Structural Parameter Optimization of a Tubular Permanent-Magnet Linear Machine for Regenerative Suspension

Abstract

The regenerative suspension can effectively recover the vibration potential energy of the vehicle suspension, thus has broad prospects in application. In this paper, a tubular permanent-magnet linear motor (TPMLM) with the Halbach array magnetic pole is analyzed. The magnetic field analysis method of the excitation source separation is proposed, and then, the transient analytical model of output electromagnetic force and the external circuit characteristic under displacement excitation is established. A modified particle swarm optimization algorithm is further adopted to optimize the structural parameters of TPMLM. By comparing with the finite element analysis, the correctness of the proposed analytical model and the optimization are verified. This work lays the theoretical foundation for extensive application of the regenerative suspension.

1. Introduction

Vehicle body vibrates while running on the uneven road surface. This potential energy is mostly dissipated by the suspension system of 10–600 Watts [1, 2], accounting for about 30% of the power output energy. The recycling of this power will benefit the traditional fuel vehicles to reduce fuel consumption and improve the battery life cycle of electric vehicles. Due to the same travel direction as the suspension vibration and a higher power level and power density, the tubular permanent-magnet linear machine (TPMLM) is able to directly convert to electric power, which is convenient for storage and utilization. Therefore, compared to common ones like piezoelectric and electrostatic, the TPMLM has more application prospects in developing regenerated suspension, and it is also widely used in wave energy, road/bridge vibration energy regeneration, and so on. [3].

The TPMLM-based regenerative suspension system requires not only to maintain the suspension performance but also to ensure high energy-feeding efficiency. It is necessary to optimize the structural parameters of the TPMLM. Scholars have carried out a lot of research studies and achieved some results. Zuo et al. [4] designed a four-phase linear generator. The finite element analysis (FEA) was used to analyze the magnetic field and assist in the design optimization. A simplified model was derived to qualitatively characterize the waveforms and regenerate power of the harvester at various vibration amplitude, frequencies, equilibrium positions, and structure parameters. The regenerative shock absorber will be able to harvest 16–64 W power. Asadi et al. [5, 6] proposed a hybrid damper combining TPMLM with hydraulic structure. The theoretical model and FEA were utilized to optimize the structural parameters. Damping and regenerative characteristics were tested by the prototype experiment, and the influence of the change of some structural parameters on the performance of the damper was revealed. Jiang et al. [7] made improvements in the structure of TPMLM. The simplified model was then established to optimize the thickness of the permanent magnet and the ratio of the pole pitch with the maximum air-gap magnetic flux. Characteristics of speed versus power under constant velocity excitation are simulated. Tang et al. [8] focused on the structural characteristics of TPMLM, such as the radial thickness of the coil. The FEA was used to optimize the regenerated power density and damping force. And, the novel TPMLM with double-layer permanent-magnet array was proposed, of which the power density was improved 5.6 times than the predesigned prototype. Liu et al. [9] established a new energy-regenerative active suspension system, employing an actuator composed of a shock absorber and a DC motor. The results verified the suspension performance and energy-regenerative efficiency. Wang et al. [10] proposed a supercapacitor mode-switching control strategy for the regenerative and semiactive suspension system.

Among the above research studies, the magnetic circuit analysis or FEA is mainly used to optimize the TPMLM structure with the targets of damping and regenerated ability, by scanning the single or multiple parameters. Nevertheless, as a solution for the parameter optimization, sweeping under the complex external excitation using FEA consumes a long calculation time. It is therefore difficult to achieve global optimization of structural parameters because of the inability to solve multiple-parameter optimization at the same time. Optimization with analytical model can reduce calculating time to solve the abovementioned problem. But, due to the discontinuous inner magnetic field distribution of the TPMLM, it is difficult to establish analytical model which has similar precision to the FEA model, especially in dynamic characteristic. Representative research is the analytical model introducing the Carter coefficient correction for a three-phase tubular modular permanent-magnet machine proposed by Wang et al. [11–13]. The model was introduced in detail on the open-circuit magnetic field distribution with a quasi-Halbach magnetized armature. In addition, the electromagnetic force and electromechanical conversion efficiency are optimized for several sets of structural parameters. The analytical model proposed by Wang mainly describes the performance of the motor under static and constant velocity excitation. However, for complex random excitation such as road surface, it is necessary to further establish the transient analytical model to obtain the dynamic and winding circuit characteristics.

