Stochastic Analysis of Nonlinear Vehicle-Track Coupled Dynamic System and Its Application in Vehicle Operation Safety Evaluation

Abstract

This paper presents a vehicle operation safety evaluation model; to this end, a nonlinear vehicle-track coupled dynamic system stochastic analysis model under random irregularity excitations based on probability density evolution method was developed. The nonlinear coupled vehicle-track dynamic system is used to accurately describe the wheel-rail contact state. The stochastic function-spectral representation is used to simulate the random track irregularity in the time domain for the first time; consequently, the frequency components in the irregularity are preserved and random variables are reduced. In the process of evaluating the safety of train operation, the probability evolution, reliability of evaluation indices for different limit values, and evaluation indices for different probability limits are calculated for more accurate evaluation. The dynamic model and safety evaluation method was verified using the Zhai-model and Monte Carlo method. The results show that, when the probability guarantee is increased, the running safety index of the vehicle increases more rapidly with running speed and the left/right wheel-rail derailment coefficient increases rapidly at running speeds above 400 km/h. The computational model provides a novel direction for vehicle operation safety evaluation.

1. Introduction

Vehicle-track coupled dynamic system is a nonlinear and stochastic system in nature as random track irregularity is one of its main random excitations. Meanwhile, the vehicle operation safety under random excitations is also the main transportation engineering concerns. In the past few decades, the popularization of high-speed railway and the continuous demand for high operating speed have brought many engineering challenges. In many countries, evaluation standards for train operation safety have been emplaced. Due to the complexity involved in the safety assessment of train operation, the problems generally need to be addressed through simulation methods. Several different train-track coupled dynamics models or train-bridge coupled dynamics models have been established to analyze the dynamic response of the system. Wu et al. [1] developed a vehicle-rail-bridge interaction model for analyzing the 3D dynamic interaction between the moving trains and railway bridge; in this established model, the wheelset has 3 degrees of freedom, the vertical, lateral, and rolling, and no jumps occur between the wheelsets and rails. After that, Chen and Zhai [2] established two dynamic models, train running on the bridge with ballasted track and the ballastless slab track. In these two models, the jump between the wheelset and the rail can be simulated. In reference [3], Zhai further extended these models to three-dimensional space, and at the same time, a three-dimensional space wheel-rail contact relationship has also been developed. Lou and Zeng [4] have derived the equations of motion in matrix form for the railway freight vehicle-bridge interaction system based on energy approach; this modeling method also has been widely used. Dinh et al. [5] have developed a formulation of three-dimensional dynamic interactions between a bridge and a high-speed train using wheel-rail interfaces; in this model, contact loss is allowed, and the contact is nonlinearly. Other than these, many scholars, such as Zhang et al. [6] and Yang and Yau [7], also have established their own vehicle-track or vehicle-track-bridge coupling dynamics models. The development of vehicle-track coupled dynamics modeling facilitates the evaluation of vehicle operational safety through numerical simulation. However, as the main excitation source in the train operation, the track random irregularity cannot be measured and predicted before the completion of the line construction, it also changes with time and environment. Therefore, it is necessary to consider the train safety operation from a stochastic point of view. Many scholars have tried to use random vibration analysis method to study the dynamic response of vehicle-track coupled dynamic system and have obtained many meaningful research results.

Due to the complexity of vehicle-track coupled dynamic system, Monte Carlo method (MCM) is a common analytical method in random analysis. Chen et al. [8] and Xia et al. [9] studied the random vibrations in a nonlinear vehicle-track coupling dynamic system by the MCM and established an early nonlinear analysis model of the system from a stochastic perspective. Subsequently, many efficient random vibration methods were applied to vehicle-track-coupled power systems. Lu et al. [11], Zhang et al. [12], and Zeng et al. [13] established random vibration analysis model for linear vehicle-track-bridge coupling system by pseudoexcitation method (PEM). This method analyzes the random vibrations in linear systems efficiently, especially the power characteristics in the frequency domain. Zhang et al. also have used the PEM and the precise integration method (PIM) to compute the nonstationary random responses of three-dimensional train-bridge systems subjected to lateral horizontal earthquakes [14]. Yu et al. [15] studied the random vibrations of a linearized vehicle-rail-bridge coupling system by generalized probability density evolution theory (originally formulated by Li and Chen [16]), which is more efficient than the MCM. Xu et al. [17, 18] proposed a stochastic space-time analysis method for vehicle-track-coupled power systems. Their method also applies generalized probability density evolution theory and is based on the measured track irregularity data. Their probabilistic model efficiently and accurately analyzes the vehicle-track-coupled power system under random track irregularities.

The introduction of stochastic vibration analysis method makes it possible to use the probability theory to evaluate the safety of vehicle-track coupled power system or vehicle-bridge coupled dynamic system. Rocha et al. presented a probabilistic methodology for the safety assessment of short-span railway bridges for high-speed traffic [19] and analysed the sensitivity of the dynamic response due to the variability of the main structural parameters [20], and the efficiency of different probabilistic methodologies for safety assessment of short-span railway bridges is compared [21]. Using the principle of virtual work, utilizing a linearized wheel-rail contact equation to avoid iterative solution at each time step of the integration, and applying rail irregularity as random excitations to the system, the probabilistic evaluation approach for nonlinear vehicle-bridge dynamic performances has been analysed by Jin et al. [22]. By developing an improved response surface method for nonlinear limit states, Cho et al. [23] evaluated the reliability of vehicle and high-speed railway bridge system.

In the existing random vibration analysis of vehicle-track coupled dynamics, due to the limitation of stochastic analysis methods or in order to improve the computational efficiency, linear or linearized models are often used. For the linearization of a model, the wheel-rail relationship is often reduced to a linear model. The wheel-rail relationship not only reflects the force state between wheel and rail, but also the excitation of track irregularity also needs to be input into the system through wheel-rail relationship; this makes the wheel-rail relationship one of the core issues in the modeling. The linearized model will not be able to accurately simulate the change of the size, direction, and action point of the wheel-rail force, and it will also lead to a difference of the input track irregularity excitation input. Other than this, models with nonlinear wheel-rail contact relationship allow for the evaluation of vehicle safety in a more realistic way than linear methods [24]. Numerous studies on vehicle-bridge dynamics have indicated that nonlinear interaction has profound effects on the system responses [25]. Therefore, the nonlinear vehicle-track coupled dynamics model is more helpful for vehicle-safety evaluation, and the calculation results are more accurate.

