Engineering Software Solution for Thermal Elastohydrodynamic Lubrication Using Multiphysics Software

Abstract

The complexity of thermal elastohydrodynamic lubrication (TEHL) problems has led to a variety of specialised numerical approaches ranging from finite difference based direct and inverse iterative methods such as Multilevel Multi-Integration solvers, via differential deflection methods, to finite element based full-system approaches. Hence, not only knowledge of the physical and technical relationships but also knowledge of the numerical procedures and solvers is necessary to perform TEHL simulations. Considering the state of the art of multiphysics software, the authors note the absence of a commercial software package for solving TEHL problems embedded in larger multiphysics software. By providing guidelines on how to implement a TEHL simulation model in commercial multiphysics software, the authors want to stimulate the research in computational tribology, so that, hopefully, the research focus can be shifted even more on physical modelling instead of numerical modelling. Validations, as well as result examples of the suggested TEHL model by means of simulated coefficients of friction, coated surfaces, and nonsmooth surfaces, highlight the flexibility and simplicity of the presented approach.

1. Introduction

Measurements, numerical simulations, and derived analytical solutions have, for decades, created detailed insights into the behaviour of thermal elastohydrodynamically lubricated (TEHL) contacts. Due to the large number of numerical investigations, it is astonishing that, so far, no commercial software package embedded in larger multiphysics software has been available to solve TEHL problems.

The simulation of TEHL contacts is, mainly due to elastic deformations and the large pressure-induced increase of lubricant viscosity, highly nonlinear and has led to various specialised numerical simulation approaches. Great computational efforts, and the tendency to instabilities at high loads when using computational fluid dynamics (CFD) [1], make the use of simulations based on the Reynolds equation necessary. Hartinger et al. [2] thereby compare TEHL solutions obtained with CFD with solutions based on the Reynolds equation which show very good agreement. Lubrecht [3] and Venner [4] develop a direct iterative finite difference based Multilevel Multi-Integration (MLMI) solver for isothermal EHL problems. Habchi [1] introduces the finite element method (FEM) based full-system approach to solve the fully coupled system of the highly nonlinear elastohydrodynamic equations, which are coupled with the energy equations by an iterative procedure. Raisin et al. [5] extend the approach based on line contacts to transient operating conditions. Although both authors [5, 6] mention the use of the commercial software, COMSOL Multiphysics [7], to solve the TEHL problem, explicit implementation guidelines are not given. For the isothermal EHL line and point contact with Newtonian fluid behaviour under transient and steady-state operating conditions, Tan et al. [8] describe some information for implementation in COMSOL Multiphysics in more detail.

Considering the large number of self-developed approaches and solvers, the modelling of TEHL contacts is hardly transparent. Hence, the promotion of using commercial software packages for solving TEHL problems is necessary to make simulation techniques available to a broader audience of the tribology society and to focus research more on physical relationships rather than on numerical procedures. Accordingly, the authors provide guidelines for the implementation and solving of TEHL problems in the commercial software, COMSOL Multiphysics, to stimulate and accelerate research in computational tribology. The possibility of developing a complex TEHL model with moderate effort is demonstrated in this paper.

2. Theory

In this section, the theory and governing equations for simulation of TEHL contacts are addressed. For simplification, a two-dimensional line contact is considered.

2.1. General

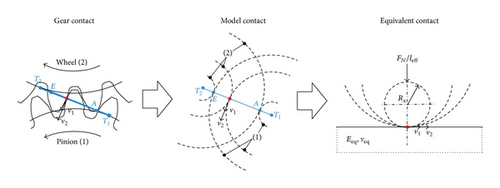

Contact conditions of, for example, gears are characterised by varying load, motion, and geometry along the path of contact. This transient contact can be interpreted as a transient model contact of two rolling elements with varying load, motion, and geometry for each meshing point. In TEHL simulations, the transient contact is usually further simplified to an equivalent contact between a single (inelastic) roller and an elastic flat body. This is adopted in this study and exemplarily shown for a line contact of a spur gear in Figure 1.

