Effects of Strain Rate and Initial Density on the Dynamic Mechanical Behaviour of Dry Calcareous Sand

Abstract

The dynamic compressive behaviour of dry calcareous sand under rigid confinement was characterised using a split-Hopkinson pressure bar (SHPB). Sand samples were confined inside a sleeve of hardened stainless steel and capped by a pair of aluminium cylindrical rods. This assembly was subjected to repeated dynamic compaction to attain precise bulk mass densities. It was then sandwiched between the incident and transmission bars of SHPB for dynamic compression testing. Sand specimens of three initial mass densities, namely, 1.26 g/cm3, 1.35 g/cm3, and 1.42 g/cm3, were loaded by incident pulses applying a stress of 35 MPa, 71 MPa, and 143 MPa, respectively. Experimental results show that in the strain rate range of 335 s−1 to 1253 s−1, the dynamic mechanical behaviours of dry calcareous sands exhibited no significant strain rate effect. The Lundborg model and the Murnaghan model could be used to describe the deviatoric and volumetric behaviours of calcareous sand with different initial densities, respectively.

1. Introduction

Calcareous sand is generally regarded as an oceanic sediment which contains an appreciable amount (>30%) of CaCO3, leading to certain mechanical properties compared with continental sediments such as quartz sand [1, 2]. It usually originates from reworked shell fragments and skeletal debris of marine organisms and is widely distributed on coral reefs and seashores throughout the world such as in the South China Sea, Red Sea, west continental platform of Australia, and the Bass Strait [3, 4]. With the rapid development of the offshore construction, the mechanical response of calcareous sand has attracted the attention of engineers. Generally, it is found that calcareous sand includes large amounts of irregular crushable particles, leading to a higher compressibility and more significant grain crushing at elevated stresses than continental sediments [5–8]; however, compared with extensive studies under quasistatic condition, few studies consider the dynamic compressive behaviour of calcareous sand, which is important in some special engineering problems such as dynamic compaction and mine blast situations, and in air-raid shelters.

Farr used a uniaxial strain device (WES 0.1 msec) to study the effect of loading rate on the one-dimensional compressibility of dense partially saturated Enewetak calcareous sand [9]. The test results show that when the strain rate of calcareous sand sample increases from 10−3 s−1 to 300 s−1, the constrained modulus can be increased by 120%. In recent years, the split-Hopkinson pressure bar (SHPB) has been widely used to study the dynamic mechanical behaviour of sand [10–12]. Bragov computed the lateral stress component of the specimen based on measurements of circumferential strain, which, together with obtaining the longitudinal stresses in the specimen using the SHPB method, make it possible to find the deviatoric stress and the hydrostatic pore water pressure in the specimen; however, in most studies, using this method, the soil under test is a quartz sand [13–18]. No experimental research has yet been aimed at the study of the deviatoric and volumetric behaviour of calcareous sand. Lv et al. studied the one-dimensional dynamic compressive behaviour of dry calcareous sand and dry silica sand with the same relative density and similar strain rate using the SHPB method [19], and the experimental results show that the apparent modulus of calcareous sand under dynamic loading is approximately 10% of that of silica sand; however, the effects of strain rate and initial density of the sample on the dynamic mechanical behaviour of dry calcareous sand under stiff confinement were not investigated in their studies. These effects will be studied by using the SHPB method in the present research, and the deviatoric and volumetric behaviours will be analysed based on the experimental results.

2. Experimental Work

2.1. Sand Samples

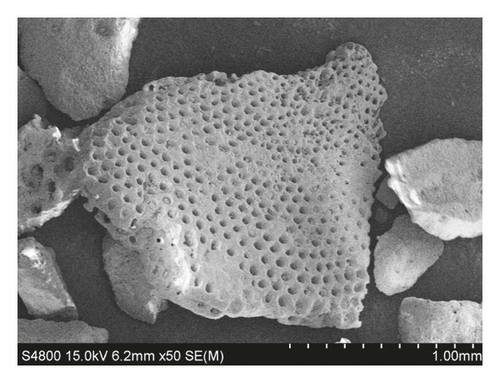

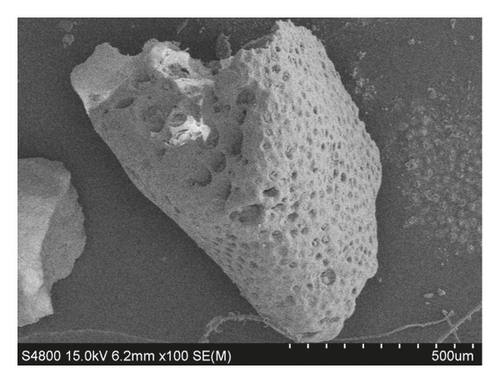

The white calcareous sand used in this research is from the South China Sea. The micrographs of calcareous sands obtained by using the Hitachi S-4800 scanning electron microscope are shown in Figure 1, which shows that the sand particles are mostly angular with many interparticle voids in the calcareous sand particles, leading to its complex microstructure and the low strength of the particles.

