Co-Effects of Graphene Oxide and Cement on Geotechnical Properties of Loess

Abstract

Improvement of geotechnical properties of soil by cementitious additives and nanomaterials is commonly used method. However, few systematic research studies on the co-effects of them on the geotechnical properties of loess have been explored. In the present research, the enhancement technique of loess was proposed based on the co-effects of graphene oxide (GO) and cement. In addition, the compactability, mechanical properties, water resistance, and microstructure of the GO/cement/loess ternary system were studied. The results revealed that, with the increase of incorporation of GO (0.03, 0.06, 0.09, and 0.12 wt. %), the optimum moisture decreased, while the dry density, mechanical properties, and water resistance increased significantly. And an optimum GO content of 0.09 wt. % was determined according to mechanical properties and water resistance. Moreover, the scanning electron microscope (SEM) results revealed that the microstructure was densified and the characteristics of pores were refined. And the co-work mechanisms of GO/cement on loess were summarized. All the results indicated that the GO/cement mixture has remarkable co-effects on the geotechnical properties of loess.

1. Introduction

As one of the earliest building materials in human history, raw soil building has been widely used for thousands of years due to its convenience, good thermal performance, and less pollution. To date, there are still billions of raw soil buildings in western China, which is the main loess region. But there is no denying that raw soil material’s application is somehow limited because of its low strength, poor durability, and volume stability. Therefore, the improvement of raw soil material is of great significance for the regeneration and development of raw soil structure [1–3].

Aiming at this problem, many studies had been conducted to improve the properties of loess. In the early stage, different kinds of plant fibers such as straws [4,5] and wood [6] were used to enhance the loess, whose positive effect was mainly on the shear strength ductility but not the compressive strength [7]. Later on, various cementitious additives like cement [8], fly ash [9], and lime [10] were incorporated into the soil [11–13], which illustrated a better effect on the durability and mechanical property of soil sample, due to the filling and hydration effects. In recent years, with the rise of nanomaterials, a novel corresponding soil enhanced technique has gained new development direction. At present, nanomaterials such as SiO2 [14], TiO2 [15], and Al2O3 [16], carbon nanotubes (CNTs) [17], and graphene oxide (GO) [18–26] have been widely used to improve the performances of cement-based materials because of the high strength, high surface activity, small size, and other advantages over conventional materials.

However, the inherent characteristics of soil make it impossible for nanomaterials to react directly with soil [27]. The enhancement of soil by nanomaterials is due to the existence of cementitious additives which can be inspired and promoted by nanomaterials [28,29]. Therefore, the enhanced technique of cementitious additives-treated soil by reinforced nanomaterials was proposed. Bahmani et al. used SiO2 nanoparticles and cement-stabilized residual soil to add 0.4% nanosilicon to the cement-treated soil, and the compressive strength of the soil increased by 85%. Additionally, the experimental results illustrated that the addition of nanomaterials had a noticeable effect on the compaction and fluidity of the soil samples [30]. Figueiredo et al. investigated the effects of CNTs on the mechanical properties of soil, which indicated that the compressive strength of soil increased by 77% based on a good dispersion of CNTs in soil matrix [31].

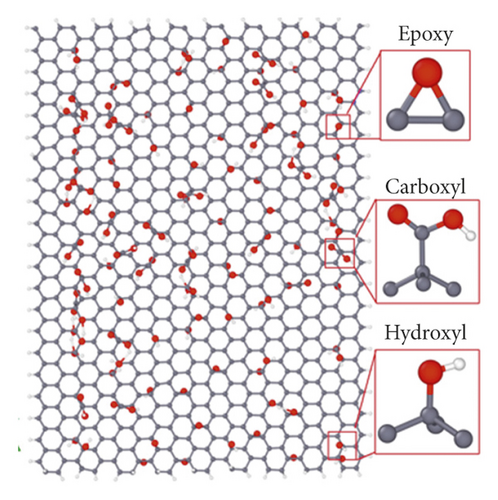

In particular, the GO is the rising star of nanomaterials in recent years, which has been commonly used to enhance metals, ceramics, and cement, due to its higher active and better dispersion with the presence of amount of functional oxygen groups on its surface (Figure 1). Nevertheless, in the field of construction, most research works as yet have focused on the cementitious materials reinforced by GO, such as cement paste, mortar, and concrete [18–26], ignoring the research with soil matrix. Up to now, only literature [27] had reported the cement-treated soil enhanced by GO with different incorporations, which showed that the incorporation of GO degraded the compressibility and plasticity, while the compressive strength and shear strength were improved with the increase of GO incorporation. The obtained results indicated that the GO as an enhanced agent had a considerable effect on the cement-treated soil. Although studies about the cement-treated soil enhanced by GO have been on the way, it is obviously still in its infant stage.

