, NBatch_size is the number of trained samples in each batch, γLearning_rate is the model learning rate, NEmbedding_dim is the vector dimension of the distributed representation layer that converts words into numerical vectors, and γDropout is the random discard rate of neurons in the model. The above parameters all affect the final effect of the model at different levels.

| Hyperparameter | Value | |||

|---|---|---|---|---|

| Control group 1 | Control group 2 | Control group 3 | Control group 4 | |

| Λ | 0.0001 | 0.001 | 0 | 0.0001 |

| Optimizer | Adam | Adam | Adam | SGD |

| NHidden_dim | 400 | 400 | 400 | 400 |

| NEpoch | 40 | 40 | 40 | 40 |

| NBatch_size | 35 | 35 | 35 | 35 |

| γLearning_rate | 0.001 | 0.001 | 0.001 | 0.001 |

| NEmbedding_dim | 200 | 200 | 200 | 200 |

| γDropout | 0.4 | 0.4 | 0.4 | 0.4 |

| Control group | Veracity (%) | Recall rate | F1 value | |||

|---|---|---|---|---|---|---|

| Training set | Test set | Training set | Test set | Training set | Test set | |

| 1 | 90.06 | 87.14 | 90.4 | 86.48 | 0.9221 | 0.8879 |

| 2 | 83.82 | 81.65 | 85.97 | 82.73 | 0.8686 | 0.8417 |

| 3 | 91.62 | 84.83 | 91.83 | 84.59 | 0.9271 | 0.857 |

| 4 | 44.62 | 48.42 | 23.74 | 6.86 | 0.3297 | 0.1399 |

It can be seen from Table 2 that the model performance of control group 1 is better than the other three control group models in the three evaluation indicators. Among them, compared with control group 1, control group 2 increases A by 10 times, and control group 3 sets A to 0, that is, there is no regularization term in the loss function. Through calculation, after the model training ends, the model loss function value of control group 2 stabilizes at around 1.36, and the model loss function value of control group 3 stabilizes at around 0.45. Combining the results shown in Table 2, it can be seen that the model of control group 2 is under-fitting. Control group 3 model is over-fitting. Compared with control group 1, control group 4 changed the solution optimizer from Adam to SGD. The results shown in Table 2 show that Adam’s solution results are better. According to the results of the above model parameter tuning process, the optimal parameters are selected finally as the corresponding parameter of control group 1 in this study.

Comparing the accuracy rate, recall rate, and F1 value evaluation indicator of the Seq2Seq-Attention model in the test set of the power system equipment CAD-aided intelligent operation and maintenance model (control group 1) proposed in this study with the traditional CRF algorithm, BiLSTM-softmax, and natural language generation model, the results are shown in Table 3.

| Model | Veracity (%) | Recall rate | F1 value |

|---|---|---|---|

| CRF | 70.02 | 70.43 | 0.7142 |

| BiLSTM-softmax | 78.73 | 71.9 | 0.7714 |

| Seq2Seq-Attention | 71.63 | — | — |

| CAD-IOMPSE | 87.13 | 86.47 | 0.8779 |

It can be seen from Table 3 that the CAD-aided intelligent operation and maintenance model of power system equipment proposed in this paper is superior to CRF, BiLSTM-softmax, and Seq2Seq-Attention model in terms of accuracy (87.12%), recall rate (86.46%), and F1 value (0.8679). In addition, when using the CRF algorithm to identify and extract the three types of entities in the power service question and answer corpus data, location, fault, and solution, an accuracy rate of more than 90% is achieved. However, as mentioned in Section 2, the defect phenomenon extracted in this study is not a typical named entity, but a more complex phrase type text, which is more difficult to be extracted. Therefore, the accuracy of the model in this study is lower than that in [10]. In fact, in the comparison model of this study, the CRF model proposed is considered. The test accuracy of this model in the dataset used in this study is only 70.01%, which also verifies the superiority of CAD-aided intelligent operation and maintenance of power system equipment.

