Fly Ash/Silica Fume Coral Concrete with Modified Polypropylene Fiber for Sustainable Building Construction

Abstract

Coral concrete made of coral sand/aggregates has attracted significant interest in the construction of coastal or artificial island buildings by saving significant economic and environmental costs for transporting the conventional building materials from mainland. However, the application of coral concrete is very limited due to the drawback such as low strength, brittleness, and high porosity. This paper develops a new coral concrete composite utilizing coral debris to replace sand and aggregates, sea water, supplementary cementitious waste materials, namely, fly ash and silica fume and modified polypropylene fiber (MPPF) to achieve both sustainable and economic development needs in coastal and island building and construction. The mechanical and durability of the new coral concrete are evaluated and the synergistic effects of fly ash and silica fume on the performance of MPPF coral concrete are discussed. It has been found out that the addition of fly ash and silica fume in MPPF coral concrete can significantly improve the strengths and reduce the chloride diffusion of coral concrete. Compared with those from the specimens without fly ash and silica fume, the compressive, splitting tensile, flexural strengths of MPPF concrete with 10% fly ash and 10% silica fume are improved by 31%, 33%, and 58%, respectively. The new coral concrete composite would be an ideal building material solution for coastal and artificial island applications as most of the materials come from the local wastes.

1. Introduction

In the next few decades, most existing raw construction materials will diminish due to limited stock on the planet, for example, river sands and virgin coarse aggregates [1–3]. Moreover, almost all major economies in the world have set out carbon neutral or net zero emission target around the middle of this century. Construction is a carbon extensive sector involving the use of high carbon embodied materials such as cement and steel and fossil fuels for transportation of the materials, building construction, and utilization [4–7]. It is widely accepted that decarbonizing the construction sector is a key to achieving the carbon neutral or net zero target. In this regard, new materials which have low embodied carbon or even negative carbon and new structural system are urgently needed.

In recent years, coral reef calcareous sands and aggregates have attracted significant interest in using them in concrete to replace the river sands and gravel aggregates [8–10]. This is especially the case for coastal construction and artificial island buildings, since the transportation of the traditional building materials from mainland might be extremely costly and environmentally unfriendly. There are a lot of atolls, platform reefs, and islands worldwide and these coral deposits are treated as solid wastes, occupying large spaces. To use these coral deposits for buildings and structures nearby would be an economic and sustainable approach.

However, the coral concrete made of coral sand and aggregates has many defects, such as low strength, brittleness, and high porosity [9–15]. Arumugam and Ramamurthy [16] investigated the compressive strength of coral aggregate concrete and found that coral concrete with nominal mixes demanded more water and also yielded relatively lower strengths than the corresponding conventional concrete. Da et al. [17] carried out the uniaxial compressive tests of coral concrete with different strength grades and found that the higher the strength grade, the steeper the downtrend of descent stage and the greater the brittleness of failure. Wang et al. [18] prepared the concrete samples with coral sand and natural river sand, respectively. They found that elastic modulus of coral sand concrete was approximately 72% of that of natural sand concrete and the porosity of coral sand concrete is higher than that of natural sand concrete. Da et al. [19] tested the chloride diffusion coefficient of concrete with coral sand and aggregate and found the chloride diffusion coefficient is 1–8 times larger than that of normal concrete. Huang et al. [20] investigated the chloride transport performance of coral aggregate concrete and found the chloride diffusion coefficient decreased with the increase of compressive strength and cement content. Due to the weaknesses of coral concrete on mechanical and durable performances, the application of coral concrete is limited to sea walls, road pavement, and other port structures [9].

To improve the coral concrete system and make it suitable for use in buildings and structures, some researchers have tried to pretreat the coral or add supplementary cementitious materials. Liu et al. [21] made surface treatment of coral aggregate by soaking it into granulated blast furnace slag slurry and sodium silicate and found the concrete compressive strength after the coral surface treatment was 26.88% higher than that without the coral surface treatment. Yao et al. [22] used hydrochloric acid to soak coral aggregate and then used water glass to form colloidal film on the aggregate surface to improve the strength of coral concrete. It has been found that the addition of fly ash and silica fume can improve the compactness of cement mortar and increase the compressive strength of concrete. Da et al. [19] replaced the ordinary Portland cement with magnesium sulfate cement to make coral concrete and found that the chloride binding capacity of magnesium sulfate cement coral concrete was 0.56–1.24 times that of ordinary Portland cement coral concrete. Wu et al. [23] tried to add fly ash and silica fume to improve the mechanical properties and durability of coral concrete and found that it can make the interfacial transition zone between coral aggregate and mortar denser. Cheng et al. [24] used the metakaolin and blast furnace slag as supplement materials in coral sand concrete and found that the addition of 5 wt% metakaolin and 15 wt% slag resulted in an increase of 19% in compressive strength of coral sand concrete.

Adding some supplementary cementitious materials can considerably increase the compressive strength and durability of the coral concrete. Research has also been carried out by adding fiber to concrete to improve concrete toughness [25–27]. Fiber can restrain the expansion of cracks in concrete, improve the cracking resistance and impermeability of concrete, and extend the service life of concrete structures [28]. The tensile and fracture property of concrete is an important criterion for the design of mix ratio, the evaluation of strength grade, and the inspection of concrete quality. Liu et al. [29] added carbon fibers into coral concrete and found that the toughness of coral concrete with carbon fibers (1.5% by weight of the cement) was 367%–586% higher than that without carbon fibers. Further, Liu tried to use hybrid fibers including carbon fibers, basalt fibers, and plastic steel fibers to improve the mechanical performance of coral concrete and found the cube compressive strength, splitting tensile strength, axial compressive strength, and elastic modulus for coral concrete with hybrid fibers can be improved by 11.2%, 25.5%, 14.1%, and 8.5%, respectively. Niu et al. [30] investigated the effects of basalt fiber on the mechanical properties of coral concrete and found the adding 0.05% basalt fiber yielded the highest improving effect on the mechanical properties.

