Nonlinear Torsional Vibration Analysis and Control of Semidirect Electromechanical Coupling Transmission System in Shearer

Abstract

The nonlinear torsional vibration and instability oscillation caused by nonlinear damping in the shearer electromechanical coupling cutting transmission system in shearer driven by the permanent magnet synchronous motor (PMSM) is investigated in this paper. The electromechanical coupling transmission system in the shearer is equivalent to a concentrated mass model for the purpose of establishing the system dynamic model by the Lagrange–Maxwell equation. Then, the Routh–Hurwitz criterion is used to determine the torsional vibration critical point and stability region for the Hopf bifurcation for the cutting transmission system. According to the Routh–Hurwitz stability criterion, the Hopf bifurcation type and the effect of the supercritical Hopf bifurcation in the torsional vibration of the cutting transmission system are analyzed. Furthermore, based on the washout filter, the Hopf bifurcation controller is designed for suppressing the transmission system’s large vibration amplitude and unstable oscillation. In addition, the influences of the linear gain and nonlinear gain on the bifurcation point and the limit cycle amplitude are discussed. Finally, the numerical simulation results indicate the effectiveness of the designed controller. The research achievements can provide a theoretical basis for design or optimize the cutting transmission system of high-reliability shearer driven by PMSM.

1. Introduction

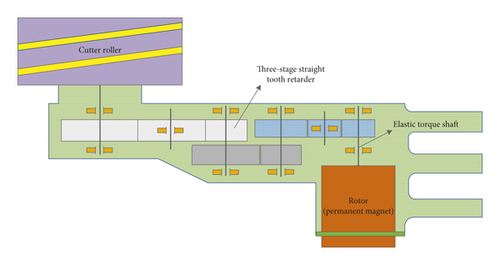

In recent years, with the continuous development of coal mining mechanization, it requires higher requirements for the fully mechanized mining equipment in high efficiency and high reliability [1, 2]. As an integral part of fully mechanized mining equipment, the shearers may easily break down due to the terrible working environment. Currently, the traditional main transmission mode of the cutting transmission system is “three-phase asynchronous motor + three-stage straight tooth retarder + planetary gear reducer + cutting drum,” which has a long transmission chain and many transmission components. The long-chain transmission mode is prone to failure [3–5]. Therefore, a semidirect driving system [6, 7] is proposed in this paper, which consists of PMSM, three-stage straight tooth retarder, and cutting drum, and is shown in Figure 1.

Comparing to the original system, the electromagnetic torque and load torque will greatly increase due to the system reduction ratio that is reduced by removing the planetary gear [8, 9], which is prone to torsional vibration of the cutting transmission system. Therefore, it has a great significance to research the torsional vibration of the cutting transmission system. Fortunately, this multimass elastic torsional system like the shearer cutting section has been researched by many domestic and foreign scholars who mainly study from the perspectives of natural frequency and disturbance. It is found that the nonlinear factors are the main cause of torsional vibration, and furthermore, bifurcation and chaos may occur in the system due to some nonlinear factors [10–12]. On the coupled bending and torsional vibration model of rubbing rotor, with rotational speed as the bifurcation parameter, the bifurcation and chaotic behavior of the rotor system are studied by Al-Bedoor [13]. Liu et al. [14] studied the static bifurcation characteristics and rotor system stability with time-delay nonlinear parameters, and then the vibration was controlled with the delay feedback. In [15], the self-excited oscillations caused by nonlinear factors in the power system are analyzed. And the system Hopf bifurcation motion was researched with nonlinear mode and Floquet theory with different resistance parameters. The mechanical rotor system Hopf bifurcation was researched by Yuan [16], which was frequently encountered in the mechanical structure, and may cause the shafting instability and damage. Saigo et al. [17] studied the suppression of forced vibration of the concentrated mass torsion system by a wave absorption. The results demonstrate that smaller mass and larger spring stiffness of an imaginary system absorb vibration energy better.

