Application of Adaptive PID Temperature Control Algorithm under Spatial Thermal Model of ALD Reaction Chamber

Abstract

The study aims to expand the application of the proportion integral derivative (PID) algorithm and improve the practical application of the PID algorithm to the atomic layer deposition (ALD) process. First, the ALD process is analyzed, and the application method of the PID algorithm is determined. Second, the research conditions of the PID algorithm based on the ALD process are designed. Finally, the temperature control operation of the PID algorithm in the ALD reaction chamber is modeled and experimentally studied under different research conditions. The results show that temperature significantly impacts the reaction chambers of stainless steel and aluminum. When the heating temperature increases, the temperature of the stainless steel chamber will also change, and the maximum difference between the chamber and the heating temperature is about 33°C. In contrast, the temperature of the aluminum chamber varies little with the heating temperature. The maximum difference between the chamber temperature and heating temperature is about 350°C, which shows that the temperature of the stainless steel chamber is better controlled and is more practical under the same temperature conditions. The pressure change has little effect on the temperature change of the reaction chamber of the two materials. The temperature curves of the two chambers show that the PID temperature control system can be used normally and has strong practicability. The study provides technical support for improving the PID temperature control system and the rational use of the PID temperature control algorithm in the ALD process.

1. Introduction

In recent years, atomic layer deposition (ALD) technology has attracted extensive attention because of its accurate material synthesis and modification characteristics (precise to nuclear scale). In particular, ALD is excellent in researching and developing new nanocatalytic materials [1]. Moreover, the PID (proportional, integral, and differential) temperature control algorithm to the ALD process can effectively control the temperature of the ALD reaction chamber, provide a suitable reaction environment for the ALD process, and improve the production speed [2].Although the application of the PID temperature control algorithm to the ALD process is not perfect, many studies provide technical support for the application of the PID temperature control algorithm.

Gilbert and Leeuwen (2020) pointed out that ALD is a thin film growth technology with surface self-limiting reaction, and it can accurately control the growth of thin films. There is no ALD alumina reaction group on the surface of polyolefin membrane, resulting in the slow growth and nucleation of ALD alumina and the low reaction efficiency in the early stage. The final development of alumina primarily forms clusters rather than intact and covered films [3]. Tomer et al. (2019) argued that temperature uniformity in the reaction chamber could be well solved by using the partition heating method, the PID controller with anti-integral saturation method, and the feed forward compensation PID control algorithm [4]. Huang et al. (2018) pointed out that temperature control is a concern of most industrial enterprises. The temperature control quality directly affects the quality of products and the efficiency of enterprises. However, temperature control accuracy is low due to temperature-controlled components’ different characteristics, and the adjustment time is long in actual production [5]. Li et al. (2020) pointed out that the PID algorithm can automatically identify different parameters according to the actual situation, which significantly simplifies the debugging process and saves time. The response and accuracy of temperature control are improved, which has a tremendous practical effect on enhancing efficiency [6].

Grillo et al. (2018) argued that the temperature control system is designed, including hardware and software design. Finally, the response ability and stability of the steep curve of the PID algorithm are tested by a simulation experiment. The results show that the system has a fast response ability and strong strength, which improves temperature control accuracy [7]. Mu et al. (2019) uttered that ALD is a nanofilm preparation technology. The controllable thickness and uniform film could be obtained by self-restrictive precursor alternating saturation reaction. It could be used as a water-insulating and oxygen-insulating layer in electronic devices, a transistor gate dielectric layer, and a surface passivation layer of solar cells. Therefore, ALD is widely used in microelectronics, solar cells, flexible electronics, and other fields. Temperature is one of the most critical factors affecting the quality and efficiency of thin films. However, the existing conventional control methods have poor temperature stability, long stability adjustment time, and significant temperature fluctuation under the condition of external interference, which directly affects the microsurface morphology of the deposited thin film. The PID temperature control algorithm can improve the transient performance of the system through rolling optimization and output correction under external interference. It has the characteristics of processing time delay, constraint ability, and low requirement for mathematical model. It has been successfully applied in the field of automatic control and temperature control [8].