2.2. Generalised Reynolds Equation

2.3. Contact Mechanics

2.4. Energy Conservation

2.5. Lubricant Properties

3. Model Description and Implementation

A guideline for the implementation of a TEHL simulation model in COMSOL Multiphysics (abbr. by COMSOL) and MathWorks MATLAB [21] (abbr. by MATLAB) is given in the following sections. All COMSOL-specific notations are written in italics.

3.1. Dimensionless Parameters

3.2. Numerical Solution Procedure

The numerical solution scheme shown in Figure 2 is similar to other schemes of, for example, Habchi [1] and Wang et al. [22]. In this work, it is based on two self-developed decoupled COMSOL FEM-models, denoted as FEM-model (P, H) and FEM-model (), and a MATLAB sequence controller, which also performs additional calculations.

After reading all the required input parameters, an initial solution based on a simple steady-state isothermal Newtonian approach is calculated in the FEM-model (P, H) for the initial operating conditions. The procedure thereby is the same as described in the following paragraph. Based on the initial solution, the time loop is launched and repeated until the last time-step has been calculated. The coupling of two consecutive time-steps is realised by an implicit backward differentiation formula (BDE) scheme of the first order as used in [23]. It is implemented by passing the required solution variables of the previous time-step for calculating the time derivatives of the generalised Reynolds equation and energy equations from the sequence controller to the FEM-model (P, H) and FEM-model ().

Within the time loop, a global loop is launched for each time-step. Firstly the pressure and film thickness distribution under consideration of non-Newtonian fluid behaviour is calculated for a given temperature distribution in the FEM-model (P, H) described in Section 3.3.1. Then, the lubricant properties acc. to Section 2.5, the integral terms in (5), and the velocity distribution vx (4) are updated in the sequence controller. Thereby, the shear stress τ is analytically derived (15). After calling up the FEM-model (P, H) again, the new calculated pressure distribution is compared with the previous calculated pressure distribution. The iterative procedure is repeated until the maximum absolute difference of two consecutive pressure distributions is smaller than 10−3.

After the convergence of P, the pressure and film thickness distributions P and H are kept constant and an iterative calculation of the temperature distribution in lubricant and solid bodies, based on the FEM-model () described in Section 3.3.2, is launched. For each new temperature distribution calculated, the lubricant properties acc. to Section 2.5, the integral terms in (5), the heat sources in (9), and the velocity distribution vx (4) are updated in the sequence controller. Thereby, the shear stress τ is analytically derived (15). The iterative calculation is repeated until the maximum absolute difference of two consecutive temperature distributions in the lubricant is smaller than 10−3.

Finally, the converged pressure distribution and temperature distribution in the lubricant of two consecutive global loops are compared. Again, convergence is assumed when the maximum absolute difference between two consecutive solutions of pressure and temperature distributions is smaller than 10−3. After saving the solution of the considered time-step, the next global loop is calculated with updated operating conditions and time derivatives of the generalised Reynolds equation and energy equations.

3.3. Implementation in COMSOL

In the following, the characteristics of the FEM-model (P, H) and FEM-model (), as well as of the solver settings and sequence controller, are described in detail. To a great extent, the structure of the FEM-models follows the outstanding work of Habchi [1], who introduces the FEM based full-system approach to TEHL achieving very high convergence rates without underrelaxation required. Thereby, the FEM approach offers the possibility of using a mesh with nonregular unstructured elements and high order approximation functions. As shown in the following, it is possible to implement the approach of Habchi in commercial multiphysics software.

3.3.1. FEM-Model (P, H)

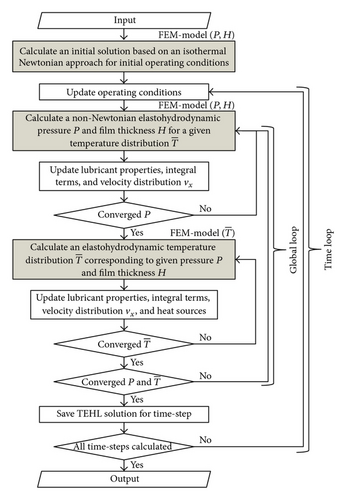

Figure 3 (top left) shows the computational domains Ωδ and ΩP on which the pressure and film thickness distribution are calculated fully coupled. Figure 3 (bottom left) illustrates in parts the corresponding model tree. For each new call-up of FEM-model (P, H), the solution of the previous call is used as an initial value.

