Study on Calculation of Pile Sliding Interval of Large-Diameter Steel Pipe Piles on Offshore Platforms

Abstract

In ocean engineering, pile sliding often occurs in the driving process of large-diameter pipe piles and will affect the engineering quality, so accurate pile sliding interval is necessary. According to the stress situation of steel pipe pile out of actual engineering, the causes of pile sliding are analysed. Using the static equilibrium equation, the mud depth at which the pipe pile may slip is calculated. The influence of pile siding friction was considered when calculating the second pile sliding, and the pile siding friction is divided into three influential areas. Using integrating method, the work done by pile resistance is calculated. Combined with the working principle and power principle, the energy transformation equation of the pipe pile in the process of sliding is obtained, and the sliding length and interval of the pile are calculated. A comparison between the measured results and the real case calculation was conducted using this new method. The comparison indicated that the total relative errors in pile sliding interval are 8% to 16%, and the new method has high accuracy. The results of the new method are in accord with the measured data, which can provide a reference for predicting the interval of pile sliding in the project.

1. Introduction

As a structure providing production and living facilities, the offshore platform integrates drilling, transportation, construction, observation, and navigation. The pile foundation construction usually uses large-diameter and super-long steel pipe piles, and the pipe piles are driven into the seabed soil layer along the pipe by a hydraulic piling hammer. In the process of piling, when steel pipe piles encounter soft soil layers in marine soil layers, pile sliding often occurs due to the decrease of pile end resistance and pile side friction resistance. Slip pile not only affects the quality of pile formation and the bearing capacity of pile foundation, but also makes more errors in the actual penetration of pile and the design elevation of pile foundation.

In recent years, scholars at home and abroad have carried out a series of studies on pile sliding, such as Guo and others [1], analysing the causes of pile sliding in combination with the actual project and putting forward corresponding preventive measures. Sun and others [2–4] put forward a calculation method for the length of the sliding pile, taking into account the strength reduction of soil around the pile and the excess pore pressure and other factors. Lehane and others [5] used the static balance method to estimate the sliding pile interval. Mijena [6] put forward a prediction method of pile slip and predicted the possibility for pile slip of 26 pipe piles. Yin [7] analysed the pile sliding mechanism for large-diameter steel pipe piles and proposed the calculation method of pile sliding length. Dover [8] analysed the influence of pile in situ stress, interface friction angle, and wall thickness on pile end resistance through experiments. Yan [9] compared the pile side friction resistance of friction piles based on theoretical and empirical mathematical models. Most of the above studies were carried out for the reduction of pile side friction and calculation of pile sliding length in the process of steel pipe pile sliding, seldom considering the change of pile side friction at different depths in the process of pile sliding, and no different calculation methods were adopted for the actual engineering situation.

Firstly, the reasons for the sliding of large-diameter steel pipe piles of the offshore platform are analysed, and then the relationship between the ultimate bearing capacity of the foundation and the pile ends resistance is calculated by considering the influence of sliding piles of the pile side friction resistance of different depths. Then, a new algorithm for the sliding interval of large-diameter steeled pipe piles is established by using the static balance and function principle, and the rationality and reliability of the algorithm are verified through the comparative analysis of engineering examples.

2. Analysis of Slipping Pile

Engineering practice shows that [10] slip piles usually occur in the following two situations: when the surface layer of marine soil is a soft soil layer with weak bearing capacity; when the pile is driven into the soil layer with lower bearing capacity from the soil layer with higher bearing capacity. Due to the nature of marine soil, each steel pipe pile will slip between 0 to 3 times during piling.

