Quantitative Identification of the Water Resistance Capacity of Composite Strata in Mining Coal Seam Floors

Abstract

In coal seam mining, the water resistance of the floor composite strata is the key to determining whether water disaster occurs or not and to formulating water control countermeasures. Taking the Pingdingshan Coalfield No. 8 mine and Shoushan mine as the research objects, the thickness ratio of plastic brittle rock, core recovery rate, thickness of effective aquiclude, fault complexity, composite compressive strength, and equivalent water resistance coefficient were selected as the index factors. The comprehensive weight of each index factor was determined by using the entropy weight theory. The water resistance of the J16-17 coal seam floor composite rock in the study area was quantitatively evaluated using the fuzzy variable set mathematical model and was divided into five grades: extremely weak, weak, medium, strong, and very strong. The results show that the J16-17 coal floor composite rock layers with strong and very strong water resistance areas account for 23.64% of the total area, the medium areas account for 58.26%, and the weak and extremely weak areas account for 18.1%. These results provide support for the accurate assessment of water inrush hazards of a coal floor.

1. Introduction

In the process of mining Permian Carboniferous coal seams in North China coalfields, water inrush from an Ordovician or Cambrian thick limestone aquifer is always a threat. These bottom plates usually experience high water pressure and are rich in water [1, 2]. The composite rock layer is composed of sandstone, mudstone, thin limestone, and a thin coal seam. Between the coal seam and thick limestone is the barrier for resisting high water pressure and preventing groundwater from rising. Therefore, it is of great theoretical and practical significance to quantitatively evaluate the water resistance capacity of the composite rock strata, which can scientifically formulate water prevention and control countermeasures to reduce the degree of harm from water inrush in an area.

At present, many experts and scholars have carried out research work on the water resistance of rock formations. Yang [3] believed that the essence of mining under pressure is the existence of combined water, which makes the rock strata have the ability of water resistance and decompression, and proposed the concept of water resistance coefficient. Qian et al. [4] and Miao and Qian [5] put forward the “key layer” theory for judging water inrush from coal floors. Xu et al. [6] based on the investigation of the floor lithology, strata combination relationship, and karst development conditions of a certain wellfield proposed that at least 25 m upper Cambrian limestone could be used as an aquiclude, which significantly improved the mining conditions of the coal seam. Zhang et al. [7] studied the relationship between water resistance capacity of rock strata and its structural composition and combination form through laboratory tests and proposed that the combination with better water resistance ability should start with soft rock strata and alternate soft and hard rock strata. Yin and Hu [8] took structure, in situ stress, and rock permeability as the influencing factors of the water resistance capacity of rock strata and concluded that the water resistance capacity of mudstone, siltstone, medium sandstone, and limestone ranges from large to small. Feng et al. [9] used experiments and numerical simulations to study the effects of different lithological characteristics of the aquiclude on its water resistance capacity. Li et al. [10] faced the problem of the stability of the water resistance rock mass of the karst tunnel, only considered the safe thickness of the water resistance rock mass, and did not consider the joints and permeability of the rock mass, which has certain limitations. Sun et al. [11] studied the influence of thickness, layer, length, cohesion, and internal friction angle on the water resistance capacity of the key composite aquiclude and concluded that the water pressure that can withstand is in a quadratic parabola relationship with its thickness. The greater the thickness, the better the water resistance capacity. Xu et al. [12] analyzed the lithology, void structure, and permeability characteristics of Fengfeng Formation from a micro-macro scale and made a quantitative study on its water resistance capacity. Lyu and Xie [13] and Zhang et al. [14] used statistical analysis and laboratory experiments to study the lithologic combination characteristics, rock mechanical strength, water properties, and permeability of coal seam overburden rock and evaluated the comprehensive water resistance capacity. Wang [15] studied the water resistance capacity of overlying rock from the strength, anisotropy, rheology, and expansibility of rock.

As shown above, the research on the water resistance capacity of rock layers has developed from the initial consideration of a single factor such as rock thickness or lithologic difference [16–20] to a comprehensive analysis of multiple factors such as lithology combination, rock mass strength, and permeability, making the evaluation system more and more perfect. However, due to insufficient field data and difficulty in quantifying index factors, the existing evaluation index system often ignores the influence of geological structure, mining failure, and equivalent water resistance of different lithology and rock formations. In addition, in the existing research results, the analytic hierarchy process or grey correlation method is commonly used to calculate the weight of index factors, so that the calculation results are greatly influenced by the subjective shortcomings. In this paper, the thickness ratio of plastic brittle rock, core recovery rate, thickness of effective aquiclude, fault complexity, composite compressive strength, and equivalent water resistance coefficient were selected as index factors, covering many factors affecting the water resistance capacity of composite strata on coal floor. The comprehensive weight determined by entropy weight theory overcomes the subjective and objective randomness of the traditional method. The fuzzy variable set theory can describe the characteristics of things under the combined action of multiple index factors and has realized the quantitative identification of water resistance capacity of composite rock strata. The research results are expected to provide technical support for an accurate evaluation of water inrush risk from coal floors.