The elastic deformation of the equivalent body in Z-direction is calculated on a quadratic two-dimensional computational domain Ωδ with the extensions X ∈ [−30, 30] and Z ∈ [−60, 0]. Hence, an influence of the boundary conditions of Ωδ on the contact area can be excluded. The physics Solid Mechanics is used with the displacement vector as the dependent variable. A linear elastic isotropic material specified by Young’s Modulus Eeq and Poisson’s ratio νeq is assumed. The boundary conditions described in Section 2.3 are implemented as a fixed constraint condition on the bottom boundary of Ωδ, a boundary load condition with the load type pressure P on ΩP, and a free boundary condition on the remaining boundaries of Ωδ. Lagrange quadratic elements are used for the linear elasticity equations.

The mesh in the FEM-model (P, H) is free triangular with a normal element size and a refinement at ΩP by a distribution with typically 1000 elements.

3.3.2. FEM-Model ()

Figure 3 (top right) shows the computational domains ΩT, ΩT,1, and ΩT,2 on which the temperature distribution in lubricant and solid bodies is calculated fully coupled. Figure 3 (bottom right) illustrates in parts the corresponding model tree. The lubricant domain ΩT has the dimensionless height of 1 with Z ∈ [0,1], whereas the solid domains ΩT,1 and ΩT,2 have the dimensionless heights of D = 3.15 with Z ∈ [−D, 0] and Z ∈ [1, D + 1], respectively. The length of the computational domains extends from Xin to Xex (see Figure 3, top left). For each new call-up of the FEM-model (), the solution of the previous call-up is used as initial value. The transient energy equations in dimensionless form are implemented and calculated in the physics Heat Transfer in Fluids for the lubricant domain ΩT and in Heat Transfer in Solids for the solid domains ΩT,1 and ΩT,2. The dependent variable is solved based on Lagrange quadratic elements. The numerical stabilisation terms ID, SUPG, and GLS are already implemented in the considered heat transfer physics in COMSOL and applied when required. The velocity distribution (4), viscosity distribution (15), density distribution (16), thermal conductivity distribution (17), and heat capacity distribution (18) in ΩT are calculated in the sequence controller and transferred to the FEM-model () by interpolation functions. Furthermore, the heat sources in the physics Heat Transfer in Fluids, due to the shearing and compression of the lubricant, are calculated in the sequence controller and transferred to FEM-model (). Note thereby that, similar to the coefficients in (21), as a dependent variable needs to be applied in the FEM-model (). The implementation of the energy equations on ΩT,1 and ΩT,2 in the Heat Transfer in Solids modules with the translation motions of solids v1 and v2 as input parameters is straightforward.

3.3.3. Sequence Controller

The communication between the MATLAB sequence controller and the FEM-model (P, H) and FEM-model () is achieved by COMSOL’s LiveLink for MATLAB function. The MATLAB sequence controller basically represents the implementation of the global numerical scheme shown in Figure 2. There, it is very convenient, for example, to implement the models for the lubricant properties, calculate the integrals by adaptive Simpson quadrature rule with typically 40 elements in Z-direction, and perform other calculations with the current values for pressure, film thickness, and temperature. As no other possibility is available, the data exchange of vectors and matrices from MATLAB to COMSOL is handled in a somewhat cumbersome manner: The quantities, calculated in the sequence controller, for example, velocity distribution, are written into a text file and read by the COMSOL interpolation functions. For data exchange from COMSOL to MATLAB, the mpheval command is used.

3.3.4. Solver

For solving the nonlinear system of equations, two separate COMSOL solvers for the FEM-model (P, H) and for the FEM-model () are required. The solver for the FEM-model (P, H) includes the dependent solution variables P, H0, and , whereas the solver for the FEM-model () includes the temperature as the dependent solution variable. For both FEM-models, a direct COMSOL MUMPS (Multifrontal Massively Parallel Direct Solver) [25] is used with a damped Newton-Raphson approach [26] and 10−3 as the tolerance factor as defined in [7].