This paper attempts to develop a new coral concrete for building construction, utilizing local coral debris for sand and aggregates, sea water, and other supplementary cementitious waste materials, to achieve both sustainable and economic development needs. We design the coral concrete using fly ash and silica fume to improve the compactness of cement mortar and increase the strength/durability of concrete and modified polypropylene fiber for enhanced tensile and fracture resistance. We then discuss the effects of fly ash, silica fume, and the modified polypropylene fiber on the performance of coral concrete. This research can provide a basis for the research and application of fly ash- and silica fume-reinforced fiber coral concrete. The new coral concrete composites would be an ideal building material solution for offshore applications as most of the materials come from the local wastes.

2. Experimental Program

2.1. Raw Materials

Cement with a grade of 42.5 N/mm2 is used, which is produced by Jiangsu Zhenjiang Helin Cement Company. The initial setting time and final setting time for the cement are 185 and 250 minutes, respectively. Figure 1(a) shows the coarse aggregates which are corals from an island in the South China Sea. The coarse aggregates are continuously graded with particle sizes of 5–16 mm. Figure 1(b) shows the fine aggregates, namely, coral sands. The specific physical parameters of the coarse and fine aggregates are presented in Table 1. Figure 2 shows the modified polypropylene fibers (MPPF) with a length of 12 mm. The basic parameters are listed in Table 2. Moreover, coal fly ash provided by Nanjing Xiaguan Power Plant and silica fume provided by Nanjing Second Thermal Power Plant are used. The basic parameters of the fly ash and silica fume are given in Table 3. Concrete mixing water is artificially prepared seawater. The main mineral components in the water are NaCl, MgCl2, Na2SO4, and CaCl2 and the mass concentration of chloride ions is 19.00 g/L. Polycarboxylic acid is added to the mix as a superplasticizer.

| Aggregate type | Fineness modulus | Apparent density (kg/m3) | Bulk density (kg/m3) | Cylindrical compress strength (MPa) | Porosity (%) | Natural water content (%) |

|---|---|---|---|---|---|---|

| Coral sand | 2.6 | 2450 | 1163 | 48 | 0.3 | 2450 |

| Coral reef | —— | 1865 | 928 | 1.6 | 55 | 0.1 |

| Fiber type | Length (mm) | Elongation at break (%) | Tensile strength (MPa) | Elastic modulus (GPa) | Diameter (μm) |

|---|---|---|---|---|---|

| MPPF | 12 | 21 | 510 | 4.8 | 22 |

| Type | Ignition loss (%) | Density (g/cm3) | BET (m2/g) | Fineness (%) | SO3 content (%) | Water content (%) | Water demand ratio (%) | Stability (mm) |

|---|---|---|---|---|---|---|---|---|

| Fly ash | 3.7 | 2.16 | 17.2 | 8.7 | 0.8 | 0.5 | 98 | 2.0 |

| Silica fume | 2.5 | 2.7 | 17.2 | 2.4 | 90.2 | 0.7 | 121 | 109 |

2.2. Specimens

We prepared 9 groups of coral concrete specimens with different fly ash and silica fume contents under a constant water to cement ratio 0.35. A control group was designed for comparisons, in which fly ash and silica fume are not added in the specimens. The contents of fly ash and silica fume are both at the range of 5%–15% because a higher amount will reduce the strength. Further, our previous exploratory experiments showed that adding MPPF of 2 kg/m3 to coral concrete can best improve the tensile and flexural performance. Table 4 shows the mix ratio design for all specimens.

| Serial number | W/C | Water (kg/m3) | Total amount of cementing material (kg/m3) | Coral sand (kg/m3) | Coral reefs (kg/m3) | Water reducing agent (kg/m3) | Fly ash content (%) | Silicon ash content (%) | MPPF content (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|

| TS0 | 0.35 | 195 | 557 | 749 | 749 | 4 | 0 | 0 | 2 |

| TS1 | 0.35 | 195 | 557 | 749 | 749 | 4 | 5 | 5 | 2 |

| TS2 | 0.35 | 195 | 557 | 749 | 749 | 4 | 5 | 10 | 2 |

| TS3 | 0.35 | 195 | 557 | 749 | 749 | 4 | 5 | 15 | 2 |

| TS4 | 0.35 | 195 | 557 | 749 | 749 | 4 | 10 | 5 | 2 |

| TS5 | 0.35 | 195 | 557 | 749 | 749 | 4 | 10 | 10 | 2 |

| TS6 | 0.35 | 195 | 557 | 749 | 749 | 4 | 10 | 15 | 2 |

| TS7 | 0.35 | 195 | 557 | 749 | 749 | 4 | 15 | 5 | 2 |

| TS8 | 0.35 | 195 | 557 | 749 | 749 | 4 | 15 | 10 | 2 |

| TS9 | 0.35 | 195 | 557 | 749 | 749 | 4 | 15 | 15 | 2 |

Compared with ordinary gravel aggregate, coral aggregate has higher porosity, smaller density, larger water absorption capacity, and a variety of shape. Moreover, a large proportion of coral aggregate is in long rod-like shape. The mixing of coral concrete follows the technical standard for application of lightweight aggregate concrete (JGJ/T12-2019) [31]. Coarse and fine aggregates and the modified polypropylene fibers were put into the mixer and mixed for 1 minute firstly to make the fibers dispersed evenly in the mixture. Then, half of the mixing water was added and then the mixture was stirred for 1 minute. Afterwards, the remaining mixing water was mixed with the superplasticizer and stirred well, before being poured with cement into the mixer and stirred for 2 minutes.

There are a large number of rod-shaped long strip coral aggregates, which have relatively poor bonding performance with cement mortar. Therefore, the mixture was poured to the mold in two times to avoid aggregate floating: first, a half concrete was added and vibrated on shaking table for 20 seconds; then the remaining concrete was added to the mold and vibrated. After casting, the samples were cured in room temperature for 24 hours and, after demolding, moved to the curing room (the temperature is 20 ± 2°C and the humidity is 95%).