2. Determination of Index Factors

2.1. Strata Structure of Coal Seam Floors

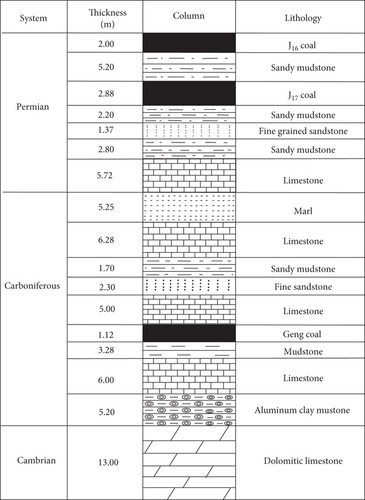

The area of the No. 8 mine and Shoushan mine, located in the eastern Pingdingshan Coalfield, is 68.35 km2. At present, mainly the J16-17 coal is mined. The thickness of the coal seam has a range of 2-3.8 m, with an average thickness of 2.44 m. The main threatening aquifer of the baseplate is a Cambrian limestone aquifer with a thickness greater than 200 m. The coal seam and Cambrian limestone are composed of sandy mudstone, medium-fine sandstone, thin coal seam, thin limestone, and bauxite mudstone. The floor rock structure of the J16-17 coal is shown in Figure 1. The thickness is 68-77 m, and the mean value is 71.3 m.

2.2. Index Factor Selection

During coal mining, the main factors controlling the water resistance of the floor composite rock layer are the lithological structure, integrity, thickness of effective aquiclude, fault development, compressive strength, and permeability.

The floor of the Ji Formation coal seam is an interbed of brittle sand (limestone) and plastic mudstone. The more sand (limestone) layers and the thicker the single layer, the more easily the floor is damaged by excavation; while the mudstone layers depend on elastic deformation to decompose stress under load, the more numerous and thicker the mudstone layers, the better the water resistance of the rock layers. Lithological structure is usually characterized by the ratio of brittle rock thickness to plastic rock thickness revealed by drilling holes (thickness ratio of plastic brittle rock).

The integrity of the rock mass represents the degree of development of cracks in the rock mass. It reflects the permeability and water-bearing capacity of the rock mass. Therefore, it is an important index for evaluating the water resistance of the rock formation. Integrity is often indicated by the ratio of the core length to the thickness of the formation (core recovery rate) during drilling. The lower the recovery is, the more fractured the rock is, the better the permeability is, and the stronger the water-bearing capacity is.

The thickness of the aquiclude is the distance between the mining coal seam and the main threatening aquifer, and the disturbance destroy depth of the floor is the disturbance destroy depth under the mining condition of the coal seam. The thickness of effective aquiclude is the difference between the two. Based on the lithological structure and rock mass integrity, the greater the effective aquiclude is, the stronger the ability to resist water pressure damage, and the lower the possibility of water inrush from the floor.

Faults and associated fissures not only destroy the integrity of the rock layers but also are important water diversion channels. The more developed the interruption layers in the coal seam floor, the denser the tensional faults are, the more serious the rock layers are damaged, and the higher the frequency of water inrush occurs. Once water inrush occurs, the greater the water volume is. Fault development is often indicated by fault complexity.

The ability of the rock formation to resist water pressure is closely related to its own compressive strength. Hard limestone and sandstone have high compressive strength, but poor plasticity and weak water-retaining ability, while soft mudstone has the opposite characteristics: low compressive strength, good plasticity, and good water-retaining ability. The compressive strength of the multirock combination of the coal floor is characterized by the composite compressive strength.

The more permeable the composite rock layer in the coal seam floor is, the higher the rise height of groundwater under the same water pressure and the greater the possibility of water inrush. In order to facilitate the uniform comparison and analysis of permeability for the different lithological rocks, the equivalent water resistance coefficient is often used to indicate the permeability of rocks. When the lithological thickness and equivalent water-proofing coefficient of each rock layer are known, the equivalent water resistance coefficient of the composite rock layer can be obtained as the basis for determining the water-resistance capacity of the floor.

Therefore, we selected six factors, including the thickness ratio of plastic brittle rock, the core recovery rate, the thickness of effective aquiclude, fault complexity, composite compressive strength, and equivalent water resistance as the index factors to evaluate the water resistance of the coal seam floor rock.