So, in the present study, different incorporations of GO was mixed with the cement to enhance loess sample in western China. The enhanced effect of GO/cement on loess was estimated based on the compactability, mechanical properties, water resistance, and microstructure tests. Furthermore, the mechanism of co-effects of GO and cement on the soil matrix was analyzed.

2. Materials and Methods

2.1. Raw Materials

The loess utilized in the experiment was collected from Lintong District of Xi’an in western China. Before the experiment, the particle contents, chemical compositions, and physical properties of the studied loess were tested in accordance with the Chinese National Specification (GB/T 50123-2019), as shown in Tables 1–3, respectively. As shown in Table 1, the most content of loess is silt with a proportionality of almost 80%, and then is the clay and the least is sand, which is consistent with the characteristics of loess particle distribution.

| Sand (%) (0.075 mm < size < 2 mm) | Silt (%) (0.005 mm < size < 0.075 mm) | Clay (%) (size < 0.005 mm) |

|---|---|---|

| 1.23 | 79.21 | 19.56 |

| SiO2(%) | Al2O3(%) | Fe2O3(%) | CaO(%) | K2O(%) |

|---|---|---|---|---|

| 65.17 | 16.22 | 3.56 | 4.01 | 2.24 |

| Moisture content (%) | Optimum moisture content (%) | Liquid limit (LL) (%) | Plastic limit (PL) (%) | Plasticity index (PI) (%) |

|---|---|---|---|---|

| 8.1 | 18.3 | 47.24 | 35.46 | 11.78 |

The P.O. 42.5 ordinary Portland cement was used in the experiment, which was produced by Tongchuan Dongguan cement Co., Ltd. The chemical compositions are shown in Table 4. The GO suspension with a solid content of 1.0% was purchased form Changzhou Sixth Element Materials Technology Co., Ltd. The results of element analysis are shown in Table 5. Ordinary tap water was used to dilute the GO and make specimens.

| SiO2 | Al2O3 | Fe2O3 | MnO2 | SO3 | CaO | Ignition loss |

|---|---|---|---|---|---|---|

| 22.60 | 4.98 | 2.90 | 2.32 | 2.31 | 61.60 | 4.48 |

| Elemental analysis (wt%) | Elemental analysis (mol,%) | |||||||

|---|---|---|---|---|---|---|---|---|

| C | H | N | O | S | C | O | S | Oxygen to carbon molar ratio/mol |

| 46.76 | 2.78 | 0.15 | 43.82 | 1.03 | 58.442 | 41.075 | 0.483 | 0.670 |

2.2. Preparation of Specimens

The mix proportion should be determined firstly to prepare the specimens used in the experiment. The cement content was 15 wt. % of the loess matrix, while the GO was added with the incorporation of 0.03, 0.06, 0.09, and 0.12 wt. % of cement. When it comes to the water content, the water/solid (cement + loess) ratio of 0.4 was chosen.

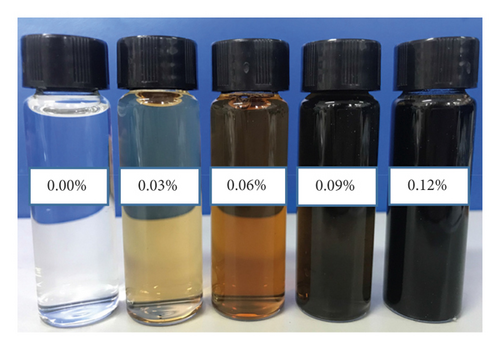

At the beginning, the GO suspension was diluted to the specified concentration needed in the experiment and then ultrasonicated for 15 minutes to obtain a homogeneous solution (Figure 2). At the same time, the cement and loess were dry mixed with each other for 5 min. Then, the prepared GO suspension was poured into the cement/loess mixture slowly, and then the GO/cement/loess system would be mixed for another 5 min to obtain homogeneous slurry.

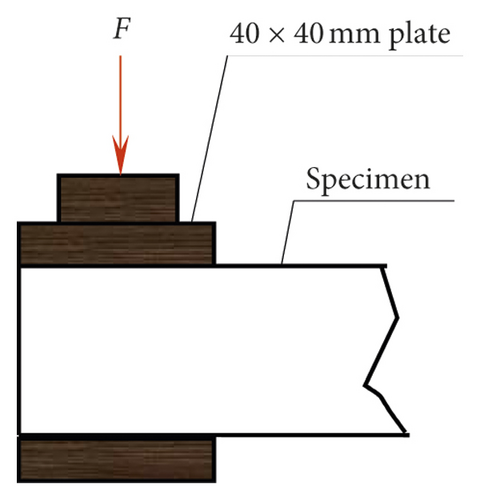

On the basis of the work described above, the fresh slurry would be poured into mold with the dimension of 40 × 40 × 160 mm on time to prepare the specimens needed for experiments of the mechanical property, water resistance, and microstructure. And then, the molds were removed after 24 hours, followed by covering plastic bags on the specimen to prevent water loss too fast and cracking (Figure 3). The composite material was cured for 7 d, 14 d, and 28 d, respectively, at room temperature for testes needed.