2.3. Testing Methods

2.3.1. Mechanical Performance

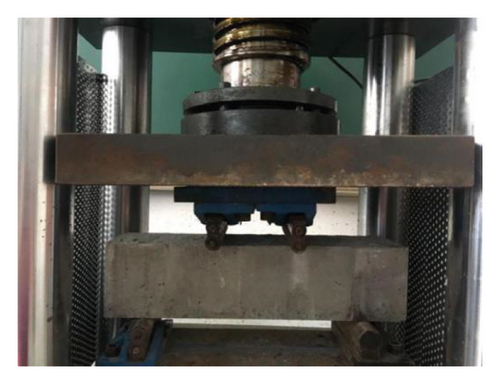

Compressive Strength Test. Uniaxial cube compressive strengths for all samples were tested with the sample size of 100 mm × 100 mm×100 mm. The center of the specimen was aligned with the center of the lower bearing plate of the testing machine and the surface of specimen should be in uniform contact with the upper and lower bearing plates. The loading speed adopted was 0.5 MPa/s. Figure 3 shows the testing equipment and specimen. Three samples for each batch were tested and the averaged value was used as the compressive strength.

Splitting Tensile Strength Test. The specimen size for the splitting tensile test is 100 mm × 100 mm×100 mm. Parallel lines across the center of the top and bottom surfaces were drawn to determine the position of the splitting surface. The specimen was placed in the center position of the bearing plate of the testing machine and the splitting surface was perpendicular to the surface of the bearing plates. The testing arrangement is shown in Figure 4. The loading speed is 0.05 MPa/s.

2.3.2. Chloride Ingress Test

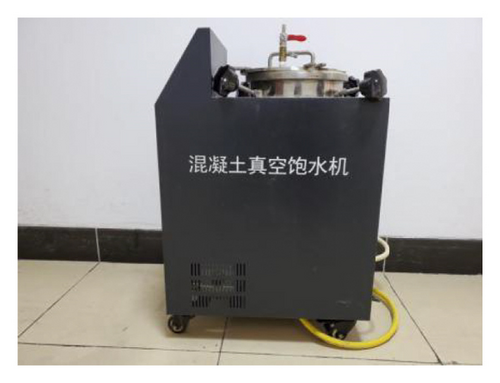

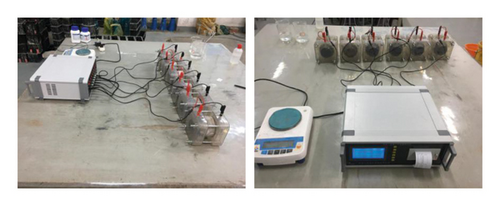

Electromagnetic flux method was used to test the chloride ion permeability of the modified polypropylene fiber (MPPF) coral concrete. The SX-SJ type concrete intelligent vacuum water filling machine was first selected to conduct water saturation treatment, as shown in Figure 6(a). The electric flux testing used SX-DTL series of electric measuring instruments, as shown in Figure 6(b). The specimens used in this test were cylindrical samples with 100 mm in diameter and 50 mm in thickness, as illustrated in Figure 6(c). Paraffin seal was applied on the side of the cylinder to ensure that chloride ions only migrate in one direction along the column height direction.

After the specimens were cast, they were exposed to air for 28 days. The top and bottom surfaces were then polished by a grinder and the side was brushed with wax. The treated specimens were then placed in the vacuum water filling machine. In the dry pumping stage, the vacuum chamber pressure was reduced to 1–5 kPa and maintained for 3 hours. Distilled water was then injected into the vacuum chamber until the specimen was completely submerged. The pressure was then maintained at 1–5 kPa for 1 hour before returning to normal pressure and we continued submerging the specimens for 18 ± 2 hours. After taking out and drying the specimens, the testing groove with screw and rubber pad was applied to ensure the seal between specimen and fixture for the electric flux test.

The electric flux test was carried out in room temperature (i.e., 20–25°C) and relative humidity above 95%. The NaCl solution with the mass concentration of 3% was injected into one side of the cathode of the test tank while the NaOH solution with molar concentration of 0.3 mol/L was injected into the other side of the anode of the test tank. The quantity of electric charge in 6 hours through the testing specimens was recorded. At the end of the test, the solution in the fixture was poured out immediately and the fixture was washed with distilled water.

