Effect of Coal Water Slurry Gasification Slag on Soil Water Physical Characteristics and Properties in Saline-Alkali Soil Improvement

Abstract

To explore the effect of coal water slurry (CWS) gasification slag on the soil water physical characteristics of saline-alkali soil in the Yellow River Basin of Inner Mongolia, CWS gasification coarse slag (GCS) and gasification fine slag (GFS) were used as improvement materials and mixed with saline-alkali soil in different proportions. The influence mechanism of GCS and GFS on saline-alkali soil water holding capacity was investigated by measuring particle size composition, water holding capacity, and the change in the soil water characteristic curve after mixing. The results showed that adding gasification slag improved the particle size composition of saline-alkali soil, with sand content increased by -3.79%~217.31% and clay and silt content decreased by 5.77%~56.50% and -0.38%~41.53%, respectively. Soil bulk density decreased significantly (P < 0.05), with a decrease range of 15.17%~45.1%. The soil texture changed from silty loam to sandy loam, and the water retention performance improved, affecting the soil saturated water content, capillary water holding capacity, and field water holding capacity (P < 0.05), with increases ranging from 20.75%~86.15%, 7.84%~27.81%, and -1.89%~34.56%, respectively. After adding GCS and GFS, the VG model fit the soil water characteristic curve of saline-alkali soil well, indicating that the addition of gasification slag enhanced soil water retention significantly. In conclusion, CWS gasification slag effectively improved the water physical properties of saline-alkali soil and significantly enhanced the water retention and water holding capabilities.

1. Introduction

Soil salinization is a worldwide issue. China is one of the most severely afflicted countries by salinization. Saline soil covers approximately 36 million hectares, or 3.75% of the total land area. The main distribution areas of saline soil in China are the coast, northwest, northeast, and north. Saline-alkali has damaged 9.2 million hectares of cultivated land, accounting for 6.62% of all cultivated land in the country. In the Inner Mongolia Autonomous Region, saline land is primarily distributed in Bayannaoer, Erdos, Hohhot, Baotou, Tongliao, Chifeng, and other cities, covering 3.55 million hectares with 1.06 million hectares of saline-alkali farmed land and 2.49 million hectares of saline-alkali wasteland [1]. Improving and exploiting saline-alkali land is a vital strategy for the Inner Mongolia Autonomous Region and even the entire country to increase reserve land resources, improve cultivated land quality and production, and ensure food security. China’s proven coal reserves account for 12.84% of global reserves, but coal use accounts for half of global consumption. Because of China’s resource endowment of “rich coal, less oil, and poor gas,” as well as the fact that the Chinese economy is currently in a period of development and peak energy demand, coal will continue to be China’s principal energy source for a long time. Coal gasification technology, as one of the main elements of clean coal technology, has developed rapidly in order to fulfill the aim of “reaching carbon peak by 2030 and carbon neutralization by 2060.”

CWS gasification slag is a kind of bulk solid waste produced by the coal chemical industry with huge annual output. Every year, CWS gasification in China produces over ten million tons of gasification slag. This figure is expected to rise as the coal chemical sector develops [2, 3]. According to preliminary experiments, the gasification slag contains a large amount of 0.5~300 μm granular or flaky microparticles [4, 5], which are loose deposits under dry conditions. Long-term stacking under the impact of the monsoon will produce a lot of dust [6, 7], which will substantially impair the air quality. The gasification slag stacking takes up a lot of land as well. Due to the huge amount of gasification slag from CWS every year, the use of CWS gasification slag must be explored and solved promptly. It has important practical significance for the local ecological environment management [8, 9]. Because the CWS gasification residue still includes around 20-30% elemental carbon akin to activated carbon and about 20% aluminum oxide, it has excellent water retention properties. In addition, gasification slag is rich in elements like silica, calcium, and magnesium. And its structural components are comparable to those of soil. As a result, it is recognized as a high-quality raw material for soil improvement [10, 11]. When 20% gasification fine slag is mixed into saline-alkali land where corn and wheat are planted, the soil bulk density is reduced, water retention performance is improved, and crop germination rate is significantly improved [12]. The addition of gasification slag into sandy soil is beneficial to sandy soil improvement and alfalfa growth [13]. The growth of Arternisia ordosica is aided by the modified gasification slag [14]. Gasification slag is also a good humic acid storage and release medium [15]. It can be used as a composting addition to extend the high temperature period and make composting more thoroughly harmless [16].