In summary, applying the PID temperature control algorithm to the ALD process is not perfect. ALD and the PID temperature control algorithm are introduced and analyzed in this case. Then, the research method of PID temperature control algorithm under different temperature and pressure conditions is designed according to the characteristics of ALD and PID. On this basis, the research model is implemented. Finally, the PID temperature control algorithm in the ALD reaction chamber is comprehensively analyzed through experiments. This research provides new ideas for using the PID temperature control algorithm to control the temperature in the ALD reaction chamber. The utilization rate of the PID temperature control algorithm in the ALD production process is improved, and the production quality and efficiency of ALD are enhanced.

2. Research Methods

2.1. Methodology and Theory

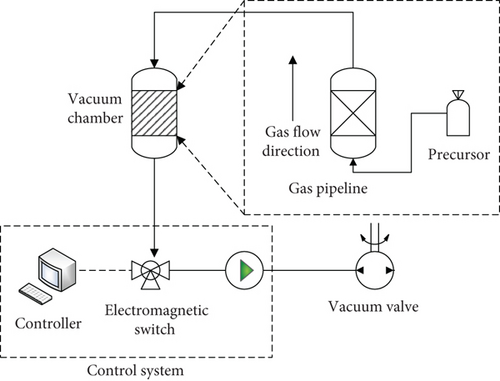

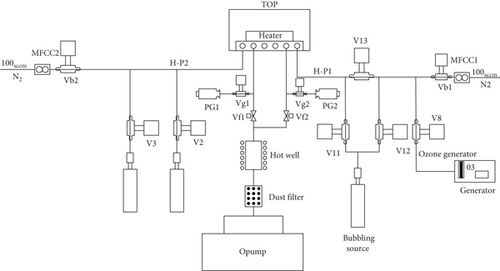

ALD is used to manufacture nanodevices, and it is a chemical vapor deposition technology [9]. It is a film growth technology with a surface self-limiting reaction, which can accurately control the growth of films. ALD coats the polyolefin membrane to produce a composite membrane of nanoalumina polyolefin. There is no ALD alumina reaction group on the surface of the polyolefin membrane, which results in slow growth and nucleation of ALD alumina and low reaction efficiency, making most of the final grown alumina forms clusters rather than completely covered films. The system of ALD is very complex. The whole system mainly includes a gas pipeline, precursor container, control system, reaction chamber, and vacuum pump. The reaction chamber comprises a wafer, vacuum chamber, and surrounding resistance wire [10]. The internal temperature control of the ALD vacuum reaction chamber is nonlinear, hysteretic, and time-varying. The materials inside the vacuum chamber should be stainless steel, aluminum, quartz, and graphite, which can meet all the above requirements [11]. The basic working process of ALD is that the bottom of the chamber is connected with the vacuum pump to pump air inside the chamber. Then, the precursor enters the vacuum chamber through the electromagnetic switch. Finally, the liquid in the precursor enters the reaction chamber through the gas pipeline to complete the reaction [12]. The reaction process of ALD is shown in Figure 1.

Figure 1 shows that the ALD reaction system includes a gas pipeline, a precursor container, a control system, a reaction chamber, and a vacuum pump. The combination of the control system and the vacuum pump provides power for the whole system. The reaction completes if the liquid in the precursor gasifies and enters the vacuum reaction chamber [13]. After each ALD reaction, the chemicals generated are rinsed with N2 to remove the determinations, and finally, a complete deposited film is formed [14]. Figure 2 shows the circulation flow of ALD.

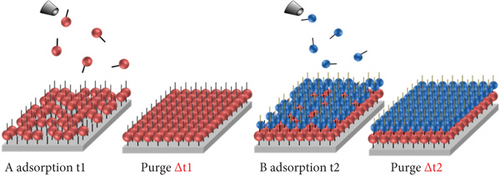

Figure 2 shows that the flow of the ALD process is controlled by programmers (t1, Δt1, t2, Δt2, t3, Δt3) to generate 2D materials. A digital control system carries out the ALD process. In the production process of the ALD process, if you need to improve the quality and efficiency of process production, you can improve the cycle times of the ALD process and keep the temperature appropriate in the cycle process. Figure 3 shows the basic software configuration in the ALD control system.