2.3.3. Water Permeability Test

2.3.4. Microstructural Morphology

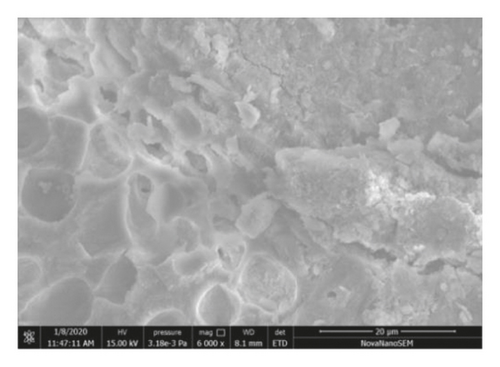

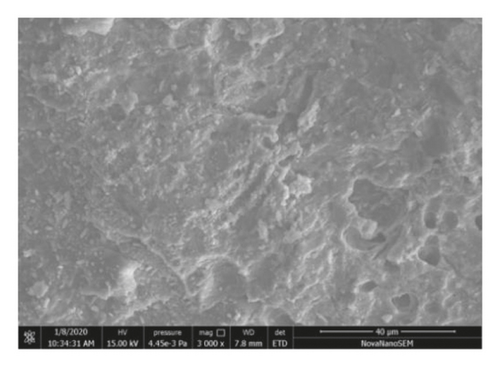

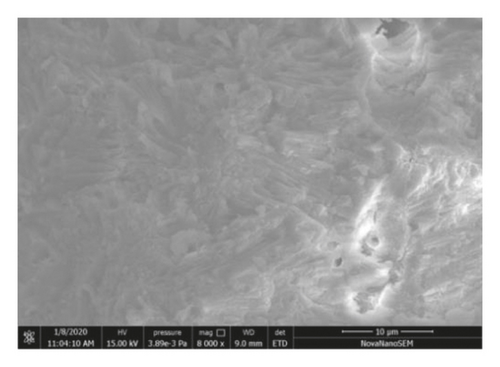

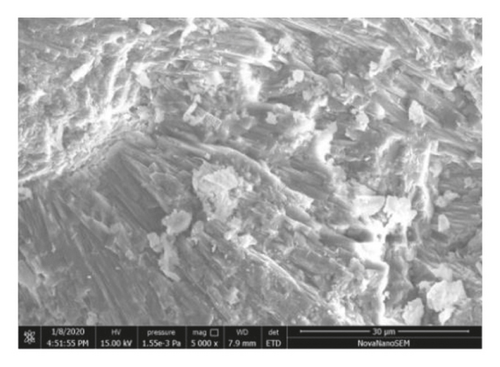

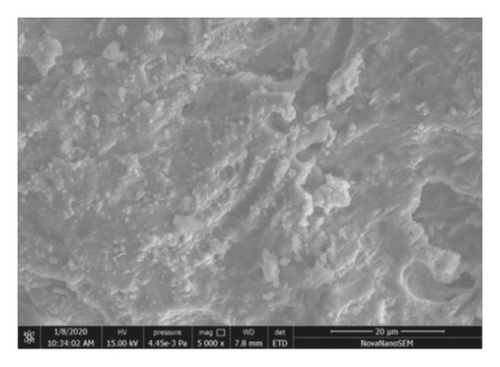

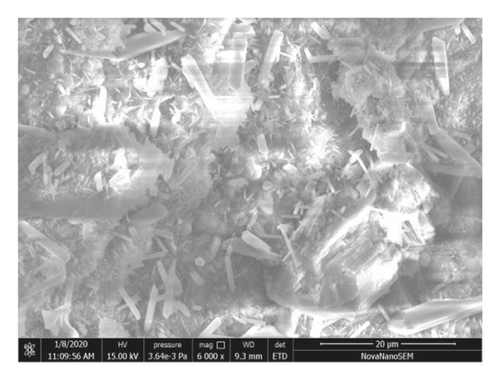

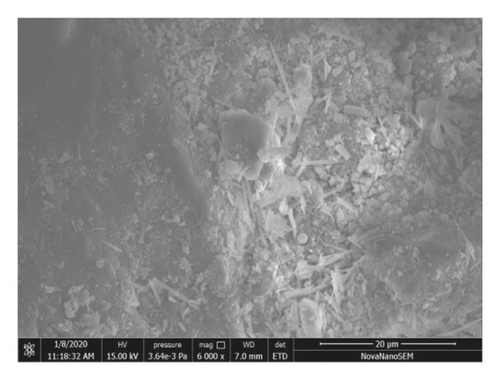

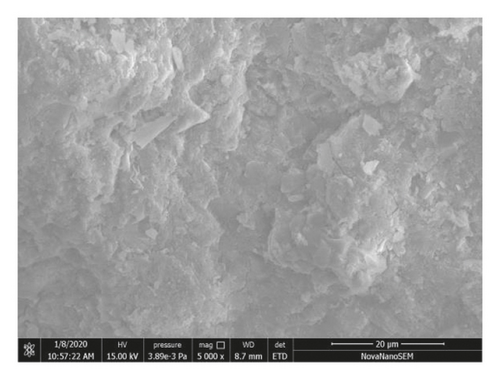

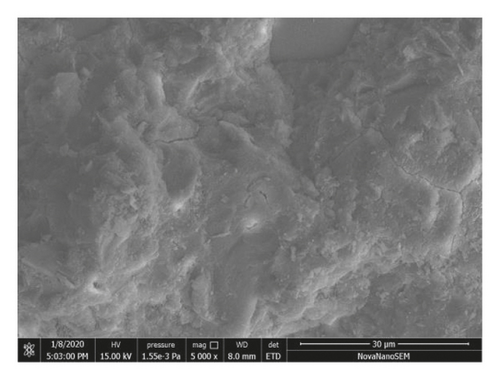

Concrete specimens with a curing age of 28 days were broken for the scanning electron microscope (SEM) tests. The surface layer samples were taken, washed with the distilled water, and soaked in anhydrous ethanol to terminate the hydration reaction. Before SEM analysis, the samples were fully dried in a vacuum oven at the temperature of 60 °C. The micromorphology of the modified MPFF coral concrete after hydration was observed by Nova Nano SEM 450 field emission scanning electron microscope.

3. Results and Analysis

3.1. Mechanical Properties

3.1.1. Compressive Strength of MPPF Coral Concrete

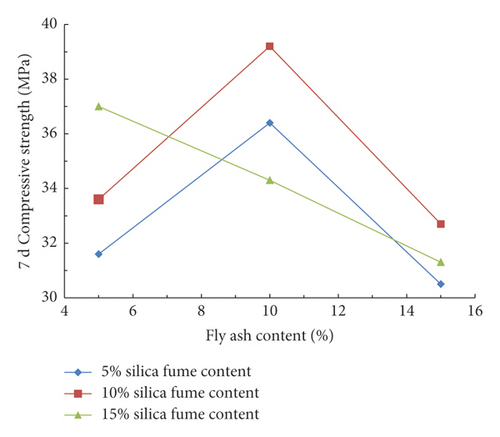

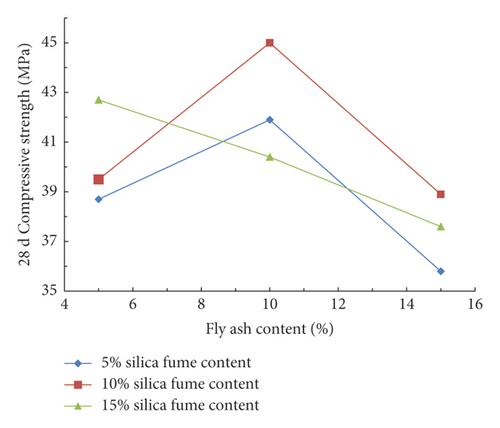

Figure 9 shows the influence of fly ash content on the compressive strength of MPPF coral concrete. It can be found that when the silica fume content is 5%, the 7-day and 28-day cubic compressive strengths of MPPF coral concrete first increase and then decrease with the increase of fly ash content. When the fly ash content is 10%, the maximum 7-day compressive strength is 36.4 MPa, and the maximum 28-day compressive strength is 41.9 MPa. When the silica fume content is 10%, the 7-day and 28-day compressive strengths of MPPF coral concrete also show a trend of increasing first and then decreasing with the increase of fly ash content. When the fly ash content is 10%, the maximum 7-day compressive strength is 39.2 MPa, and the maximum 28-day compressive strength is 45 MPa. When the content of silica fume is 15%, the compressive strength of MPPF coral concrete cube decreases with the content of fly ash increasing.