3. Index Factor Quantization

3.1. Thickness of Effective Aquiclude

The average destruction depth of the Ji Group coal floor disturbance for the No. 8 mine and Shoushan mine calculated by formula (2) is shown in Table 1.

| Mine | α (°) | L (m) | H (m) | Cp (m) |

|---|---|---|---|---|

| No. 8 mine | 17 | 140 | 804.76 | 20.41 |

| Shoushan mine | 10.17 | 160 | 713 | 20.65 |

We take drilling hole No. 1 as an example, located in the No. 8 coal mine. The total thickness of the floor rock of the J16-17 coal exposed by drilling is 68.14 m. First, the disturbance damage depth of the floor rock is 20.41 m (Table 1). Then, according to Equation (1), the effective thickness of the aquiclude is calculated to be 47.73 m. Analogously, the effective water-resistant thickness of 48 boreholes is calculated, and their contours are drawn (as shown in Figure 2).

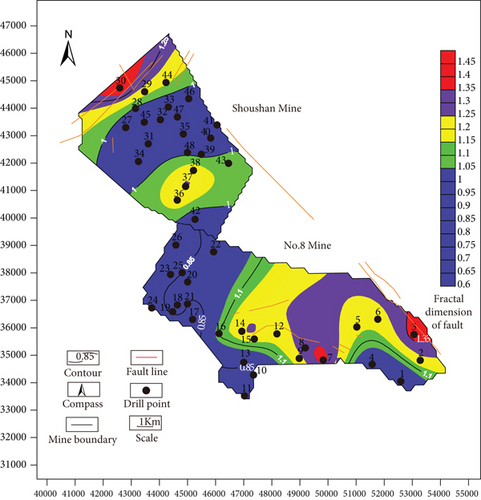

3.2. The Complexity of the Fault

Firstly, the region containing fractal is divided into several square blocks according to certain rules. The blocks containing fractal are numbered one by one, and the similarity ratio r = 1, 1/2, 1/4, and 1/8 are taken, respectively. The blocks are subdivided into 1, 4, 16, and 64 square grids. Count the number of grids N(r) occupied by the fractal body at different scales in a certain segment and establish the lg(r)-lgN(r) double logarithmic coordinate system with formula (3). Then, the slope of the fitted line and the correlation coefficient are obtained by the least square method, and the absolute value of the slope is the value of the fractal dimension.

According to the actual situation, this paper divided the mining area into 600 × 600 mm square blocks. The number of mesh N(r) covering faults when r = 600, 300, 150, and 75 mm is calculated successively, and the obtained results are shown in Table 2. The contour of fault fractal dimension is shown in Figure 3.

| Drilling hole | Thickness ratio of plastic brittle rock | Core recovery rate | Thickness of effective aquiclude | Fault factor values | Composite compressive strength | Equivalent water resistance coefficient |