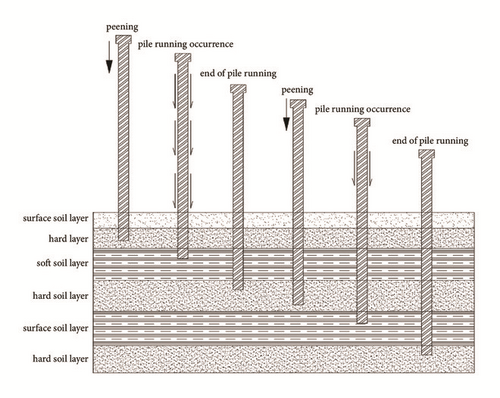

When the steel pipe pile has just entered the soil layer on the ocean surface, due to the weak bearing capacity of the soil layer, the pile will freely penetrate into the soil layer to a certain depth without hammering the pile hammer. When the pile enters the hard soil layer, the pile end resistance and side friction resistance become larger, and the steel pipe pile gradually penetrates into the soil under the action of hammering. When the pile enters the soft clay layer, the pile end resistance decreases and the pile side friction resistance is not enough to bear the quality of the pile and the pile hammer. At this time, the pile will penetrate into the soil layer without hammering; i.e., the pile body will slip. When the friction resistance of the pile entering the hard soil layer or the pile side increases to a certain value, the sliding of the pile stops. As the pile continues to penetrate, although the side friction area increases, the side friction of the pile actually decreases due to the remolding of the soil. Therefore, when entering the soft soil layer again, the phenomenon of secondary pile sliding will occur, and Figure 1 is a schematic diagram of the phenomenon of pile sliding.

When the total soil resistance of the pile body meets one of the following conditions, it is possible to slip the pile: (1) the total soil resistance is less than the weight of the pile body; (2) the total soil resistance is less than the gravity of pile and pile hammer; (3) the total soil resistance is less than the inertia force of pile and pile hammer [11].

3. Calculation of Pile Driving Resistance

3.1. Calculation of Pile End Resistance

| φ/(°) | 0 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 |

|---|---|---|---|---|---|---|---|---|---|---|

| Nr | 0 | 0.51 | 1.20 | 1.80 | 4.0 | 11.0 | 21.8 | 45.4 | 125 | 326 |

| Nq | 1.0 | 1.64 | 2.69 | 4.45 | 7.42 | 12.7 | 22.5 | 41.3 | 81.3 | 173.3 |

3.2. Calculation of Pile Side Friction

Through the analysis of pile sliding phenomenon, it can be seen that the soil at the bottom of the pile will undergo shear failure during the process of pile penetration into the soil, the soil will form a remodelled area, and the soil strength will change accordingly [15]. This phenomenon will cause the plastic strength of the soil to be lower than the strength of the original soil and the side friction coefficient to be reduced. Therefore, the static friction between piles and soil is not suitable for the side friction of piles, and the dynamic friction between piles and soil needs to be calculated.

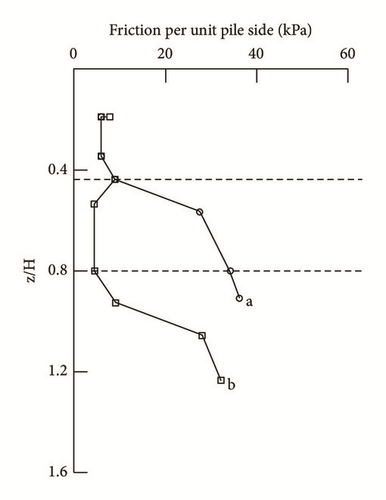

The calculation of friction resistance of steel pipe pile in clay layer also needs to reduce the strength of soil. Li [17] found, through analysis and experiment, that the pile side friction at different positions below the surface of the excavated body is affected by sliding piles in different degrees, dividing the depth of pile penetration into three affected areas, and Figure 2 shows the change of unit side friction in different affected areas.

As shown in Figure 2, curve a represents the unit side frictional resistance at each depth at the end of pile sliding. Curve b shows the unit side friction at each depth at the end of pile driving, z is the depth of soil below the mud surface, and H is the depth at the end of pile sliding. According to the ratio between the depth z of soil below the mud surface and the depth H at the end of pipe pile sliding, the pipe pile entering the soil layer is divided into a complete influence area, an incomplete influence area, and a non-influence area.

For the case of secondary sliding of steel pipe piles, when calculating the dynamic side friction of piles in clay layer, it is necessary to consider the influence of the first sliding of piles on the side friction of piles, and according to the different degree of influence, the interval of pile penetration depth is divided into three influence zones, namely, fully affected area, semi-fully affected area, and no affected areas.