4. Model Validation

In order to show the functionality and the plausibility of the TEHL simulation model described in Section 3, its solutions are compared with steady-state solutions from Hartinger et al. [2] and with transient solutions presented by Venner [4].

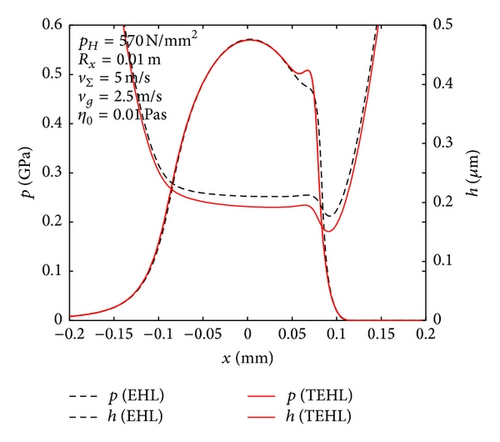

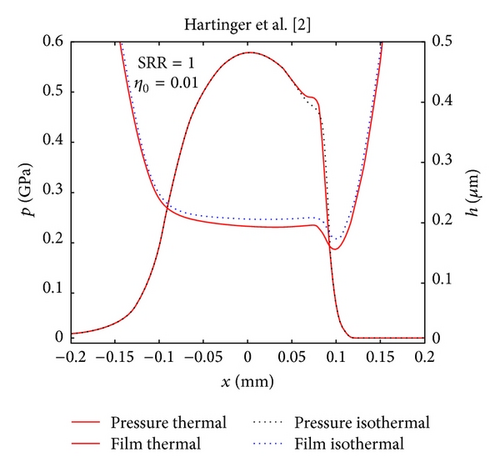

4.1. Steady-State Validation

Hartinger et al. [2] investigated the TEHL contact by CFD simulations for various conditions. They show that the assumptions of the generalised Reynolds equation are reasonable and provide representative results for thermal and isothermal contacts. For comparison of their results in [2] with the presented TEHL simulation model, the same lubricant property models and properties for lubricant and solids are used. Note that cavitation effects considered by the CFD approach cannot be depicted by the cavitation model of Wu [12]. Figure 4 shows the calculated pressure and film thickness distributions for a thermal (TEHL) and isothermal (EHL) contact with high sliding proportion (vΣ = 5 m/s, vg = 2.5 m/s) in comparison to the presented TEHL simulation model (a) and CFD model of Hartinger et al. [2] (b). The results show very good agreement. Furthermore, the local distributions of shear rate, temperature, and viscosity (not shown) correlate very well with the results of Hartinger et al. [2]. The calculation time for the TEHL solution in Figure 4 is approximately 6 to 8 minutes on a computer with a 3.5 GHz processor for the presented TEHL simulation model and in the order of 24 hours for the CFD model [2].