This paper, therefore, proposed an analytical method based on excitation source separation for a moving-coil TPMLM. The transient model of the electromagnetic force and winding circuit under universal external excitation was derived. Furthermore, particle swarm optimization (PSO) algorithm is easy to implement, especially does not require different objective functions and constraints. Thus, the global optimal solution can be obtained with a large probability. A modified dual adaptive PSO was used to optimize the structural parameters globally, taking regenerated power as the target function. The FEA of TPMLM was then employed to verify the correctness of the transient analytical model and the effectiveness of structural optimization.

2. Analytical Model

2.1. Structure of TPMLM

- (1)

The axial length is sufficiently large relative to its radial length, and the axial direction can be made infinitely long when resolving magnetic field

- (2)

Linearization of the B-H curve of the motor magnetic medium

2.2. Magnetic Vector Potential

Amongst, E1, E2, G1, and G2 are the coefficients of the nonhomogeneous Bessel function (refer to the appendix).

2.3. Thrust Force and Winding Circuit

2.4. Model Verification

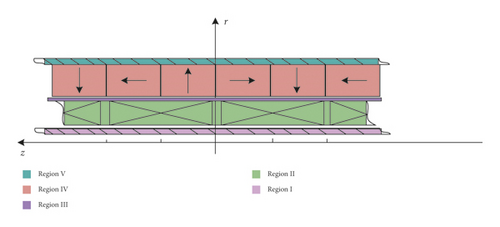

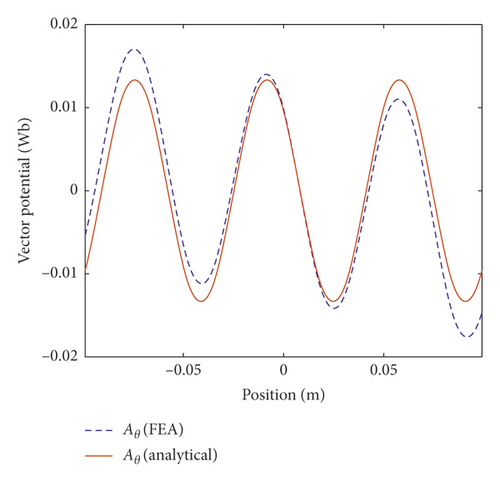

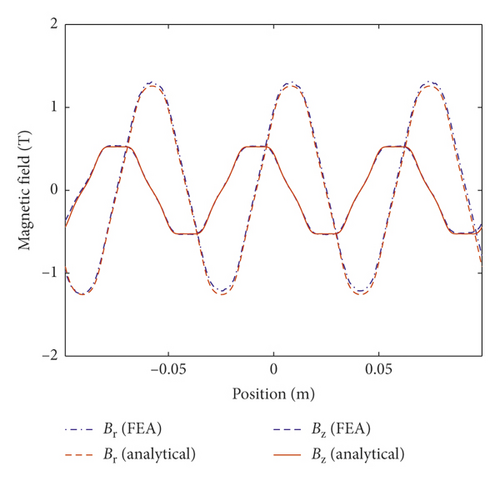

A set of TPMLM structural parameters is selected, namely, motor dimensions R0 = 4 mm, Rs0 = 8 mm, Rs = 16 mm, Rm = 17 mm, Rmb = 36 mm, and Rb = 40 mm. Relative permeability of each region are μrI = 800, μrII = 1, μrIII = 1, μrIV = 1.02, and μrV = 800. Pole pitch and residual magnetism of the permanent magnet are τp = 33 mm and Brem = 1.41 T, respectively. At the same time, the TPMLM FEM is established in the FEA software, to verify the proposed analytical model. According to Figure 1, the model is composed of iron core in direct-axis, winding coil, air-gap, permanent magnet, and back iron. The parameters of winding are mN = 6, Nw = 100, and Kc = 0.9. The boundary condition of solved region is balloon boundary. For the exterior area of iron core and back iron, the boundary condition is vectorpotential boundary. The motionsetup is moving along the direction of z-axis. The solver time is set as 0 to 5 s with the step of 0.001 s. Figure 2 shows the comparison between the FEA and the analytical analysis of the magnetic field in the winding region (r = 12 mm) along the z-axis, when the current density is zero.