4. Calculation of Pile Sliding Interval

Based on the analysis of pile sliding mechanism, the calculation process of the existing pile sliding interval algorithm is improved. First, the pile end resistance is obtained by using Berezantzev′s formula, and then the friction resistance is calculated by using different reduction factors in different influence areas. In sandy soil, the friction resistance of the pile side is calculated by conventional methods. Based on the dynamic process of pile sliding, a new algorithm of large-diameter steel pipe pile sliding interval is established by using static balance and functional principles.

According to (14), the length L of the slip pile can be obtained, and the slip interval of the steel pipe pile can be obtained by combining the depth L of the pipe pile into the mud when the slip pile occurs.

5. Engineering Case Checking

According to the engineering data collected during the construction of Liwan pile foundation platform in the South China Sea, reasonable soil parameters are selected, and the new algorithm is used to calculate the pile sliding interval of steel pipe piles. The calculation results are compared and analysed with the actual pile sliding interval, and the rationality of the new algorithm is verified through the comparison results.

The pile foundation platform has 16 steel pipe piles, which are evenly distributed on the four corners of the pile foundation platform. Each steel pipe pile weighs 643.9kg and has a diameter of 2.74m and a pile length of 158m. The model of hydraulic hammer is MHU1200s, and the rated output energy is 1200kJ. In order to ensure the same soil properties around steel pipe piles, four steel pipe piles on one corner of the platform were selected for calculation and analysis. Through the analysis of soil parameters, it can be seen that the soft and hard soil layers of the soil layer, where the steel pipe pile is located, alternate, and the shallow soil layer has a long clay layer, so it is easy to slip the pile. At the soil depths of 58.8m and 108m, the soft clay layer appears again; at this time, it is likely that the secondary slip pile or even the tertiary slip pile will occur. The soil parameters of the soil layer where the steel pipe pile is located are listed in Table 2.

| number | property | thickness/m | cohesion/kPa | friction angle/(°) | unit weight/kN·m−3 | floor elevation/m | pile end resistance/kN | dynamic friction resistance/kN | static friction resistance/kN |

|---|---|---|---|---|---|---|---|---|---|

| 1 | medium dense fine to coarse sand | 2.4 | 0 | 39 | 8.5 | 3.0 | 3291.7 | 39 | / |

| 2 | soft to hard clay | 7.9 | 35 | 0 | 8.9 | 10.9 | 259.9 | / | 1024.1 |

| 3 | dense silt | 2.3 | 0 | 37 | 8.9 | 13.2 | 5944 | 112.3 | / |

| 4 | dense sandy silt and hard clay interbedded | 7.8 | 70 | 0 | 8.6 | 21.0 | 519.8 | / | 1644.2 |

| 5 | hard silty clay | 3.6 | 50 | 0 | 9.2 | 24.6 | 371.25 | / | 411.9 |

| 6 | dense silty fine sand | 8.4 | 0 | 39 | 8.5 | 33.0 | 9084.6 | 271.7 | / |

| 7 | dense silty fine sand | 20.3 | 90 | 0 | 8.3 | 53.3 | 668.3 | / | 5501.6 |

| 8 | hard silty clay | 6.1 | 80 | 0 | 9.0 | 59.4 | 594 | / | 1447.9 |

| 9 | hard silty clay | 5.4 | 0 | 36 | 8.6 | 64.8 | 15598.1 | 582.7 | / |

| 10 | hard clay | 11.4 | 100 | 0 | 8.8 | 76.2 | 742.5 | / | 3389.1 |

| 11 | dense sandy silt | 3.4 | 0 | 36 | 8.3 | 79.6 | 13963.5 | 717 | / |

| 12 | hard silty clay | 29.3 | 120 | 0 | 8.5 | 108.9 | 891 | / | 10587.5 |

| 13 | dense sandy silt | 2.9 | 0 | 36 | 8.5 | 111.8 | 2655.4 | 1394.5 | / |

| 14 | hard clay | 19.6 | 160 | 0 | 9.0 | 131.4 | 1188 | / | 9443 |

Combined with the soil parameters selected in the actual project, the pile end resistance, sand dynamic side friction resistance, and clay static friction resistance of each layer of soil in the pile driving process of steel pipe piles are calculated using (1)-(7). From the calculation results in Table 2, it can be seen that the pile end resistance received by the pile body in the sand layer is larger, the pile side friction resistance is smaller, the pile end resistance in the clay layer is smaller, and the pile side friction resistance is larger. When the pipe pile just penetrates the soil layer, the pile end resistance bears the gravity of the pile and the pile hammer, which also verifies the reason for the slip pile.