2.3. Testing Method

The microstructure of the GO/cement/loess sample was characterized by adopting the FEI Quanta200 scanning electron microscope (SEM) after gold coating.

3. Results and Discussion

3.1. Characterization of GO

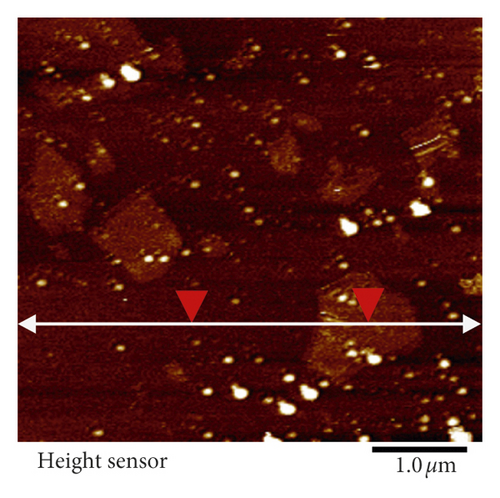

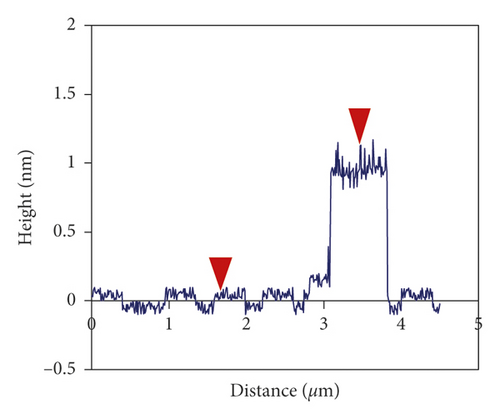

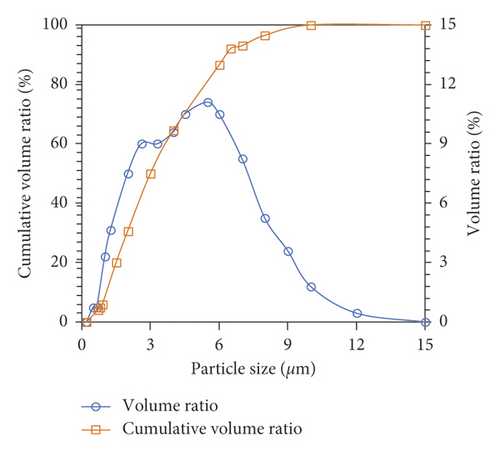

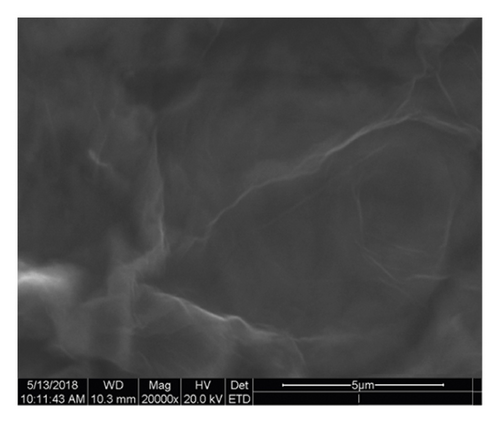

The GO nanosheets after ultrasonication were characterized by AFM, as shown in Figures 5(a) and 5(b). According to the AFM images, the mean thickness of GO nanosheets is about 1.0 nm, indicating that the thickness has reached the monolayer. Figure 5(c) shows the size distribution curves of the GO, which indicates that the size distribution is approximate normal distribution and the mean lateral dimension is about 5.12 μm. Figure 5(d) shows the SEM image of GO. In accordance with the image, GO is a wrinkled sheet.