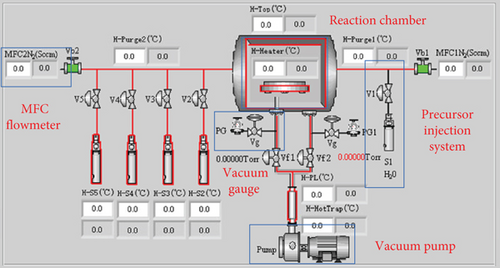

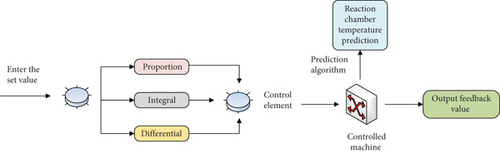

Figure 3 shows that each link of the ALD process can be managed separately in the control software. The PID adaptive temperature control system in the ALD reaction chamber can control the temperature of ALD in real time and ensure that the liquid in the precursor can be gasified normally and enter the reaction chamber smoothly, promoting the complete reaction in the reaction chamber [15]. And the temperature in the ALD reaction chamber can keep high through PID temperature control technology to increase the number of ALD cycles and improve production efficiency. The PID temperature control algorithm calculates and controls the system temperature through P (proportion), I (integral), and D (differential) parameters. The PID temperature control system can only predict and adjust the system temperature by adjusting P, I, and D parameters in real time [16]. Figure 4 shows the basic principle of the PID temperature control system.

Figure 4 shows that when the predetermined temperature is set, the PID temperature control algorithm will adjust the temperature through P, I, and D, making the temperature of the controlled element reach the predetermined value. Real-time feedback will output through the feedback system [17].

2.2. Temperature Control System and ALD Control System

The improved ALD control system can realize the substantial increase of the total output and the intellectualization of the control system [18]. Usually, an ALD control system consists of an upper computer human-computer interaction system and a lower computer, a vacuum chamber, a temperature control system, and other modules. The upper computer can obtain and interact with data through human operation. When the data are input, the basic parameters of each overall control point are also included [19]. The model of the upper computer is the InTouch configuration software of Wonder-Ware Company. The essential control of the lower computer is realized through the InTouch configuration software. Table 1 shows the basic parameters of the upper computer.

| Components | Parameters |

|---|---|

| CPU | Morethanthe3G |

| Main memory | Morethanthe2G |

| Hard disk | Morethanthe100G |

| Graphics card | 2GDiscretegraphicscard |

| System | WindowsXPSP3 |

| Program | Intouch9.6 |

| Server | OPCLink8.0 |

| Number | Heater | Pumpline | Purge1 | Purge2 | Hottrap |

|---|---|---|---|---|---|

| 1 | 50 | 150 | 100 | 100 | 400 |

| 2 | 70 | 150 | 100 | 100 | 400 |

| 3 | 100 | 150 | 100 | 100 | 400 |

| 4 | 150 | 150 | 100 | 100 | 400 |

| 5 | 200 | 150 | 100 | 100 | 400 |

| 6 | 250 | 150 | 100 | 100 | 400 |

| 7 | 300 | 150 | 100 | 100 | 400 |

| 8 | 350 | 150 | 100 | 100 | 400 |

| 9 | 400 | 150 | 100 | 100 | 400 |

| 10 | 450 | 150 | 100 | 100 | 400 |

| 11 | 500 | 150 | 100 | 100 | 400 |

| 12 | 550 | 150 | 100 | 100 | 400 |

Table 2 shows that the temperature of the ALD reaction chamber is measured under different initial chamber temperatures and different channels. The time change is as follows: change the initial temperature, last for one hour and record the information; change the initial pressure, last for 15 min; and record the relevant information. And the commonly used stainless steel and aluminum reaction chambers are analyzed in six channels of the ALD reaction chamber. The two reaction chamber materials are compared to determine what materials fit the PID temperature control system. The PID temperature control system is adjusted to make it suitable for more materials and promote its application and development. The comparison between PID and other temperature control algorithms is shown in Table 3.

| Temperature control algorithm | Advantages | Shortcomings |

|---|---|---|

| PID | Easy to debug, high control precision, strong anti-interference ability, high stability ability | Coordination is not good enough |

| Fuzzy control | Strong robustness and fast response | The parameters are complex and expensive |

| Neural network control | The algorithm is simple and easy to implement in hardware and software | The system is complex and requires more human coordination |

Table 3 shows that the PID temperature control algorithm is more suitable because of its flexibility, convenient debugging, and high control accuracy.