The results indicate that the curve of analytical magnetic induction is nearly consistent with that of FEA. Note, the vector potential has a not-too-large offset at the edge, which is because the number of permanent magnet arrays is limited. The comparison verifies the correctness and accuracy of the proposed internal vector potential analysis method.

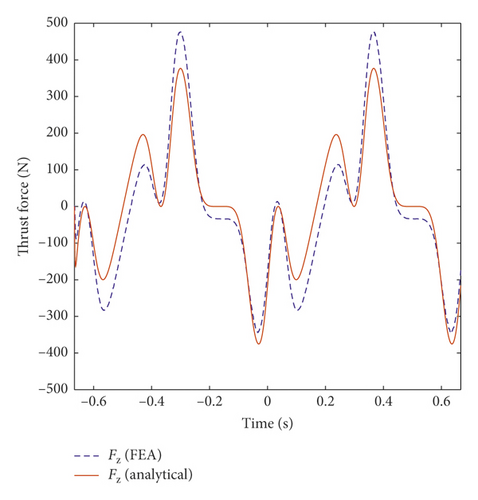

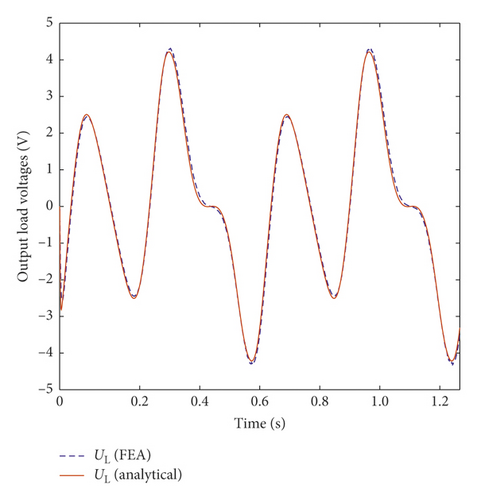

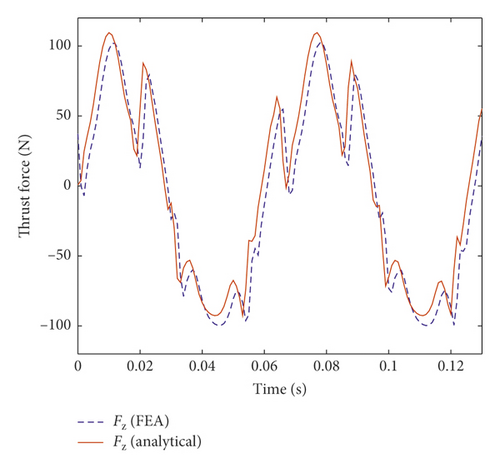

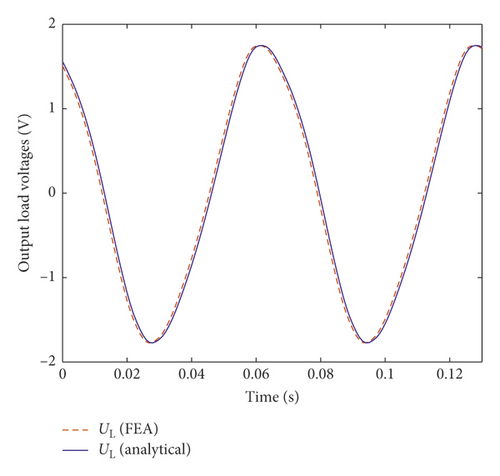

The axial damping force and the load voltage of the TPMLM when RL = RDC are further carried out, under harmonic excitation x(t) = Am sin(2πft), where Am = 25 mm and f = 1.5 Hz, 15 Hz(the first and second resonant frequency of vehicle suspension is around 1.5 Hz and 15 Hz [14]). The two outputs of TPMLM, namely, axial damping force and load voltage, are selected as comparison data. They also represent mechanical and electrical properties, respectively. Figure 3 shows the comparison of FEA and the analytical result. Due to the finite length of the axial length of the iron and iron core and a limited number of permanent magnet arrays, the analytical damping force is somewhat different from the FEA, but the overall trend and the numerical values are basically consistent. Most of all, the analytical calculation process takes far less time than FEA.

3. Structural Parameter Optimization

- (1)

Both particles a and b are in the feasible region, and the particle with smaller fitness(i) is better.