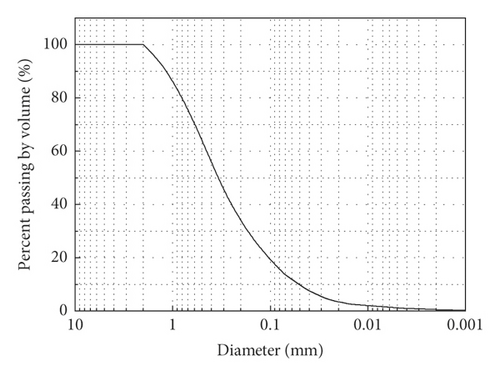

All the sand samples used in this research were first oven-dried. The grain size distribution curve of the sample is shown in Figure 2, which was determined by using the laser-diffractometry instrument called Mastersizer 3000E. According to the result, the average particle size and the uniformity coefficient of the calcareous sand are 0.348 mm and 8.84, respectively. The particle density of sand particle was determined to be 2.81 g/cm3. The minimum and maximum dry density of the sand is 1.12 g/cm3 and 1.47 g/cm3; these properties were tested based on ASTM methods [19–22].

To study the effect of the initial mass density of the sample on the dynamic mechanical behaviour of calcareous sand, three types of samples with initial dry density of 1.42 g/cm3, 1.35 g/cm3, and 1.26 g/cm3 were designed. The relative densities of these samples are 89%, 72%, and 47%, respectively.

2.2. Experimental Setup

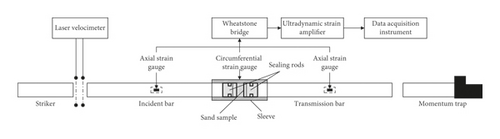

Dynamic experiments are carried out with a standard split-Hopkinson pressure bar apparatus (Figure 3), including a set of solid bars and a strain data acquisition system. The striker, the incident bar, and the transmission bar are made of aluminium alloy with a diameter of 37 mm and lengths of 600 mm, 2000 mm, and 2000 mm, respectively. The density, Young’s modulus, Poisson’s ratio, and bar wave speed of the aluminium material used are 2.8 g/cm3, 73 GPa, 0.324, and 5107 m/s, respectively. As its impedance is lower than that of steel, the aluminium material is suitable for the SHPB tests associated with low-impedance soil. The sand samples were loaded by the striker and the incident bar, and their dynamic strain and stress during loading were obtained by calculating the stress wave velocity in the incident bar and transmission bar based on elastic wave theory [23].

To study the strain rate effect on the dynamic mechanical behaviour of calcareous sand, the sand samples were loaded by the striker with three nominal velocities, namely, 5 m/s, 10 m/s, and 20 m/s. Based on the elastic wave theory [24], the corresponding nominal stresses applied via the incident impulse are 35 MPa, 71 MPa, and 143 MPa, respectively. The actual velocity of the striker was measured by using a laser velocimeter with 0.1 m/s resolution.

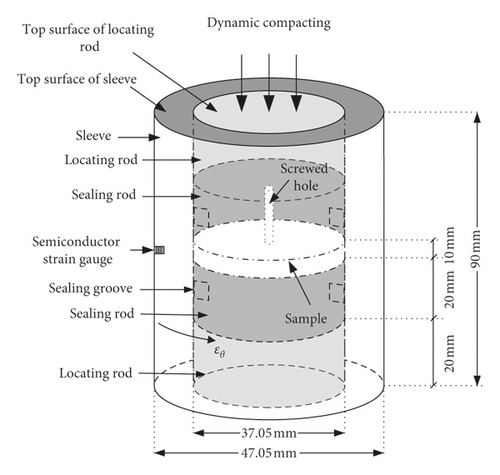

The sample container consists of a sleeve, a pair of sealing rods, and a pair of locating rods. The sleeve was made of stainless steel and was designed to provide rigid confinement for the samples. The inner diameter, the outer diameter, and height of the sleeve are 37.05 mm, 47.05 mm, and 90 mm, respectively. The sealing rods together with the locating rods were used to locate and control the initial height and density of the sample. They were made of the same aluminium alloy as the pressure bar with a diameter of 37 mm and length of 20 mm. The sealing rod has a sealing groove with a width of 4.2 mm and a depth of 5 mm for mounting the Glyd Ring, which was used to fix the sealing rod in the sleeve during sample preparation and prevent the loss of sand particles during loading.