2.3. PID Temperature Control Algorithm

2.4. Modeling of PID Based on ALD Reaction Chamber

The PID temperature control algorithm based on the ALD reaction chamber is studied, and the specific equipment used is the dual cavity ALD system. Figure 5 shows the basic structural framework of the dual cavity ALD system.

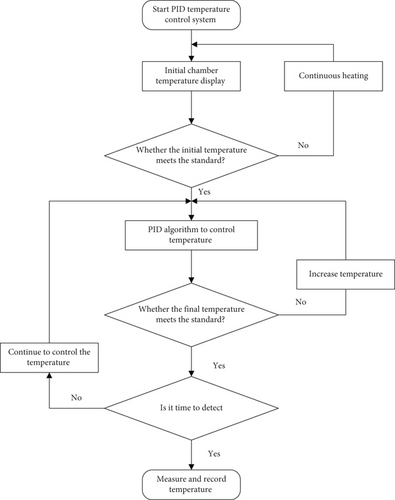

Figure 5 shows that the PID temperature control algorithm can be compared with different materials with strong responses in the dual cavity ALD system. After that, the PID temperature control algorithm can automatically select ALD chamber materials and improve its performance through the feedback of different materials [34]. The PID temperature control algorithm is studied by recording and analyzing the reaction chamber temperature in the ALD process system [35]. Figure 6 shows the basic process of using the PID temperature control system to control the reaction chamber temperature in the ALD process system.

Figure 6 shows that at the beginning, the reaction chamber of the ALD process needs to be heated, and the temperature should reach the initial temperature required by the experiment. Then, the initial temperature of the chamber is detected to judge whether the temperature meets the standard. If the temperature does not meet the standard, the reaction chamber needs to be heated again. If the temperature meets the standard, the next step is continued. The PID temperature control algorithm is used to control the temperature in the reaction chamber. During the control process, it is necessary to change the chamber temperature regularly and then detect whether the temperature meets the standard. If it does not meet the standard, it needs to be reheated. If it meets the standard, go to the next step to judge whether it is time to record. If the temperature cannot be recorded, continue maintaining the temperature by PID. If it is recorded, the temperature is recorded and adjusted in real time, and the research results are analyzed according to the recorded data.

3. Research Results

3.1. ALD Reaction Chamber

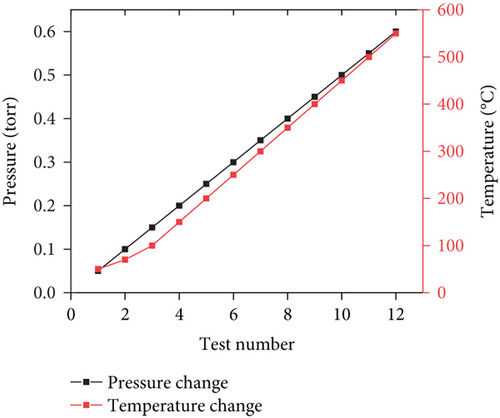

According to the above research methods, the PID temperature control algorithm is studied based on different materials of the ALD reaction chamber. Figure 7 shows the research conditions of other chamber materials.

Figure 7 shows that the chambers of the two materials are experimentally studied under the same conditions, in which the pressure changes are 0.05, 0.1, 0.15, 0.2, 0.25, 0.3, 0.35, 0.4, 0.45, 0.5, 0.55, and 0.6, respectively, and the temperature changes are 50, 70, 100, 150, 200, 250, 300, 350, 400, 450, 500, and 550°C, respectively. The research under different pressures and temperatures can reflect the temperature tolerance of the two materials and test the influence of the two materials on the temperature tolerance under different pressure conditions

