[Retracted] Utilization of Flex Controlled Robotics on Prosthetic Hand instead of Damaged Body Parts

Abstract

Scientists have researched human anatomy and biology to produce human-like prosthetic hands. In the absence of a hand, prosthetics assist in reestablishing independence and confidence. Prosthetic hands are limited in functionality and cost. A low-cost anthropomorphic prosthetic hand was designed. With five independently operated fingers and powered thumb roll movement, the design is unlike anything else on the market. This research aims to provide a cheaper alternative to the market’s robotic prostheses. Inability to use limbs causes psychological and physical issues for amputees. Arduino, an open-source microprocessor, was used to build a prototype prosthetic hand. An Android app allows users to select a hand motion to circumvent myoelectric prosthesis control mechanisms. The Arduino uses this data to power servos that individually trigger each finger.

1. Introduction

A prosthesis is a medical device that substitutes a missing body part due to damage, disease, or congenital disorders. A transradial prosthesis, or below elbow (BE) prosthesis, replaces the arm between the elbow and the wrist. They can be practical or purely cosmetic, depending on their purpose. An amputee who undertakes a lot of manual labour may choose a hook prosthesis. Opting for a cosmetic prosthesis means sacrificing functionality for a more natural appearance (fast-changing field). Currently, only a few specialists need to know this. The demand for bionic hands is expected to expand as technology progresses. An ancient hook prosthesis gave way to today’s bionic limb. We describe modern prosthetic hands’ primary functionalities. However, bionic prostheses still lag behind biological prostheses. A bionic hand that can fully duplicate or even surpass the human hand’s intrinsic capabilities is the ultimate goal of bionic limb research.

Develop a highly versatile upper body prosthetic device that overcomes the current prosthetics’ cost and usability issues. This saves money and frustration for myoelectric prosthesis users. The Arduino uses this data to power servos that individually trigger each finger. Cheap materials and ubiquitous technology like cellphones make it easy for amputees to purchase new prosthetics.

This project develops an anthropomorphic robotic hand that can handle objects with minimal human input. This study attempts to create a prosthetic hand that is as natural and easy to use as a person’s biological limb. Nearly 6,000 upper limb amputations occur annually in India, leaving many disabled. Aside from the pain caused by curious onlookers, these injuries can severely impede daily activities. Prosthetics have mechanical hooks and pincers that are useful but not adaptable. Amputees’ abilities have improved with recent technologies like the i-Limb and bebionic prosthetic hands, yet consumers still find the user interface confusing and restricted (“i-Limb Ultra,” 2014). However, they are substantially more expensive than their predecessors, which many potential customers deem unnecessary. Develop a highly versatile upper body prosthetic device that overcomes the current prosthetics’ cost and usability issues. An anthropomorphic robotic hand can decide the ideal grip for an object and execute it with minimal human input. This study attempts to create a prosthetic hand that is as natural and easy to use as a person’s biological limb. Simply take an object and tell the gadget to close. Choosing and executing a grip pattern will be instinctive. Plastics and low-cost manufacturing processes like laser cutting and 3D printing will be used to reduce costs. The IRIS system can also be utilized as a gripper for modular robot platforms. Our method allows a robot to hold different items without altering them. Input ports for the IRIS controller’s grip and release are already connected to the robot leads. It could be modified to communicate with a robot platform through USB.