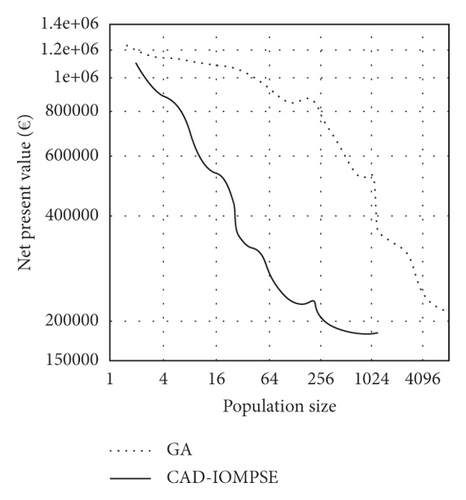

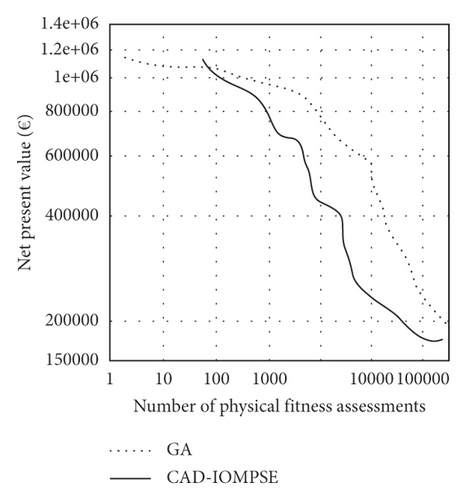

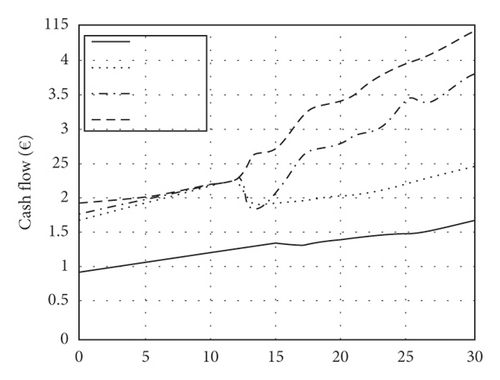

The left and middle images of Figure 6 show the performance comparison between CAD-IOMPSE and traditional GA. The best solution includes a new cable connection, the placement of a new NOP, the repositioning of two existing NOPs, and the upgrade of a cable. The graph on the right shows the related cash flow (CF) and the CF generated by the transformer expansion program.

The knowledge subgraphs of the protection device ontology and the safety automatic device are shown in Figures 7 and 8, respectively. In addition, the dotted lines between the entities in Figures 7 and 8 mean the possible corresponding relationships between the two types of entities, which need to be determined based on actual data.

Application layer: in the application layer, the open source web application framework Django is chosen as the front-end page development framework in this study, integrating the CAD-aided intelligent operation and maintenance model of trained power system equipment and the established knowledge graph in the framework, to build the CAD-aided intelligence operation and maintenance platform of equipment functional defects. The platform reasoning process is shown in Figure 9.

It can be seen that, by using less topology evaluation, CAD-IOMPSE is faster than GA in solving (close to) the best solution. In order to get close to the results obtained by CAD-IOMPSE, traditional GA requires more adaptive evaluation (i.e., longer calculation time, because adaptive evaluation dominates other operations at runtime) and a larger overall scale, which is too troublesome and cannot be handled neatly. It is also interesting that when comparing the standard deviations of the results obtained by the two algorithms, the performance of CAD-IOMPSE is more reliable than traditional GA. Under the same population size, the results of GA will fluctuate in a larger range, which may be due to premature convergence to the local optimal value in some operations.

In the case of solving variant B, both algorithms can find the optimal solution by using very little adaptive evaluation, and the optimal solutions of variants A and B are both very simple (that is, only need to satisfy all constraints). This may indicate that the immediate problem instance is actually easy. It may be a difficult problem in general, but in this particular case, especially when considering radial constraints and setting a maximum number of new connections from the substation, it is easy to be solved. Generally, it is beneficial to solve the problem by reducing the search space and adding constraints to prevent the optimization algorithm from considering unnecessary solutions so that we can effectively solve larger problem instances. However, the immediate problem instance may belong to the complexity category. For these complexity categories, evolutionary algorithms are usually not the most suitable optimization program. Considering the simplicity of the best solution, a simpler algorithm (such as mountain climbing from the existing network topology) is sufficient to solve the problem and can solve the problem more effectively.

7. Conclusions

The CAD-aided intelligent operation and maintenance model of power system equipment is built based on the cluster intelligent complex optimization algorithm in this study. From the perspective of three evaluation indicators of accuracy, recall, and F1 value, the algorithm proposed in this study is compared with the traditional algorithm. Finally, the experimental results show that the CAD-aided intelligent operation and maintenance model of power system equipment constructed in this study has improved evaluation indicators, which can provide a theoretical basis for the later power system knowledge graph and can also provide basis for reading and standardized processing of power system data information. It can effectively improve the performance of CAD-aided intelligent operation and maintenance of power system equipment to compare historical data and ensure that the constructed model is more intelligent and more suitable for actual application scenarios.

Conflicts of Interest

The authors declare no conflicts of interest.

Acknowledgments

This study was sponsored by Xiamen University of Technology.

Open Research

Data Availability

The labeled dataset used to support the findings of this study are available from the corresponding author upon request.