Study on Road Performance of Cement-Stabilized Recycled Aggregate Base with Fiber and Rubber

Abstract

The purpose is to enhance the recycling utilization rate of old base material and make the cement-stabilized recycled aggregate (RCA) maintain good toughness and crack resistance; rubber particles and basalt fiber admixtures were added to the recycled aggregate. The effects of two different dosages of admixtures on the mechanical properties of the mixture were analyzed; the durability of cement-stabilized base was evaluated; the influence of basalt fiber and rubber particles on the road performance of cement-stabilized recycled aggregate was studied; and scanning electron microscopy was used to analyze the cement-stabilized recycled aggregate mixed with two kinds of admixture. The results show that the increase of basalt fiber dosage improves the mechanical properties of the mixture. The dry shrinkage strain of the mixture decreases, and the frost resistance coefficient increases, indicating that the increase of rubber particles improves the durability of the mixture. When the rubber particles dosage is 0.5%, the basalt fiber dosage is 0.1%, and the recycled aggregate dosage is 50%, the comprehensive rode performance of the mixture is the best. Rubber particles can effectively improve the frost resistance and dry shrinkage of the mixture through its own deformation and shrinkage without damage and slow down the tensile stress caused by dry shrinkage and the compressive stress caused by frost heave. The easy bonding effect of basalt fiber and its pullout effect in the mixture increase the compressive strength and dry shrinkage resistance of the mixture.

1. Introduction

The rapid development of the national economy resulted in the great achievement of infrastructure in China. In the highway construction in our country, the semirigid base is widely used in all kinds of highway bases or subbases because of its high strength, low cost, and extensive sources of raw materials. Among them, the semirigid material with the highest frequency of use in highway bases in modern society is cement-stabilized natural aggregate [1]. But, at the same time, with the increasing growth of construction solid waste in China, increasingly acute social and environmental problems have been exposed, and the recycling technology and regeneration process of pavement base materials have been gradually improved. In recent years, the regeneration and application of base materials have attracted attention from all aspects [2]. Using recycled aggregate to replace a part of natural aggregate as the base material, on the basis of ensuring the strength of the base, the advantages of cement-stabilized aggregate can be effectively exerted, and the recycling of construction waste is obviously improved [3].

Cement-stabilized macadam base material is easy to form condensation cracks due to water loss or temperature change, which leads to reflection cracks in the surface layer above the base, thereby reducing the service life of the highway [4]. Water is easy to enter the interior of the base through the cracks of the pavement, thus causing water damage to the semirigid base, which worsens the chronic disease of cracks in the pavement. Meanwhile, RCA has the characteristics of low strength, high hygroscopic rate, and poor drying shrinkage performance. The bulk density and apparent density of RCA are lower, and the crushing value is larger. The drying shrinkage crack of concrete mixed with RCA is larger than that of natural aggregate concrete [5, 6]. At home and abroad, both in the reinforcement of recycled aggregate and in the application of recycled aggregate concrete, its study has been more common, but the exploration of concrete recycled aggregate used in the semirigid base still lacks systematic and in-depth research [7].

With the widespread application of automobiles, the treatment of waste rubber tires has become an urgent problem to be solved [8]. In order to respond positively to the national green development strategy, rubber is more and more widely used in road engineering. The rubber particles replace part of the fine aggregate, which can reduce the workability of concrete [9]. Rubber can play its blocking role in concrete, blocking the connected pores of the concrete internal [10]. Concrete mixed with rubber has the property of ductile failure, which has produced large length deformation before compression failure [11]. The compressive strength of cement-stabilized macadam base mixed with rubber particles is negatively correlated with the dosage of rubber particles [12]. Adding 15% fine recycled aggregate in cement-stabilized macadam can improve the crack resistance of materials [13]. The suitable rubber particle content can significantly improve the dry shrinkage, impermeability, and frost resistance of cement-stabilized recycled aggregate [14]. A recycled aggregate mixture of cement-stabilized construction waste has good erosion resistance and can ensure the reliability of the structure in the process of scouring [15]. Although China’s exploration of recycling engineering waste materials is not long, China’s technical exploration of recycling concrete has achieved certain results. The addition of rubber particles can effectively improve the antierosion properties of cement-stabilized macadam [16]. The compressive strength of cement-stabilized natural aggregate mixture is related to the particle size of rubber particles. The smaller the particle size of rubber particles is, the smaller the loss rate of compressive strength is [17–19].

Basalt fiber is a kind of fiber made by drawing stone after melting, which has high strength, has resistance to chemical erosion, and is not affected by high temperature. It is generally brown or yellow. Moreover, basalt fiber produces less pollutants and does not cause harm to the environment. It is a kind of real environmental protection material. It is proved that basalt fiber has high strength properties by wrapping cracks in beams instead of the previous method of carbon fiber reinforcement [20]. Basalt fiber has good resistance to high temperature and good tensile properties, which can effectively improve the crack resistance of asphalt pavement [21]. At present, many achievements have been made in the utilization of basalt fiber in road asphalt pavement at home and abroad, but not too many basalt fibers are incorporated into the pavement base. Adding an appropriate amount of polypropylene fiber can significantly improve the mechanical properties and durability of cement-stabilized macadam [22]. The incorporation of polyester fiber can effectively improve the mechanical properties and antierosion properties of cement-stabilized recycled aggregate and reduce its dry shrinkage deformation [23].