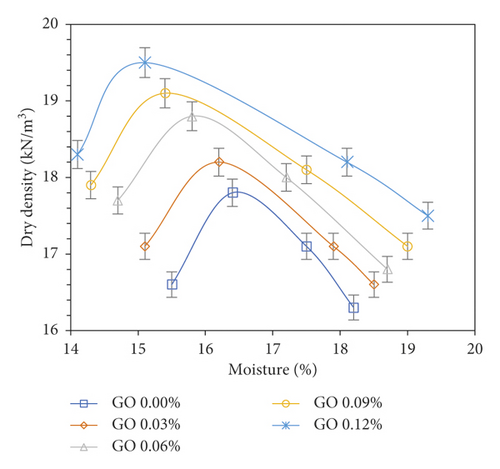

3.2. Effect of GO on the Compactability

Figure 6 presents the dry density and moisture of cemented loess with different incorporations of GO. As shown, the dry density increased with the increasement of GO incorporation in the cemented loess, while the optimum moisture showed a decreasing trend. In more detail, corresponding to the GO content of 0.03, 0.06, 0.09, and 0.12 wt. %, the dry density increased by 2.25%, 5.62%, 7.3%, and 9.55% compared with the cement/soil without GO, respectively. And the optimum moisture decreased by 1.22%, 3.66%, 6.1%, and 7.93%, respectively.

The results may be due to the synergistic effect of GO and cement on loess matrix; that is, the microstructure with the presence of C-S-H gel and the interface bonding will be denser. Based on the agreement that the GO can facilitate the hydration process of cement and improve the formation of C-S-H gel, it can be concluded that the pore characteristics of GO/cement/loess would be improved, resulting in the abovementioned results, which had been also reported by Naseri [27]. In addition, the decease of the optimum moisture content may be attributed to the decrease of the pore characteristics of samples refined by the stronger interconnection between GO, cement, and C-S-H gel.

3.3. Effect of GO on the Compressive Stress-Strain Behavior

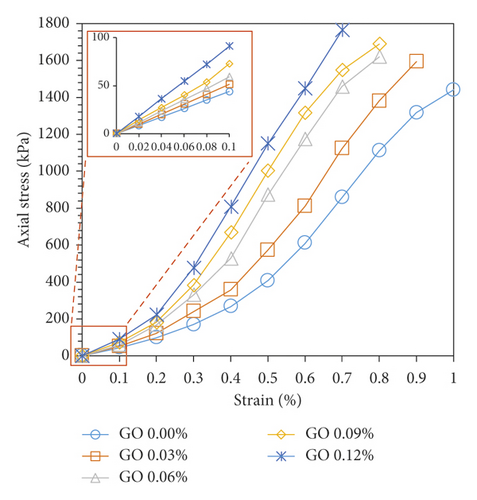

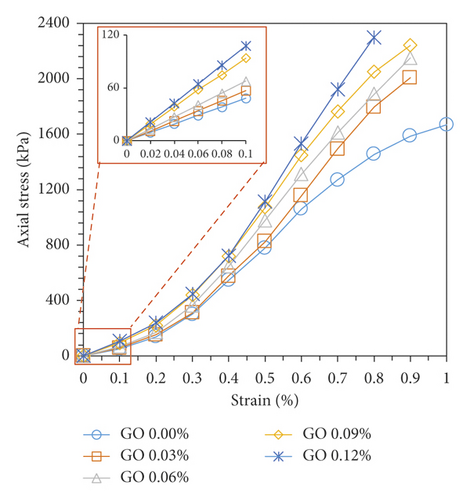

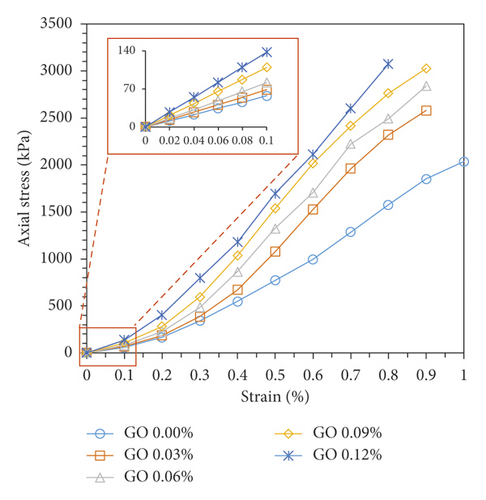

Figure 7 shows the effect of GO nanosheets on the compressive stress-strain behavior of the soil samples for 7, 14, and 28 d. As observed, the increase of GO concentration led to the increase of stiffness and the decrease of strain. The stiffness of the specimen increased more obviously as the curing time becomes longer.