Figure 4 schematically shows the sample height and its position in the container. As is shown, the initial height of the sand sample is 10 mm, so the initial volume of the sample is 10.75 cm3. The mass of the sample that is needed to fill the container could be calculated through multiplying its initial density and volume. To prepare a sample with a given density, a locating rod and a sealing rod were firstly put into the vertically placed sleeve. Then, the sample with the corresponding mass was poured into the container, and another sealing rod and locating rod were placed in the container. A 1.25 kg hammer was continuously dropped from a height of 300 mm to strike the top surface of the locating rod until it was flushed with the top surface of the sleeve. Finally, two locating rods were taken out of the container, and a bolt was screwed into the hole in the top sealing rod to prevent the loss of sand particles under loading. The container, together with the sand sample, could then be sandwiched between the incident bar and the transmission bar (Figure 3).

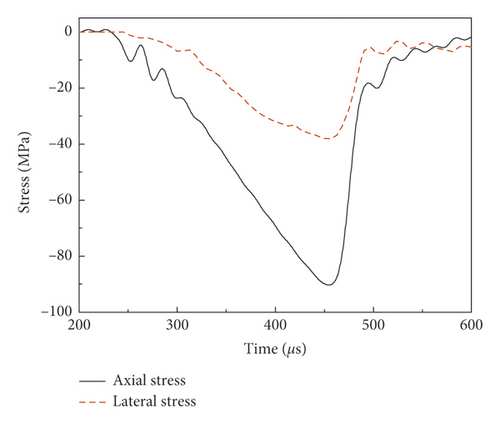

A strain gauge was attached to the external surface of the sleeve to measure the circumferential strain of the sleeve, and the strain will be used to calculate the lateral stress on the specimen based on elastic mechanics [25].

3. Experimental Results

3.1. Axial Strain-Stress Relationship of Dry Calcareous Sand

In this research, three independent replicates were performed for each test group with different sample densities and striker velocities, and the corresponding basic results are summarised in Table 1.

| Test group number | Initial sample density (g/cm3) | Average striker velocity (m/s) | Average sample strain rate (s−1) | Average sample peak strain | Average sample peak stress (MPa) |

|---|---|---|---|---|---|

| CS1 | 1.26 | 5.3 | 385 | 0.104 | 6.4 |

| CS2 | 10.5 | 748 | 0.192 | 18.5 | |

| CS3 | 19.2 | 1253 | 0.314 | 61.5 | |

| CS4 | 1.35 | 5.1 | 412 | 0.097 | 10.2 |

| CS5 | 9.6 | 693 | 0.177 | 24.7 | |

| CS6 | 19.9 | 1189 | 0.293 | 77.1 | |

| CS7 | 1.42 | 4.0 | 335 | 0.080 | 12.5 |

| CS8 | 9.8 | 487 | 0.118 | 17.8 | |

| CS9 | 21.4 | 1128 | 0.273 | 90.8 | |

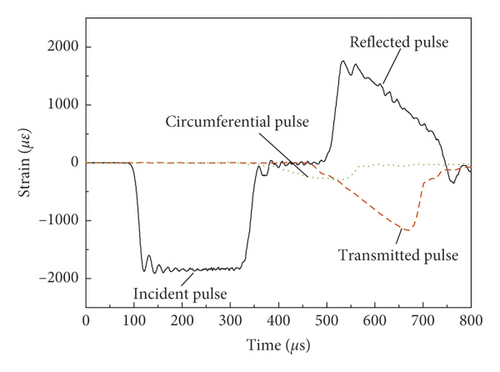

Figure 5 shows a typical set of strain records of calcareous sand in test group CS9. It could be found that the rise time of the incident pulse is very short, so the dispersive effects of the pulses need to be corrected. In this research, Bussac’s and Tyas’s correction methods were used to correct for dispersive effects [26–28]. After correction, the strain records could be used to calculate the strain and stress histories of the sample based on equation (1).