In this paper, a stochastic analysis model of nonlinear vehicle-track coupled dynamic system under random irregularity excitations was established based on probability density evolution method. The nonlinear wheel-rail relationship has been considered to facilitate more convenient and accurate evaluation of vehicle operational safety. Generalized probability density evolution theory has been used, which has been widely applied to linear and nonlinear stochastic systems and have proven to obviously improve the efficiency the analysis [15, 16, 26]. In addition, function-spectral representation method has been used to accurately simulate the random track irregularities in the time domain, which retains a large number of frequency components in the samples while reducing the required number of random variables. It also avoids the clustering phenomenon in the point selection of high-dimensional random variables. The probability density evolution of the left/right wheel-rail load reduction, the left/right wheel-rail derailment coefficient, and the vertical/transverse acceleration of the car body were calculated by the generalized probability density evolution theory. Based on the results, a safety evaluation model of train operation is presented and validated by comparison with previous study. The developed computational model provides a new research direction for train safety evaluation.

2. Stochastic Analysis Model of Nonlinear Vehicle-Track Coupled Dynamic System

Figure 1 shows the calculation flow of the nonlinear vehicle-track coupled dynamic system stochastic analysis model, which is based on generalized probability density evolution theory. The main steps are the establishment of the nonlinear system, the numerical simulation of Npt random track irregularities time-domain samples, the dynamic response calculation of the coupled vehicle-track system under random excitations, calculation of the probability density evolution of the safety evaluation index, and the train safety evaluation.

2.1. Stochastic Analysis Method Based on Generalized Probability Density Evolution Theory

2.1.1. Generalized Probability Density Evolution Theory

In this formula, is the free velocity of ξ (t) under the random sample {Θ = θ}. Its initial probability is .

For the probabilistic conservative vehicle-track coupled dynamic system under the random track irregularity excitation, the system dynamic response ξ satisfies the generalized probability density evolution equation shown in equation (5). Simultaneously, the generalized probability density evolution equation decouples the probability space from the physical space. As shown in Figure 1, first solve the vehicle-track coupled dynamic system equation (1) to obtain under each random sample θ, and then solve the generalized probability density evolution equation for each random sample θ. When all random samples have been calculated, by solving equation (6), the probability density evolution process of the dynamic response can be obtained. Finally, a stochastic analysis of the nonlinear vehicle-track coupled dynamic system is realized.

2.1.2. Selection of Random Variable Samples and the Probability Assignment

In generalized probability density evolution theory, selecting the random variable samples is directly related to the computational efficiency of the random analysis. In this paper, the random variables are described by a low-deviation sequence selected by number theory, which reduces the required number of random samples and accelerates the convergence of the calculation. However, as the low-deviation sequence is uniformly distributed, it cannot be selected from a high-dimensional space without forming void and cluster structures. Therefore, the uniformity will degrade and the calculation results will contain large errors.

Random irregularity is the superposition of irregular waves of different wavelengths, different phases, and different amplitudes. To accurately simulate the random track irregularities, more random frequencies and phase components (i.e., more selections) are needed. To avoid clustering in the random sample selection, the random track irregularities were simulated in the time domain by a stochastic function-spectral representation method, which requires just eight random variables. The generation method and validation of the sampling will be discussed in Section 2.4. The random variables were sampled as Sobol sequences.

This method obtains the initial probability of each random point sample.

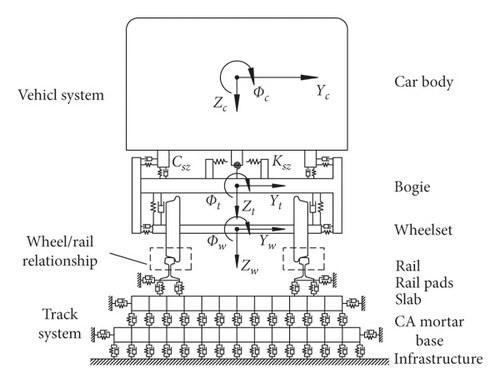

2.2. Vehicle-Track Coupled Dynamics Model

Figure 2 shows the vehicle-track coupling dynamic model. The vehicle is modeled by multirigid body dynamics, and the rail is regarded as a finite-length, elastic-point supported Euler beam. The dynamic vibration equation of the beam is solved by the Ritz method. The wheel-rail relationship is modeled by nonlinear Hertz contact theory and wheel-rail nonlinear creep theory. The fastener is modeled by a linear spring damping element in the transverse and vertical directions. The track structure is modeled by the finite element method; the slab, mortar layer, and base are modeled as plate elements. The foundation support is simplified as a linear spring damping surface element. The wheel-rail relationship connects the vehicle and rail models, whereas the fastener force connects the rail model and the track slab-foundation structure.

2.2.1. Vehicle Dynamics Model

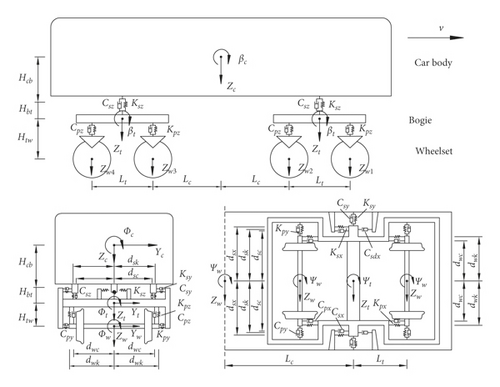

Figure 3 schematizes the vehicle model composed of one car body, two bogies, and four wheelsets. Each part is treated as a rigid body with freedom in the longitudinal, transverse, bounce, roll, and yaw directions (giving 35 degrees of freedom per vehicle).

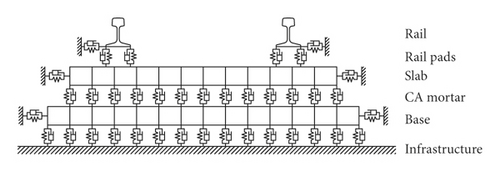

2.2.2. Dynamic Model of the Track Structure

The track structure is divided into two main parts: the rail and the track plate. The rail is treated as an elastic support for an Euler beam, and the track plate and base plate are modeled by a plate element with high rigidity in the transverse direction, lateral displacement using beam element to simulate. Since the numerical integration solution step length is short and requires a lot of numerical calculation work, the method of the literature [3] is used in the modeling of the rail, and the dynamic response of the rail is obtained by solving the rail vibration differential equation, which can greatly reduce the calculation work. At the same time, the track plate is modeled by the finite element method to facilitate the modeling of various ballastless track structures. The track-structure model and rail forces are shown in Figures 4 and 5, respectively.