The paper investigates the irrigation areas in Inner Mongolia on both sides of the Yellow River basin, where land salinization is severe, with numerous types of salinization, a vast area, wide distribution, and challenging improvement and application, all of which have a negative impact on and limit the long-term development of local production and economy. Using gasification slag as a novel saline-alkali soil improvement material not only allows for full utilization of the beneficial components in gasification slag, but also reduces the environmental impact of gasification slag stacking. There are currently limited research results on the improvement of saline-alkali soil in Inner Mongolia’s Yellow River Basin, particularly in terms of soil water properties. Based on the foregoing analysis, this research mixed saline-alkali soil with CWS gasification slag (including coarse slag and fine slag) in various amounts. Explored the water retention effect of gasification slag on saline-alkali soil through changes in soil water physical properties such as soil particle size composition, water retention performance, and soil water characteristic curve. In order to provide technical support and theoretical basis for the improvement of saline-alkali soil using gasification slag in the Yellow River Basin of Inner Mongolia.

2. Materials and Methods

2.1. Overview of Research Areas

The research experimental site is located at Sandaoqiao Town (106 54′ 35.18 ″E, 40 49′ 34.49 ″ N) in Hangjinhou Banner, Bayannaoer City, Inner Mongolia. Hangjinhou Banner is located in the central and western region of Bayannaoer City, Inner Mongolia Autonomous Region. It is situated in Hetao Plain, with Linhe District to the east, Wulanbu Desert and Dengkou County to the west, the Yellow River and the Hangjin Banner in Erdos City to the south, and Yinshan Mountain to the north.

Hangjinhou Banner formed an inland faulted basin during the geological neotectonic movement. The lower part is covered by a huge, thick lacustrine sedimentary layer. Due to multiple Yellow River diversions, long-term alluviation of Yellow River water, and a considerable amount of deposition of mountain torrents, the upper half is an alluvial and proluvial plain with high topography and flat surface, at an altitude of 1,032~1,046 meters (As shown in Figure 1(a)).

The annual average temperature in a typical continental climate of the semiarid plateau in the temperate zone is 6.8°C. The annual average precipitation is 245 mm, and 60% of the precipitation falls between July and September in summer. The annual average evaporation is 2720 mm. The relative humidity is 49%, and the dryness is 1.98. The annual average wind speed is 3.0 m/s. The average frost-free period is 155 days, and multiyear soil freezing depth is 1.5 m.

2.2. Test Materials

The saline-alkali soil used in the test was taken from Chengni Village, Sandaoqiao Town, and Hangjinhou Banner. We used a root drill with a diameter of 10 cm to drill 0-50 cm topsoil, then put it into a plastic bag for sealing and mixing. The gasification slag came from Boda Shidi Chemistry Co., Ltd., Wushen County, Erdos City, Inner Mongolia. Table 1 shows the soil basic properties and gasification slag in the soil of the experimental area.

| Sample name | Bulk density (g/cm-3) | Particle size composition/% | Saturated water content (%) | Field water holding capacity (%) | Soil cation exchange capacity (cmol/kg) | Loss on ignition/(%) | Soil texture | pH | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Sand particle (>50 μm) | Powder particle (2–50 μm) | Cosmid (<2 μm) | ||||||||

| GCS | 0.88 | 81.09 | 17.18 | 1.73 | 65 | 24 | 7.81 | 16 | Loamy sand | 9.3 |

| GFS | 0.36 | 43.21 | 51.95 | 4.85 | 224 | 97 | 3.88 | 29 | Silty loam | 8.2 |

| Saline-alkali soil | 1.43 | 16.64 | 73.13 | 10.23 | 32 | 22 | 14.07 | / | Silty loam | 8.5 |

2.3. Experiment Design

The experiment adopted a three-factor orthogonal design with multiple levels and nine treatments, with each treatment being repeated three times. The main characteristics of saline-alkali soil are that the clay content and specific surface area of the soil are large and there are many water-soluble salts or alkaline substances. Saline-alkali soil is generally sticky when wet and hard when dry. There are always white salt deposits on the soil surface, and the ventilation and permeability are poor. Therefore, the relative content of clay particles in saline-alkali soil can be reduced by adding gasification slag with relatively coarse particles, which is the basis of the test design. Increasing the amount of gasification coarse slag in the soil may increase pores between particles, weaken capillary action, loosen the soil texture, improve soil permeability, speed up water transport (which follows the water-salt movement rule of “salt is provided with water and salt is removed with water”), and reduce soil salinization. The weight of each sample was 1000 g. The specific treatment scheme is shown in Table 2.