4.2. Transient Validation

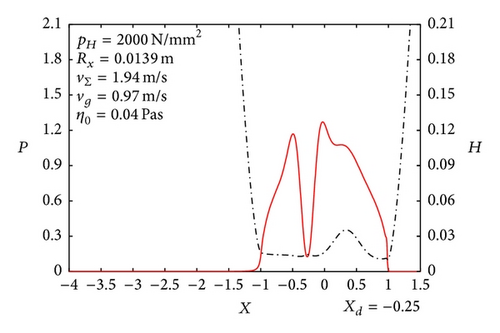

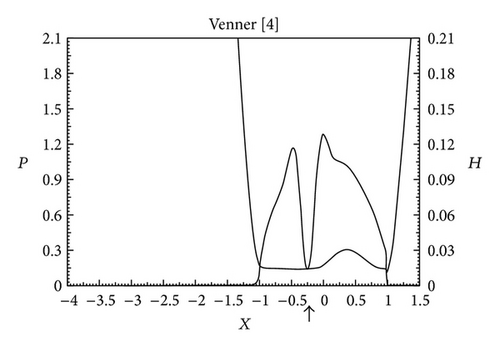

Venner [4] investigated an EHL contact with a moving surface indentation under high sliding conditions by using a transient isothermal Newtonian approach. For the sake of comparison, the authors also assume isothermal and Newtonian simplifications in their presented TEHL simulation model. Input parameters and the investigated surface indentation are thereby adopted from [4]. Figure 5 shows the comparison of pressure and film thickness distribution for the example time, when the surface indentation is located at the dimensionless position Xd = −0.25. It is thereby shown that the moving surface indentation initiates a significant film thickness change, which hurries ahead the actual position of the indentation. This can occur under high sliding conditions. The comparison in Figure 5 shows very good agreement. Small differences in the results may be caused by different elastic deformation calculations (FEM in the TEHL simulation model in this study and elastic half-space assumption in [4]).

The validation of the TEHL simulation model shows its functionality and plausibility.

5. Example Results

In this section, examples of possible application opportunities, such as simulating coated surfaces, coefficients of friction, and nonsmooth surfaces, of the described TEHL simulation model are demonstrated.

5.1. Thin Surface Coatings

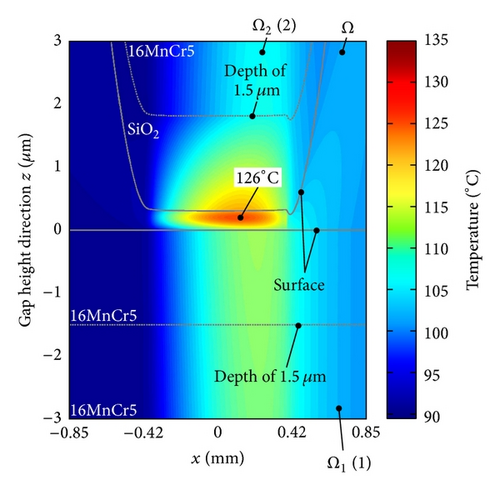

Firstly, the possibility of investigating the effect of thin surface coatings on the TEHL contact behaviour is shown. Results based on the TEHL model described in this study with slightly different lubricant properties have already been published by Lohner et al. [27]. There, the influence of thin surface coatings on the steady-state TEHL contact temperature was analysed by adding coating layers with separate thermophysical properties to the FEM-model (). The FEM-model (P, H) is unchanged. In the FEM-model (), additional geometries with the physics Heat Transfer in Solids including adopted boundary and continuity conditions as described in Section 3.3.2, additional interpolation functions in COMSOL, and additional meshes for the thin surface coatings are integrated. The corresponding handling in the sequence controller is the same as for solids ΩT,1 and ΩT,2. This is very convenient to implement and shows the flexibility of the presented TEHL model approach. For simplification, it has been assumed that the deformation of the solid bodies is not affected by the very thin coatings (1.5 μm) [6].

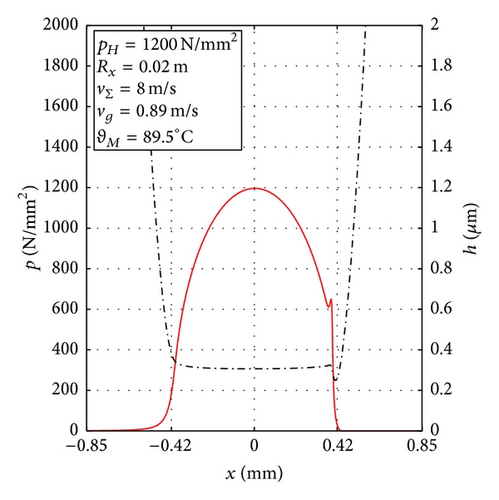

Figure 6 shows an example of the pressure and film thickness (a) and the corresponding temperature distribution of the lubricant and solid bodies (b) for a TEHL contact including a coating with a thickness of 1.5 µm on the upper solid body. The bulk material is case-carburised steel 16MnCr5 and the coating material SiO2 with a significant different thermal conductivity (λ(16MnCr5) = 44 W/m/K, λ(SiO2) = 1.4 W/m/K). The SiO2 coating shows an insulating effect and leads to significantly higher temperatures compared to an uncoated TEHL contact. This also affects the coefficient of friction as shown by, for example, Habchi [6] for TEHL point contacts.