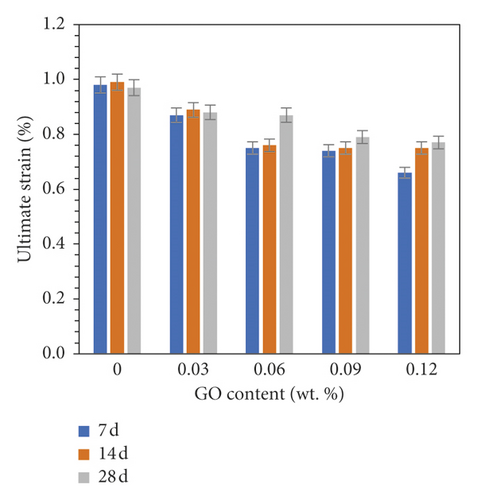

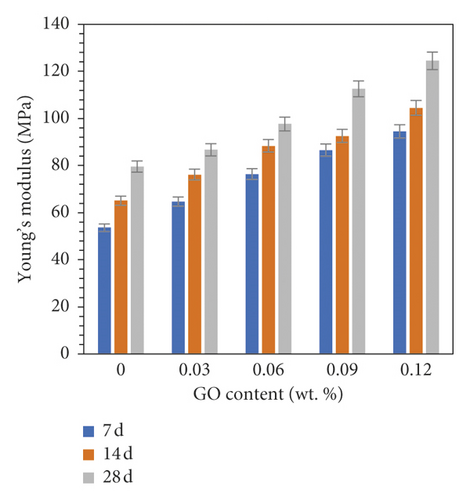

According to Figure 7, the ultimate strains of the studied cement/loess sample with different GO incorporations are shown in Figure 8(a). Additionally, according to the insets in Figure 7, for the 0-0.1% strain stage, the stress is almost proportional to the strain, so we chose the stage as the elastic region; then Young’s modulus could be obtained by calculating the secant slope, as shown in Figure 8(b).

As observed in Figure 8(a), the ultimate strain decreased obviously with the increasement of GO content, but for the same GO content there seems to be no noticeable difference. For Young’s modulus presented in Figure 8(b), the noticeable increase trend with the increasement of GO content can be found. As mentioned above, generally the higher the GO content in the cemented loess, the denser the microstructure due to presence of more C-S-H gel, thus resulting in the higher stiffness of the material [27]. Therefore, the deformation capacity like ultimate strain would be degraded, while Young’s modulus would be improved.

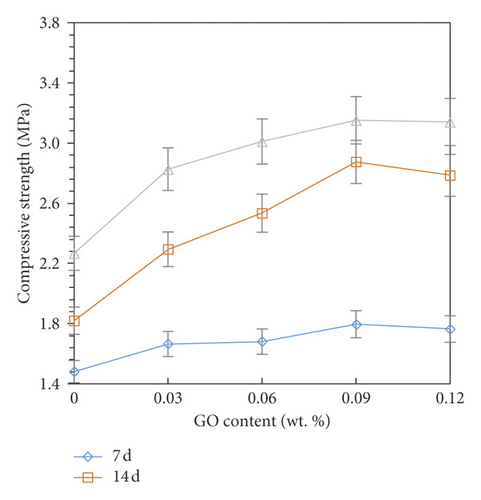

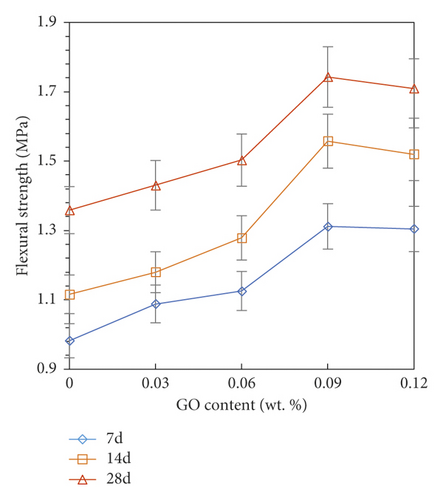

3.4. Effect of GO on the Compressive and Flexural Strength

Figure 9 presents the compressive and flexural strength of GO/cement/loess composite with different GO content for 7 d, 14 d, and 28 d. As indicated, for different ages, both the compressive and flexural strength increased progressively with the increase of GO content. Additionally, compared with the samples without GO, the corresponding compressive strength of 7 d, 14 d, and 28 d showed maximum increasement of about 21.29%, 57.97%, and 39.00%, while the corresponding flexural strength of 7 d, 14 d, and 28 d was 33.57%, 39.56%, and 28.26%, respectively. Another interesting phenomenon was that the mechanical strength seemed to stop increasing when the GO dosage exceeded 0.09 wt. %. This may be due to the fact that the dispersion of GO in the matrix becomes worse as the dosage increases, thus degrading the effect of enhancement just as it does in cement matrix [24].