However, the cutting transmission system in shearer not only includes the motor but also mechanical parts, which belongs to the electromechanical coupling system. Due to the effect of electromechanical coupling, the cutting transmission system will exhibit complex dynamic behavior [18–20]. Therefore, the torsional vibrations of the system cannot be interpreted rationally, neither from electrical nor from mechanical aspect. It is important to establish an accurate model of the electromechanical coupling system to further analyze the torsional vibration dynamic characteristics in the semidirect transmission system of the shearer and control the torsional vibration from the aspect of motor [21]. Gustavsson and Aidanpää [22] established the model of electromagnetic excitation produced by the uniform magnetic field, and the influence of nonlinear magnetic pull on rotor vibration of the hydrogenerator unit was discussed. Szolc et al. [23] researched the dynamic electromechanical coupling effects in machine drive systems driven by asynchronous motors, and the electromagnetic stiffness and damping coefficients of the interaction between motor and mechanical system were determined by means of the analytical method. Ju et al. [24] constructed the global electromechanical-coupling dynamic models for the main transmission system of the scraper conveyor, and the Hopf bifurcation characteristic is analyzed, which was caused by sliding friction. In view of the above mentioned, Hopf bifurcation is a significant factor affecting the stability of the electromechanical coupling transmission system. However, the dynamic analysis of the electromechanical coupling system mainly focus on the induction motor, and the PMSM are rarely considered. It is a remarkable fact that the damping of the semidirect transmission shafting would change with the shafting vibration, the shaft fatigue, the wear, and lubrication of the bearing [25, 26]. Torsional vibrations of the cutting transmission system caused by shaft damping variations would further lead to the shafting destabilization [27, 28].

Different from the above references, this paper analyses the effect of Hopf bifurcation produced by variable damping in shearer semidirect transmission system driven by the PMSM. Furthermore, based on the washout filter, the Hopf bifurcation controller is designed for suppressing the transmission system’s unstable oscillation. Finally, this paper is organized as follows. The electromechanical-coupling dynamics modelling for the main transmission system of the shearer driven by the high-torque and low-speed PMSM is provided in Section 2. The Hopf bifurcation characteristics analysis for the system torsional vibration and numerical simulation verification is given in Section 3. The washout filter controller for the system torsional vibration is designed, and numerical simulation verification is given in Section 4. Finally, the conclusions are drawn in Section 5.

2. Electromechanical Coupling Torsional Vibration Modelling

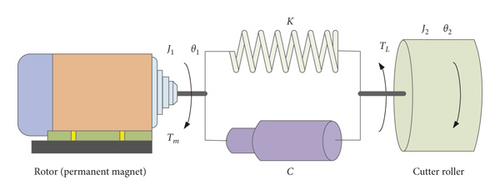

The semidirect cutting transmission system of the shearer driven by PMSM mainly consists of PMSM, three-stage gear, shafting, cutting drum, and so on. There are both resilient elements with small quality and inertia with large mass. Therefore, it is a multimass spring damping system with electromechanical coupling. To analyze the coupling dynamic characteristic of the electrical parameters and mechanical parameters, the PMSM and the cutting drum are regarded as the power source and load system, respectively, and ignore the effect of the reducer gear clearance. As a protective shaft for PMSM, the elastic torque shaft is more vulnerable to damage due to the relief groove and the low torsional strength. However, all other components have the feature of large mass and the small elasticity. Hence, the effect of the elastic torque shaft is only considered, and the other shaft and gear are equivalent to the PMSM and cutting drum. Then, the transmission system is equivalent to the two-mass spring torsional vibration system with resilient elements (PMSM and cutting drum) and inertia element (elastic torque shaft), as shown in Figure 2. To simplify the analysis, take the following assumptions: (1) neglecting the iron core saturation effect in the PMSM; (2) no consideration of eddy current and hysteresis loss in the PMSM; and (3) the motor stator winding current is a three-phase symmetric sine current.

In Figure 2, J1 is the PMSM inertia; J2 is the sum of the moment of the cutting drum and the transformation of the gear and other elements inertia; ia, ib, and ic are the three-phase stator current of the PMSM, respectively; K and C are the torsional stiffness and damping coefficient of the elastic torque shaft; Tm and TL are the electromagnetic torque of the PMSM and load torque of cutting drum; and θ1 and θ2 are the mechanical angle of the PMSM shaft and cutting drum shaft.

In equation (13), Id, Iq, θ1, and θ2 are variable items which will change with time. This system will exhibit complex dynamical behavior due to the variation of the damping C.