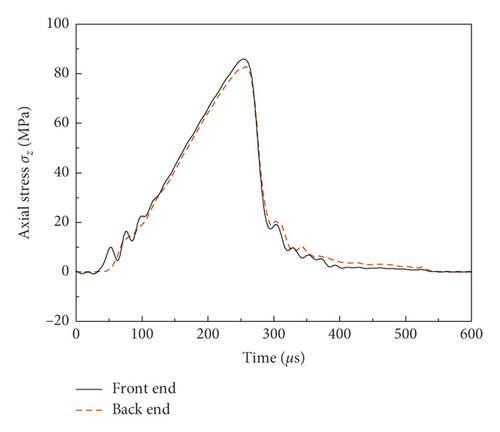

Dynamic stress equilibrium was checked by the “2-wave,” “1-wave” method as used by Song [14] (Figure 6). The stress history of sample front end was calculated by adding the incident stress wave to the reflected stress wave, while the stress history of sample back end equals the transmitted stress wave. It can be seen from the figure that the stress histories at both ends of the sample almost overlapped except during the initial stage of loading, indicating that the stress in the specimen was uniform under most load conditions.

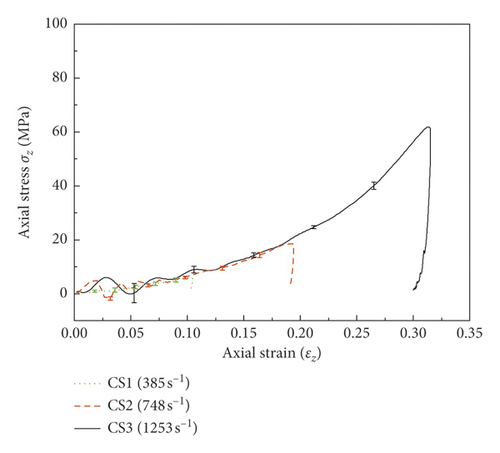

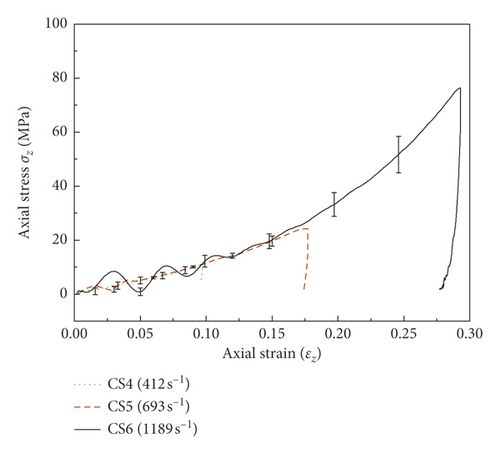

After the dynamic stress equilibrium is satisfied in the sample, the strain-stress curve of the experiment calculated by equation (1) is valid. Following the similar procedure, the mean curves with error bars for samples of the same initial density are plotted (Figures 7(a)–7(c)). There are oscillations in the stress-strain curves at small strains. By comparing the stress from the stress-strain curves and the corresponding stress histories at both ends of the sample (Figure 6), it was concluded that the oscillations were caused by out-of-equilibrium stresses in the sand sample. Despite the stress nonequilibrium at the initial deformation stage, the results showed no significant differences under overlapping stress ranges with different strain rates, indicating that, in the strain rate range of 335 s−1 to 1253 s−1, the dynamic compression characteristics of dry calcareous sand exhibited no significant rate effect.

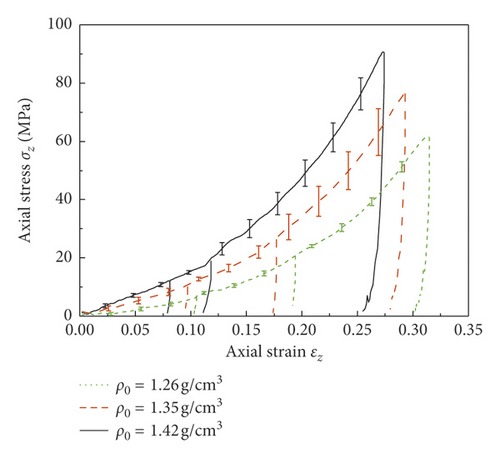

After discarding the nonequilibrium stage of the experimental result, the axial strain-stress curves of the sample with different initial densities could be obtained (Figure 8(a)). The stress-strain curves shift upwards with the increase of initial mass density. The unloading curve shows an initial steep reduction in stress without recovery of deformation, followed by a further reduction in stress with a slight recovery of deformation.