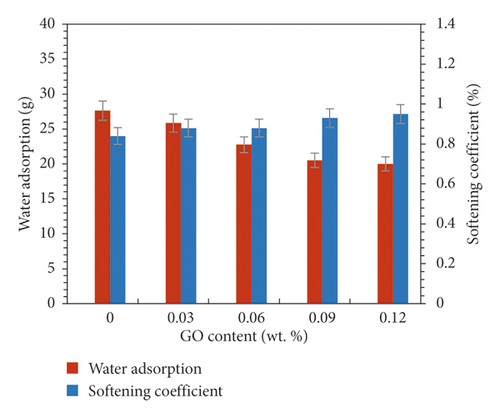

3.5. Effect of GO on the Water Resistance

Figure 10 shows the water adsorption and softening coefficient changing with GO content from 0 to 0.12 wt. %. As observed, the water adsorption decreased progressively, while the softening coefficient increased with the increasement of GO content. In more detail, the adsorption deceased by 9.67%, 8.82%, 4.09%, and 0.96%, respectively, with the GO content from 0 to 0.12%, while the softening coefficient increased by 5.95%, 4.49%, 1.08%, and 0.64%, respectively. Therefore, for both water adsorption and softening coefficient, the extent of reduction decreased gradually with the increasement of GO content and remained almost the same after 0.9 wt. % of GO content, which may be also due to the adverse effect of GO overdosage in the matrix [24].