The differential equations of the vertical, transverse, and torsional vibrations of the rail are, respectively given in the following [3].

2.2.3. Wheel-Rail Contact Relation

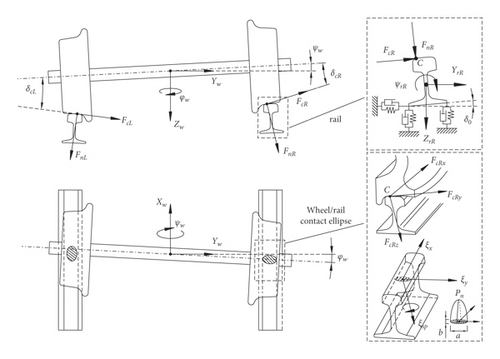

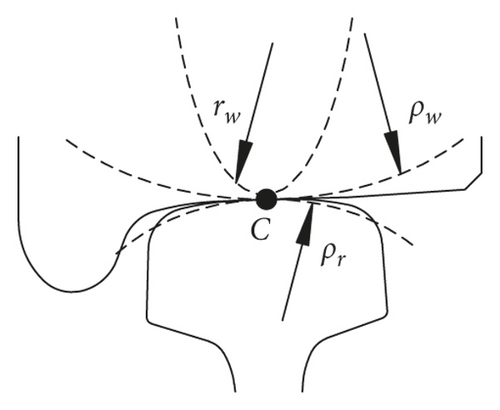

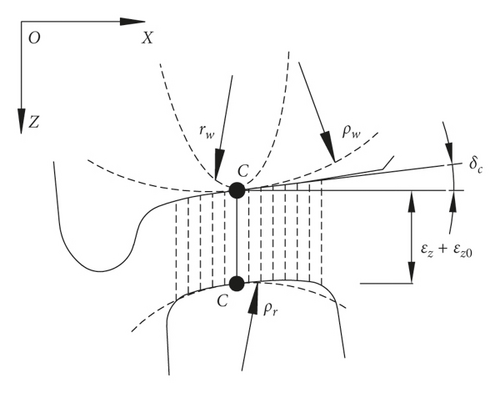

The wheel-rail relationship links the vehicle system to the track system. In the vehicle-track coupled dynamics, the wheel-rail relationship mainly includes the wheel-rail normal-seeking solution, the wheel-rail creep solution, and the wheel-rail contact geometry. The wheel-rail relationship is shown in Figure 6.

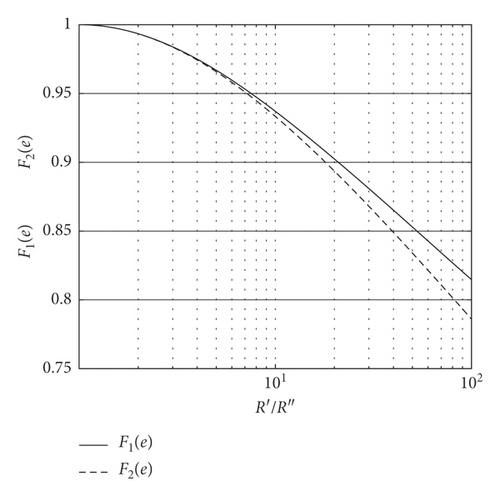

In the above expressions, E∗ is the equivalent modulus of elasticity, given by , and , where a and b are the lengths of the long and short axes, respectively, of the contact ellipse (with b < a). F1(e) and F2(e) are correction factors that depend only on the ratio of relative curvature radii R′/R″. The variations of these factors with increasing R′/R″ are plotted in Figure 8.

| F1(e) | F2(e) | ||||

|---|---|---|---|---|---|

| Parameters | Error of fitting | Parameters | Error of fitting | ||

| q1 | 0.001227 | SSE: 3.522e-07 | q1 | 0.002195 | SSE: 3.156e-07 |

| q2 | −0.05683 | R-square: 1 | q2 | −0.07143 | R-square: 1 |

| q3 | 0.7315 | Adjusted R-square: 1 | q3 | 0.4331 | Adjusted R-square: 1 |

| q4 | 4.087 | RMSE: 5.935e-07 | q4 | 4.816 | RMSE: 5.618e-07 |

| q5 | 20.1 | q5 | 41.2 | ||

| q6 | 36.46 | q6 | 21.94 | ||

| p1 | 4.599 | p1 | 5.123 | ||

| p2 | 20.1 | p2 | 41.2 | ||

| p3 | 36.46 | p3 | 21.94 | ||

Here, δcLi and δcRi are the left-sided and right-sided wheel-rail contact angles, respectively, obtained from the wheel-rail contact geometry (details will be given in Section (2)).

Finally, the normal force between the wheel and rail is obtained by inserting the wheel-rail normal compression into the wheel-rail normal contact model.