|---|---|---|---|---|---|---|

| 1 | 1.4158 | 0.7840 | 47.73 | 0.8432 | 4.87 | 0.9410 |

| 2 | 1.0978 | 0.8795 | 54.39 | 1.2114 | 5.38 | 0.9685 |

| 3 | 1.1437 | 0.7255 | 60.16 | 1.4051 | 5.24 | 0.9251 |

| 4 | 0.9832 | 0.7500 | 61.49 | 0.8772 | 5.52 | 0.9196 |

| 5 | 0.4547 | 0.7626 | 82.06 | 1.1708 | 6.75 | 0.8285 |

| 6 | 0.8891 | 0.6579 | 68.03 | 1.1863 | 5.74 | 0.9492 |

| 7 | 1.2344 | 0.6879 | 51.77 | 1.3911 | 5.14 | 0.9528 |

| 8 | 0.9676 | 0.8300 | 59.51 | 1.3214 | 5.54 | 0.9143 |

| 9 | 0.9948 | 0.8100 | 62.23 | 1.2141 | 5.51 | 0.9310 |

| 10 | 0.8373 | 0.7243 | 50.35 | 0.8021 | 5.70 | 0.9042 |

| 11 | 1.2413 | 0.5881 | 55.18 | 0.7392 | 5.03 | 0.8816 |

| 12 | 0.9411 | 0.5223 | 56.52 | 1.1883 | 5.52 | 0.8659 |

| 13 | 0.8551 | 0.7988 | 72.24 | 0.8609 | 5.74 | 0.8913 |

| 14 | 0.6670 | 0.7131 | 66.02 | 1.2704 | 6.13 | 0.8490 |

| 15 | 0.7282 | 0.7300 | 54.06 | 1.1801 | 5.99 | 0.8629 |

| 16 | 0.7286 | 0.6500 | 55.42 | 1.1174 | 5.73 | 0.8533 |

| 17 | 0.8972 | 0.5178 | 80.13 | 0.6891 | 5.66 | 0.9018 |

| 18 | 0.4423 | 0.5650 | 87.61 | 1.0870 | 6.81 | 0.8354 |

| 19 | 0.8691 | 0.5500 | 81.05 | 0.8817 | 5.69 | 0.8818 |

| 20 | 0.7293 | 0.6975 | 69.32 | 0.9017 | 6.05 | 0.9053 |

| 21 | 0.9372 | 0.4363 | 89.77 | 0.8195 | 5.53 | 0.8659 |

| 22 | 0.6177 | 0.9226 | 75.05 | 0.8745 | 6.27 | 0.8508 |

| 23 | 0.6608 | 0.7508 | 59.65 | 0.7917 | 6.18 | 0.8750 |

| 24 | 0.7382 | 0.5876 | 74.00 | 0.6451 | 5.93 | 0.8342 |

| 25 | 0.6804 | 0.9000 | 65.17 | 0.8504 | 6.14 | 0.8847 |

| 26 | 0.7033 | 0.8996 | 66.95 | 0.7936 | 6.06 | 0.8705 |

| 27 | 0.8139 | 0.9060 | 61.15 | 0.8942 | 5.36 | 0.9137 |

| 28 | 0.7064 | 0.8471 | 74.35 | 0.9661 | 5.78 | 0.8677 |

| 29 | 0.3347 | 0.7330 | 58.90 | 1.1468 | 6.93 | 0.8736 |

| 30 | 0.7952 | 0.7953 | 54.25 | 1.3911 | 5.63 | 0.8872 |

| 31 | 0.2857 | 0.8829 | 60.65 | 0.8917 | 7.06 | 0.8500 |

| 32 | 0.6667 | 0.9149 | 62.90 | 0.8060 | 5.96 | 0.9001 |

| 33 | 0.5720 | 0.9098 | 56.93 | 0.8794 | 6.26 | 0.9179 |

| 34 | 0.4793 | 0.8400 | 60.37 | 0.8929 | 6.37 | 0.8885 |

| 35 | 0.8096 | 0.8694 | 68.65 | 0.8635 | 5.78 | 0.9527 |

| 36 | 0.4583 | 0.8462 | 55.81 | 1.1781 | 6.46 | 0.8629 |

| 37 | 0.5239 | 0.8464 | 55.18 | 1.2118 | 6.22 | 0.8500 |

| 38 | 1.3847 | 0.8479 | 55.25 | 1.1817 | 4.77 | 0.9226 |

| 39 | 0.6517 | 0.8700 | 77.83 | 0.9677 | 5.84 | 0.8673 |

| 40 | 0.1599 | 0.7889 | 79.58 | 0.8598 | 7.43 | 0.7724 |

| 41 | 0.2780 | 0.6980 | 75.73 | 0.8697 | 6.84 | 0.7943 |

| 42 | 0.5179 | 0.8500 | 78.00 | 0.8837 | 6.28 | 0.8772 |

| 43 | 0.6748 | 0.8540 | 77.80 | 1.0656 | 5.61 | 0.8444 |

| 44 | 0.4013 | 0.9300 | 81.41 | 1.1236 | 6.71 | 0.8844 |

| 45 | 0.7415 | 0.9150 | 86.90 | 0.7696 | 5.80 | 0.9075 |

| 46 | 0.4563 | 0.8520 | 77.09 | 0.9230 | 6.46 | 0.8845 |

| 47 | 0.6197 | 0.9490 | 79.80 | 0.8511 | 6.02 | 0.9158 |

| 48 | 0.7681 | 0.8090 | 80.72 | 0.9761 | 5.70 | 0.9040 |

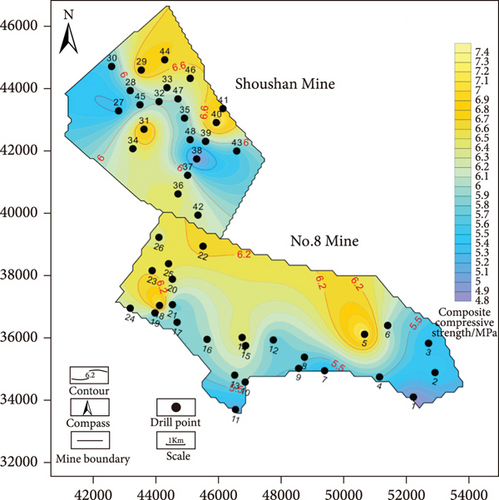

3.3. Composite Compressive Strength

In this study, a total of 60 cores were collected from seven boreholes in the J16-17 coal floor, including 25 mudstone, 25 sandstone, and 10 limestone samples. The test results of the compressive strength are shown in Table 3.