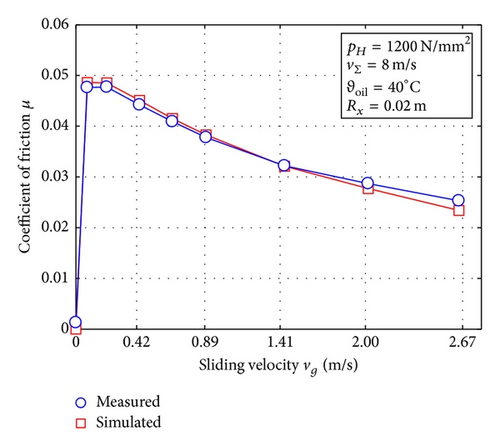

5.2. Coefficient of Friction

For comparing measurement and simulation results, the coefficient of friction is a suitable quantity with integral character. Coefficient of friction measurements in fluid film lubrication regime can be performed at the FZG twin disk test rig with, for example, cylindrical discs (r1 = r2 = 40 mm, leff = 5 mm) made from case-carburised steel (16MnCr5) with a polished surface structure. Further information about the test rig is documented in [28], for example. Table 1 shows the main properties of the considered lubricant MIN100 and the physical properties of the bulk material. Model constants of Section 2.5 of the considered lubricant have been obtained from regression of measurement data. The Eyring shear stress of τc = 6 N/mm2 has been adopted from [29] as there a mineral oil of the same viscosity has been considered. Note that based on the Eyring shear model the increase of the shear stress with shear rate is not limited. To achieve a more realistic representation of the rheological behaviour of the lubricant, a shear stress model based on a limiting shear stress is currently being developed by the authors. However, this is not the focus of this study as it can be easy implemented once it is ready.

| Bulk material properties | |

|---|---|

| 16MnCr5 | |

| Ei in N/mm2 | 206000 |

| νi | 0.30 |

| ρi in kg/m3 | 7760 |

| λi in W/m/K | 44 |

| cp,i in J/kg/K | 431 |

| Lubricant properties | |

| MIN100 | |

| υ (40°C) in mm2/s | 95 |

| υ (100°C) in mm2/s | 10.5 |

| ρ (15°C) in kg/m3 | 885 |

| λ0 in W/m/K | 0.137 |

| cp (15°C) in J/kg/K | 1921 |

| τc in N/mm2 | 6 |

A comparison of measured and simulated coefficients of the friction of lubricant MIN100 with very good correlation is shown in Figure 7. The considered sliding velocities vg = {0, 0.08, 0.21, 0.42, 0.64, 0.89, 1.41, 2.00, 2.67} m/s are thereby accompanied with corresponding bulk temperatures of the slower disc of ϑM = {42, 47, 56, 69, 80, 90, 109, 123, 140}°C.