2.3. Numerical Simulation and Verification of the Random Track Irregularity Model

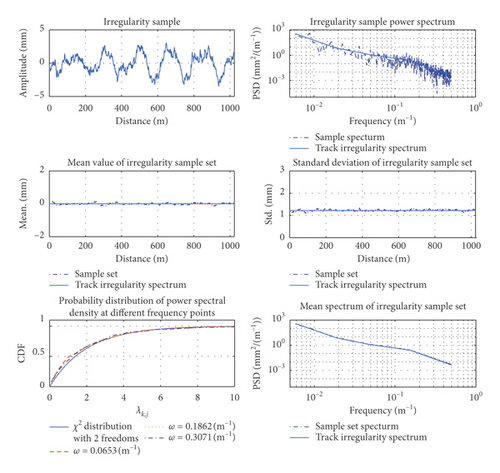

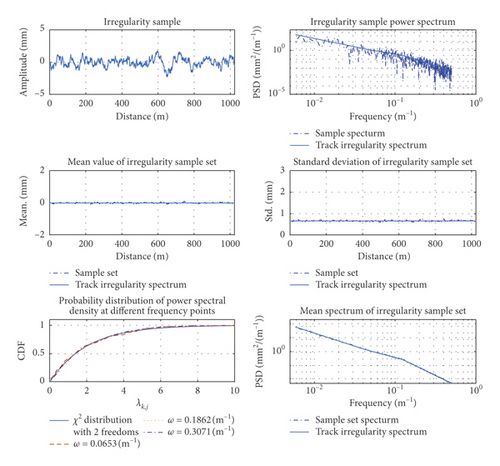

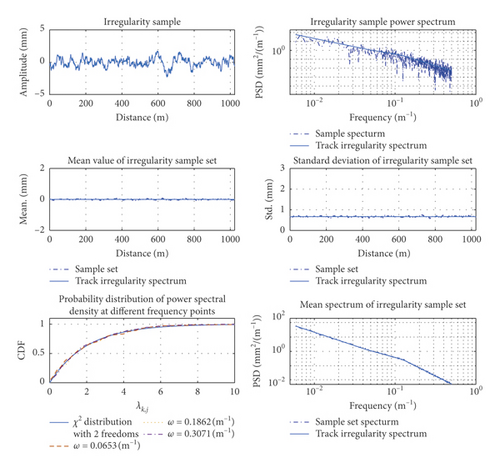

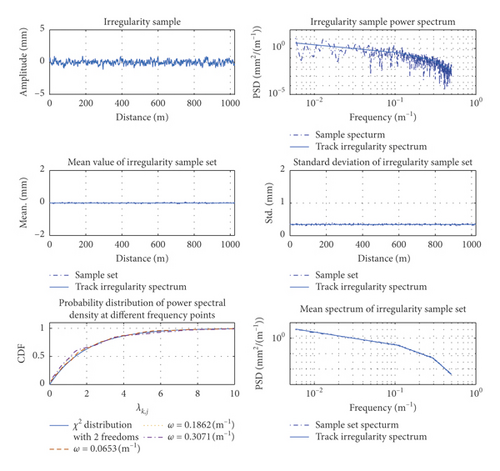

As an example, we consider the “TB/T3352-2014 high-speed railway ballastless track irregularity spectrum” implemented in 2015. Three hundred samples of random track irregularities were generated by the spectral representation random-function method. When generating the power spectrum of the track irregularities, the unit length and sampling interval were set to 1024 m and 0.25 m, respectively, with 4096 points in a single unit [31]. Therefore, when simulating the samples in the time domain, the discretized number of frequencies Nω was 4096. The vertical profile, alignment, cross-level, and gage irregularity of the track were, respectively, expressed as follows:

It should be noted that the track irregularity spectrum is averaged over many measured data. As the random error between a single sample and the track irregularity spectrum is 100%, the accuracy of the simulation method cannot be validated by comparing the simulated power spectrum of the track irregularity with that obtained from a single or finite-length sample, but validated by comparing the simulated power spectrum of the track irregularity with that obtained from a sample set.

Figure 10 compares the means and standard deviations of the track irregularity in the time domain and the track irregularity spectrum in [31]. The power spectrum of each frequency point in the sample set was tested by χ2 distribution with a significance level of α = 0.05 and two degrees of freedom with the Kolmogorov–Smirnov method, verifying the accuracy of the random track irregularities simulated by the present method.

The power spectral density and track irregularity power spectrum derived from a single sample did not accurately estimate the vertical profile, alignment, cross-level, or gage irregularity of the track (Figure 10). However, the mean power spectrum calculated from the sample set of track irregularities favorably agreed with the target spectrum. The maximum difference between the mean vertical profile, alignment, cross-level, and gage irregularity and those obtained from the target spectrum were 0.18 mm, 0.10 mm, 0.07 mm, and 0.08 mm, respectively, with maximum standard deviations of 4.68%, 5.77%, 6.97%, and 6.99%, respectively. In contrast, the maximum deviations in the power spectrum of the sample set were 14.54%, 10.23%, 10.07%, and 9.87%, respectively. In the power spectral densities at different frequencies of the sample set, the vertical profile, alignment, cross-level, and gage irregularity of the track all satisfied the 2-degree-of-freedom χ2 distribution (with 98.00%, 96.33%, 98.00%, and 98.33% of the frequency points satisfying the distribution, respectively). Each index of the sample set well agreed with the target spectrum, and only eight random variables were required to extract the indices from the time-domain samples. The method also retained a large number of frequency components. The commonly used trigonometric method, when simulating track random irregularity time-domain samples, requires enough random phase. When there are only 8 random phases, the simulated track random irregularity time-domain samples will have periodic repeatability and cannot be used in the calculation of the vehicle-rail coupled dynamic system. It can be seen that the numerical simulation method in this paper can greatly reduce the number of random variables required to simulate track random irregularity time-domain samples.

2.4. Numerical Solution Method

The track-vehicle coupled dynamic model was solved by an explicit-implicit integration method, with time integral step less than 0.0001 seconds, and the mode number of rail is taken as half the number of rail support points. The displacement and speed of the train and rail at the (n + 1)th moment were computed from the displacement, speed, and acceleration in the nth and (n − 1)th moments. The wheel-rail force was then calculated by the wheel-rail contact model, using the freedoms of the wheelset and rail at the (n + 1)th moment. After forming the wheel-rail load matrix, the fastener model was solved with the rail and slab freedoms, obtaining the wheel-rail load matrix. The vehicle and rail acceleration at the (n + 1)th moment was solved by the vehicle and rail motion equation, and the dynamic response of the slab and base at the (n + 1)th moment under the fastener force load was obtained by the Newmark-β integral method. Finally, the generalized probability density was evolved by the finite difference discretization of the modified Lax–Wendroff scheme [16].

3. Numerical Calculation and Analysis

3.1. Model Verification

3.1.1. Calculation Conditions

The vehicle parameters are shown in Table 2. The analysis was performed on the Chinese high-speed ballastless railway irregularity spectrum, with an irregularity wavelength range of 2–120 m. The vehicle speed was 350 km/h. The track irregularities in the time domain were sampled by the random irregularity numerical simulation method described in Section 2.3. The evaluation indices were the left/right wheel load reduction rates, the left/right wheel derailment coefficients, lateral force of the wheel axis, and the lateral/vertical accelerations of the car body. The calculation results of single and multiple samples were compared and verified.