In conclusion, the rubber particles have an adverse effect on the mechanical strength of the mixture, but it has an excellent improvement effect on the erosion resistance, water stability, frost resistance, and dry shrinkage strain of cement-stabilized macadam mixture, which is beneficial to delay the cracking of the base. Basalt fiber has the properties of high strength, has resistance to chemical erosion, and is not affected by high temperature. It can be well integrated with the coarse and fine aggregates in cement-stabilized macadam mixture. And basalt fiber easy to disperse in cement-stabilized macadam mixture has good bonding performance in the mixture. Domestic and foreign scholars have done some research work on cement-stabilized recycled aggregate base with rubber particles, mainly including the analysis of dry shrinkage, impermeability, and frost resistance of cement-stabilized recycled aggregate. However, only the cement-stabilized recycled aggregate base with rubber particles is analyzed, and the performance of cement-stabilized recycled aggregate base with basalt fiber is not systematically analyzed. For this reason, this paper will explore the mechanical properties, durability, and microscopic mechanism of cement-stabilized recycled aggregate base with rubber particles and basalt fiber, enhance the toughness and crack resistance of cement-stabilized recycled aggregate, and reduce the reflection crack of the pavement caused by base cracking.

2. Raw Materials

2.1. Recycled Aggregate

Recycled concrete aggregate used in the test mainly comes from abandoned concrete beams. After removing the lime soil and garbage on the surface of the concrete, the concrete block is separated from the steel bar inside by simple treatment such as hammering. After separation, the concrete with large blocks is processed by a jaw crusher to form recyclable recycled aggregate [24–27]. The processed recycled aggregate is screened by a shaker, and the results are shown in Table 1.

| Size of screen mesh (mm) | 31.5 | 26.5 | 19 | 9.5 | 4.75 | 2.36 | 0.6 | 0.075 |

| Throughput (%) | 100 | 93.6 | 75.6 | 55.8 | 25.2 | 22.3 | 12.3 | 2.0 |

| Specification requirement | 90–100 | — | 67–90 | 45–68 | 29–50 | 18–38 | 8–22 | 0–7 |

| Median gradation | 95 | — | 78.5 | 56.5 | 39.5 | 28 | 15 | 3.5 |

A series of performance indexes of recycled aggregate and natural aggregate after crushing and processing of waste concrete beams are tested on the basis of the requirements of Test Methods of Aggregate for Highway Engineering JTG E42-2005 [28]. It is proved that the basic physical properties of recycled aggregate meet the requirements of the specification, and the test results are shown in Table 2.

| Performance index | Apparent density (g/cm3) | Hygroscopic rate (%) | Bulk density (g/cm3) | Crush value (%) | Needle sheet content (%) | Mud content (%) | Clay lump content (%) |

|---|---|---|---|---|---|---|---|

| Recycled aggregate | 2.662 | 4.87 | 1.398 | 23.4 | 15.3 | 0.4 | 0.3 |

| Natural aggregate | 2.737 | 0.48 | 1.836 | 16.1 | 6.7 | 0.2 | 0.1 |

| Specification requirement | ≥2.35 | ≤5.0 | — | ≤35 | ≤22 | ≤0.7 | — |

2.2. Cement

The cement used in the test is P·C32.5 cement produced by Zhengzhou Tianrui Cement Co. Ltd. The test results show that the cement meets the relevant requirements in Technical Guidelines for Construction of Highway Roadbases JTG/T F20-2015 [29] and can be used. The test results are shown in Table 3.

| Project | Experimentation results | Standard specification | ||

|---|---|---|---|---|

| Fineness (F) | 2.0% | F is the residual percentage of 0.08 mm square-mesh sieve, ≤10% | ||

| Standard consistency water consumption(P) | 27.0% | P is the standard stiffness water consumption | ||

| Initial setting time | 290 min | >3 hours | ||

| Final setting time | 442 min | >6 hours, <10 hours | ||

| Stability | 2.0 mm | ≤5 mm | ||

| Strength of cement mortar (MPa) | Flexural strength | 7 d | 3.57 | ≥2.0 MPa |

| 28 d | 6.95 | ≥5.5 MPa | ||

| Compressive strength | 7 d | 16.5 | ≥10.0 MPa | |

| 28 d | 34.8 | ≥32.0 MPa | ||

2.3. Water

Running water is used in this experiment, which fully meets the test water standard.

2.4. Rubber Particles

The test uses Samsung brand rubber particles produced by Henan national standard plastic processing factory, as shown in Figure 1. The particle size is 1∼2 mm; the apparent density is 1,250 kg/m3; the bulk density is 540 kg/m3; and the hygroscopic rate is 17.2%.

2.5. Basalt Fiber

The short-cut basalt fiber of 12 mm is adopted in the experiment, as shown in Figure 2. In the experimental study, the basalt fiber incorporate method adopts the equal volume replacement for mixing, and the selected volume content does not exceed 0.1%. The detailed parameters of the fiber are shown in Table 4.

| Fiber diameter (micron) | Fiber length (mm) | Tensile strength (MPa) | Elastic modulus (GPa) | Density (g/cm3) |

|---|---|---|---|---|

| 17.4 | 12 | 2,380 | 88.2 | 2.66 |

3. Experimental Method

3.1. Mix Design of Cement-Stabilized Recycled Aggregate Mixed with Fiber and Rubber

3.1.1. Compaction Test

In the compaction test, five different cement contents were designed for cement-stabilized pure recycled aggregate and cement-stabilized pure natural aggregate. The cement dosage was calculated according to the mass percentage of aggregate. The specimens were made under the optimum moisture content of each kind of cement, and the unconfined compressive strength of the five kinds of cement specimens were tested after seven days of curing. The optimum moisture content and maximum dry density of the mixture under five kinds of cement content are shown in Table 5, and the compression results of seven days are shown in Table 6.