The reason for the strength difference is that partly replacing a small amount of cement with fly ash can improve the compactness of the concrete, due to the combined active effect of fly ash and the microaggregate effect. The active SiO2 and Al2O3 in fly ash react with the cement hydration product Ca(OH)2 to generate calcium silicate hydrate and calcium aluminate hydrate, which reduces the crystal content in the concrete and fills the pores in the concrete, increasing the compactness of the concrete. However, with the increase of fly ash content, the excess fly ash will not be reactivated [33, 34], which reduces the compressive strength of the MPPF coral concrete.

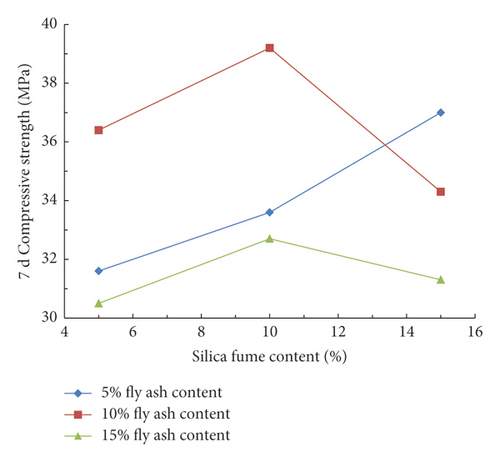

Figure 10 shows the influence of silica fume content on the compressive strength of MPPF coral concrete. When the fly ash content is less than 5%, the 7-day and 28-day compressive strengths of MPPF coral concrete both increase with the increase of silica fume content. When the fly ash content is 10%, the 7-day and 28-day compressive strength of MPPF coral concrete increase first then decrease with the increase of silica fume content. When the silica fume content is 10%, the maximum 7-day and 28-day compressive strengths are 39.2 MPa and 45 MPa, respectively. When the fly ash content is 15%, the 7-day and 28-day compressive strength of MPPF coral concrete also show a trend of increasing first and then decreasing with the increase of silica fume content. When the silica fume content is 10%, the maximum 7-day compressive strength is 32.7 MPa, and the maximum 28-day compressive strength is 38.9 MPa. The mechanical property enhancement is attributed to two aspects: first, the physical microparticle filling effect of silica fume particles. Tiny silica fume particles are evenly distributed between the cement particles, improving the particle size grading of cementing material and increasing the density of the cement mortar, as well as improving the compactness and the bond strength between the coral aggregate and cement paste. Second, the main chemical component of silica fume is silicon dioxide, which is a highly active material at room temperature. It can react with calcium hydroxide produced by cement hydration and convert calcium hydroxide into calcium silicate gel [35], thereby improving the strength of MPPF coral concrete.

When the contents of fly ash and silica fume are both above 10%, the compressive strength of MPPF coral concrete tends to decrease. This is because a large amount of excess silica fume can combine with water and form a silicon-rich gel, which absorbs a large amount of water and reduces the workability of concrete, thus reducing the quality of concrete and, in particular, the strength of MPPF coral concrete.

Compared with MPPF coral concrete of TS0 group (without fly ash and silica fume), the 28-day compressive strength of MPPF coral concrete of TS1 to TS9 group was increased by 13%, 15%, 24%, 22%, 31%, 18%, 4%, 13%, and 10%, respectively. Therefore, fly ash and silica fume can significantly improve the compressive strength of MPPF coral concrete. The addition of fly ash and silica fume can change the particle size distribution and hydration products of cementing materials and increase the compactness of the concrete.