With the advent of consumer 3D printers, 3D manufactured prosthetics have gained popularity and utility. Free printable hand models are obtainable on the open-source library called Thingiverse. Unlike typical prosthetics, which can cost tens of thousands of dollars, these alternatives are affordable. Personalized prostheses are now more affordable than typical operations. Control is important in high-end prosthetics, aside from cost. In electromyography, electrical impulses from an amputee’s residual muscles are read and mimicked. Electromyography can be used by people with or without forearm muscles, although it is complicated and incorrect. For the average amputee, a 3D-printed hand that works with everyday items like phones is essential. It is much easier to use a smartphone than myoelectric or motion-detecting Also, consumer robotic hands have developed in recent years. Users from all across the world can now access thousands of 3D-printed hands. These prostheses may be easily resized and reintegrated into the control system for toddlers and teenagers. Despite meeting most of its goals, this project had a few snags. Stress-generated palm cracks owing to slight hand printing errors. Acetone was utilized to soften leftover ABS filament before rehabilitating cracks. Initially, the fishing line rotated beneath the servo arms. We used eyeglass screws in the servo blade holes to increase the rotation distance. A larger circumference than diameter prevents further finger traction. Instead of around the servo screws, the fishing line would often wrap underneath them, preventing proper closure. For sealing the arm’s internal piping, the plastic or O ring was placed. The fishing line was threaded through the ring’s openings. Another issue was the hand’s inability to rest. Rubber bands were employed to fix it. Rubber bands held the servos from dragging their fingers into the palm. Thinner elastic bands restore the finger movement by replacing the rubber bands. It would not work if the hinge joints were nylon. Molding and curing silicone joints may be gone. The original arm’s outer shell fit the servos perfectly. Enlarging the casing solved the problem.

The project’s main purpose is to improve amputees’ quality of life by constructing a human-like prosthetic arm. Data capture and transmission mechanisms are examined. This breakthrough paves the way for a prosthetic limb that works with the human nervous system. Unlike a normal prosthesis that only provides motion, this design aims to provide tactile feedback to the nervous system. The hand’s physical structure has been developed for simplicity of assembly using traditional coordinate reference systems. It now has only six degrees of freedom while retaining some vital hand motions. A one-finger model was constructed. With this model, you can grasp anything with force. A Visual Basic package to manipulate the model and display the project’s potential was produced. The project was built in two stages due to its intricacy. As part of a holistic approach, a model based on the human nervous system was created. The simplified model is meant to highlight optimal design and functionality. This ensured that design flaws were addressed in both designs.

In this work [1], the aim is to craft humanoid artificial appendages that mimic biological counterparts. Although much has changed since the days of the wooden peg leg, modern orthoses and prostheses cannot be employed in daily activities [2]. In the Dextrus Hand, each finger is controlled by a string and servomotor, allowing the hand to grip the object perfectly. However, some robotic hands move the fingers in unison, with only one motor and string controlling all fingers [3]. 2.2″ SEN-10264 Flex Sensors were used here. They may measure the bend by measuring the sensor’s resistance. The applied resistance is 25 k Ohms at rest and 125 k Ohms at the maximum bend, weaved into the glove. As per them [4], there are 5 pressure sensors attached to the fingertips of the robotic hand and 5 servomotors attached to the sensor glove. Each servomotor is responsible for providing stopping force to each finger. The servomotor and the corresponding finger are connected by two strings.

It is hard to act as precisely as a human. Picking up an egg, for example, requires precise strength control to avoid breaking or dropping it. Shoelace tying requires a robotic hand and outstanding coordination. Both flex sensor gloves and robotic hands must meet technical requirements. Unlike losing a leg, the functional limits following hand loss are catastrophic. Hand loss is caused by trauma, dysvascularity, and neoplasia. Men lose their hands more than women, with 67 percent of upper limb amputees being male. Upper limb amputations occur most frequently between the ages of 16 and 54. This patient group has significant functional demands and high expectations of a prosthetic limb. Modern prosthetic hands are designed to look and feel like natural limbs. Although the bionic hand has lately been praised as a victory of engineering excellence6, it is still inferior to the actual thing and so faces challenges in gaining acceptance among upper limb amputees. These issues prohibit the prosthetic hand from achieving its ultimate goal: user acceptability [5–7]. It consists of a suitable motor and a position sensor. It also necessitates a complex controller [8], often a dedicated servomotor module. Servomotors are not a specific type of motor, but rather a motor appropriate for use in closed-loop control systems. Servomotors are utilized in robotics, CNC, and automated manufacturing. Most current servomotors are built around a single manufacturer’s controller module. Controllers can also be built around microcontrollers to save money in high-volume applications. They are tiny, light, and powerful. Servos can rotate around 180 degrees (90 in each direction) and are similar to ordinary ones. You can control them with any servo code, hardware, or library. It is good for novices who wish to move items without developing a motor controller with feedback and gearbox. This project intends to provide a less expensive alternative to the robotic prostheses now available on the market.