| Cement content (%) | 3 | 4 | 5 | 6 | 7 | |

|---|---|---|---|---|---|---|

| Water-stabilized recycled aggregate | Optimum moisture content (%) | 7.3 | 7.7 | 8.5 | 8.7 | 9.1 |

| Maximum dry density (g/cm3) | 1.96 | 2.01 | 2.02 | 2.03 | 2.05 | |

| Water-stabilized gravel | Optimum moisture content (%) | 4.1 | 4.4 | 5.2 | 5.5 | 5.8 |

| Maximum dry density (g/cm3) | 2.21 | 2.22 | 2.23 | 2.23 | 2.26 | |

| Water-stabilized gravel recycled aggregate | Optimum moisture content (%) | 5.2 | 5.6 | 6.2 | 6.6 | 7.8 |

| Maximum dry density (g/cm3) | 2.01 | 2.04 | 2.12 | 2.14 | 2.15 | |

| Cement content (%) | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|

| Water-stabilized recycled aggregate (MPa) | 2.89 | 3.75 | 4.18 | 4.75 | 5.74 |

| Cement-stabilized macadam (MPa) | 2.20 | 3.31 | 3.69 | 4.20 | 5.11 |

Table 5 shows that the optimal moisture content and maximum dry density of the mixture increase with the increase of cement dosage. Due to the higher the cement content, the more water is essential for the cement in the reaction process, so the optimum moisture content of the mixture increases accordingly. Under the same cement dosage, the optimum moisture content of the mixture is positively correlated with the dosage of recycled aggregate, and the maximum dry density is negatively correlated with the dosage of recycled aggregate. The reason is that the structure of recycled aggregate is multihole and fluffy, the density is small, and the surface is covered with old cement mortar, resulting in lower density and higher hygroscopic rate of recycled aggregate than natural aggregate.

Table 6 shows that the seven-day unconfined compressive strength of cement-stabilized recycled aggregate with different cement dosage is higher than that of reference cement-stabilized macadam. This is because the early strength of the water-stabilized base is provided by the strength of the mixture interface. Due to the old cement mortar attached to the water-stabilized recycled aggregate itself, part of the cement is still active, and the strength of the early stage is higher than that of the water-stabilized gravel with relatively low cement activity. According to the Technical Guidelines for Construction of Highway Roadbases JTG/T F20-2015 [29] in the cement-stabilized material seven-day old unconfined compressive strength standard as shown in Table 7, the base of second- and below-order highways, medium and light traffic 2.0–4.0 MPa requirements, cement-stabilized base seven-day compressive strength at least to 2.0 MPa. When the cement dosage is 3% and 4%, the specimen made under the corresponding optimal moisture content cannot meet the minimum requirements of the specification. When the cement dosage is 5% and the optimum moisture content is 8.5%, the unconfined compressive strength of the seven-day old specimen meets the specification requirements. When the cement dosage is 6% and 7%, the strength can also meet the requirements of the specification. However, considering that the increase of cement content will lead to the increase of hydration reaction heat of cement, which will lead to the increase of water stability base cracking. This is because too much heat released from the hydration reaction of cement will cause an excessive temperature change of the water stability base to produce cracks and affect the quality of the water stability base. Therefore, the cement content in water-stabilized base should not exceed 5.5% as far as possible. When the cement content of water-stabilized macadam is 5%, it is easy to meet the requirements of the specification for seven-day compressive strength. In order to carry out the comparative test, the cement-stabilized natural aggregate also uses the cement content of 5%. Therefore, considering comprehensively, for cement-stabilized recycled aggregate base, the optimal moisture content is 8.5%, and the cement content is 5%. For cement-stabilized natural aggregate base, the water content is 5.2%, and the cement content is 5%. For cement-stabilized 50% natural aggregate and 50% recycled aggregate, the water content is 6.2%, and the maximum dry density is 2.12 g/cm3.

| Structural layer | Highway grade | Extremely heavy and special heavy traffic | Heavy traffic | Medium and light traffic |

|---|---|---|---|---|

| Base | Expressways and first-grade highways | 5.0∼7.0 | 4.0∼6.0 | 3.0∼5.0 |

| Second- and below-order highways | 4.0∼6.0 | 3.0∼5.0 | 2.0∼4.0 | |

| Base course | Expressways and first-grade highways | 3.0∼5.0 | 2.5∼4.5 | 2.0∼4.0 |

| Second- and below-order highways | 2.5∼4.5 | 2.0∼4.0 | 1.0∼3.0 | |

3.1.2. Orthogonal Test

In this experiment, there are recycled aggregate content, rubber particle content, and basalt fiber content of these three factors; each factor is divided into three levels. The recycled aggregate content is 0%, 50%, and 100%, respectively. The rubber particle content is 0%, 0.5%, and 1%, respectively. The basalt fiber content is 0%, 0.05%, and 0.1%, respectively. Design the experiment according to the L9 (3) orthogonal table and do only 9 experiments. The orthogonal test factor-level table is shown in Table 8, and the mix design table of basalt fiber rubber water-stabilized recycled aggregate base is shown in Table 9.

| Level | Factor A (quality fraction) | Factor B (volume fraction) | Factor C (quality fraction) |

|---|---|---|---|

| Recycled aggregate content (%) | Basalt fiber content (‰) | Rubber particle content (%) | |

| 1 | 0 | 0 | 0 |

| 2 | 50 | 0.5 | 0.5 |

| 3 | 100 | 1 | 1 |

| Number | Water (%) | Cement (%) | Natural aggregate (%) | Recycled aggregate (%) | Fiber (%) | Rubber particle (%) |