- (2)

Both particles a and b are not in the feasible region, and the particle with smaller voilation(i) is better.

- (3)

The particle a is in the feasible region, while the particle b is not. If the voilation(b) < ε, the particle with smaller fitness(i) is better, otherwise the particle a is better.

The comparison of two fitness functions allows the particles to quickly approach the feasible domain boundary and obtain a feasible solution that satisfies the constraints. At the same time, a certain infeasible solution ratio can be ensured by controlling the tolerant boundary, thus making the optimization be more quick and stable.

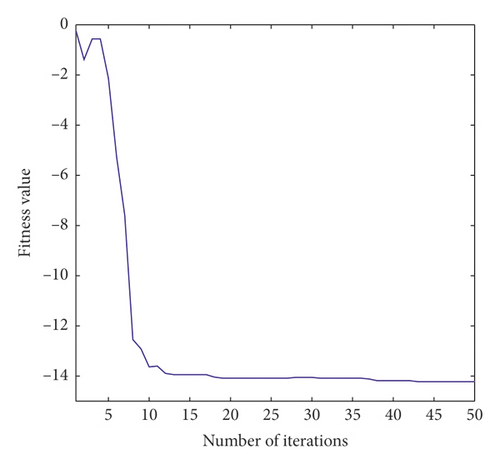

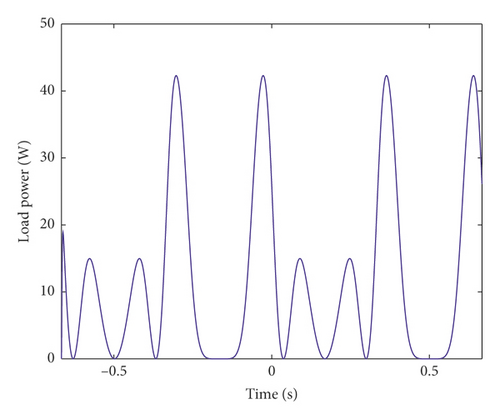

Figure 4(a) shows the PSO calculation process. The population size n is set to 80, the tolerance boundary ε = 0.02 mm, the infeasible solution ratio p is 0.15, and the excitation is a harmonic with a amplitude of 25 mm and a frequency of 1.5 Hz. Waves, the particle swarm converges to the optimal solution after 30 iterations. Figure 4(b) shows the optimal instantaneous output power. Table 1 is comparison of performance with structural parameters before and after optimization. The results demonstrate the feasibility of the TPMLM maximum power optimization model and the applicability of the established TPMLM dynamic and electric transient models.

| Structure parameters {RX} (mm) | Average power (W) | RMS of damping force (N) | |||

|---|---|---|---|---|---|

| 1.5 Hz | 15 Hz | 1.5 Hz | 15 Hz | ||

| Before optimization | {4, 8, 16, 17, 36, 40} | 11.80 | 1.86 | 172.75 | 67.68 |

| After optimization | {4, 10.9, 15.9, 16.9, 36, 40} | 13.36 | 2.59 | 195.54 | 74.36 |

4. Conclusions

In this paper, a Halbach magnetized single-phase nonslot moving-coil TPMLM is designed. The magnetic analysis method which separates excitation is proposed, and then, transient analysis model of the damping force and winding circuit is established under external excitation. The transient model has the similar accuracy to FEA. Based on the analytical model, the improved dual-adaptive particle swarm optimization algorithm is utilized to obtain the optimal parameter of the TPMLM maximum power point operation with a short calculation time, which further indicates that the proposed TPMLM analytical model is applicable for optimization. The proposed analytical model can also be applied to the dynamic analysis of combined vibration damping system.

Conflicts of Interest

The authors declare that there are no conflicts of interest regarding the publication of this paper.

Acknowledgments

This research has received funding from the National Science Foundation of China (grant nos. 51475246 and 51075215), National Science Foundation for Young Scientists of Jiangsu Province, China (grant no. BK20171039), National Science Foundation for Postdoctoral Scientists of China (grant no. 2017M611855), Natural Science Foundation of the Higher Education Institutions of Jiangsu Province, China (grant no. 17KJB470010), and the Research Innovation Program for College Graduates of Jiangsu Province (KYCX17_1080).

Appendix

Coefficient Expression

Open Research

Data Availability

The data used to support the findings of this study are available from the corresponding author upon request.