3.6. Effect of GO Nanosheets on the Microstructure

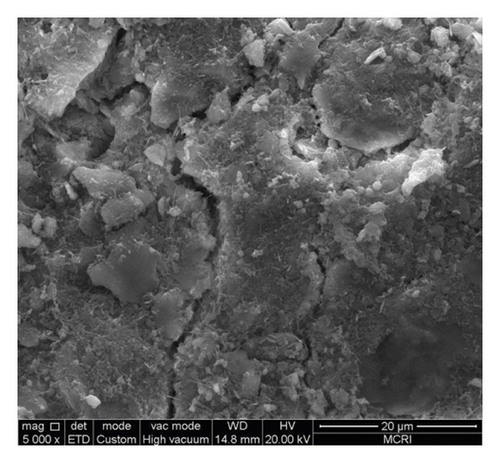

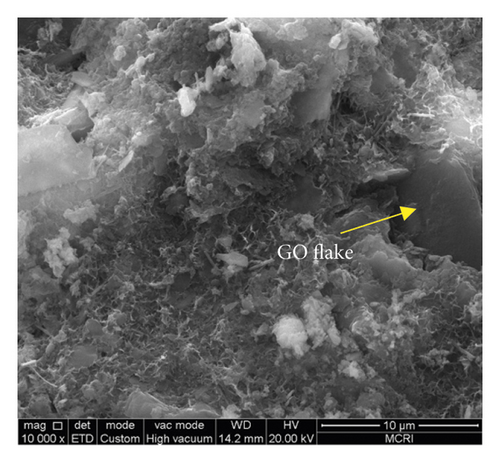

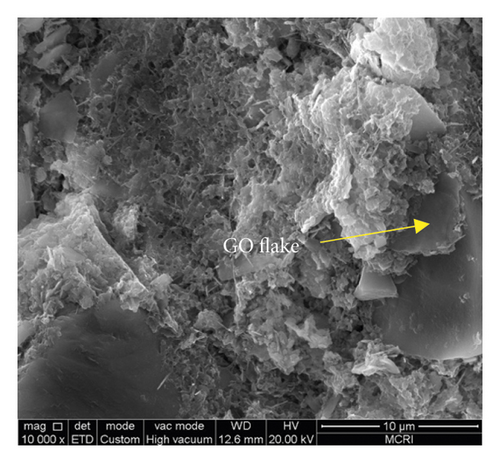

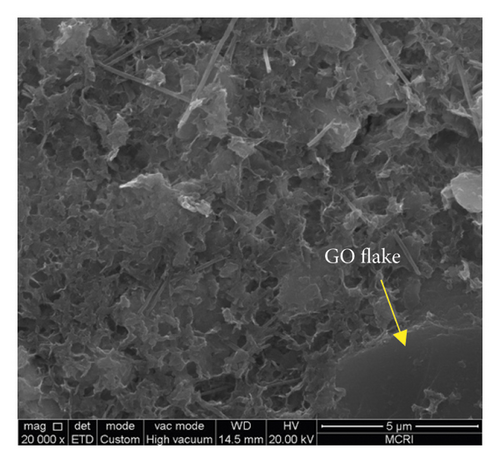

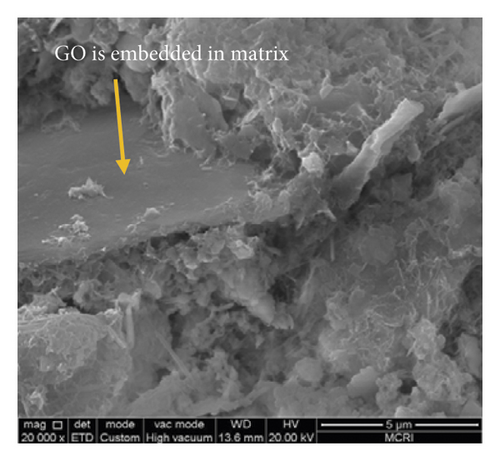

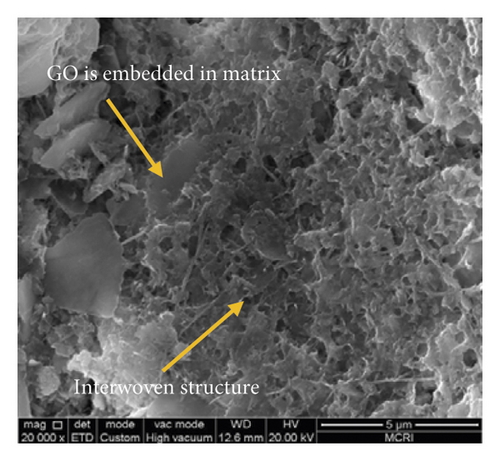

To study the co-effects of GO and cement on the microstructure of the studied loess, the SEM tests were conducted, as presented in Figure 11. The SEM image of cement/loess without GO (Figure 11(a)) showed a loose microstructure with some voids and straight-through cracks. Additionally, just few hydration products could be observed for the cement/loess sample. Compared with that of cement/loess sample, the SEM image of GO/cement/loess presents a denser microstructure shown in Figures 11(b)–11(f).

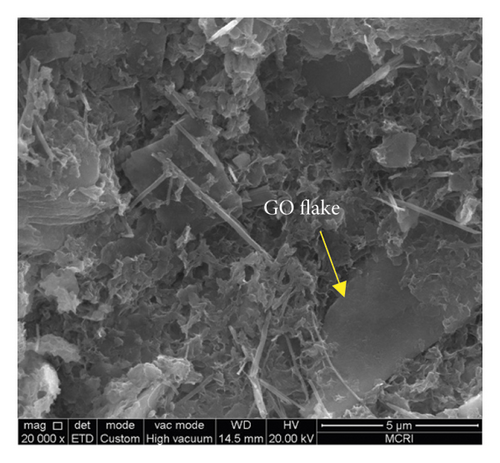

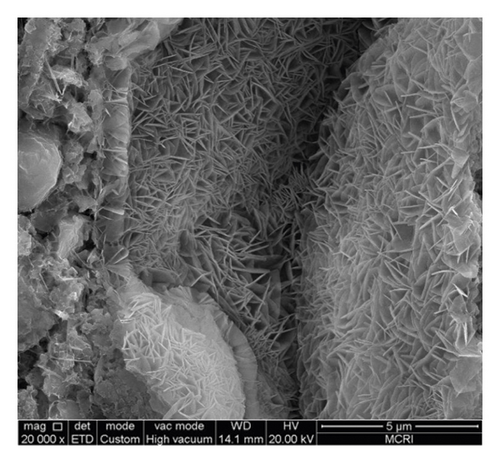

Generally, the dispersion in matrix and contact with other particles are two main factors of GO responsible for the enhancement effect. As indicated in Figures 11(b)–11(e), the GO sheets were randomly oriented in the matrix. And the agglomerated phenomenon was not detected, illustrating a good dispersion of GO/cement in the loess matrix. Moreover, according to the SEM results abovementioned, the morphology of GO was thin and wrinkled with a high aspect ratio, which was helpful for a bigger contact area between GO and other particles, thus improving the mechanical properties due to a higher debonding energy. Figure 11(f) showed the interwoven and flower-like structure which had been observed in the GO/cement composite [24]. The reason was that GO can regulate hydration products to form neat crystal structures, resulting in denser microstructure and higher mechanical properties [21,24].

4. Discussion

On the basis of the abovementioned results, the mechanisms of co-effects of GO and cement on the loess matrix can be illustrated as follows.

First of all, the noticeable nucleation effect of GO should be mentioned. As is known, because of the large specific surface, the GO would adsorb the cement and loess particles and become the core of the hydration reaction; that is, particles may tend to concentrate on GO surface. As a result, particles are more likely to react with each other and a denser and interwoven hydrated C-S-H gel structure would become as observed in Figure 11. Thus, it provides a greater possibility for the optimization of microstructure and the improvement of mechanical properties.