| Mine | Mudstone | Sandstone | Limestone |

|---|---|---|---|

| Shoushan mine | 41.43 | 73.72 | 90.10 |

| No. 8 mine | 37.60 | 84.83 | 93.12 |

The order of compressive strength is plastic mudstone < brittle limestone < brittle sandstone. Although brittle rock has a high compressive strength, it easily fractures under load, and its water resistance performance is poor, while plastic mudstone exhibits contrary behaviors. The research results show that when the compressive strength of brittle rock is twice that of plastic rock, the water resistance capacity of the latter is 2.5-3 times that of the former [24]. According to the manual of mine geology [25], the conversion coefficient of the compressive strength for different rocks is shown in Table 4.

| Lithology | Conversion factor (MPa/m) |

|---|---|

| Mudstone, marl, clay, shale | 0.05 |

| Sand shale | 0.07 |

| Sandstone, no karst limestone, marl | 0.10 |

Taking the No. 1 drilling hole of the No. 8 mine as an example, the thickness ratios of the mudstone, limestone, and sandstone are 58.61%, 31.57%, and 9.83%, respectively. The composite compressive strength calculated by using Equation (4) combined with Tables 3 and 4 is 4.87 MPa. Following the same procedure, the composite compressive strength of the 48 boreholes can be obtained, and the contour lines are drawn (as shown in Figure 4).

The figure shows that the compressive strength of the J16-17 coal floor composite rock layer is 4.00-7.43 MPa, and the mean value is 5.71 MPa. At present, the water pressure of the Cambrian limestone in the study area is 0.38-4.94 MPa, and the mean value is 2.63 MPa. The composite rock layer in its natural state can fully resist water pressure. However, under the influence of faults and mining, the water-resistant performance of the coal seam floor rock will be significantly reduced, which shows the necessity of a multifactor evaluation of the water-resistance capability.

3.4. Equivalent Water Resistance Coefficient

Referring to the existing literature [26–28], the equivalent water resistance coefficients of different rock layers are listed in Table 5.

| Lithology | Conversion value of equivalent water resistance coefficient |

|---|---|

| Mudstone, marl, clay, shale | 1.0 |

| Sandstone | 0.4 |

| Sand shale | 0.8 |

| Mine | 0.7 |

| Gravel, gravel, etc. | 0 |

Based on the rock layer thickness revealed by drilling and the equivalent water resistance coefficient values listed in Table 5, the equivalent water resistance coefficient of the composite rock layers for the J16-17 coal floor in 48 drilling holes was obtained. The contours are shown in Figure 5.

3.5. Index Factor Set

The thickness ratio of the plastic brittle rock and core recovery rate can be counted according to the drilling disclosure information. Quantitative values of the six index factors corresponding to the 48 boreholes are shown in Table 2. In order to correspond to the evaluation of the water-resistance of the rock formation, the value of the fault complexity factor is taken as the reciprocal of the fractal dimension.

4. Index Factor Weight

It is very important to choose a scientific mathematical method to determine the weight of the index factors. Referring to the existing research results [29], this paper chooses nine-scale AHP and gray correlation analysis to calculate the subjective and objective weights and then couples them to determine the comprehensive weights.

4.1. Subjective Weight

The AHP establishes a hierarchical structure model, constructs a judgment matrix, and calculates the weight of each factor’s influence on the overall goal [30, 31]. As shown in Table 6, the target layer is the evaluation of the water resistance of the coal seam floors. The criterion layer divides the index factors into 3 categories, and the scheme layer includes 6 index factors.

| Target layer | Criteria layer | Scheme layer |

|---|---|---|

| Evaluation of water resistance of the coal seam floors (A) | Geological structure and disturbance damage (B1) | The thickness of effective aquiclude (C1) |

| Fault factor values (C2) | ||

| Compression resistance and permeability (B2) | Composite compressive strength (C3) | |

| Core recovery rate (C4) | ||

| Lithology combination and water blocking performance (B3) | Equivalent water resistance coefficient (C5) | |

| Thickness ratio of plastic brittle rock (C6) |

The calculated feature vector ωB = (0.5242, 0.1973, 0.2785). CRB = 0.0036 < 0.1; it satisfies the consistency condition.

The calculated feature vector ωC1 = (0.25, 0.75), ωC2 = (0.2, 0.8), ωC3 = (0.1667, 0.8333). CRC1 = CRC2 = CRC3 = 0 < 0.1; it satisfies the consistency condition.