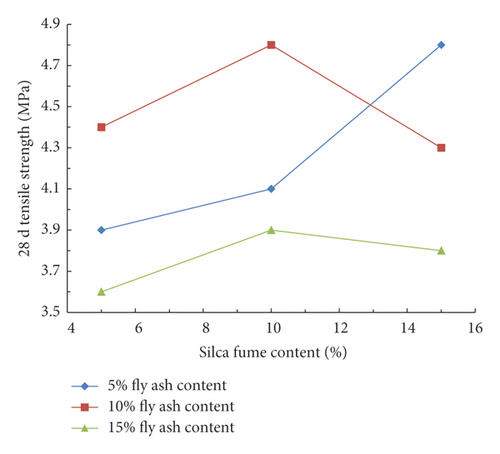

3.1.2. Tensile Strength of MPPF Coral Concrete

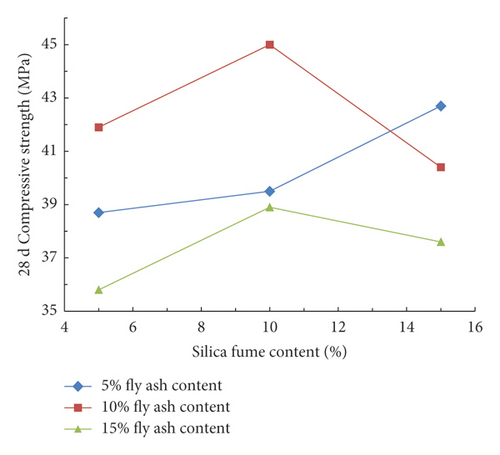

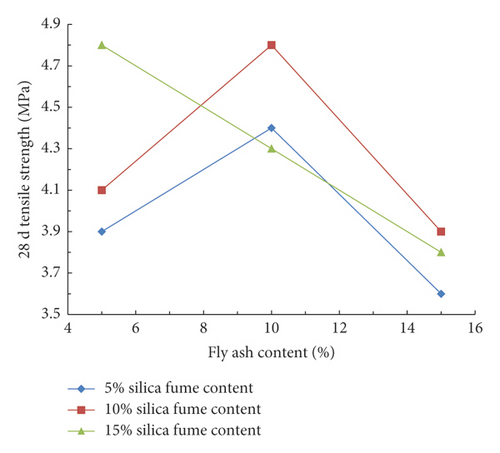

Figure 11 shows the effect of fly ash and silica fume on the tensile strength of MPPF coral concrete. When the silica fume content is 5%, the splitting tensile strength of MPPF coral concrete gradually increases with the fly ash content increasing from 5% to 10%. When the fly ash content is 10%, the maximum splitting tensile strength is 4.4 MPa. When the silica fume content is 10% and the fly ash content increases from 5% to 10%, the splitting tensile strength of MPPF coral concrete also increases with the increase of the fly ash content. When the fly ash content is 10%, the maximum splitting tensile strength is 4.8 MPa. This is because the SiO2 and Al2O3 in fly ash can react with cement hydration products to produce low-calcium silicate hydrate and calcium aluminate hydrate.

When the silica fume content is 5% and the fly ash content increases from 10% to 15%, the tensile strength of MPPF coral concrete will gradually decrease. When the silica fume content is 10% and the fly ash content increases from 10% to 15%, the tensile strength of MPPF coral concrete also decreases gradually. When the silica fume content is 15%, the MPPF coral concrete splitting tensile strength decreases with the increase of fly ash content. This is because the total amount of cementing material remains unchanged; the increase of fly ash content means the reduction of cement content, while most fly ash does not cause hydration reaction.

According to Figure 11(b), when the fly ash content is 5%, the MPPF coral concrete splitting tensile strength increases with the increase of silica fume content. When the fly ash content is 10%, the splitting tensile strength of coral concrete increases first and then decreases with the increase of silica fume content. When the silica fume content is 10%, the maximum splitting tensile strength is 4.8 MPa. When the fly ash content is 15%, the MPPF coral concrete splitting tensile strength first increases and then decreases with the increase of silica fume content. When the silica fume content is 10%, the maximum splitting tensile strength is 3.9 MPa. This is because the fly ash effect and microaggregate effect of silica fume greatly improve the pore structure of concrete, which not only reduces the porosity but also reduces the orientation degree, quantity, and grain size of Ca(OH)2 at the interface. It thus improves the splitting tensile strength of MPPF coral concrete. When the content of fly ash is 10% or 15%, the tensile strength of MPPF coral concrete shows a trend of decreasing with the silica fume content increasing from 10%. This is because the products generated by the reaction of silica fume and Ca(OH)2 can fill the capillary holes inside the concrete and change its stress distribution, but the resulting gel after absorbing water will produce a certain volume expansion, increasing the internal stress of the concrete. It may lead to the generation of cracks and affect the improvement of the concrete tensile strength.

Compared with MPPF coral concrete of TS0 group (without fly ash and silica fume), the 28-day splitting tensile strength of MPPF coral concrete of TS1 to TS9 group was increased by 8%, 14%, 33%, 22%, 33%, 19%, 0%, 8%, and 6%, respectively, indicating that fly ash and silica ash can significantly improve the splitting tensile strength of MPPF coral concrete.

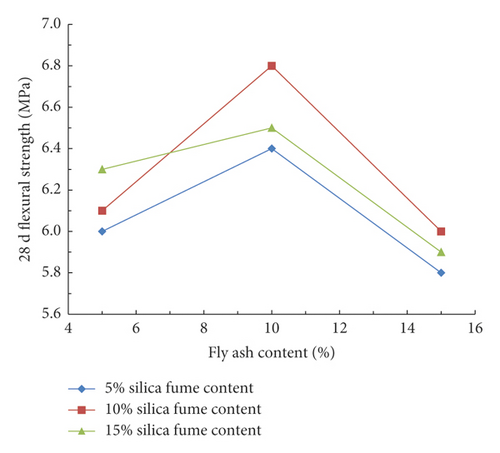

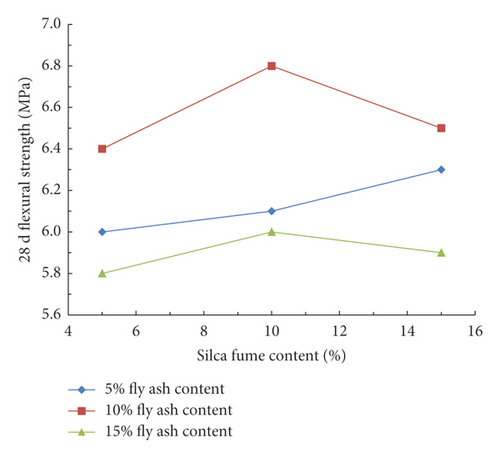

3.1.3. Flexural Strength of MPPF Coral Concrete

Figure 12(a) shows that when the content of silica fume is constant, the 28-day flexural strength of MPPF coral concrete increases as the content of fly ash increases from 5% to 10%. This can be explained as smaller fly ash particles can present between the cement hydration products and gradually form strong and interconnected material phase. This will not only reduce the porosity of the coral concrete but also fill the gap between fiber and cement paste, thus improving the degree of the bond between them. However, when the content of fly ash increases from 10% to 15%, the flexural strength of MPPF coral concrete presents a downtrend. The main reason is that an excessive amount of fly ash mixed will result in a decline in the proportion of cement, and there is no enough calcium hydroxide generated by hydration of cement to convert all active silica to CSH gel.

According to Figure 12(b), when the fly ash content is 5%, the flexural strength of MPPF coral concrete increases with the increase of silica fume content. When the fly ash content is 10% and 15%, the flexural strength of MPPF coral concrete tends to decrease first and then increase with the increase of silica fume content. When the silica fume content is 10%, the maximum flexural strengths are 6.8 MPa and 6 MPa, respectively. Mixing with silica fume can improve the cement matrix and the interface between the fibers. Therefore, adding the right amount of silica fume can improve MPPF coral concrete flexural strength. However, the inappropriate content of fly ash and silica fume can reduce the interaction and bridging effect, weakening the performance of MPPF coral concrete.