Secondly, it should be attributed to the acceleration effect of GO on the hydration process of cement. For the cement/loess system, the enhancement effect is mainly attributed to the higher bonding force generated by C-S-H gel from cement hydration products. So, the more and faster the C-S-H generation, the better the enhancement effect on the loess. Based on the previous research studies [18–26], it had been an agreement that the GO can facilitate the hydration progress of cement due to the amount of active functional oxygen groups (-OH, -COOH) on the GO surface, thus promoting the generation of C-S-H, which is responsible for the improvement of mechanics performance. Therefore, depending on the synergistic effect of GO and cement on loess matrix, more and faster C-S-H gel will be generated, resulting in a denser microstructure and better mechanical properties.

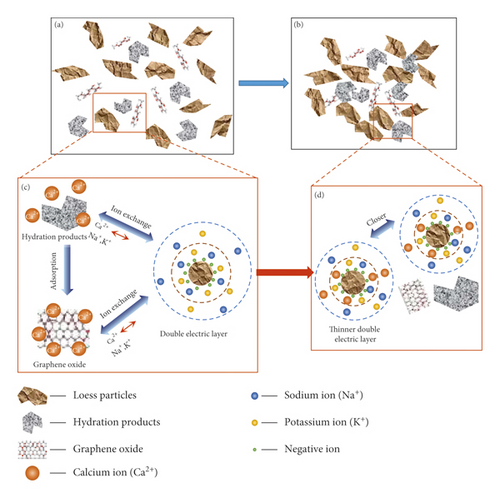

Thirdly, the ion exchange absorption effect is another important mechanism of the synergistic effect of GO/cement on loess matrix, as presented in Figure 12. As is known, the exchange absorption would occur between ions of K+, Na+ on the surface of loess particles and the Ca2+ ion generated from the cement hydration. With the addition of these high-valence ions, the double electric layer thickness of loess will become thinner, resulting in higher bonding force between loess particles, thus improving the microstructure and mechanical properties of the composite. Therefore, depending on the facilitating effect of GO on cement hydration, the amount of Ca2+ would be generated, resulting in more broadly and deeply exchange absorption between ions. Then, a better enhancement effect would come into being.

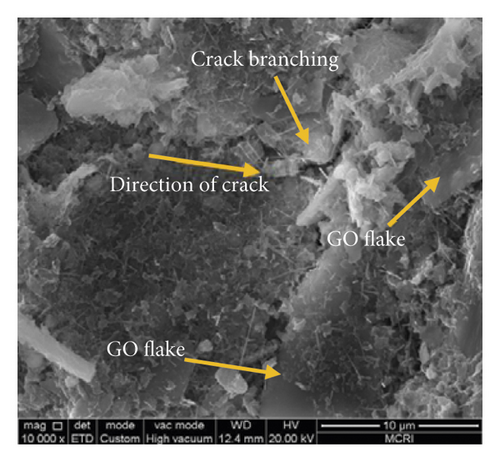

Additionally, the filling and bridging effects are also responsible for the enhancement effect. With the incorporation of GO, the voids between the particles would be filled by the nanosized GO, resulting in improved characteristics of pores. What is more, for the addition of GO, cracks would be effectively refined, bridged, and forced to twist around the GO sheets, as shown in Figure 13, which is similar to the results concluded by Pan et al. [21] for GO/cement composites. Consequently, depending on the co-effect of GO and cement, a denser and optimum microstructure of GO/cement/loess composite was generated.

5. Conclusions

- (1)

The compaction tests revealed that the dry density increased with the increasement of GO incorporation in the cemented loess, while the optimum moisture showed a decreasing trend, which was due to the synergistic effect of GO and cement on loess sample and the microstructure with the presence of C-S-H gel and the interface bonding will be denser.

- (2)

Both the mechanical properties and water resistance were improved with the increase of GO content. In the present paper, the optimum enhancement effect of mechanical properties and water resistance were detected corresponding to the 0.09 wt. % GO content.

- (3)

The SEM results showed that due to the synergistic filling effect and hydration effect of cement/GO, the microstructure was denser and characteristics of crack were refined.

- (4)

The enhanced mechanism includes both physical and chemical aspects, including nucleation effect, ion exchange adsorption effect, and filling effect, and bridging effect.

Conflicts of Interest

The authors declare that there are no conflicts of interest regarding the publication of this paper.

Acknowledgments

This research was funded by the National Natural Science Foundation of China (Grants nos. 51878547 and 51641809), China Postdoctoral Fund (Grant no. 2018M633478), the Opening Fund of State Key Laboratory of Green Building in Western China (Grant no. LSKF202010), and Basic Research Program of Natural Science in Shaanxi Province (Grant no. 2020JQ-671).

Open Research

Data Availability

The data are available upon request to the authors.