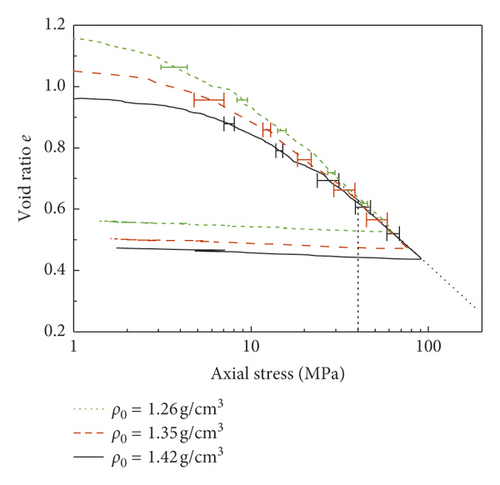

According to equation (2), the axial strain-strain experimental results shown in Figure 8(a) could be transferred into e-log σ curves (Figure 8(b)). As the sand particles are crushable, the initial skeleton of calcareous sand is unstable under high stresses. With increasing stress, the initial skeleton structure of the calcareous sand was gradually destroyed and a stable structure formed. So at a certain stress, the e-log σ curve is independent of the initial sample skeleton properties and the initial density of the sample. So, all the loading curves of calcareous sands with different initial densities in Figure 8(b) merge into a same straight line at an axial stress of about 40 MPa. The slope of the line is the compression index and is 0.239 for this calcareous sand under dynamic compression. Luo et al. studied the dynamic compression behaviour of quartz sand, and the compression index is 0.281 to 0.312 [15], indicating the calcareous sand is “softer” than quartz sand.

3.2. Deviatoric and Volumetric Behaviours of the Sand

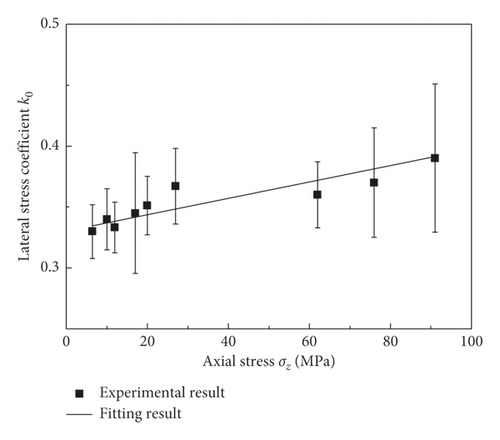

The material constants μ and σYmax could be obtained by fitting the experimental results from equation (9), and the corresponding results are μ = 1.21 and σYmax = 363 MPa. The fitting curve is shown in Figure 10, and the yield function is shown in Figure 11.