| Treatment | CK | Treatment 1 | Treatment 2 | Treatment 3 | Treatment 4 | Treatment 5 | Treatment 6 | Treatment 7 | Treatment 8 |

|---|---|---|---|---|---|---|---|---|---|

| GCS (%) | 0 | 10 | 20 | 10 | 20 | 30 | 20 | 30 | 40 |

| GFS (%) | 0 | 20 | 10 | 40 | 30 | 20 | 50 | 40 | 30 |

| Saline-alkali soil (%) | 100 | 70 | 70 | 50 | 50 | 50 | 30 | 30 | 30 |

2.4. Experimental Indicators and Methods

The composition of soil particle size is determined by a laser particle size analyzer (BT9300ST, as shown in Figure 2(a)). The soil and gasification residue are dried in a cool area, fully rolled with a wooden roller, and then screened with a 1 mm sieve. Select appropriate suspension and dispersant, mix the sample with the suspension, and allow the sample particles to be fully dispersed in the suspension with the aid of dispersant. Then put the sample into the ultrasonic cleaning machine, make the liquid level in the cleaning tank reach about 1/2 of the total height of the measuring cup, turn on the power supply and let it vibrate for about 2 min (for the sample that is easy to sink, it should be vibrated while stirring with a glass rod). Put the prepared samples into the laser particle size analyzer for measurement, and use the particle size analysis software Talwin to process the data to determine the particle size composition and soil texture [17].

The cutting ring method is used to determine water retention performance. First, weigh the cutting ring containing each treated soil sample. Place it on flat bottom tray and add water to the upper edge of the cutting ring. Weigh it after 24 hours of water absorption. Place the cutting ring on the dry sand and weigh after 2 hours and 24 hours. The cutting ring was then dried at 105°C and weighed once again. Using the weighing data, the saturated water content, capillary water capacity, field water capacity, capillary porosity, and noncapillary porosity of each treatment were calculated [18].

The pressure film instrument (1500F2,as shown in Figure 2(b)) was used to determine the modified soil water characteristic curve. Set the cutting ring filled with each treated soil sample in a flat bottom tray and add water. When the cutting ring is completely saturated, weigh it. Place the cutting ring in a pressure cooker to pressurize. Remove the cutting ring after the water has stopped flowing out and weigh it. Return it back to the pressure cooker, raise the pressure, and pressurize the cutting ring continuously until it reaches equilibrium, then weigh it again. Repeat the process to acquire a series of soil water suction forces and corresponding soil water contents for the soil water characteristic curve.

2.5. Data Analysis Method

The data were statistically analyzed by Excel 2010 and SPSS 19.0 software. LSD method was used for the significance test (P < 0.05). Single factor analysis of variance (ANOVA) was used to compare the difference of water retention performance between different treatments, and Duncan method was used to test the significance. The soil water characteristic curve was fitted using RETC software. Principal component analysis was used to assess the improvement effect of each treatment.

3. Results and Analysis

3.1. Effect of Addition of Gasification Slag on Particle Size Composition

The particle size composition of each treatment and CK is shown in Table 3. As the amount of gasification slag increased, the content of soil sand and capillary porosity increased significantly (P < 0.05), with increases ranging from -3.79% to 217.31% and from 112.61% to 502.10%, respectively. With reduction ranges of 15.17% ~45.1%, 5.77% ~56.50%, and -0.38% ~41.53%, the soil bulk density, clay, and silt contents all indicated significant decrease trend (P < 0.05). Bulk density had significant negative correlation with sand content (r < 0, P < 0.05) and significant positive correlation (r > 0, P < 0.05) with silt and clay content.