3. Cutting Transmission System Bifurcation Analysis

After the cutting transmission system of the shearer is changed to semidirect drive, the damping will change in the following cases: (1) the intensity of the vibration in the shaft system and (2) the wearing and the lubrication condition of the shaft. In addition, there may be oscillation vibration and Hopf bifurcation with the damping changes in the shafting, so the damping C is selected as the bifurcation parameter.

According to the Hopf bifurcation theory, the necessary and sufficient conditions for Hopf bifurcation are expressed as follows: there are only one pair of conjugate imaginary roots in the characteristic root of A(x0, C) and the other n − 2 characteristic roots have negative real parts. The system is unstable at the origin when positive real part exists. While the eigenvalues have all negative real parts, the system is asymptotically stable. In order to simplify the calculation, the Hurwitz criterion is used to determine the existence of the Hopf bifurcation in this paper.

According to the value of , the stability of periodic solutions of Hopf bifurcation in the original system can be determined. If , the bifurcation type of the system is subcritical Hopf bifurcation, and the periodic solution is unstable. On the contrary, , the bifurcation type of the system is supercritical Hopf bifurcation, and the bifurcated periodic solution is stable. The stability index of Hopf bifurcation is through calculation, and therefore, the type of Hopf bifurcation is supercritical Hopf bifurcation.