By calculating CR = 0.0000 < 0.1, it satisfies the consistency condition, indicating that the constructed judgment matrix is reasonable. The subjective weight of the six index factors is shown in Table 7.

| Indicators | Thickness ratio of plastic brittle rock | Core recovery rate | Thickness of effective aquiclude | Fault factor values | Composite compressive strength | Equivalent water resistance coefficient |

|---|---|---|---|---|---|---|

| Subjective weight | 0.2321 | 0.1578 | 0.1311 | 0.3932 | 0.0395 | 0.0464 |

4.2. Objective Weight

Then, the weights of the six index factors [34] can be obtained, and their values are shown in Table 8.

| Indicators | Thickness ratio of plastic brittle rock | Core recovery rate | Thickness of effective aquiclude | Fault factor values | Composite compressive strength | Equivalent water resistance coefficient |

|---|---|---|---|---|---|---|

| Objective weight | 0.1366 | 0.1616 | 0.1617 | 0.1529 | 0.1601 | 0.2271 |

4.3. Comprehensive Weights

The comprehensive weights of the six index factors determined by formula (11) are shown in Table 9. The relative entropies of the comprehensive weights with the subjective and objective weights can be calculated by formula (12) (as shown in Table 10).

| Indicators | Thickness ratio of plastic brittle rock | Core recovery rate | Thickness of effective aquiclude | Fault factor values | Composite compressive strength | Equivalent water resistance coefficient |

|---|---|---|---|---|---|---|

| Comprehensive weight | 0.1955 | 0.1753 | 0.1599 | 0.2692 | 0.0873 | 0.1127 |

| Weight | Comprehensive weight and subjective weight | Comprehensive weight and objective weight |

|---|---|---|

| Relative entropy | 0.073 | 0.089 |

Obviously, the relative entropies are less than 0.1 and tend to 0, which indicates that the consistency between the comprehensive weight and the subjective and objective weight is high [36]. That is, the comprehensive weight can effectively combine the subjective and objective weights, and its weight distribution is more scientific and reasonable.

5. Identification of Water Barrier Ability

5.1. Model Building

5.1.1. Level Matrix Establishment

According to the existing index factor data with reference to the existing research results [37], the water-insulation capacity of the composite strata in the coal seam floor can be divided into five grades, namely, extremely weak (I), weak (II), medium (III), strong (IV), and very strong (V).

5.1.2. Level Eigenvalue Determination

The mean of the level eigenvalue is 3.8091. Similarly, the mean value of the grade characteristics of other boreholes can be calculated as shown in Table 11 (Note: α and β are the parameters of the compound operation of the fuzzy variable sets).