|---|---|---|---|---|---|---|

| X1 (A1B1C1) | 5.2 | 5 | 100 | 0 | 0 | 0 |

| X2 (A1B2C2) | 5.2 | 5 | 99.426 | 0 | 0.074 | 0.5 |

| X3 (A1B3C3) | 5.2 | 5 | 98.853 | 0 | 0.147 | 1 |

| X4 (A2B1C2) | 6.2 | 5 | 49.75 | 49.75 | 0 | 0.5 |

| X5 (A2B2C3) | 6.2 | 5 | 49.403 | 49.43 | 0.097/0.074 | 1 |

| X6 (A2B3C1) | 6.2 | 5 | 49.807 | 49.85 | 0.193/0.147 | 0 |

| X7 (A3B1C3) | 8.5 | 5 | 0 | 99 | 0 | 1 |

| X8 (A3B2C1) | 8.5 | 5 | 0 | 99.90 | 0.097 | 0 |

| X9 (A3B3C2) | 8.5 | 5 | 0 | 99.31 | 0.193 | 0.5 |

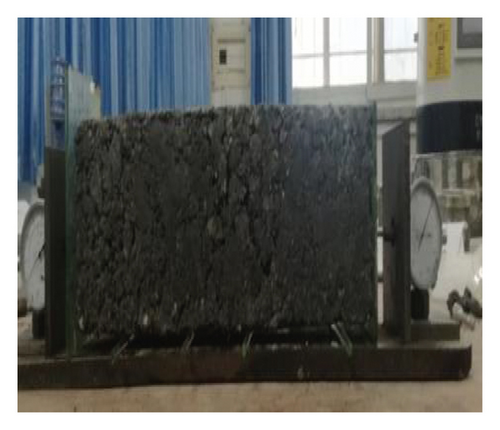

3.2. Unconfined Compressive Strength Test

The aggregate made from waste concrete has a nominal maximum particle size greater than 19 mm, which belongs to coarse-grained soil. The specimen size was selected as diameter × height = 150 mm × 150 mm with 13 specimens in each group. The unconfined compressive strength was measured according to different ages (9 days, 9 days, and 28 days). Hualong WAW-600 microcomputer electrohydraulic servo testing machine is used in this experiment, and the compression test procedure is shown in Figure 3.

3.3. Splitting Strength Test

The specimens were formed by the vibration compaction method. The specimen size was selected as diameter × height = 50 mm × 150 mm, with 13 specimens in each group. A total of 9 groups were kept for 90 days under standard conditions, and the splitting strength was measured. In this experiment, Hualong WAW-600 microcomputer electrohydraulic servo testing machine was used for the test, and the maximum pressure P (N) of the specimen was recorded when it was crushed. The splitting test procedure is shown in Figure 4.

3.4. Flexural Tensile Strength Test

The beam specimens with the size of 100 mm × 100 mm × 400 mm were made, with 12 specimens in each group. Nine groups were kept under standard conditions for 90 days, and the ultimate failure load P (N) was recorded. The flexural tensile test process is shown in Figure 5, and the bending tensile specimens after destruction are shown in Figure 6.

3.5. Shrinkage Performance Test

A beam specimen of 100 mm × 100 mm × 400 mm was made with six specimens in each group. A total of nine groups were kept under standard conditions for seven days. The preparation of specimens is shown in Figure 7, and the drying shrinkage test specimens and devices are shown in Figure 8.

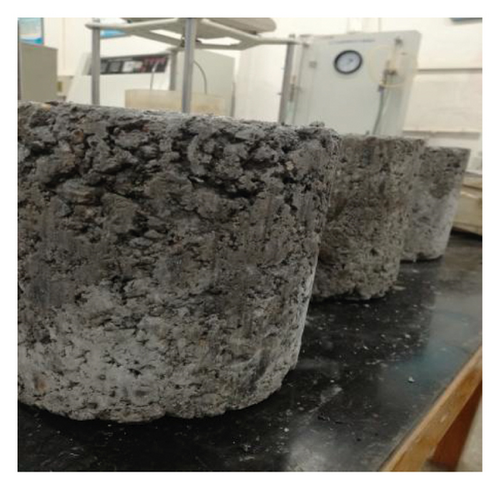

3.6. Freeze-Thaw Cycle Test

The cylindrical specimens were made, and the diameter × height = 150 mm × 150 mm was selected as the specimens. Eighteen standard specimens were formed, including 9 freeze-thaw specimens and 9 non-freeze-thaw comparative specimens. Standard curing for 28 days after completion of specimen preparation and standby for 1 day of soaking on the last day, which requires a total of 5 freeze-thaw cycles. The freeze-thaw process is shown in Figure 9; the specimen after freeze-thaw cycles is shown in Figure 10; and the compressive strength of the specimen after freeze-thaw cycles is shown in Figure 11.

3.7. Scanning Electron Microscope

The SEM test was carried out on the mixture mixed with rubber particles and basalt fiber to better analyze the influence of rubber particles and basalt fiber on the water-stable recycled aggregate base [30]. The scanning electron microscope (SEM) of JEOL-JSM-7500F from Zhengzhou University was used in this experiment. The scanning electron microscope is shown in Figure 12, and the coating instrument is shown in Figure 13.

4. Results and Analysis

4.1. Unconfined Compression Strength

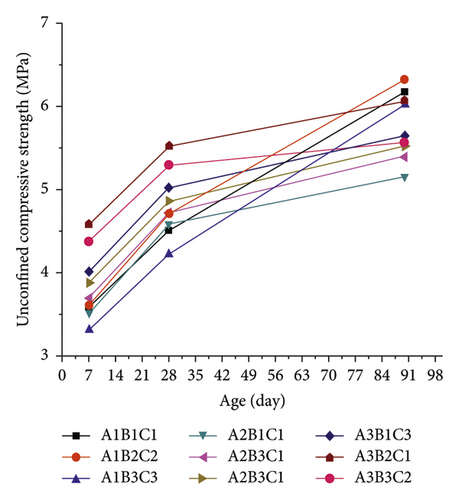

The results of unconfined compressive strength of 9 groups of mixtures for 7 days, 28 days, and 90 days in the orthogonal test are shown in Figure 14.