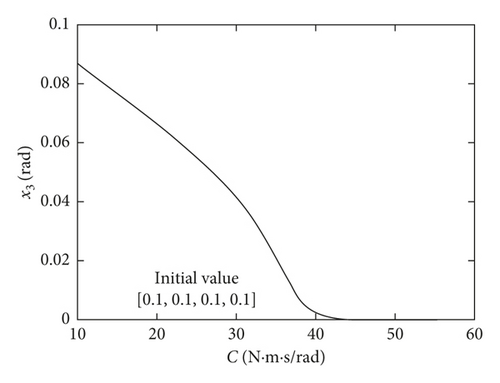

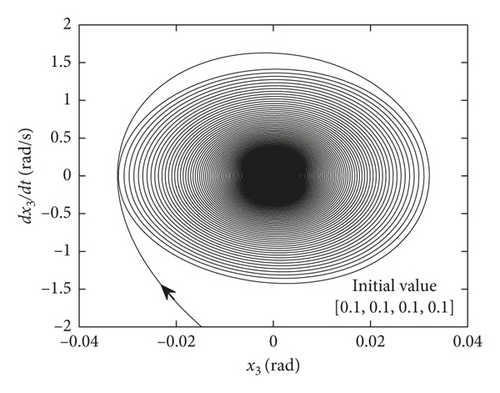

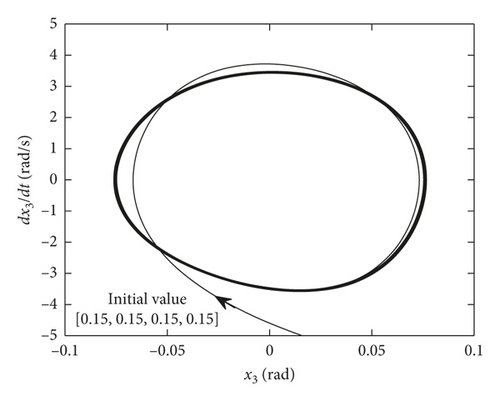

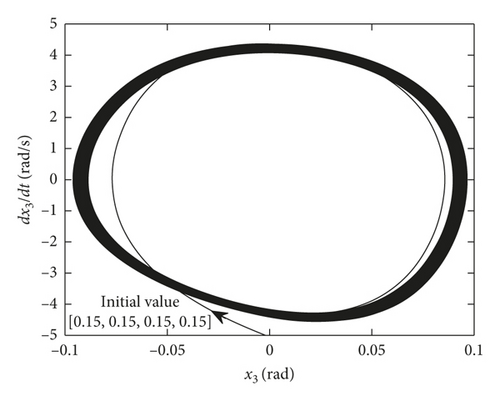

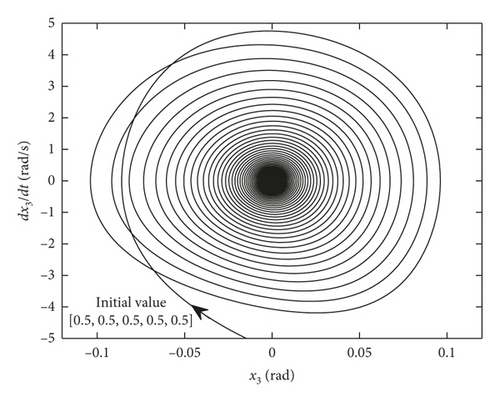

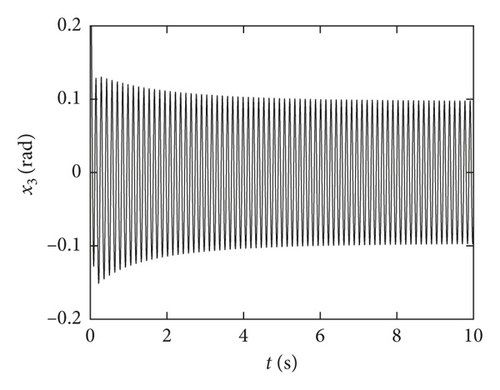

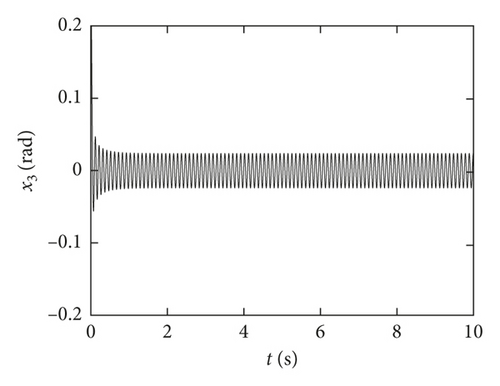

The Runge–Kutta method is used to verify the dynamic characteristics generated by the system Hopf bifurcation point C∗, and the parameters are brought into equation (16). In Figure 3 of torsional vibration amplitude figure variation with the damping C, the system exhibits different dynamics on both sides of the bifurcation point because of supercritical Hopf bifurcation. When C is greater than the bifurcation point C∗, the running state of the main transmission system is stable and no limit cycle appears, as shown in Figure 4.

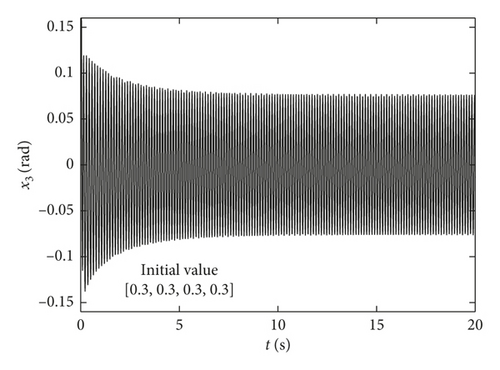

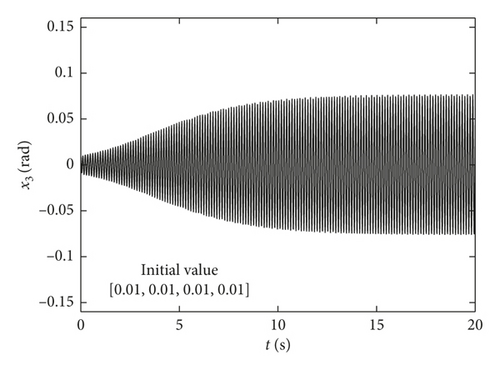

When C is smaller than the bifurcation point C∗, the system exhibits a stable limit cycle motion. Figure 3 shows that when the C is less than the critical value C∗, the smaller the value of the damping C, the bigger the limit cycle. At the same time, when the damping is greater than the critical damping, the amplitude of the vibration is close to 0. It can be available from the comparison of time-history response of identical initial value in Figure 5, and the amplitude of the limit cycles is obviously larger in the case of smaller damping. Furthermore, when C is fixed, the amplitude of the limit cycle has nothing to do with the initial value, as shown in Figure 6, which shows that the amplitudes are basically the same under two different initial values. From the above analysis, the conclusion of the simulation results is consistent with the theoretical analysis.