| Item | Notation | Unit | Value | |

|---|---|---|---|---|

| Car body | Mass | mc | kg | 33.2 × 103 |

| Mass moment of inertia about x-axis | Ixc | kg·m2 | 1.07568 × 105 | |

| Mass moment of inertia about y-axis | Iyc | Kg·m2 | 1.6268 × 106 | |

| Mass moment of inertia about z-axis | Izc | kg·m2 | 1.4027 × 106 | |

| Bogie | Mass of bogie | mt | kg | 2.6 × 103 |

| Mass moment of inertia about x-axis | Ixt | kg·m2 | 2106 | |

| Mass moment of inertia about y-axis | Iyt | kg·m2 | 1424 | |

| Mass moment of inertia about z-axis | Izt | kg·m2 | 2600 | |

| Wheelset | Mass of wheelset | mw | kg | 1.97 × 103 |

| Mass moment of inertia about x-axis | Ixw | kg·m2 | 623 | |

| Mass moment of inertia about y-axis | Iyw | kg·m2 | 78 | |

| Mass moment of inertia about z-axis | Izw | kg·m2 | 623 | |

| Primary suspension system | Longitudinal spring stiffness | kpx | N/m | 9.8 × 106 |

| Lateral spring stiffness | kpy | N/m | 9.8 × 106 | |

| Vertical spring stiffness | kpz | N/m | 1.176 × 106 | |

| Longitudinal damping coefficient | cpx | N·s/m | 0 | |

| Lateral damping coefficient | cpy | N·s/m | 0 | |

| Vertical damping coefficient | cpz | N·s/m | 0.196 × 103 | |

| Second suspension system | Longitudinal spring stiffness | ksx | N/m | 1.784 × 105 |

| Lateral spring stiffness | ksy | N/m | 1.931 × 105 | |

| Vertical spring stiffness | ksz | N/m | 1.931 × 105 | |

| Longitudinal damping coefficient | csx | N·s/m | 0 | |

| Lateral damping coefficient | csy | N·s/m | 5.88 × 104 | |

| Vertical damping coefficient | csz | N·s/m | 9.8 × 104 | |

| Half the transverse distance between vertical primary suspension systems | dwk | m | 1.0 | |

| Half the transverse distance between vertical primary suspension system absorber | dwc | m | 1.0 | |

| Half the transverse distance between vertical second suspension systems | dsk | m | 1.25 | |

| Half the transverse distance between vertical second suspension systems absorber | dsc | m | 1.25 | |

| Vertical distance between center of gravity of car body and lateral secondary suspension system | Hcb | m | 0.644 | |

| Vertical distance between lateral secondary suspension system and center of gravity of bogie | Hbt | m | 0.29 | |

| Vertical distance between center of gravity of bogie and lateral primary suspension system | Htw | m | 0.08 | |

| Half the longitudinal distance between center of rear bogie and center of front bogie | Lc | m | 8.75 | |

| Half the bogie axle base | Lt | m | 1.25 | |

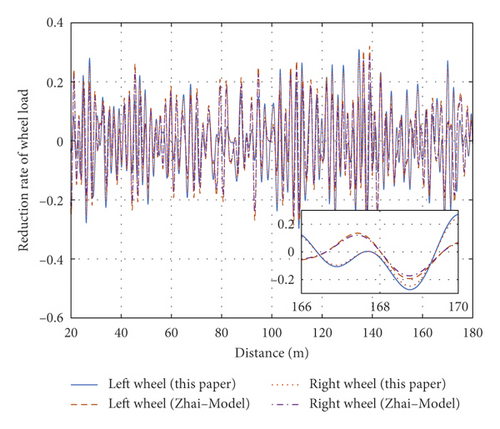

3.1.2. Comparison and Verification of the Single-Sample Calculations

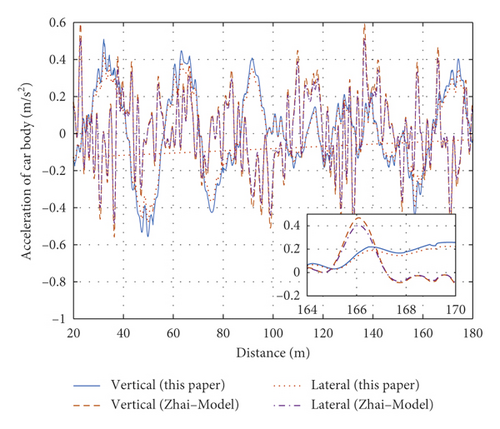

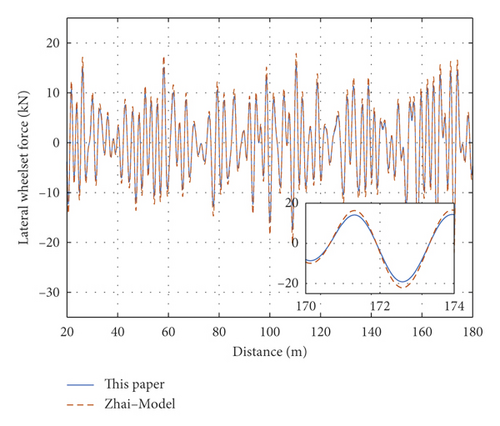

The vehicle-track coupled dynamic model proposed by Zhai and Chen [2, 3] has been widely used, so the dynamic model is verified by comparing the model in this paper with Zhai-model. Figure 11 compares the present calculation results with those of the Zhai-model in the case of a single time-domain sample from the track irregularity data. The calculation parameters and random track irregularity sample were the same in both methods. As the forces on the left and right wheel-rail are unequal, the wheel load reduction rates and derailment coefficients differed between the left and right wheel-rail contacts; see of Figures 11(a) and 11(b) for comparisons of the left and right wheel-rail states, respectively. The maximum differences between the left and right wheel-rail load reduction rates and derailment coefficients were 0.35 and 0.19, respectively. Therefore, the left or right wheel-rail state alone cannot fully reflect the wheel-rail state; both substates must be considered together. Comparing the present calculation model with the Zhai-model, the wheel load reduction rates and derailment coefficients differed by (at most) 8.74% and 7.62%, respectively. Meanwhile, the maximum differences in the vertical and transverse accelerations of the car body were 7.21% and 8.99%, respectively, and the maximum difference in the transverse force of the wheel axle was 6.78%. In summary, the results of the vehicle-track coupled dynamics model and the classical Zhai-model differed by less than 10%, confirming the accuracy of the model developed here.