Figure 14 shows that the unconfined compressive strength of cement-stabilized recycled aggregate gradually increases with the increase of recycled aggregate content. When the recycled aggregate dosage is more than 50%, the unconfined compressive strength of cement-stabilized recycled aggregate decreases gradually, which is related to the mix proportion design of materials. When the recycled aggregate dosage is too much, the replacement of natural coarse aggregate by recycled aggregate will weaken the overall strength of the material and reduce the skeleton support effect.

The compressive strength of specimens with basalt fiber is larger than that without basalt fiber, and the effect of resisting load pressure is more obvious when the basalt fiber dosage increases. Xue Zhenhua studied the impact of basalt fiber on the road performance of cement-stabilized construction waste and concluded that when the basalt fiber content is 0.06% and the length is 18 mm, the seven-day compressive strength of cement-stabilized construction waste is the highest [31]. In this experiment, with the growth of age, the influence of basalt fiber on the strength growth of the mixture is reduced, that is, basalt fiber is helpful to the early strength growth of the mixture. This is because basalt fiber acts as a tie bar in cement-stabilized recycled aggregate mixture, the early compressive strength of the mixture is mainly determined by the joint surface. The fiber in the joint surface reinforces the strength of the joint surface and enhances the early strength of the mixture of water-stabilized specimens.

The compressive strength of the mixture with rubber particles was significantly reduced, and with the increase of the content of rubber particles, the strength reduced more severely. Chen Aijiu studied the impact of rubber dosage on the cube compressive strength of steel fiber rubber recycled concrete and found that with the increase of rubber particle dosage, the number of holes in concrete increased, and the compressive strength of steel fiber rubber recycled concrete decreased [32]. This is because rubber particles are very elastic, and the elastic effect occurs when subjected to pressure, which weakens the force of the specimen and the development of the later strength of the specimen. Rubber particles cannot provide stiffness like sand when the mixture is under external load. Another reason is that there are different joint surfaces among aggregate, cement hydration products, and rubber particles: (1) the bonding effect of cement hydration products and the interface between cement slurry and rubber particles, (2) interface between hydration products wrapped by rubber particles and aggregate formation, and (3) interface formed between each rubber particle or formed by gravel material and rubber particle.

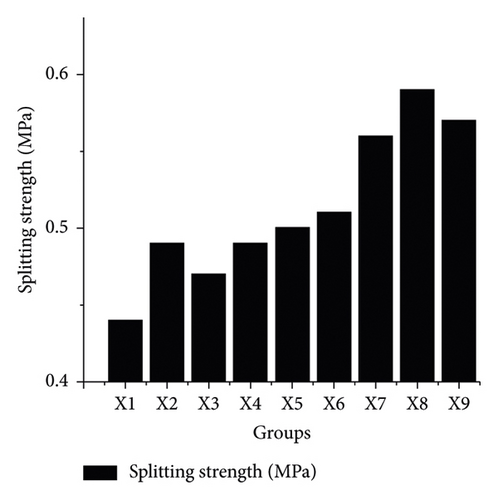

4.2. Split Strength

The splitting strength results of each group of specimens are shown in Figure 15.

Figure 15 shows that the splitting strength of both cement-stabilized recycled aggregate base and cement-stabilized macadam base is greater than the minimum splitting strength of 0.4 MPa, which meets the requirements of pavement base for splitting strength. The formation of splitting strength is fast in the initial stage and slow in the later stage. The variation of splitting strength of cement-stabilized recycled mixture at different ages with the increase of the strength of waste concrete is consistent with the unconfined compressive strength, showing an increasing trend [33]. In this experiment, the growth trend of splitting strength is consistent with that of unconfined compressive strength. With the increase of compressive strength, indirect tensile strength also increases positively.

The splitting strength of specimens with basalt fiber is stronger than that of specimens without basalt fiber, and the splitting strength of specimens increases when the basalt fiber dosage increases. In the splitting test, basalt fiber in the mixture is equivalent to the tie bar in the masonry structure wall. Due to its high tensile strength and good bonding ability, the integrity of basalt fiber and binder is improved, and its high tensile resistance is better played.

The splitting strength of the water stability base specimen with rubber particles is lower than that of the specimen without rubber particles, and the splitting strength of the specimen decreases when the rubber particles dosage increases. Because the splitting strength of the test block has a great relationship with the strength of the binder, the bonding surface becomes complex in the water-stabilized mixture with rubber particles. The more content of rubber particles, the weaker the interface of the water-stabilized mixture, which is not conducive to the increase of splitting strength. The tensile strength of the interface between rubber particles and aggregates decreases because of the flexible material rubber. On the other hand, with the increase of the rubber particles content, the bonding surface between the original aggregates is relatively reduced, which further weakens the splitting resistance of the specimen.

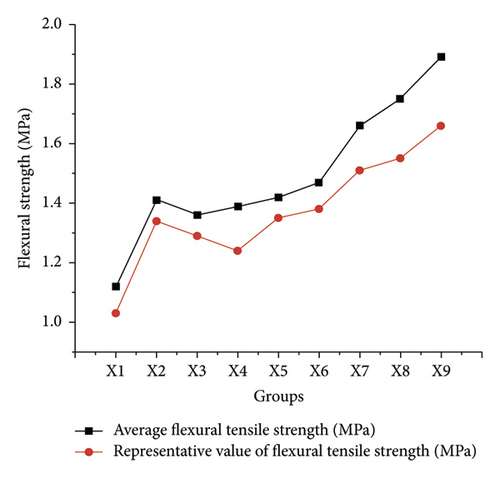

4.3. Flexural Tensile Strength

The flexural tensile strength test results are shown in Figure 16.