5.3. Nonsmooth Surfaces

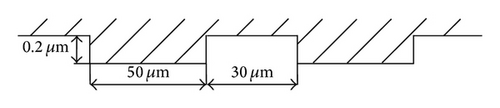

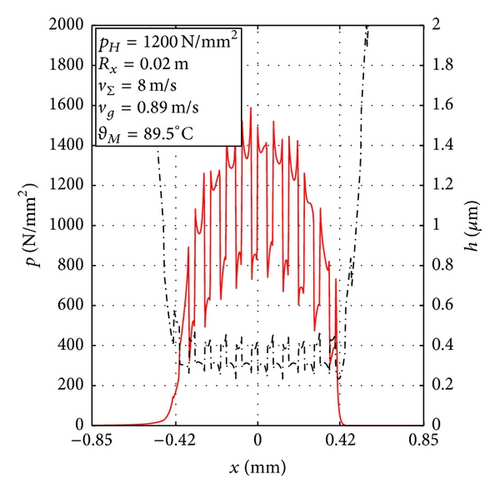

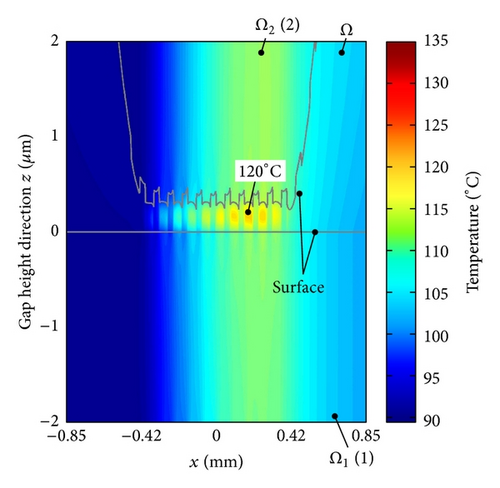

Surface features have a significant influence on TEHL contact behaviour [30, 31]. As an example, the contact of a deterministically structured surface (upper body) with repetitive protruding bars with a height of 0.2 µm and a length of 50 µm every 30 µm shown in Figure 8 with a smooth surface (lower body) is investigated. The deterministically structured surface is represented by the term in (7).

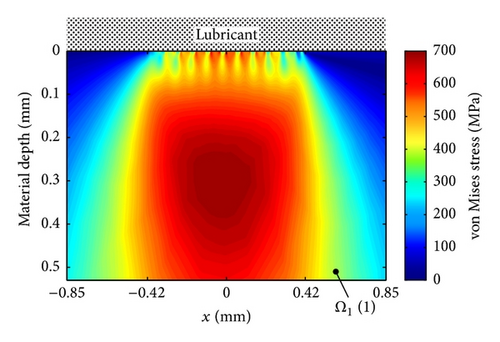

The considered lubricant and material parameters are shown in Table 1 and the operation conditions are pH = 1200 N/mm2, vg = 0.89 m/s, vΣ = 8 m/s, and ϑM = 89.5°C. The model constants of the considered lubricant MIN100, as well as the macrogeometry of the discs, are the same as in Section 5.2. Figure 9 shows the simulated pressure, film thickness, and temperature distribution, which are significantly influenced by the deterministically structured surface. Very local changes of the pressure, film thickness, and temperature distributions are observed thereby. The maximum temperature rise in the lubricant is simulated to be 4 K higher for the deterministically structured surface than for a TEHL contact with smooth surfaces. The transient calculation time is approximately 5 to 10 hours on a computer with a 3.5 GHz processor. Postprocessing the simulated pressure and shear stress distribution by applying it to the upper and lower solid body with bulk material properties acc. to Table 1 easily delivers the stress distributions in the solid bodies based on linear elastic isotropic material behaviour. Figure 10 shows an example of the von Mises stress distribution in the lower (a) and upper (b) solid body corresponding to the pressure and shear stress distribution in Figure 9. Stresses due to temperature are omitted. Due to the deterministically structured surface, stress maxima close to the surface occur in addition to the well-known stress maxima in the deeper material depth.

6. Conclusion

In this paper, guidelines for the implementation of a TEHL model in commercial multiphysics software are presented. The introduced approach can be implemented with moderate effort, and the resulting TEHL model is very easy to extend for various applications. The TEHL model divided in a sequence controller in MathWorks MATLAB and in two self-developed decoupled COMSOL Multiphysics FEM-models is also capable of calculating the transient TEHL contact along the path of contact of gears. Even more challenging tasks, too, such as the extension of the described model to mixed lubrication regimes, are possible. By providing implementation guidelines for a TEHL simulation model in commercial multiphysics software, the authors are confident that the research in computational tribology has been stimulated and accelerated.