2. Software Approach to Design Prosthetic Hand

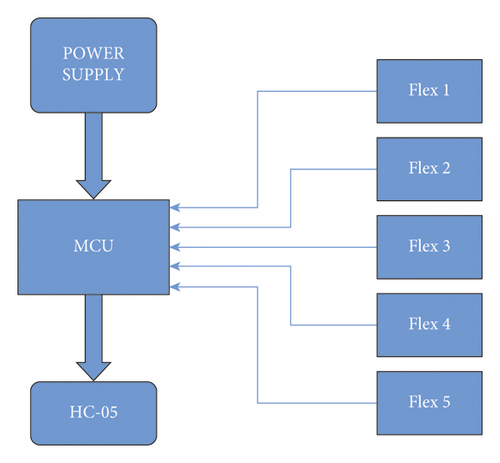

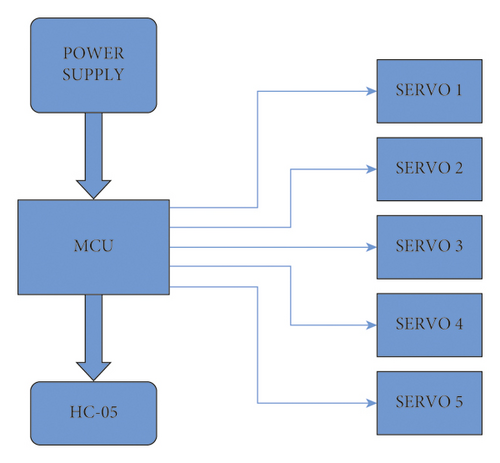

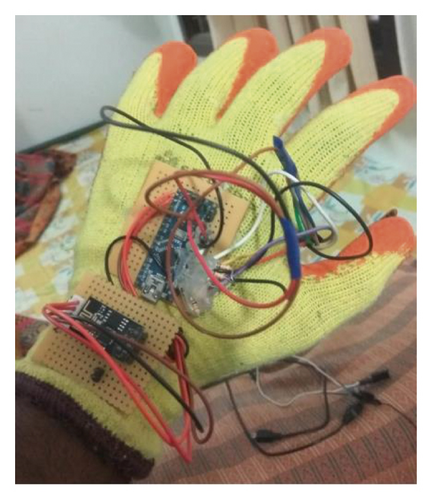

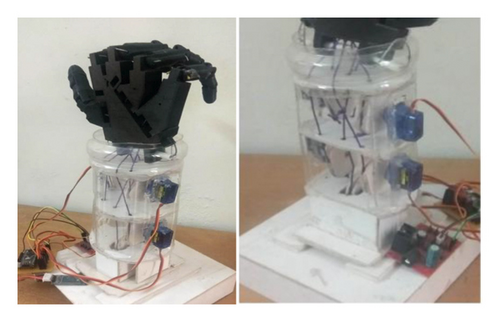

The hand prosthesis could be made available for universities and other relevant individuals to use as a mechanical evaluation and study of research in the future. When it comes to being utilized as a demonstration tool, the prototype is practically finished. Many people are investigating the use of increased electrical signals or brainwave nerve mapping to operate prosthetic devices, which is becoming increasingly popular. There are no devices available that are designed to emulate the shape and function of the human hand or that can be easily adjusted. The control code would be made available to the public as open source. The Arduino is a popular hobbyist and professional tool that may be connected serially to a computer via a USB connection. This is why the microcontroller was chosen; it is simple to work with and easy to understand. On the controls side, users may want to experiment with adding extra touch and grip sensors to see if they can increase the performance of their prosthetic hands [9–11]. Create innovative fingertip forms that can be made from a variety of materials in order to investigate how they affect the user experience on the mechanical side of things. Even if they are working on a more advanced solution, a design team needs to get their hands on something quickly so they can have a sense of what is expected of them. Figure 1 shows the master module and Figure 2 shows the slave module of this process.