| Treatment | CK | Treatment 1 | Treatment 2 | Treatment 3 | Treatment 4 | Treatment 5 | Treatment 6 | Treatment 7 | Treatment 8 |

|---|---|---|---|---|---|---|---|---|---|

| Bulk density/g/cm-3 | 1.430 | 1.161 | 1.213 | 0.947 | 0.999 | 1.051 | 0.785 | 0.837 | 0.889 |

| Sand/% | 16.64 | 16.01 | 16.95 | 27.71 | 24.31 | 25.82 | 22.57 | 25.16 | 52.8 |

| Clay/% | 10.23 | 10.58 | 10.82 | 7.89 | 8.88 | 8.2 | 9.29 | 8.45 | 4.45 |

| Particle/% | 73.13 | 73.41 | 72.24 | 64.4 | 66.81 | 65.98 | 68.15 | 66.39 | 42.76 |

| Capillary porosity/% | 5.71 | 13.06 | 12.14 | 21.12 | 21.45 | 20.29 | 34.34 | 34.38 | 31.27 |

Capillary porosity had significant positive correlation with sand content (r > 0, P < 0.05) and significant negative correlation with silt and clay content (r < 0, P < 0.05). This indicated that as the addition volume of gasification coarse slag and gasification fine slag increased, the bulk density of saline-alkali soil gradually decreased, and the proportion of clay and silt particles decreased continuously, increasing the pores between particles, weakening the capillary effect, improving the disadvantages of poor ventilation and permeability of saline-alkali soil, loosening the soil texture, speeding up water transport, and reducing soil salt content. Moreover, according to the soil texture classification, the soil texture of the reconstructed soil gradually changed from silty loam to sandy loam as the proportion of GCS and GFS increased, improving the soil texture of saline-alkali soil. In the results data, the size grading and soil texture are all approaching loam, which is in line with the assumption of the saline-alkali soil improvement scheme.

3.2. Effect of Adding Gasification Slag on Water Retention Performance

Saturated water content refers to the water content when all pores of soil are filled with water under natural conditions, including capillary pores and noncapillary pores. It represents the maximum water holding capacity of soil, that is, the water content when all pores between soil particles are filled with water. Table 4 showed that following the addition of gasification coarse and fine slag, the water retention performance of saline-alkali soil increased with the continual increase in the addition volume. The saturated water content increased significantly (P < 0.05). Treatment 6 had the highest saturated water content, followed by treatment 7, treatment 3, treatment 4, treatment 5, treatment 1, and treatment 2, all of which were higher than the CK. Treatments 1–8 increased by 33.70%, 20.75%, 56.09%, 50.23%, 42.00%, 86.15%, 71.20%, and 71.60%, respectively, as compared to the CK, indicating that the addition of gasification slag improved the water retention capacity of saline-alkali soil.

| Soil water constant | CK | Treatment 1 | Treatment 2 | Treatment 3 | Treatment 4 | Treatment 5 | Treatment 6 | Treatment 7 | Treatment 8 |

|---|---|---|---|---|---|---|---|---|---|

| Total porosity/% | 40.66 | 48.94 | 43.86 | 51.26 | 48.22 | 45.56 | 51.98 | 45.02 | 48.31 |

| Capillary porosity/% | 5.71 | 13.06 | 12.14 | 21.12 | 21.45 | 20.29 | 34.34 | 34.38 | 31.27 |

| Noncapillary porosity/% | 46.37 | 62.01 | 56.00 | 72.39 | 69.67 | 65.86 | 86.32 | 79.40 | 79.58 |

| Saturated water content/% | 32.43 | 43.36 | 39.16 | 50.62 | 48.72 | 46.05 | 60.37 | 55.52 | 55.65 |

| Capillary water holding capacity/% | 28.44 | 34.23 | 30.67 | 35.85 | 33.72 | 31.86 | 36.35 | 31.48 | 33.79 |

| Field water holding capacity/% | 22.80 | 28.13 | 23.82 | 30.68 | 25.58 | 24.36 | 29.69 | 22.37 | 24.63 |

Capillary water holding capacity refers to the maximum amount of capillary rising water that can be held in the soil. The capillary water holding capacity also showed an upward trend, with treatment 6 being the highest, followed by treatment 3, treatment 1, treatment 8, treatment 4, treatment 5, treatment 7, and treatment 2, all of which were higher than the CK. Treatments 1–8 were 20.36%, 7.84%, 26.05%, 18.57%, 12.03%, 27.81%, 10.69%, and 18.81% higher than CK, respectively.