3.2. PID Research and Analysis Based on ALD

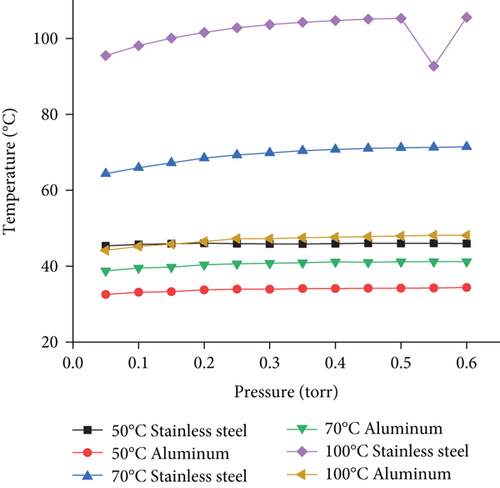

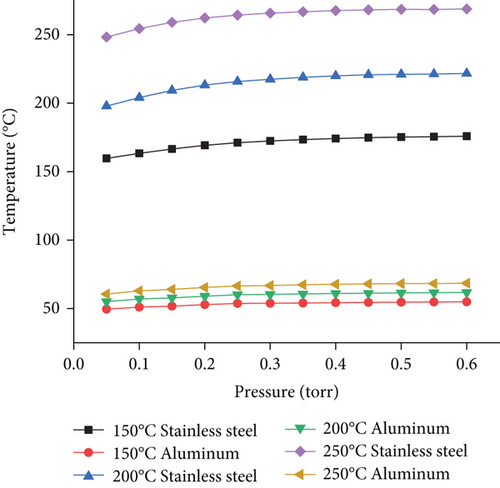

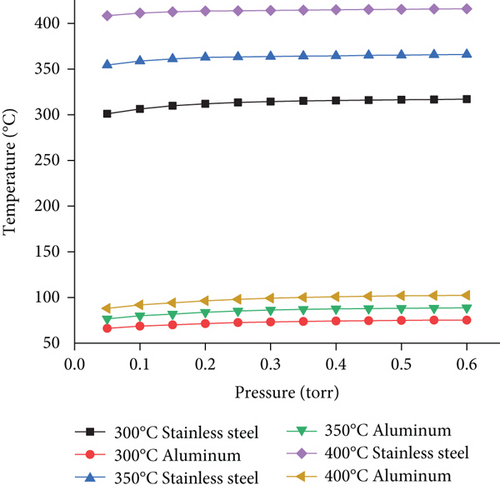

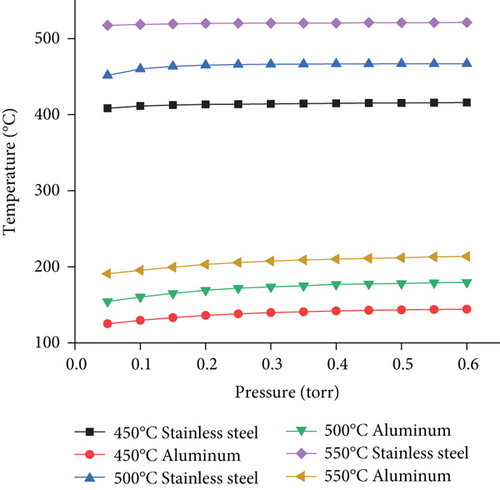

Through the research on the PID temperature control test for reaction chambers of different materials under different conditions, the heat resistance and pressure resistance of other materials are analyzed, which can reveal the service status of the PID temperature control algorithm. This verifies the performance of the PID temperature control algorithm through different materials and improves the authenticity and feasibility of the research. Figure 8 shows the temperature recording results.

Figure 8 shows that when the results of the PID temperature control records are 50°C, 70°C, and 100°C, the temperature of the stainless steel chamber is at 100°C with an error of about ±5°C. The temperature of the aluminum chamber is at 50°C, which is maintained at about 30°C, and the error is about ±3°C.

Figure 9 shows that when the results of the PID temperature control algorithm are 150°C, 200°C, and 250°C, the temperature of the stainless steel chamber is at 250°C with an error of about ±2°C. The temperature of the aluminum chamber is at 150°C with an error of about ±1°C.

Figure 10 shows that when the results of the PID temperature control algorithm are 300°C, 350°C, and 400°C, the temperature of the stainless steel chamber is at 400°C with an error of about ±1°C. The temperature of the aluminum chamber is at 300°C with an error of about ±3°C.