| Drilling hole | Level eigenvalue | Waterproof ability grade | ||||

|---|---|---|---|---|---|---|

| α = 1, β = 1 | α = 1, β = 2 | α = 2, β = 1 | α = 2, β = 2 | Mean | ||

| 1 | 3.6544 | 3.5047 | 4.1654 | 3.9117 | 3.8091 | IV |

| 2 | 3.502 | 3.4306 | 4.0213 | 3.9278 | 3.7204 | IV |

| 3 | 3.6759 | 3.5109 | 4.239 | 3.9485 | 3.8436 | IV |

| 4 | 3.7136 | 3.5287 | 4.2675 | 3.9754 | 3.8713 | IV |

| 5 | 2.2395 | 2.3538 | 1.9527 | 2.1855 | 2.1829 | II |

| 6 | 3.7877 | 3.6014 | 4.5335 | 4.2561 | 4.0447 | IV |

| 7 | 3.588 | 3.4534 | 4.2084 | 3.9854 | 3.8088 | IV |

| 8 | 3.7403 | 3.5429 | 4.2758 | 3.9915 | 3.8876 | IV |

| 9 | 3.6678 | 3.5091 | 4.2116 | 3.9349 | 3.8308 | IV |

| 10 | 3.2876 | 3.2574 | 3.6278 | 3.5052 | 3.4195 | III |

| 11 | 3.1764 | 3.2221 | 3.2825 | 3.3479 | 3.2572 | III |

| 12 | 2.3663 | 2.2988 | 2.5043 | 2.4577 | 2.4068 | II |

| 13 | 3.3073 | 3.2887 | 3.5358 | 3.5015 | 3.4083 | III |

| 14 | 2.1647 | 2.2678 | 1.9389 | 2.1243 | 2.1239 | II |

| 15 | 2.5617 | 2.606 | 2.5215 | 2.6208 | 2.5775 | III |

| 16 | 2.279 | 2.3811 | 2.0797 | 2.2682 | 2.252 | II |

| 17 | 3.296 | 3.2668 | 3.6164 | 3.5123 | 3.4229 | III |

| 18 | 2.2245 | 2.3447 | 1.9259 | 2.1655 | 2.1652 | II |

| 19 | 3.182 | 3.2255 | 3.2919 | 3.354 | 3.2634 | III |

| 20 | 3.7163 | 3.5353 | 4.1929 | 3.9606 | 3.8513 | IV |

| 21 | 2.3663 | 2.2988 | 2.5043 | 2.4577 | 2.4068 | II |

| 22 | 2.2127 | 2.3157 | 1.9924 | 2.1817 | 2.1756 | II |

| 23 | 2.9916 | 3.0838 | 2.9515 | 3.1097 | 3.0342 | III |

| 24 | 2.2272 | 2.3463 | 1.9305 | 2.1691 | 2.1683 | II |

| 25 | 3.2634 | 3.2673 | 3.4148 | 3.4315 | 3.3442 | III |

| 26 | 2.8611 | 2.9716 | 2.7547 | 2.9459 | 2.8833 | III |

| 27 | 3.7387 | 3.5425 | 4.2704 | 3.9899 | 3.8854 | IV |

| 28 | 2.4441 | 2.3738 | 2.5554 | 2.5058 | 2.4698 | II |

| 29 | 2.9519 | 3.0502 | 2.886 | 3.0575 | 2.9864 | III |

| 30 | 3.2971 | 3.288 | 3.4872 | 3.4804 | 3.3882 | III |

| 31 | 2.1914 | 2.2944 | 1.9676 | 2.1556 | 2.1522 | II |

| 32 | 3.3017 | 3.2728 | 3.608 | 3.5157 | 3.4246 | III |

| 33 | 3.7246 | 3.5343 | 4.2739 | 3.9827 | 3.8789 | IV |

| 34 | 3.3003 | 3.2884 | 3.5022 | 3.4872 | 3.3945 | III |

| 35 | 3.5887 | 3.4537 | 4.2099 | 3.9861 | 3.8096 | IV |

| 36 | 2.5617 | 2.606 | 2.5215 | 2.6208 | 2.5775 | III |

| 37 | 2.1914 | 2.2944 | 1.9676 | 2.1556 | 2.1522 | II |

| 38 | 4.6934 | 4.5189 | 5.2535 | 4.9613 | 4.8568 | V |

| 39 | 2.4271 | 2.3573 | 2.5431 | 2.4942 | 2.4554 | II |

| 40 | 1.8025 | 1.8694 | 1.6102 | 1.7337 | 1.754 | I |

| 41 | 1.7928 | 1.8653 | 1.6009 | 1.7255 | 1.7461 | I |

| 42 | 3.0531 | 3.1345 | 3.0596 | 3.1939 | 3.1103 | III |

| 43 | 2.2044 | 2.3317 | 1.8922 | 2.1376 | 2.1415 | II |

| 44 | 3.255 | 3.2636 | 3.4034 | 3.4245 | 3.3366 | III |

| 45 | 4.7221 | 4.5373 | 5.2134 | 4.9691 | 4.8605 | V |

| 46 | 3.2578 | 3.2649 | 3.4072 | 3.4269 | 3.3392 | III |

| 47 | 4.7378 | 4.541 | 5.2804 | 4.9908 | 4.8875 | V |

| 48 | 3.2883 | 3.2582 | 3.6268 | 3.5059 | 3.4198 | III |

5.2. Water-Resistant Capacity Zoning

According to the hydrogeological conditions of the study area and the research results of others [38], the eigenvalue thresholds corresponding to the five levels of water insulation capacity are shown in Table 12.

| Waterproof ability grade | Extremely weak (I) | Weak (II) | Medium (III) | Strong (IV) | Very strong (V) |

|---|---|---|---|---|---|

| Level eigenvalue | W < 2.0 | 2.0 ≤ W < 2.5 | 2.5 ≤ W < 3.5 | 3.5 ≤ W < 4.5 | W ≥ 4.5 |

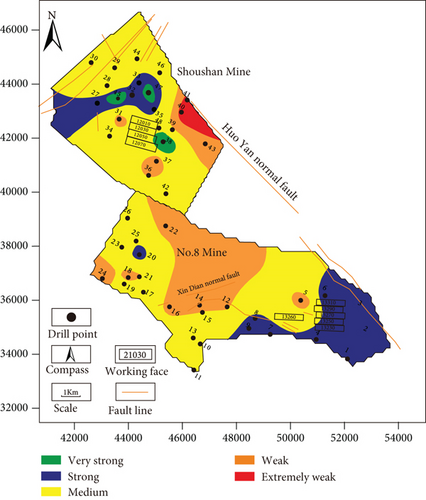

According to the characteristic values of 48 drilling levels of the No. 8 mine and the Shoushan mine listed in Table 11, the water resistance capacity grade can be determined by the classification standard in Table 12. The values are also listed in Table 11. The corresponding partition of the water resistance capacity of the composite strata in the coal floor of the J16-17 is shown in Figure 6.