Field water capacity is the highest soil water content that can be stably maintained by the soil, the maximum amount of suspended water that can be maintained in the soil, and the highest soil water content that is effective for crops. The field water capacity also showed an upward trend, with treatment 3 being the highest, followed by treatment 6, treatment 1, treatment 4, treatment 5, treatment 8, and treatment 2, all of which were higher than the CK, with treatment 7 being the lowest. In comparison to the CK, treatments 1–8 increased 23.38%, 4.47%, 34.56%, 12.19%, 6.84%, 30.22%, 1.89%, and 8.03%, respectively.

Capillary pore refers to the pore with capillary function. Its pore diameter is larger than that of inactive pore. It is the place for water movement and storage. It is the key factor affecting soil permeability and determining surface runoff and runoff time. As Table 4 has shown, the capillary porosity rises with the addition of gasification slag, indicating that it improved the compact texture and few pores of saline-alkali soil. It is a key factor affecting soil permeability and surface runoff and runoff generation time. Compared with CK, the capillary porosity of treatments 1–8 increased by 128.72%, 112.61%, 269.88%, 275.66%, 255.34%, 501.40%, 502.10%, and 447.64%%, respectively.

Noncapillary porosity is the percentage of noncapillary porosity in soil volume. Noncapillary pores are also called macropores. For soil pores with a pore diameter greater than 0.1 mm, macropores are often filled with air and are filled with water only when there is a large amount of gravity water. Noncapillary pores have no water holding capacity, but can make the soil aerated and permeable. As shown in Table 4, the noncapillary porosity shows an upward trend, which is represented by CK < treatment, 2 < treatment, 1 < treatment, 5 < treatment, 4 < treatment, 3 < treatment, 7 < treatment, and 8 < treatment 6. Treatment 1–8 was 33.73%, 20.77%, 56.11%, 50.25%, 42.03%, 86.15%, 71.23%, and 71.62% higher than CK, respectively. It can be seen that increasing the amount of gasification slag can improve the water retention performance of saline-alkali soil.

3.3. Effect of Adding Gasification Slag on Soil Water Characteristic Curve

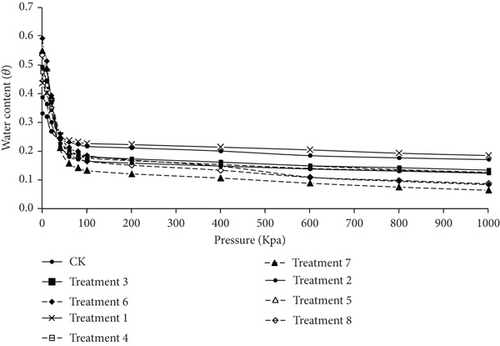

The soil water characteristic curve is a curve that depicts the changing relationship between soil water suction and content. It can reflect soil water holding capacity and soil water availability as well as the changing relationship between soil water quantity and energy. The soil water characteristic curve of saline-alkali soil under varying proportions of gasified slag is shown in Figure 3. Adding gasified slag to the soil water characteristic curve causes the soil water characteristic curve to shift downward compared to the control, indicating that the soil water content with gasified slag added under the same PF value (soil water suction) is less than that without gasified slag. As the amount of gasified slag addition increases, the soil water content under the same PF value decreases.

The main reason is that adding gasification slag improves the soil pore structure, making it more permeable and accelerated the water transport. Therefore, the CK water content under the same pressure is higher than other treatments. The J-chart showed that in the suction range between PF 0 and 50 kPa, the water content difference between treatment and CK decreased as the PF value increased. In the suction range between PF 50 to 1000 kPa, the soil water content of treatment 1 is higher than the soil water content of CK. While treatments 2~8 are lower than that of the CK under the same PF value. It is clear that the addition of gasification slag had significant impact on the soil water characteristic curve, assisting in the improvement of soil pore structure, porosity, and permeability and accelerating the soil water transport. The Van Genuchten model was used to further analyze the effect of gasification slag content on the soil water characteristic curve quantitatively.