4. Cutting Transmission System Vibration Control

The numerical simulation results in Figures 3 and 5 show that, the system oscillates and the limit cycle appears when the damping C is smaller than C∗. When the system responds to a smaller limit cycle, it has little harm to the elastic torque shaft. However, when the external conditions cause damping C to be smaller, the amplitude of the limit cycle will increase. At this time, the cutting transmission shaft system of the shearer will have strong vibration, which will cause great harm to the fatigue damage of the elastic torque shaft. In order to control the unstable oscillation of shafting, the washout filter controller is introduced, which is a kind of the extended linear or nonlinear state feedback method.

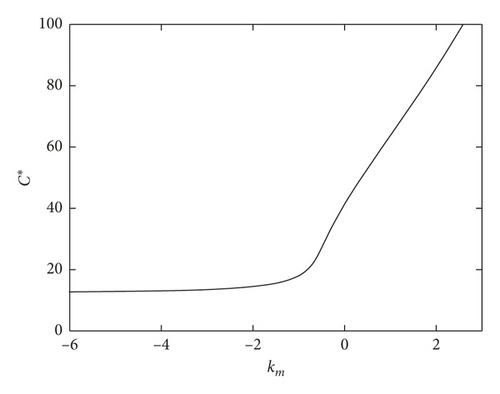

If all eigenvalues of matrix B(x0, C) have the negative real part, the controlled system will not occur Hopf bifurcation at C∗, which means Δi > 0(i = 1,2,3,4), km < −0.006597. When ε = 0.1, km = −1, and kn = 0, the roots of B(x0, C) have negative real parts at this time, and the system is asymptotically stable, as shown in Figure 7(b). At this moment, the bifurcation characteristics are controlled at the Hopf bifurcation point C∗, but the other dynamics of the system have not been determined.