The statistical analyses showed that the strong and very strong water resistance areas occupy 23.64% of the total area. The medium area accounts for 58.26%, and the weak and extremely weak areas account for 18.1%. The medium water insulation capacity is relatively high, and the weak and very weak areas are relatively small.

6. Discussion

It can be seen from the calculation process of AHP that the determination of the weight of indicator factors depends on the expert opinions or scores, and the results are easily affected by the subjective will of experts. Grey correlation method is based on the actual drilling data to determine the weight; it can avoid the impact of evaluator’s subjective will, but the grey correlation analysis method uses the same weight set when calculating the optimal solution, it is difficult to reflect the optimization of the evaluation. Combined with the previous two methods, the comprehensive weight determined by the entropy weight method can not only reduce the interference of human factors but also fully reflect the actual field, and its results are more scientific and reliable.

In the present mine excavation project, the water resistance capacity is usually judged according to the thickness of the aquiclude. It can be seen from Table 2 that the effective water resistance thickness of Nos. 38, 40, and 41 are 55.25 m, 79.58 m, and 75.73 m, respectively. Based on this, it is judged that the water resistance of the rock formation near No. 38 borehole is weaker than 40 and 41 drilling. In fact, the existence of the Huoyan fault near boreholes 40 and 41 not only reduces the distance between the coal seam and the aquifer [39] but also destroys the integrity of the coal seam floor [40–42]. At the same time, it also changed the migration characteristics of groundwater [43], which greatly reduced the water resistance of the rock formation. In this paper, it is determined that the water resistance capacity of the rock strata at borehole No. 38 is class V, and that of the rock strata at boreholes Nos. 40 and 41 is class I (Table 11), that is, the water resistance capacity of borehole No. 38 is greater than that of boreholes Nos. 40 and 41. The results are credible.

It can be seen from Figure 6 that the water resistance level characteristic value of the composite rock layer of the coal seam floor in the west of the Shoushan mine and the southeast of the No. 8 mine is above 2.5, and the water resistance is relatively strong. Therefore, the possibility of water inrush from the floor during coal mining is relatively small. The mining activities of the No. 8 mine and the Shoushan mine are mainly carried out in areas with strong and medium water resistance. The 13230, 13250, 13260, 13270, 13290, and 13310 working faces of No. 8 mine have stopped mining. The 12010, 12030, 12050, and 12070 working faces of Shoushan mine have stopped mining.

There is no floor water inrush accident in these working faces, which shows that the evaluation results are in good agreement with the actual situation.

7. Conclusions

- (1)

Based on the comprehensive analysis of multiple influencing factors on the water resistance of the J16-17 coal seam floor composite rock in the Pingdingshan Coalfield No. 8 mine and the Shoushan mine, we select the thickness ratio of plastic brittle rock, core recovery rate, thickness of effective aquiclude, fault complexity, composite compressive strength, and equivalent water resistance coefficient as the evaluation index factors. It provides a guarantee for identifying the water resistance of the composite rock layer of the coal seam floor

- (2)

Based on the analytic hierarchy process and grey relational analysis, the subjective and objective weights of the index factors are defined. The entropy weight theory is used to determine the comprehensive weights. Based on the fuzzy variable set theory, the mathematical model of water resistance evaluation is constructed, and the J16-17 coal floor is quantitatively identified. The water resistance of the coal seam floor composite rock layer is divided into five grades: extremely weak, weak, medium, strong, and very strong, laying the foundation for the accurate assessment of the water inrush risk from the coal seam floor

- (3)

The areas with strong and very strong water resistance capacity of the J16-17 coal floor composite rock in the No. 8 mine and the Shoushan mine account for 23.64% of the total area, the medium area accounts for 58.26%, and the weak and extremely weak areas account for 18.1%. Areas with medium water-resisting capacity accounting for relatively high, weak, and very weak areas are relatively small. The accurate evaluation and zoning of water-resistance capacity indicate the direction for the mine to take targeted measures to prevent and control floor water hazards

- (4)

The comprehensive weight of the index factors determined by the entropy weight theory reduces the interference level of human factors. The fuzzy variable set theory realizes the quantitative evaluation of the water resistance of the composite rock under the action of multiple index factors. The actual excavation results on site have proved the reliability of the evaluation results. It provides a reference method for accurately distinguishing the water resistance of rock formations

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (41802186 and 41972254), Innovative Science and Technology Talents Team Construction Project of Henan Province (CXTD2016053), and Special Funds for Higher Education Basic Scientific Research Funds of Henan Province (NSFRF200103).

Open Research

Data Availability

The data used to support the findings of this study are included within the article.