In Table 5 when the determination coefficient R2 in the Van Genuchten model ranged from 0.972 to 0.991, the deviation between the VG function-simulated soil saturated water content and the results measured by the experiment is from -3.38% to 4.12%. This indicated that the VG model well simulated the influence of gasification slag content on the soil water characteristic curve. CK had a lower water retention content (θr) than all the other treatments. Value a is the reciprocal of the inflection point suction value when the water characteristic curve is close to saturation. The higher value a is, the poorer the soil water retention capacity. Treatment 1–8 had lower value a than the CK due to the addition of gasification slag (Figure 3). Therefore, adding gasification slag to saline-alkali soil improved the soil water retention performance and enhanced its water holding capacity.

| Treatment | θr | θs | a | n | R2 |

|---|---|---|---|---|---|

| CK | 0.414 | 0.336 | 0.277 | 1.516 | 0.972 |

| Treatment 1 | 0.194 | 0.437 | 0.064 | 2.208 | 0.981 |

| Treatment 2 | 0.128 | 0.389 | 0.053 | 2.246 | 0.987 |

| Treatment 3 | 0.143 | 0.489 | 0.056 | 2.384 | 0.991 |

| Treatment 4 | 0.130 | 0.475 | 0.060 | 2.186 | 0.991 |

| Treatment 5 | 0.136 | 0.447 | 0.058 | 2.300 | 0.982 |

| Treatment 6 | 0.073 | 0.580 | 0.081 | 1.874 | 0.984 |

| Treatment 7 | 0.074 | 0.545 | 0.056 | 2.483 | 0.989 |

| Treatment 8 | 0.092 | 0.537 | 0.062 | 2.080 | 0.987 |

3.4. Principal Component Analysis on Influence of Gasification Slag on Soil Water Retention Performance

Using the principal component analysis approach, it is possible to screen out many unrelated comprehensive indicators in a complex index system for dimension reduction. These comprehensive indicators can reflect most of the information provided by all the original indicators. Five factors, including saturated water content, capillary water holding capacity, field water holding capacity, capillary porosity, and noncapillary porosity of each treatment were selected. The eigenvalues, eigenvectors, contribution rates, and cumulative contribution rates of the matrix were further calculated using factor analysis in SPSS, as shown in Table 6.

| Principal component | Eigenvalue | Contribution rate % | Cumulative contribution rate % | Water retention performance index | Factor load | Score coefficient | ||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 1 | 2 | |||||

| 1 | 3.197 | 63.947 | 63.947 | Saturated water content | 0.928 | -0.364 | 0.450 | 0.446 |

| 2 | 1.635 | 32.705 | 96.652 | Capillary water holding capacity | 0.925 | 0.334 | 0.498 | -0.211 |

| 3 | 0.131 | 2.623 | 99.275 | Field water holding capacity | 0.693 | 0.706 | 0.399 | -0.567 |

| 4 | 0.026 | 0.528 | 99.803 | Capillary porosity | -0.323 | 0.930 | 0.498 | -0.212 |

| 5 | 0.010 | 0.197 | 100.000 | Noncapillary porosity | 0.946 | -0.170 | 0.378 | 0.625 |

Two principal components were derived using the eigenvalue λ ≥ 1 principle. The variance contribution rates of the two principal components were 63.947% and 32.705%, respectively. The cumulative variance contribution rate was 96.652%, which has reflected the basic information on soil water retention performance. The five components’ original data were normalized. And the comprehensive water retention performance score was calculated using principal component score coefficient matrix (Table 6). The water retention performance is reflected in the comprehensive score IFI value. As shown in Table 7, treatment 6 had the highest ranking scores, followed by treatment 3, treatment 8, treatment 7, treatment 4, treatment 1, treatment 5, treatment 2, and CK. Therefore, treatment 6 had the highest water retention capacity, whereas CK had the lowest.

| Treatment | CK | Treatment 1 | Treatment 2 | Treatment 3 | Treatment 4 | Treatment 5 | Treatment 6 | Treatment 7 | Treatment 8 |

|---|---|---|---|---|---|---|---|---|---|

| F1 | -3.54 | 0.27 | -1.94 | 1.91 | 0.32 | -0.75 | 2.96 | -0.16 | 0.93 |

| F2 | -0.45 | -1.41 | -0.28 | -1.3 | -0.06 | 0.27 | 0.11 | 2.05 | 1.06 |

| IF value | -2.78 | -0.13 | -1.54 | 1.14 | 0.23 | -0.51 | 2.27 | 0.36 | 0.95 |

| Ranking | 9 | 6 | 8 | 2 | 5 | 7 | 1 | 4 | 3 |

4. Discussion

The gasification slag comprises of coarse slag and fine slag. The gasification coarse slag is slag discharged from the bottom of the gasification furnace through the processes of melting, chilling, condensation, and the like while the gasification furnace is operating at high temperatures and pressures, with particle sizes ranging from 16 to 4 meshes. The gasification coarse slag is characterized by higher sand particle composition ratio and larger sand particle size, which improves the pore structure of the soil, increases internal pores, reduces soil bulk density, and improves soil water retention. Gasification fine slag is slag generated by the airflow from the top of the gasification furnace after being preliminary washed, purified, and precipitated, with particle sizes of fewer than 16 meshes. It is distinguished by high clay-particle ratio, large clay-particle surface area, and strong adsorption effect. When mixed with soil, it could fill the macropores of soil, improving the soil texture and water retention [18].