2.1. Arduino IDE

Arduino is a single-board computer corporation, project, and user community that uses open-source hardware and software, and a built-in microcontrollers for developing digital devices and interactive things that can sense and control physical and digital objects. The project’s products are open-source hardware and software licensed under the LGPL or GPL [12–15] allowing anybody to produce Arduino boards and distribute software. Arduino boards are available commercially assembled or as DIY kits.

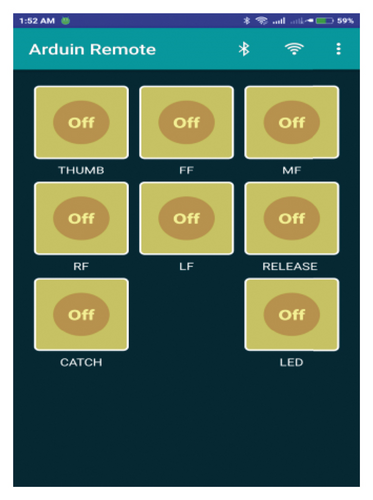

2.2. Mobile App

Any computer software that runs on a phone, tablet, or watch is a mobile app. It is worth noting that mobile web browsers are often used instead of mobile devices to access mobile applications. Figure 3 shows the mobile application.

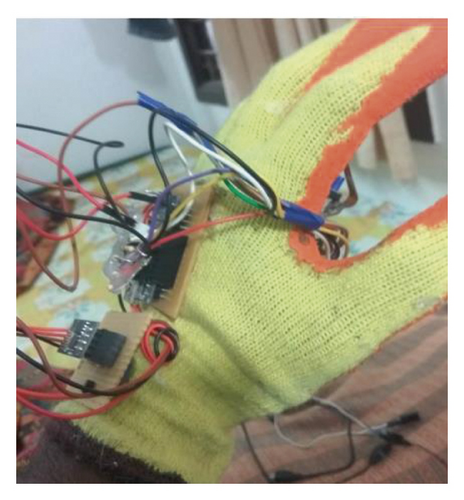

3. Flex Sensor Interface Gloves

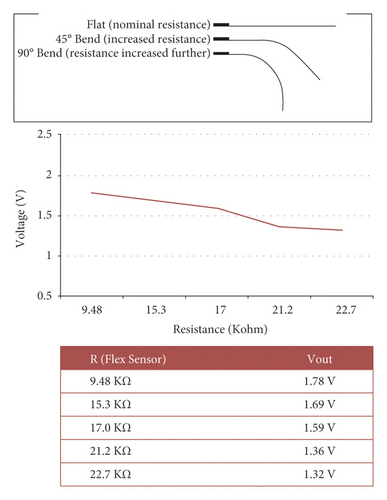

A flex sensor is a mechanical device that offers varied resistance after being bent. Figures 4(a) and 4(b) show the flex sensor interfaced in glove and finger gesture detection using the sensor. It is feasible to measure the resistance of a flex sensor by feeding a voltage through it and into an analogue input on an Arduino UNO board. Moreover, potentiometer is also called as variable resistor. Resistive carbon components make up flex sensors. A flex sensor is a changeable printed resistor on a flexible thin substrate. It creates output resistance proportional to the bent angle of the substrate [16–20]. It is obvious that when a flex sensor’s bend angle increases, so does the resistance. A flex sensor’s flat state has nominal resistance. The resistance increases with the radius. The variations of the parameters using the flex sensor are given in Figure 5.