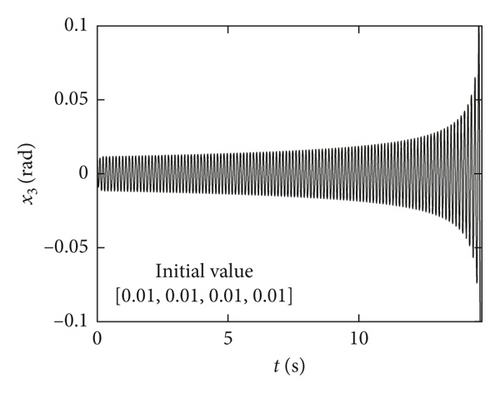

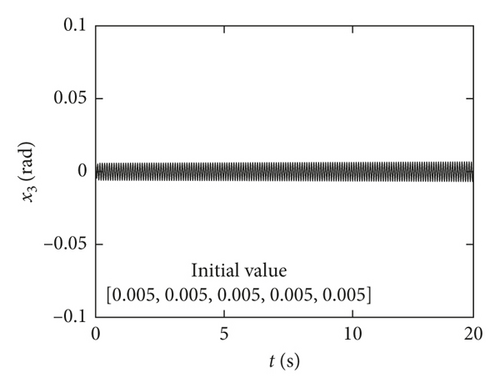

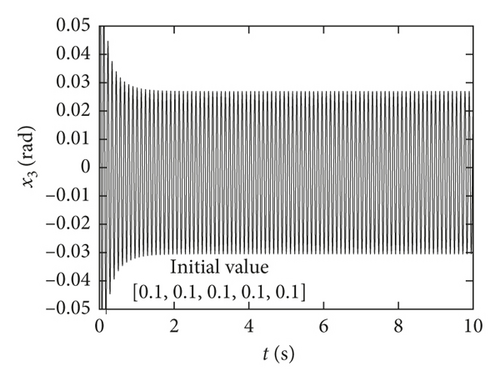

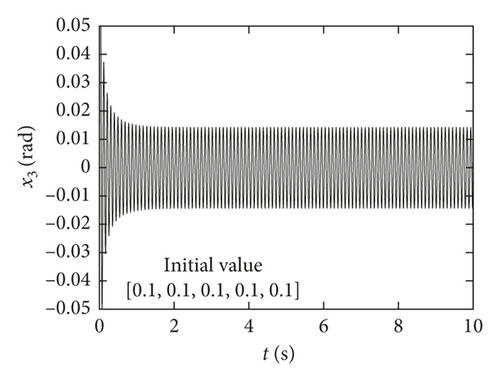

According to the Hopf bifurcation theory, the controlled system will have a supercritical bifurcation at C = 18.09 when Re(E) < 0 and kn < −0.009. The bifurcation type of the system stays the same by calculating. At the same time, subcritical Hopf bifurcation will occur at kn > −0.009, as shown in Figure 9. It can be seen from Figure 9(b) that the time-history response is stable when the initial values are close to the equilibrium point. When initial values are far from the equilibrium point, the time-history response increases with time in Figure 9(a). It is necessary to avoid the generation of subcritical bifurcation in the actual situation.

The amplitude of the limit cycle can be effectively controlled through the selection of the value of km and kn reasonably. Figure 10 shows that the amplitude of the controlled system is obviously lower than that of the original system without subcritical Hopf bifurcation (Figure 10(b) is the time-history diagram of the controlled system at km = −1 and kn = −1), and the significant effect is achieved after addition of the control system. In contrast to the two controlled systems in Figure 11 (km = −1 and kn = −0.1 in Figure 11(a); km = −1 and kn = −10 in Figure 11(b)), if the case of km is fixed, the smaller the kn is, the smaller the amplitude of the limit cycle is.

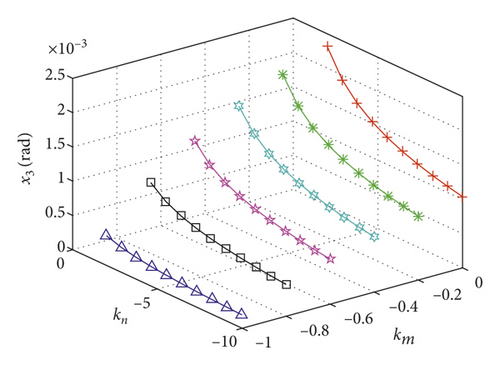

The bifurcation point will vary with km, and the bifurcation type will change with kn. At the same time, it is necessary to calculate the eigenvalue and eigenvector of the system to determine the type of bifurcation, but the eigenvalue and eigenvector are difficult to calculate due to the change of km. So it is hard to calculate the type of bifurcation for the system through the theoretical method when km and kn change simultaneously. However according to the simulation, the subcritical Hopf bifurcation only occurs when kn is near 0. Figure 12 shows the amplitude variation of km and kn change at the same time when kn is far less than 0. It can be seen from Figure 12 that the vibration amplitude decreases with the reduction of linear gain km and nonlinear gain kn.

5. Conclusion

- (1)

Due to the harsh environment of coal cutting, there is the supercritical and subcritical Hopf bifurcation with the diversification of the damping in the cutting transmission system. When the C is less than the critical value C∗, the smaller the value of the damping C, the bigger the limit cycle in supercritical Hopf bifurcation. Simultaneously, the amplitude of the limit cycle has nothing to do with the initial value.

- (2)

Based on the normative theory, the Hopf bifurcation controller of the shearer cutting transmission shaft was designed by the washout filter. The results show that the system stability domain increases with the linear gain of the controller and the generation of the subcritical Hopf bifurcation can be inhibited by the cube nonlinear parts.

- (3)

For supercritical Hopf bifurcation, selecting the linear and nonlinear gain reasonably can effectively control the torsional vibration and the shafting torsional vibration. And the limit cycle amplitude decreases with the nonlinear gain of the controller when the linear gain is zero. At the same time, when kn and km are varied simultaneously, the limit cycle amplitude decreases with the reduction of linear gain km and nonlinear gain kn in supercritical Hopf bifurcation.

All these results are of important theoretical significance to reduce the torsional vibration caused by nonlinear factors in the shearer cutting transmission system and provide a guarantee for the safe and reliable application of the low-speed and large-torque PMSM on the shearer.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant no. 51775543), the Key Research and Development Project of Xuzhou (Grant no. KC17014), and the project funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Open Research

Data Availability

All data included in this study are available upon request by contact with the corresponding author.