Due to the large proportion of fine particles such as silt and clay in the saline-alkali soil, the soil is relatively dense, the soil permeability is poor, and there are fewer capillary pores in the total pores. This structure makes the soil water transport difficult, the soil water conductivity is poor, and the soil water and nutrients are difficult to release effectively. The improvement of saline-alkali soil is mainly based on different proportions of gasification coarse slag and fine slag. With the addition of gasification slag, the relatively large gravel in the gasification slag particles expands the small pores of saline-alkali soil, and the soil texture gradually changes from silty loam to sandy loam, reducing the soil bulk density, improving the soil pore structure, increasing the soil porosity, improving the soil permeability, and making the soil texture loose. The application of gasification slag optimizes the pore structure of saline-alkali soil, thus effectively increasing the proportion of capillary porosity and improving the hydraulic conductivity. At the same time, it follows the water salt movement law of “salt comes with water, and salt goes with water”. Therefore, the application of gasification slag also reduces the salt content of soil, weakens the degree of soil salinization, and has obvious improvement effect on saline-alkali soil.

Soil water is one of the most critical elements impacting plant growth in saline-alkali regions. Soil saturated water content, capillary water holding capacity, and field water holding capacity are the most prevalent markers of soil water retention. Previous studies have shown that application of solid additives in the soil, such as fly ash and biochar [19, 20], enhanced the overall porosity of the soil, therefore raising the soil saturated volumetric water content and improving the soil water retention performance significantly. The results of this study suggest that adding gasification slag to saline-alkali soil increased saturated water content, capillary water holding capacity, and field water holding capacity and improved water retention performance, which is consistent with the findings of earlier studies [13, 14]. By studying the effect of different content of gasification slag on soil water characteristic curve of saline-alkali soil, it was found that the water holding capacity and water retention performance of saline-alkali soil were significantly improved with the addition of gasification slag. The reason was that the gasification slag has large specific surface area and porous and uniformed pores [21, 22] due to the high temperature (800–1300°C) and chilling effect of the coal gasification process, allowing it to absorb more water than its own weight; thus improved the soil structure, increased aggregates and other functions and improved soil water holding capacity and water retention performance. Improvements in soil water retention performance not only minimizes water and soil loss and erosion but also promotes crop development.

5. Conclusions

The results demonstrated that adding gasification slag to saline-alkali soil reduced the soil bulk density. With the addition of gasification slag, the texture of saline-alkali soil changed from silty loam to sandy loam. The decrease of soil bulk density and the gasification slag’s filling action into macropores lead to the increase of soil pores in saline-alkali soil, which greatly increased the water availability, improved the soil permeability, and solved the problem of poor water holding capacity and water retention performance of saline-alkali soil.

The water retention performance of saline-alkali soil showed an upward trend with the increase of gasification slag dosage. The improvement of water retention performance was related to the addition amount of gasification slag. With different addition proportions of gasification slag, the saturated water content, capillary water holding capacity, and field water holding capacity of soil were all significantly affected (P < 0.05). However, there were no obvious correlations between total porosity, noncapillary porosity of soil and the addition amount of gasification slag.

The Van Genuchten model well fit the soil water characteristic curve of saline-alkali soil after gasification slag addition. The model shows that the addition of gasification slag significantly improved the soil water holding capacity and water retention performance. In the principal component analysis on soil water holding capacity of saline-alkali soil, the higher the addition amount of gasification slag, especially gasification fine slag, the more obvious the improvement of soil water holding capacity and water retention performance.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Acknowledgments

This study was supported by the Science and Technology Plan Program of Inner Mongolia Autonomous Region (2020GG0181, 2021GG0060, 2019GG027) and Projects for the Central Government to Guide Local Scientific and Technological Development (2021ZY0031).

Open Research

Data Availability

The data used to support the findings of this study are available from the corresponding author upon request.