4. Results and Discussion

Demand for bionic hands is projected to grow as technology advances, necessitating a broader knowledge. The modern bionic limb has come a long way from the centuries-old hook prosthesis. We describe how current prosthetic hands artificially duplicate the human hand’s key functions. Despite great developments, bionic prostheses are inferior to organic prostheses. Finally, we outline significant research areas that could lead to vast increases in bionic limb capability that could one day fully mimic or even surpass the biological hand’s inherent capabilities and develop a highly versatile upper body prosthetic device that overcomes the challenges of cost and usability of today’s commercially available prostheses. For myoelectric prostheses, the user can select a gesture via an Android smartphone application, saving money and frustration. The Arduino receives this information from the phone and uses it to power servos that independently trigger each finger. As a result of low-cost materials and the use of popular electronics such as cell phones, amputees may afford to purchase cutting-edge prosthetics with relative ease. The pulley string action is given in Figure 6.

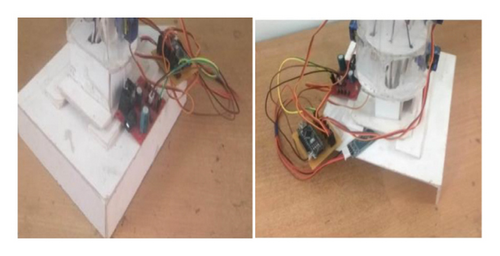

PWM controls the position of each servo motor. The motors are controlled by transmitting data from a PC to the appropriate motor controller over a serial line. The data sent down the serial line contains both the intended location and the requested motor number. This data is delivered to all motor control circuits in a daisy-chain configuration. Each control circuit’s microcontroller checks the desired motor’s number against its own. It converts the requested location into a pulse width signal and sends it to the motor until each circuit receives a new position request. If it is not needed, the controller keeps sending the last requested signal. Each microcontroller includes two timers; one to keep the motor in place and the other to run the microcontroller, including data collection. Each motor thus requires a microcontroller. The circuit next translates the signal into the proper pulse output to hold the motor in place. To demonstrate the system’s real-time nature, a Visual Basic simulation was created that displays the model’s motions on the screen. The simulation uses the same data as the model and displays the desired outcome so that the actual and desired outputs can be compared [21, 22].

The finished prototype has 5 servos coupled to pulleys and strings to move the 3D-printed fingers. The servos are coupled to the strings and pulleys to move the 3D-printed fingers. Connectors link the joints. The 3D-printed elements are linked together with myothreads. They are connected via pulleys. This project uses an Arduino NANO microcontroller. A 16 MHz quartz crystal and 14 digital input/output pins show the Arduino NANO pinout schematic. It connects the robotic hand and sensor glove by obtaining signals from the flex sensor in the sensor glove and the pressure sensor on the robotic hand. The power supply supplies 5 V to the servo and the Arduino board. Bluetooth data transmission and reception require 5 V. The power supply and microcontroller interface with servo are given in Figure 7.

5. Conclusion

- (i)

Compound thumb gearboxes enable powered articulated thumb roll actuation. This technique is unique; it uses serial Bluetooth communication between master and slave to detect finger movement. Serial communication is used between the transmitter and receiver.

- (ii)

In order to facilitate programming and algorithm development, a long-term test platform has been built. It is no longer necessary to look for ultra-precision industrial components because of the readily available hobby and remote control industry components available today.

- (iii)

Because designers are neither directly responsible for research and development costs nor concerned with the final cost of a high-end item, large corporations have developed a standard strategy for researching and constructing new systems for their products. When an individual creates a novel system, they might challenge existing design and manufacturing methods to produce an equal product faster and easier.

- (iv)

In the future, robots will be widely used in every engineering industry reducing human efforts.

Conflicts of Interest

The authors declare that there are no conflicts of interest regarding the publication of this article.

Acknowledgments

The authors appreciate the supports from Haramaya University, Ethiopia, for providing help during the research and preparation of the manuscript. This work is also supported by Taif University researchers supporting project number (TURSP–2020/40), Taif University, Taif, Saudi Arabia.

Open Research

Data Availability

The data used to support the findings of this study are included within the article. Further data or information is available from the corresponding author upon request.