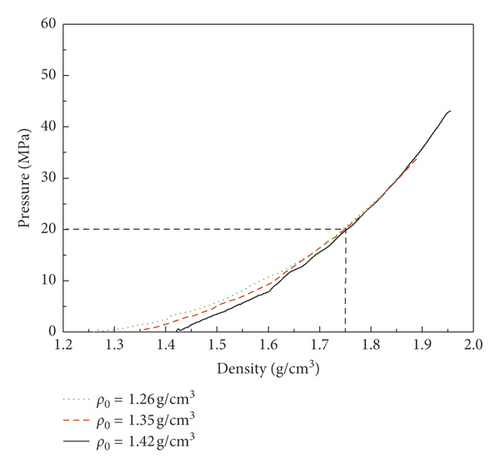

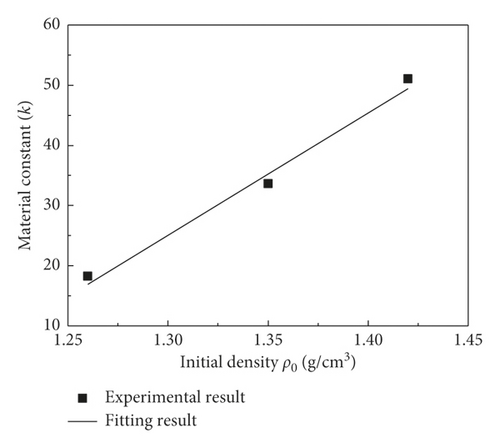

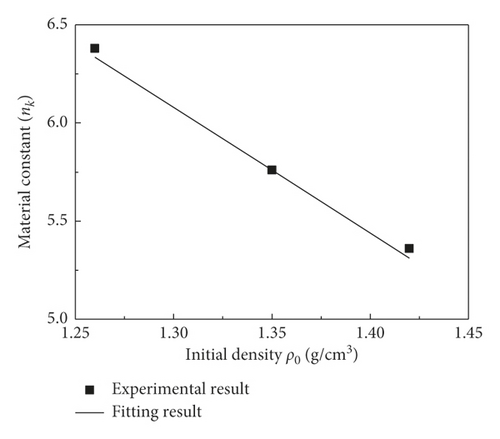

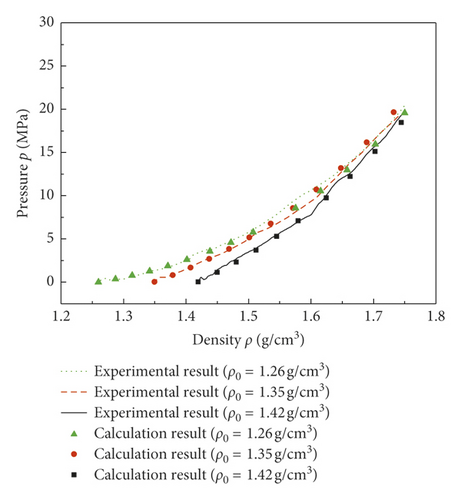

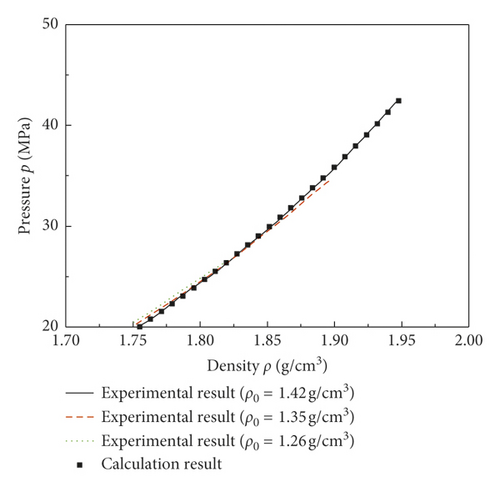

The experimental results shown in Figure 12 show that the density-pressure curves of samples with different initial densities could be separated into two segments at the point where the density is 1.75 g/cm3. In the first segment, the curves are dependent on the initial density of the sample, whereas in the second segment, the curves are independent of the initial density of the sample; therefore, the curves should be fitted separately.

The second segment of the density-pressure curve is independent of the sample initial density, so ρ0 in equation (10) could be chosen as 1.42 g/cm3. The corresponding material parameter fitting results are nk = 5.46 and k = 50.1.

4. Conclusions

The dynamic mechanical behaviour of dry calcareous sand under rigid confinement provided by a thick-wall stainless steel sleeve was investigated using a split Hopkinson pressure bar (SHPB) at high strain rates (335 s−1 to 1253 s−1). A new sand specimen assembly by using Glyd Ring was developed, and the assembly relies on repeated dynamic compaction to prepare sand samples with precise initial mass densities. Sand samples with three initial mass densities (1.26 g/cm3, 1.35 g/cm3, and 1.42 g/cm3) were compressed at three nominal striker velocities (5 m/s, 10 m/s, and 20 m/s). A strain gauge was attached to the external surface of the sleeve to measure the circumferential strain therein, and hence, the deviatoric and volumetric behaviours of calcareous sand could be determined.

Experimental results show that, in the strain rate range of 335 s−1 to 1253 s−1, the dynamic compression characteristics of dry calcareous sand exhibited no significant rate effect. The e-log σ curves of samples with different initial densities merge into one straight line whose slope is 0.239 at an axial stress of 40 MPa. The dynamic compression index of dry calcareous sand is much smaller than that of quartz sand, indicating that the dry calcareous sand is much “softer.” The lateral stress coefficient of calcareous sand increases with axial stress, so the Lundborg model could be used to describe its deviatoric behaviour. The density-pressure curves of dry calcareous sand could be separated into two segments when the density is 1.75 g/cm3; in the first segment, the curve is dependent on the initial density, whereas in the second segment, it is independent thereof. In both segments, the curve could be described by the Murnaghan equation.

Conflicts of Interest

The authors declare that there are no conflicts of interest regarding the publication of this paper.

Acknowledgments

The financial support was provided by the National Natural Foundation for Young Scientists of China (Grant no. 51409257).

Open Research

Data Availability

The data used to support the findings of this study are available from the corresponding author upon request.