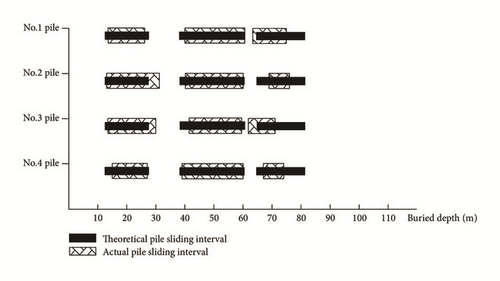

According to the calculated pile end resistance and pile side friction of each soil layer in Table 2, the mud entry depth L of the pipe pile when slip pile occurs is calculated by formula (8), and the mud entry depths L satisfying formula (8) are 13.3m, 38.0m, and 64.9m m. Then, the work expression of pile side friction including slip pile interval l is obtained through formulas (9)-(11), and three slip pile intervals are defined. Through the formulas (12) and (13), the expressions of friction resistance and buoyancy work at the pile end containing the slip pile interval l are obtained. By substituting the above expressions into formula (14), the slip pile interval l is obtained as 13.7m, 22.5m, and 17.1m m. Therefore, under this actual working condition, the slip interval of pipe pile is 13.3 m ~ 27 m, 38.0 m ~ 60.5 m, and 64.9 m ~ 84.0 m. Through the comparison between the theoretical pile sliding interval and the actual engineering pile sliding interval, the comparison result shown in Figure 3 is obtained.

From the comparison results, it can be seen that the depth of pile entry and the interval of the first two pile slips are basically consistent with the actual engineering situation. There are some deviations in the calculation of the third pile sliding interval because the second pile sliding also affects the soil mass and changes the pile side friction, but the third pile sliding interval is smaller than the theoretical calculation interval length and within the safe range of pile foundation engineering, so the theoretical pile sliding interval can still provide a reference for the design of pile foundation and also verify the theory that the calculation of the pile sliding interval needs to consider the influence of the pile sliding on the soil mass, so the new algorithm and the traditional method are more consistent with the actual pile sliding interval and have higher accuracy. The pile sliding interval obtained by the new algorithm is basically consistent with the actual pile sliding interval, and the rationality of the new algorithm is verified.

6. Conclusions

Through the analysis and research on the process of pile sliding and its causes, the conclusions are as follows:

(1) When the steel pipe pile slips for the second time, considering the different influence degree of sliding pile on the pile side friction, the side friction of the pile in the clay layer is divided into three influence areas, namely, full influence area, half influence area, and no influence area. Using different reduction factors to calculate the side friction of the pile in different influence areas will make the new calculation result closer to the engineering practice.

(2) When calculating the sliding interval of steel pipe piles, the static balance principle is used to calculate the depth of pipe pile entering the mud at the beginning of sliding, the expression of pile side friction resistance and pile end resistance in different influence areas is listed by integrating theory, and according to the functional principle, the energy equation of pipe pile is listed, thus obtaining the sliding interval of steel pipe piles.

(3) Through the verification of an engineering example, the error range between the calculation result of the first and second sliding pile interval of the new algorithm and the actual situation is 8 % ~ 16 %, with high accuracy. Although the third result is somewhat deviated, the actual sliding pile interval is smaller than the theoretical actual sliding pile interval and is within the safe range of pile foundation engineering, which can still provide a reference for the design and construction of offshore platform pile foundation.

Conflicts of Interest

The authors declare that they have no conflicts of interest regarding the publication of this paper.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (no. 41372288) and the Project of Science and Technology Innovation Fund for graduate students of the Shandong University of Science and Technology (no. SDKDYC180212).

Open Research

Data Availability

The data used to support the findings of this study are included within the article.