Figure 16 shows that the flexural strength of the mixture with fiber is higher than that without fiber, and there is a positive correlation. Chen Yuhong et al. studied the road performance of recycled aggregate base with brucite fiber and concluded that when the fiber content is less than 4%, the flexural strength of recycled aggregate base material increases step by step. The growth rate is relatively slow when the fiber content is greater than or equal to 4% [34]. The addition of rubber particles is not conducive to the flexural strength of the specimen. This is because the combination ability of rubber particles and mortar is not high, its own strength is low, and its resistance to deformation is weak. When subjected to tension, it is easy to produce tensile deformation, resulting in the development of cracks. Thus, the flexural tensile strength of water-stabilized specimens is weakened.

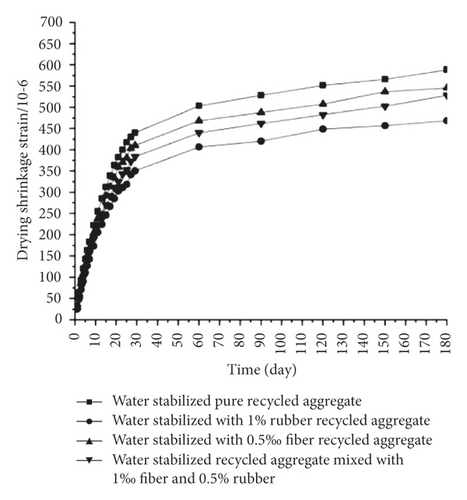

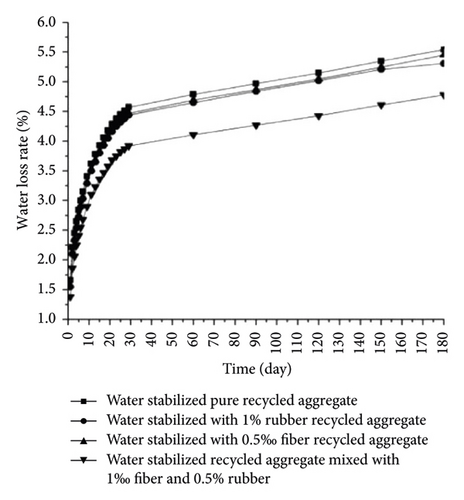

4.4. Drying Shrinkage

In this experiment, 4 × 6 = 24 specimens were made. The comparison of the results of the dry shrinkage test is shown in Figure 17, and the comparison of moisture loss rate of the dry shrinkage test is shown in Figure 18.

Figure 17 shows that in the dry shrinkage strain curve of the mixture, the dry shrinkage strain of the water-stabilized pure recycled aggregate is the largest, and the dry shrinkage strain of the water-stabilized mixture with 1% rubber particles is the lowest. Studies have shown that when the content of rubber particles is 3%∼7%, the shrinkage resistance of mortar specimens is significantly improved, and it is gradually improved with the increase of the content [14]. It shows that rubber particles help reduce the dry shrinkage strain of the mixture, and with the increase of rubber particles content, the dry shrinkage strain of the mixture decreases more. The rubber particles are elastic. When subjected to tensile stress, they absorb energy and reduce the tensile force on the interface, so the shrinkage deformation of the mixture is less. The incorporation of fiber also helps reduce the dry shrinkage strain, but the effect is not as obvious as rubber particles.

Figure 18 shows that the optimum moisture content of the mixture added with rubber particles will be reduced, which is conducive to less internal moisture of the mixture. The existence of basalt fiber and rubber particles reduces the relative component of recycled aggregate and the overall water absorption of the mixture. The incorporation of rubber particles changes the bonding properties of the joint surface of the mixture. In the early shrinkage of the mixture, the rubber particles hinder the penetration hole, reduce the loss of free water, and reduce the speed of plastic shrinkage of the mixture.

4.5. Frost Resistance

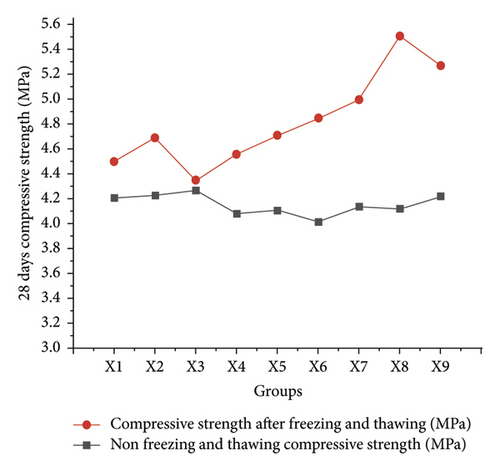

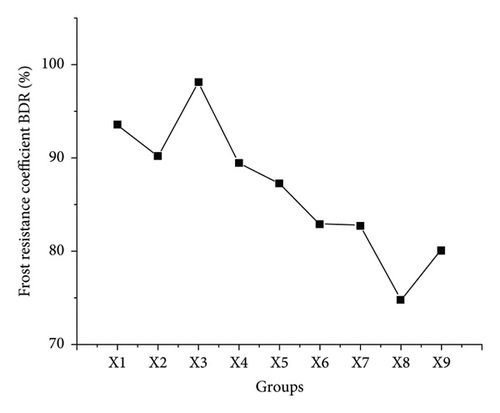

The results of freeze-thaw compressive strength of 9 groups of orthogonal tests at 28 days are shown in Figure 19, and the frost resistance coefficient BDR is shown in Figure 20.

Figure 19 shows that the compressive strength of specimens after five freeze-thaw cycles was significantly lower than that of specimens without freeze-thaw cycles. The main reason is that during the freeze-thaw process, the water in the mixture keeps expanding and dissipating. The frost-heaved mixture has a loose structure, low strength, and even collapse. The internal structure of the specimen without freeze-thaw is denser, and the bonding surface is not destroyed, so the compressive strength of the specimen after freeze-thaw is reduced.