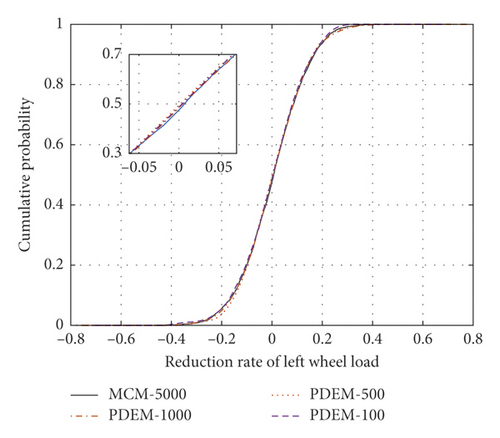

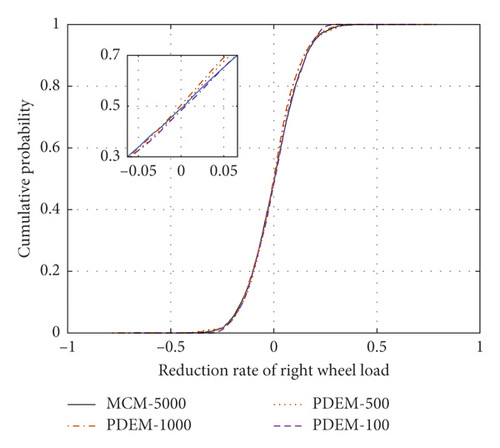

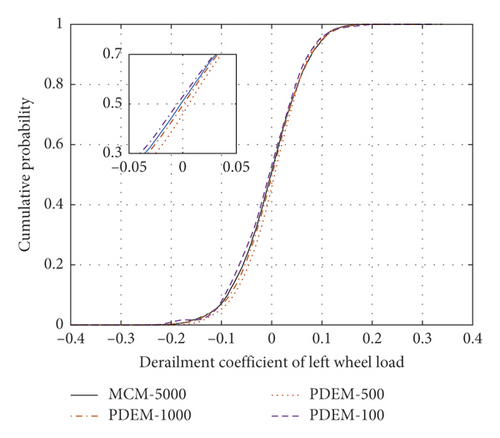

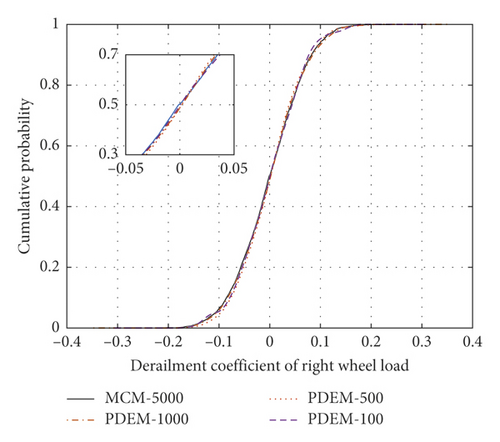

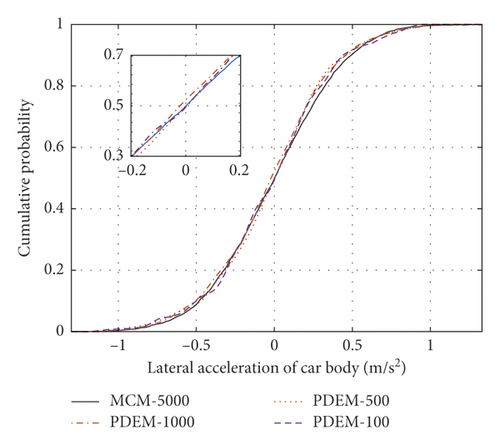

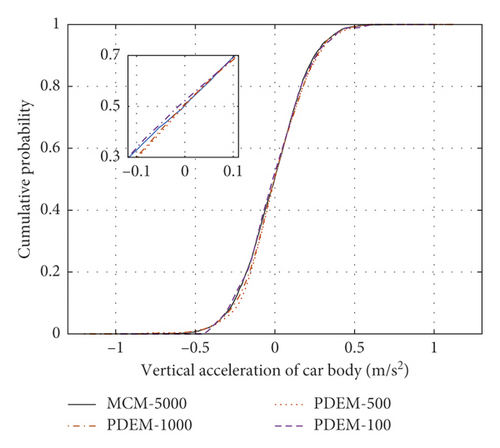

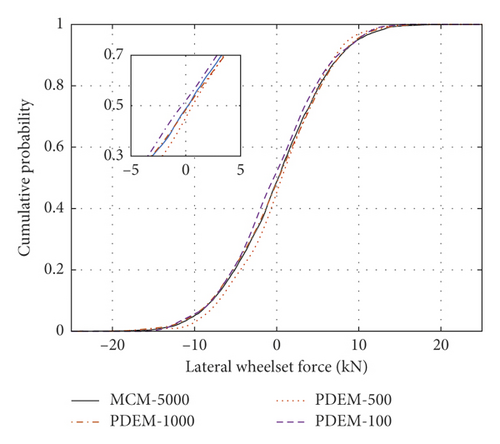

3.1.3. Comparison and Verification of Multisample Calculation Results

Random variables were selected by the MCM, and the random track irregularity was solved by the trigonometric series method. Five thousand random track irregularity samples were selected for computing the dynamic response of the vehicle-track coupled power system, and the statistical characteristics of each evaluation index were calculated. The probabilistic evolution processes of the indices were then calculated by the developed model, varying the number of samples as 100, 500, and 1000. Figure 12 plots the cumulative probabilities of each index for the different numbers of samples and (for comparison) the cumulative probability in the MCM method with 5000 samples. The sectional cumulative probabilities of the left/right wheel load reduction rates, the left/right wheel derailment coefficients, the vertical/transverse accelerations of the car body, and the lateral force of the wheel axle well agreed with the statistical results of many MCM calculations. However, the developed model greatly reduced the number of required irregularity samples. Figures 12(a) and 12(c) show the sectional cumulative probabilities of the wheel load reduction rates and derailment coefficients, respectively, in the four cases at a fixed distance on the left side (the equivalent plots on the right side are shown in Figures 12(b) and 12(d), respectively). In the single sample analysis, the load reduction rates and derailment coefficients largely differed between the left and right sides, but after selecting 100, 500, or 1000 samples, the cumulative probability distributions of the left and right wheel-rail indices were consistent. The wheel load reduction rates of the developed model with 100, 500, and 1000 samples differed by (at most) 0.068, 0.049, and 0.033, respectively, from those of the MCM with 5000 samples. The corresponding differences between the derailment coefficients computed by the developed method and the MCM were 0.075, 0.040, and 0.029, respectively. Clearly, the developed computational model with multisampling achieves the same computational accuracy as the largely sampled MCM.