Compared with TS0 group of MPPF coral concrete (without fly ash and silica fume), TS1 to TS9 cooperated by the nine groups of MPPF coral concrete flexural strength were increased by 40%, 42%, 47%, 49%, 58%, 51%, 35%, 40%, and 37%, respectively. This shows that the fly ash and silica fume can significantly increase the flexural strength of concrete MPPF coral.

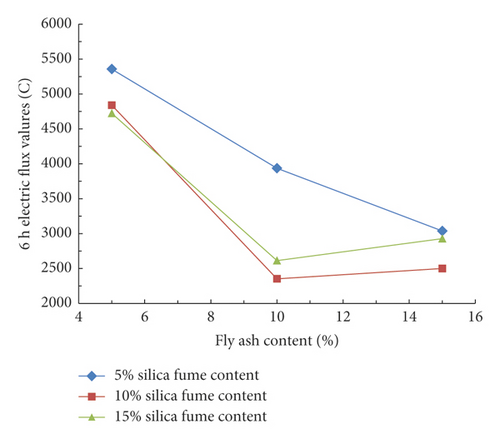

3.2. Durability of MPPF Coral Concrete

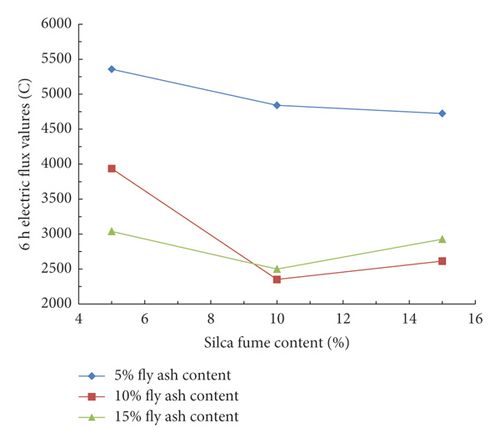

The permeability determines the service life of the components and is one of the key factors affecting the durability of concrete. At present, in the research of concrete's permeability, the water permeability and chloride ion permeability are usually used to evaluate the concrete permeability. According to Figure 13(a), when the silica fume content is 5%, the 6-hour electric flux value of MPPF coral concrete decreases with the increase of the fly ash content. When the content of silica fume is 10% and 15%, respectively, and the content of fly ash is increased from 5% to 10%, the 6-hour electric flux value of MPPF coral concrete shows a trend of decrease. This is due to the filling effect of fly ash and the pozzolanic reaction, reducing the porosity of hardened concrete, and improving the pore characteristics of concrete. The secondary filling effect of fly ash and the secondary hydration product reduce the amount of calcium hydroxide and the porosity, refine the pore diameter, and increase the compactness of concrete. It can thus reduce the electric flux property in concrete and improve the chloride ion permeability of the coral concrete. However, excessive fly ash does not contribute to the pozzolanic effect; thus, in the interface transition zone, a certain amount of needle crystal plate and hydration of fly ash particles still exist, leading to osteoporosis of interface transition zone structure.

Figure 13(b) shows the effect of silica fume content on electric flux of concrete. When the fly ash content is 5%, the 6-hour electric flux value of MPPF coral concrete decreases with the increase of silica fume content, indicating that its resistance to chloride ion penetration gradually improves. When the fly ash content is 10% and 15%, respectively, the 6-hour electric flux value of MPPF coral concrete shows a trend of decreasing with the silica fume content increasing from 5% to 10%. This is because the fineness of silica fume is smaller than that of cement and fly ash, and silica fume can well fill the pores between fly ash and cement, which makes the gradation of cementing materials more reasonable and compacts the microstructure of concrete. For concrete, the formation of low permeability, dense microstructure, and discontinuous pore system is very important to reduce the penetration of chloride ions in concrete. The pozzolanic reaction of silica fume can more easily form a discontinuous pore system. When the fly ash content is 10% and 15%, the 6h electric flux value of MPPF coral concrete shows an increasing trend as the silica fume content increases from 10% to 15%. Compared with the MPPF coral concrete of TS0 group (without fly ash and silica fume), the flux values of MPPF coral concrete of TS1 to TS9 group were reduced by 9%, 30%, 45%, 17%, 60%, 56%, 18%, 52%, and 48%, respectively.

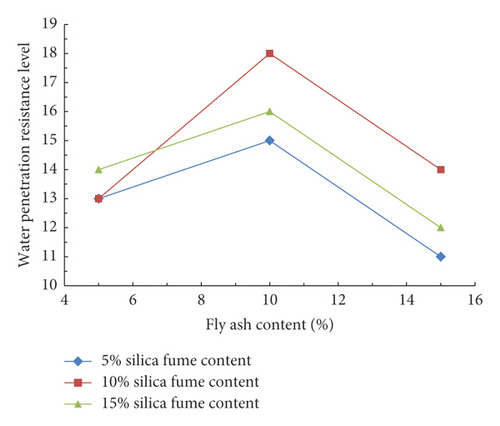

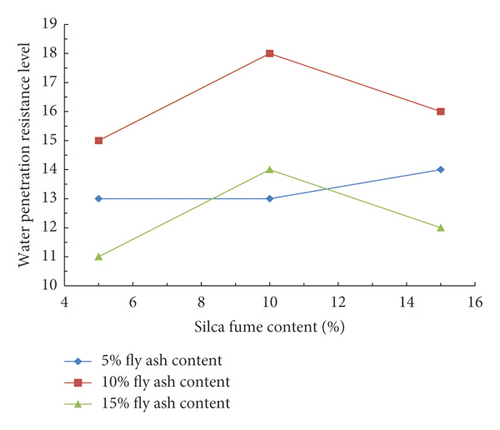

Figure 14 shows the effect of silica fume and fly ash on the water penetration resistance of MPPF coral concrete. When the silica fume content is constant, the water penetration resistance of MPPF coral concrete tends to increase first and then decrease with the increase of the fly ash content. This is because the fly ash particles are spherical and have a smooth surface, which has a strong morphological effect to improve the fluidity of concrete. And most of the fly ash particles generally do not react with the cement hydration products and the microaggregate effect of fly ash makes the fine fly ash particles be evenly distributed among the cement particles, reducing the air content of cement paste, preventing the cement particles sticking. Moreover, in the dispersed state of hydration reaction, the water consumption and porosity are reduced at the same time. However, too much fly ash will damage the original structure and performance of concrete, resulting in negative effects on the water penetration resistance.