Nomenclature

-

- Ac1,…,5:

-

- Coefficients of lubricant heat capacity model

-

- A, B, and C:

-

- Coefficients of lubricant Vogel temperature model

-

- bH:

-

- Hertzian contact half-width in m,

-

- :

-

- Compliance matrix in Pa

-

- cp:

-

- Lubricant specific heat capacity in J/(kg K)

-

- cp,1, cp,2:

-

- Specific heat capacity of solids 1 and 2 in J/(kg K)

-

- d:

-

- Height of solids in the FEM-model () in m

-

- dλ1, dλ2:

-

- Pressure coefficients of lubricant thermal conductivity model in 1/Pa

-

- r1, r2:

-

- Radius of solids 1 and 2 in m

-

- Dρ0, Dρ1, and Dρ2:

-

- Coefficients of lubricant Bode density model

-

- E1, E2:

-

- Young’s Modulus of solids 1 and 2 in Pa

-

- :

-

- Coefficients of lubricant pressure-viscosity coefficient model in 1/Pa and K

-

- Eeq:

-

- Equivalent Young’s Modulus in Pa,

-

- :

-

- Reduced Young’s Modulus in Pa,

-

- FN:

-

- Normal force in N

-

- FR:

-

- Friction force in N

-

- h:

-

- Film thickness in m

-

- h0:

-

- Constant parameter of film thickness in m

-

- leff:

-

- Effective contact length in width direction in m

-

- p:

-

- Pressure in Pa

-

- pH:

-

- Hertzian pressure in Pa

-

- pη0:

-

- Coefficient Roelands equation (p0,Roe = 1.96 · 108 Pa)

-

- Rx:

-

- Reduced radius in m, Rx = r1 · r2/(r1 + r2)

-

- :

-

- Deviation from the smooth profile in m

-

- t:

-

- Time in s

-

- T:

-

- Temperature in K

-

- TM:

-

- Bulk temperature in K

-

- :

-

- Displacement vector in m

-

- vΣ:

-

- Sum velocity in m/s

-

- v1, v2:

-

- Velocity of solids 1 and 2 in m/s

-

- vg:

-

- Sliding velocity in m/s

-

- vx:

-

- Lubricant velocity distribution in m/s

-

- x:

-

- Space coordinate in gap length direction in m

-

- xin, xex:

-

- Left and right boundary of ΩP in m

-

- z:

-

- Space coordinate in gap height direction in m

-

- z(T):

-

- Roelands pressure-viscosity parameter.

Greek Symbols

-

- αp:

-

- Pressure-viscosity coefficient in 1/Pa

-

- αs:

-

- Coefficient of lubricant Bode density model in 1/K

-

- :

-

- Shear rate in 1/s

-

- δ:

-

- Deformation of the equivalent body in m

-

- :

-

- Strain tensor

-

- η:

-

- Lubricant viscosity in Pas

-

- ϑM:

-

- Bulk temperature in °C

-

- ϑoil:

-

- Oil inlet temperature in °C

-

- λ:

-

- Lubricant thermal conductivity in W/(m K)

-

- λ1, λ2:

-

- Thermal conductivity of solids 1 and 2 in W/(m K)

-

- μ:

-

- Coefficient of friction

-

- ν1, ν2:

-

- Poisson’s ratios of solids 1 and 2

-

- νeq:

-

- Equivalent Poisson’s ratio νeq = (E1ν2(1 + ν2) + E2ν1(1 + ν1))/(E1(1 + ν2) + E2(1 + ν1))

-

- ρ:

-

- Lubricant density in kg/m3

-

- ρ1, ρ2:

-

- Density of solids 1 and 2 in kg/m3

-

- ρs:

-

- Coefficient of the lubricant Bode density model in kg/m3

-

- :

-

- Stress tensor of equivalent body in Pa

-

- τ:

-

- Shear stress in Pa,

-

- τc:

-

- Eyring shear stress in Pa

-

- υ:

-

- Kinematic viscosity in mm2/s

-

- ΩT:

-

- Lubricant domain in the FEM-model ()

-

- ΩT,1, ΩT,2:

-

- Solid domains 1 and 2 in the FEM-model ()

-

- ΩP:

-

- Domain of Reynolds equation in the FEM-model (P, H)

-

- Ωδ:

-

- Equivalent body domain in the FEM-model (P, H).

Disclosure

Upon request, the authors are pleased to offer to provide all the input parameters for recalculation of the result examples in Section 5.

Conflict of Interests

The authors declare that there is no conflict of interests regarding the publication of this paper.