Figure 20 shows that the frost resistance coefficient (BDR) increases when the rubber particle dosage increases, so the addition of rubber particles can greatly improve the frost resistance of cement-stabilized recycled aggregate base mixture. Zhang Jinxi et al. carried out a freeze-thaw cycle test on concrete with different carbonation times and concluded that carbonation has a constant promoting effect on improving frost resistance of concrete [35].

In summary, the addition of rubber particles can enhance the drying shrinkage and frost resistance of the mixture because when the content of rubber particles increases, the drying shrinkage strain of the mixture decreases, and the frost resistance coefficient increases. However, when the content of rubber particles is 1%, the mechanical strength of the mixture decreases by 12.2%, so adding excessive rubber particles will greatly reduce the mechanical strength of the mixture. When the rubber particle content is 0.5%, the basalt fiber content is 0.1%, and the recycled aggregate content is 50%, it not only can ensure the strength requirements of the mixture but also can enhance the crack resistance and shrinkage performance of the mixture. At this time, the comprehensive pavement performance of the mixture is the best.

4.6. Microscopic Mechanism

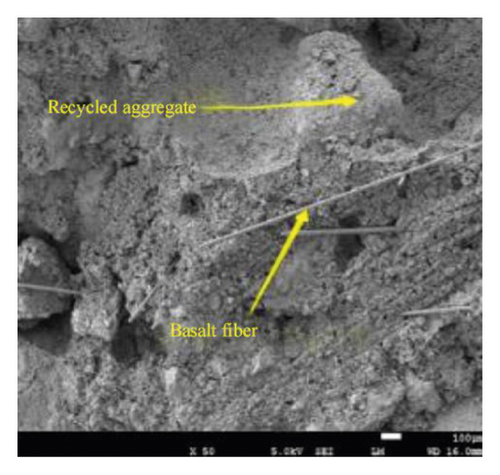

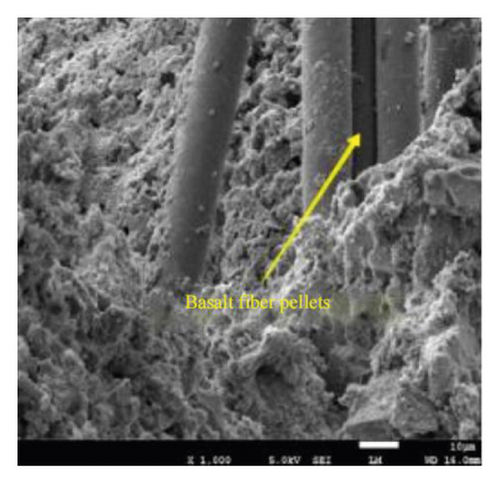

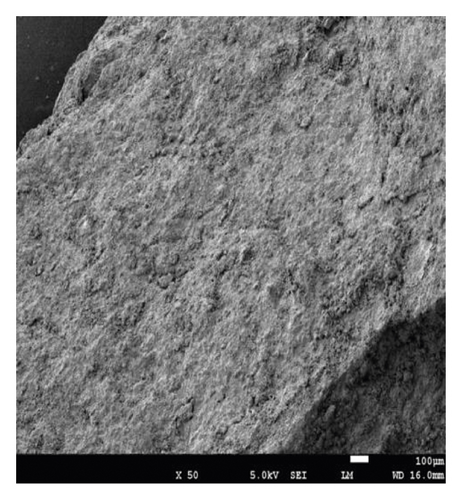

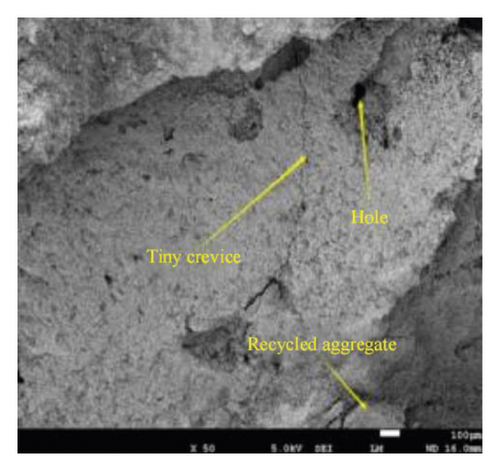

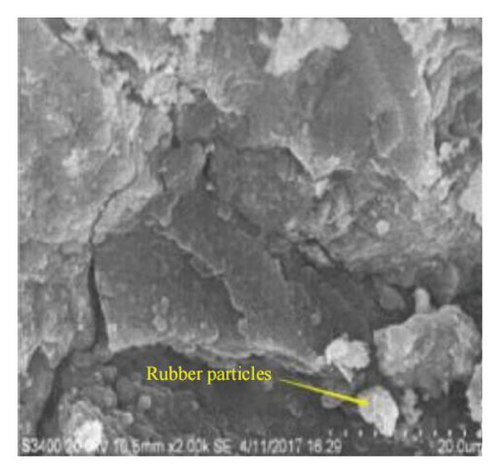

Figure 21–24 are the scanning results of cement-stabilized fiber recycled aggregate, cement-stabilized pure natural aggregate, cement-stabilized pure recycled aggregate, and cement-stabilized recycled aggregate with rubber particles by scanning electron microscope.

Figure 21(a) shows that the tiny “villi” on the basalt fiber surface help adhere to the cement mortar binder, thereby improving the bonding force and integrity of the fiber and the mixture and laying the material foundation for the fiber to provide pull-bonding. Figure 21(b) shows the combination state of fiber and water-stabilized recycled aggregate. A bundle of basalt fiber can provide tensile force to the mixture, reduce crack, and enhance compressive strength. The cement-stabilized recycled aggregate with basalt fiber should be fully mixed, which is conducive to the uniform distribution of fibers.