When the fly ash content is 5%, the water penetration resistance of MPPF coral concrete shows a trend of increasing with the gradual increase of silica fume content: when the fly ash content is 10% and 15%, respectively, the water penetration resistance of MPPF coral concrete also increases gradually when the silica fume content increases from 5% to 10%. This is because the silica in silica fume combines with the calcium hydroxide precipitated during hydration to form a compact and dense C-S-H gel hydrate. In addition, silica fume is filled in the wool pores and large pores inside the concrete, blocking or partially blocking the capillary channels of the concrete, thus forming a more compact concrete structure. And when the dosage of fly ash was 10% and 15%, the dosage of silica fume increased from 10% to 15%, and the water penetration resistance of the MPPF coral concrete showed a trend of decline.This is because of an unreasonable proportion of fly ash and silica fume content., A large amount of silica fume and water formed rich silicon gel, which reduced the compactness of the coral concrete.

3.3. Microstructure Analysis of MPPF Coral Concrete

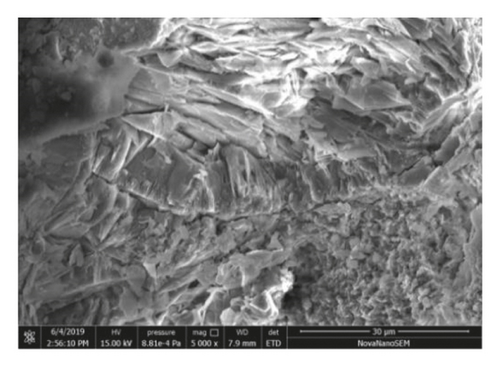

The main products of hydration reaction of Portland cement are calcium silicate hydrate (C-S-H), calcium aluminate hydrate gel (C-A-H), calcium hydroxide crystal (CH), ettringite (AFt), and calcium sulfoaluminate hydrate (AFm). And the hydrated calcium silicate gel has a larger surface energy, no fixed shape, and the largest proportion in the hydration products. It is combined with the surrounding free ions and then tends to balance. The aggregate particles contained in the hydrated calcium silicate gel can combine with each other to form a spatial system, and many forms of hydrated calcium silicate gel to a large extent determine the strength of the concrete. Figure 15(a) shows the microscopic morphology of MPPF coral concrete without fly ash and silica fume. It can be seen that the main product of the concrete hydration is dense type C-S-H. There are also a lot of calcium hydroxide crystal, which affects the development of the bond strength in the transition interface zone between the aggregate and mortar and reduces the overall strength of the coral concrete. But a part of the hydration products is formed by cement mortar penetrating into the pores of the coral aggregate and connecting to the aggregate closely around the cement matrix. This nested structure makes the aggregate-mortar interface transition area of MPPF coral concrete stronger than that of normal concrete.

Figures 15(b)–15(j) show the hydration products of MPPF coral concrete mixed with fly ash and silica fume. The micromorphology of the interfacial transition zone between the coral aggregate and the mortar changes greatly with the addition of fly ash and silica fume. The interface transition zone between the coral aggregate and the mortar without adding fly ash and silica fume is mainly connected by hydration products that penetrate into the pores inside the coral aggregate. Figure 15(e) shows the presence of a thin sheet of calcium hydroxide at the junction of the aggregate and the mortar, which helps to fill the gap between the hydration product and the aggregate. In addition, flocculent substances are interlinked with calcium hydroxide, filling the interface transition zone, reducing porosity, improving pore structure, increasing the compactness inside the coral concrete, and improving the performance of the coral concrete.

Moreover, for specimens with fly ash and silica fume, hydrated calcium silicate gel also exists in a compact state. Due to the reaction of fly ash and silica fume ash, the amount of calcium hydroxide and crystal size are both reduced. The amount of the hydrated calcium silicate and ettringite are increased, which improves the macro strength of coral concrete. In particular, some plate-like calcium hydroxide crystals, the dense C-S-H gel, and fibrous and cloud C-S-H are found in Figure 15(f). Different forms of C-S-H gel combine with each other, forming a uniform spatial reticulated structure. With the development of hydration reaction, the original water filling space is gradually replaced by hydration products. The hydration reaction of the original cement is affected by the inappropriate mixing ratio of fly ash and silica fume. As shown in Figure 15(h), even if the product contains less calcium hydroxide, the insufficient cement content involved in hydration results in the relatively loose CSH gel structure. So the strength of this group was lower than the others with fly ash and silica fume. The inappropriate mixing ratio of fly ash and silica fume will not fully play the interaction and composite effect of the admixture. Generally, 10% fly ash and 10% silica fume can mostly improve the density, strengths, and durability of the MPPF coral concrete.

4. Conclusions

- (1)

Adding fly ash and silica fume can significantly improve the strengths of MPPF coral concrete. 10% fly ash and 10% silica fume yield the highest improvement of the strengths; that is, compared with those for the specimens without fly ash and silica fume, the compressive, splitting tensile, and flexural strengths for specimens with 10% fly ash and 10% silica fume are improved by 31%, 33%, and 58%, respectively.

- (2)

The addition of fly ash and silica fume can effectively reduce the chloride diffusion and water penetration resistance of MPPF coral concrete. 10% fly ash and 10% silica fume make the MPPF most durable.

- (3)

Due to the reaction of fly ash, the concentration of calcium hydroxide is reduced. SEM analysis shows that different forms of C-S-H gels (fibrous and cloud flocculent) are combined to form a uniform and dense spatial network structure, which improves the density of the structure and the strength of the whole coral concrete.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Open Research

Data Availability

All data generated or analyzed during this study are included in this published article.