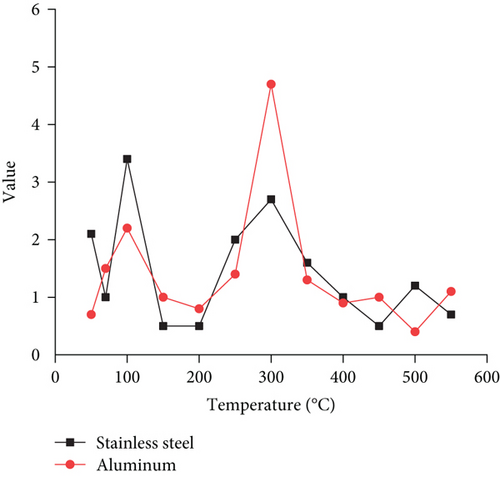

Figure 11 shows that when the results of the PID temperature control algorithm are 450°C, 500°C, and 550°C, the temperature of the stainless steel chamber is at 550°C with an error of about ±3°C. The temperature of the aluminum chamber is at 450°C with an error of about ±5°C. Figure 12 shows the difference between the predicted error and the actual error of the two materials.

Figure 12 shows that the maximum difference between the prediction error of the cavity temperature of stainless steel and its actual error is about 3°C. In contrast, the maximum difference between the prediction error of the cavity temperature of aluminum and the actual error is about 5°C. Therefore, the PID temperature control system is reasonable for error control.

Figures 8–11 show that the temperature changes of the two materials are not significant by applying the PID temperature control algorithm to the reaction chambers of the two materials under different conditions. It is concluded that the pressure has little effect on the temperature resistance of the ALD reaction chamber. Still, the temperature of the reaction chamber varies significantly at different initial temperatures. When the initial temperature is 50°C, the temperature difference between the two materials is not significant, maintaining at about 20°C. Therefore, the reaction chambers of these two materials are suitable for temperature regulation with a temperature control system above 50°C. With the initial temperature increase, the temperature difference between different materials begins to increase gradually under the PID temperature control algorithm. The temperature difference has risen to about 50°C under the condition of 70°C. At 550°C, the reaction chamber gap of the two materials reached the maximum, maintaining at about 320°C. However, when the change of the reaction chamber of the two materials under the PID temperature control algorithm is analyzed, it is found that the temperature change of stainless steel is more significant than that of the aluminum chamber. The temperature tolerance of the reaction chamber made of stainless steel is sensitive. When the heating temperature increases, the temperature of the stainless steel reaction chamber increases rapidly, while the temperature of the aluminum reaction chamber decreases. This proves that the temperature tolerance of the aluminum reaction chamber is high. Still, the overall temperature of the reaction chamber made of different materials does not change much under the PID temperature control algorithm, and the performance of the PID temperature control system is also stable under different pressures. The curve remains stable and in an ideal state. This shows that the PID temperature control algorithm can be used under different temperatures and pressures.

4. Conclusion

The PID temperature control algorithm is used to analyze its application to the ALD reaction chamber. The test is taken in the reaction chamber with different materials, different reaction temperatures, and different pressure changes. The simulation experiment found that the reaction chambers with different materials have different tolerance sensitivity to different temperature changes. Among them, the temperature sensitivity of stainless steel is more significant than aluminum, and the difference between the two is very large. Then, the temperature changes of the two materials under different pressure conditions are compared. The results show that the pressure changes have little effect on the temperature changes of the reaction chamber of different materials. Finally, it is concluded that different temperature changes and different pressure changes have little influence on the PID temperature control algorithm. This proves that the PID temperature control algorithm can be used normally in reaction chambers with different materials, temperatures, and pressures. The optimization of the traditional PID algorithm found that the error of the optimization algorithm is fewer in the temperature control process, and the maximum difference between the prediction error and the actual error is 3°C and 5°C. The optimization results of the PID temperature control algorithm are ideal. Although this study provides a lot of research data, the sample size used in the comparison is still small. The size will be expanded in the future, and the practical application of the PID temperature control algorithm will be strengthened.

Conflicts of Interest

The author declares no competing interests.

Open Research

Data Availability

The labeled dataset used to support the findings of this study are available from the corresponding author upon request.