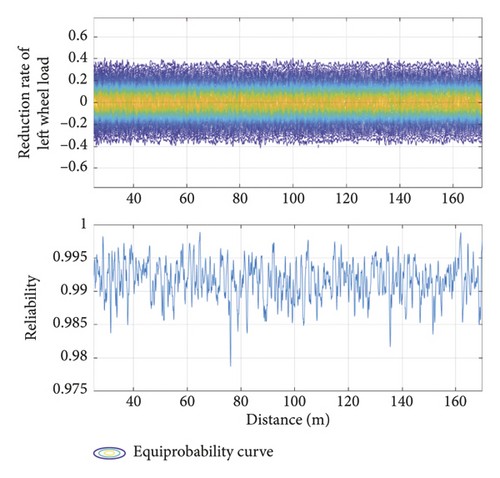

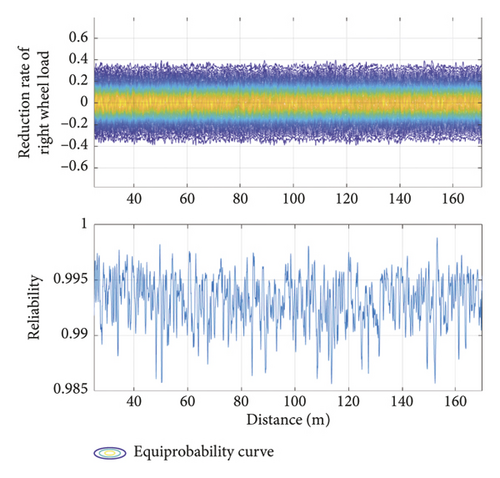

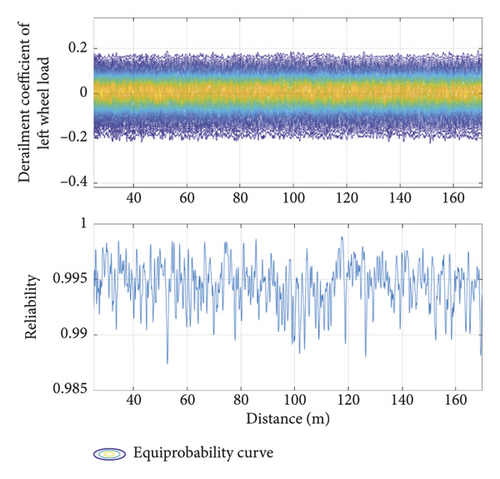

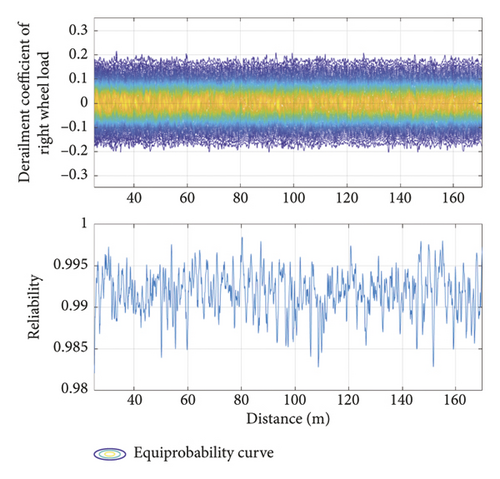

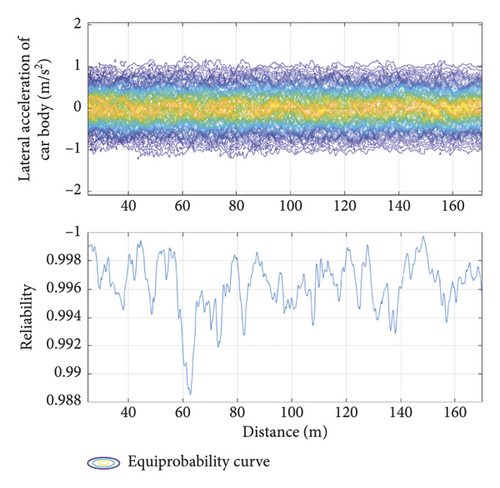

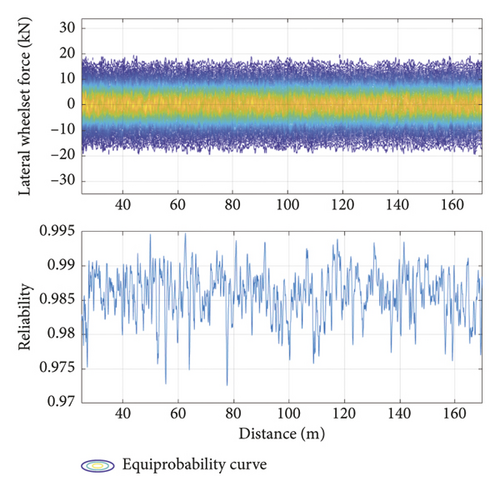

3.2. Reliability Analysis of Vehicle Operation Safety

The ballastless track structure in China offers a comfortable riding experience. When a single vehicle is traveling at 350 km/h, its safety evaluation index (calculated by the developed method) meets the requirements of common specifications. As limiting values in the safety evaluation, the wheel load reduction rate was taken as 0.3, the derailment coefficient as 0.15, the lateral and vertical accelerations of the car body as 1.0 m/s2 and 0.5 m/s2, respectively, and the lateral force as 13 kN. Figure 13 plots the equal-probability and reliability curves of the safety evaluation indices of the running vehicle. The developed model easily evolved the probability of each evaluation index, and all indices spatiotemporally varied with the running mileage. Although the running mileage influenced the reliability of the different indices, it did not affect their equal-probability evolution curves, because the random track irregularity time-domain samples obtained from the track irregularity spectrum is a stationary random process. Table 3 lists the maximum and minimum probabilities of each safety evaluation index under the calculation conditions. The probability values under different limits were quickly calculated, confirming the convenience of the developed model in train operation safety evaluation.

| Evaluating indicator | Reduction rate | Derailment coefficient | Vertical acceleration of car body | Lateral acceleration of car body | Lateral wheelset force | ||

|---|---|---|---|---|---|---|---|

| Left | Right | Left | Right | ||||

| Min | 0.9787 | 0.9857 | 0.9874 | 0.9821 | 0.9885 | 0.9853 | 0.9725 |

| Max | 0.9989 | 0.9988 | 0.9989 | 0.9984 | 0.9997 | 0.9987 | 0.9948 |

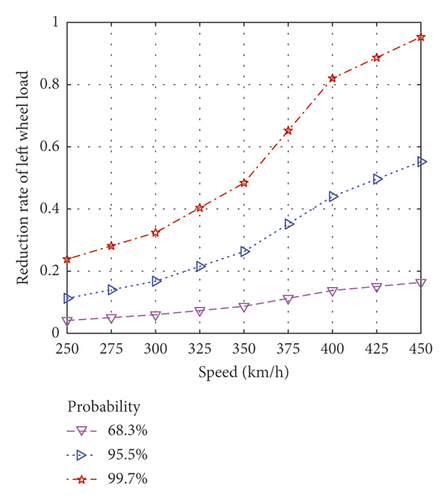

3.3. Train Safety Evaluation Indices Limit Value with Different Probabilities

Given a vehicle and track structure with random track irregularities, the calculation results of a single sample cannot obtain the limits of the evaluation indices. In the presence of random irregularities, the limit values can be obtained only with a certain probability. For this purpose, the probabilistic index was introduced, providing a new way of computing the limit values of the indices of vehicle-track coupled dynamics.