As can be seen from the comparison of Figures 22 and 23, the microscopic picture of cement-stabilized pure recycled aggregate is more porous and loose so that the loose structure makes the mixture easier to absorb water and increases the water demand during mixing. So cement-stabilized recycled aggregate is more prone to dry shrinkage cracks and temperature shrinkage cracks, and its later strength is lower than cement-stabilized macadam. In the related research, due to the surface of recycled aggregate being rougher than natural aggregate, it can form a stronger bonding force and interlocking force with cement mortar and promote the improvement of strength [36]. In this experiment, it is precise because of the rough surface of cement-stabilized recycled aggregate and the stronger bonding ability with cement slurry that the initial compressive strength is determined by the strength of the bonding surface. In the initial stage, the cement-stabilized recycled aggregate is still active in cement due to the old cement slurry, so the strength of cement-stabilized recycled aggregate is large.

As shown in Figure 24, there are cracks and voids between rubber particles and cement mortar, and such a fragile bonding interface is the microscopic reason for the poor macroscopic compressive strength of rubber cement mortar. Rubber materials are hydrophobic. Compared with the hydrophilic aggregate such as sand and gravel, the water absorbed by rubber particles is very small, which reduces the water-cement ratio of the mixture and also means a decrease in the degree of hydration of cement. As a result, the strength of the bonding surface is lower than that of the interface formed between natural sand aggregate and cement stone.

Compared with Figures 21(b) and 23, it can be seen that the cement-stabilized recycled aggregate base structure with basalt fiber and the cement-stabilized pure recycled aggregate base structure without basalt fiber are relatively loose. The mixture with fiber has the effect of fiber pullout and better integrity. The existence of fiber makes the distribution of mixture particles more reasonable, and fiber plays a link and link role in various particles. When the cement-stabilized recycled aggregate base is subjected to tensile stress, the fiber can share a part of the tensile force in the middle, which reduces the influence of tensile force on cement-stabilized mixture, reduces the crack development caused by tensile, and improves the crack resistance of cement-stabilized mixture.

Comparing Figures 23 and 24, it can be seen that the base structure of cement-stabilized recycled aggregate with rubber particles is looser than that of cement-stabilized pure recycled aggregate, and the existence of rubber particles is not conducive to the combination of cement stone and granular materials in the mixture. One is that the adhesion of rubber particles and cement mortar is not as good as the binding force of particles and cement mortar. The other is that the elastic characteristics of rubber particles are not conducive to their combination with cement mortar. Therefore, the existence of rubber particles is not conducive to the formation and increase of the mechanical strength of the mixture. However, it can be seen from the diagram that the content of closed pores in the mixture with rubber particles is significantly higher than that of cement-stabilized recycled aggregate without rubber particles. The existence of these closed pores improves the internal gas state of the mixture and is not conducive to the invasion of water, thereby reducing the harm of frost heave.

5. Conclusion

- (1)

The initial mechanical strength of cement-stabilized recycled aggregate base is greater than that of cement-stabilized macadam, and when the basalt fiber dosage is 0%–0.1% and the rubber particles dosage is 0%–1%, the strength increases with the increase of recycled aggregate dosage. In the later stage, the mechanical strength of cement-stabilized recycled aggregate is less than cement-stabilized macadam.

- (2)

The mechanical strength of the mixture decreases with the increase of rubber particle content. In the mixture with rubber particles, the joint surface becomes complex, and the combination of rubber particles with aggregate and binder is not good enough. The joint surface between rubber particles is also very fragile, which reduces the overall compressive strength and is not conducive to the growth of splitting strength. Due to the flexible material rubber, the tensile strength of the interface between rubber particles and aggregates decreases. On the other hand, with the increase of rubber particles content, the joint surface between the original aggregate is relatively reduced, which further weakens the splitting resistance of the mixture.

- (3)

The incorporation of rubber particles helps enhance the dry shrinkage and frost resistance of the mixture. Rubber particles can slow down the tensile stress on the joint surface damage, thereby reducing the dry shrinkage crack rate; it can also reduce the damage of expansion compressive stress on the joint surface, so as to ensure that the compressive strength of the mixture after freeze-thaw decreases not too much.

- (4)

The mechanical strength, dry shrinkage, and frost resistance of the mixture increase with the increase of basalt fiber content. In the mixture with basalt fiber, basalt fiber acts as a tie bar in the mixture. When the dry shrinkage tensile stress is generated, basalt fiber can bear the tensile stress before the binder, which weakens the tensile stress to cope with the tensile force of the joint surface.

- (5)

Considering the two conflicting requirements of increasing the content of rubber particles on the weakening effect of mechanical properties and the enhancement of durability, the comprehensive road performance of the mixture is the best when the content of rubber particles is 0.5%, the content of basalt fiber is 0.1%, and the content of recycled aggregate is 50%.

Conflicts of Interest

The authors do not have any conflicts of interest with other entities or researchers.

Authors’ Contributions

Y. Z. Chen and J. Wang wrote the original draft of the manuscript; Z. X. Li, C. H. Wang, and J. Guan reviewed and edited the manuscript; L. Zhang, X. Q. Wang, X. G. Hu, Y. J. Zhang, H. J. Chen, and Y. W. Li did the investigation; and Z. X. Li, C. H. Wang, and J. Guan performed discussion. All authors have read and agreed to the final version of the manuscript.

Acknowledgments

This work was supported by Key R&D and Promotion of Special Scientific and Technological Research Projects of Henan Province (Grant nos. 182102210061 and 212102310089) and Key Scientific Research Projects of Colleges and Universities in Henan Province in 2021: Study on pavement performance of cotton straw cellulose modified asphalt (Grant no. 21A580004).

Open Research

Data Availability

Some or all data, models, or codes that support the findings of this study are available from the corresponding author upon reasonable request.