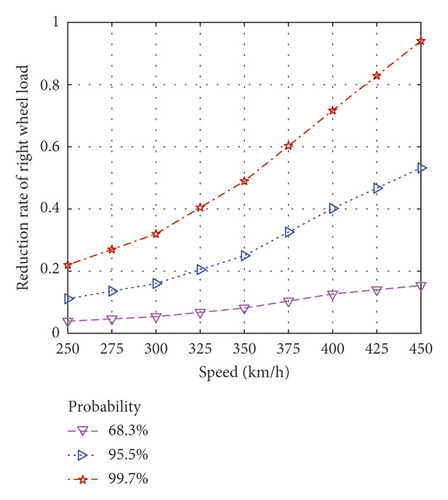

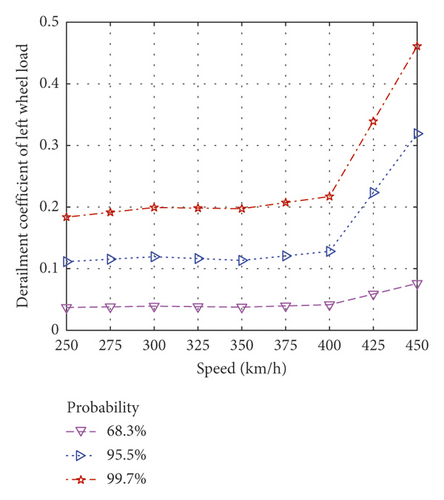

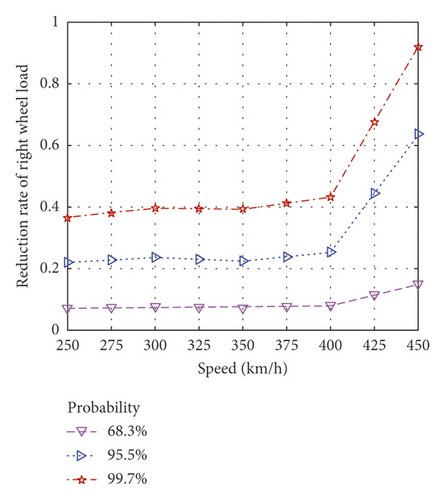

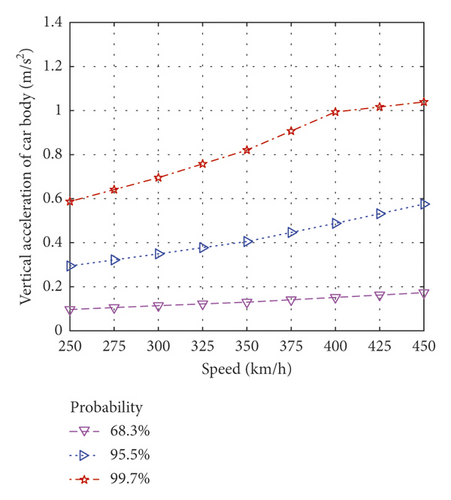

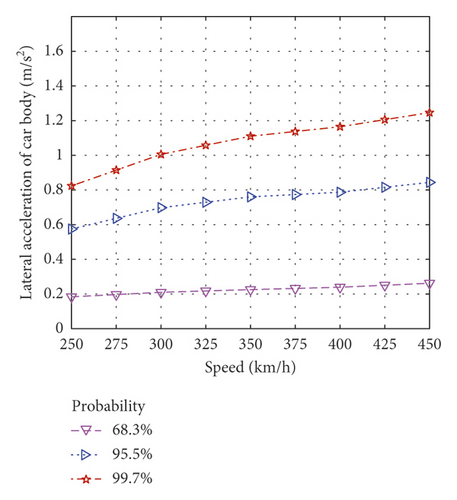

Figure 14 plots the evaluation indices variation curve with vehicle speed computed by the developed model with different index probabilities (1, 2, and 3 times the standard deviation of a normal distribution). At 68.3% probability, the evaluation indices were relatively insensitive to vehicle speed, but at 99.7% probability, they significantly increased with speed. The derailment coefficient was barely affected by vehicle speeds below 400 km/h but rapidly increased at higher speeds (at 450 km/h, the derailment coefficient value at 99.7% probability increased by 123.8%).

4. Conclusions

This paper presents an evaluation model of safe railway operation based on probability theory and a nonlinear vehicle-track coupled power system. The model more accurately captures the force state between the wheel and rail than the linearized vehicle-track coupling dynamic system. The random track irregularities were sampled in the time domain by a stochastic function-spectral representation method, which reduces the required number of samplings. The developed simulation method was verified in comparisons with an established method. The safety of the running vehicles was probabilistically determined by the evaluation indices (derailment coefficient, acceleration of the car body, and the lateral force of the wheel axle). The model results were compared with those of the Zhai-model and the MCM. Next, the vehicle-safety evaluation indices were computed for different probabilities of their limit values. At the lower probability (68.3%), the limiting evaluation indices were little affected by the vehicle speed, but at the highest probability (99.7%), they were significantly increased at higher vehicle speeds. The derailment coefficient deserves special attention when driving at high speed. The developed computational model provides a new research direction for vehicle operation safety evaluation. In future work, the model will be applied to safe railway operation under different conditions, such as different structures, different track or foundation diseases, and different track irregularities.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Acknowledgments

The research work described in this paper was supported by the High-speed Railway Joint Fund of National Natural Science Foundation of China (grant U1734208), the Major Program of National Natural Science Foundation of China (grant 11790283), the Hunan Provincial Natural Science Foundation of China (grant 2019JJ40384), and the Hunan Provincial Innovation Foundation for Postgraduate (CX2017B058).

Open Research

Data Availability

The analysis result data used to support the findings of this study are included within the article. The calculation data used to support the findings of this study are available from the corresponding author upon request.