Radial Body Forces Influence on FGM and Non-FGM Cylindrical Pressure Vessels

Abstract

This study deals with the influence of radial body forces on FGM and non-FGM pressure vessels. It contains an extended overview of pressure vessels made from both kinds of material. Furthermore, full mathematical development of stress-strain field for both kinds of cylindrical vessels while being influenced by body forces has been performed. In addition, a new power law model for FGM materials was suggested and discussed. Finally, tables of composed plastic-elastic states are discussed.

1. Introduction

Pressure vessels have many engineering applications in many aspects of life, like energy, electronics, mechanics, and biomedical engineering as described by the author and others [1–3]. In continuation to the author previous essay [1], a unique group of pressure vessels made from special materials will be discussed here. These pressure vessels are often called FGM pressure vessels. FGM is a well-known shortcut to functionally graded materials, from which many structures and constructions including pressure vessels are made. These materials are heterogeneous (nonhomogenous) while its materials constituent’s composition is varying continuously gradually in the microscopic phase. These materials have been proved to have special thermomechanical properties. However, their applications are numerous, especially, for military and aerospace applications industry, thermal loading, heat resistance, and so forth. Recent researchers and studies on this field are well described by Kalali and Hadidi-Moud [2], Ansari Sadrabadi and Rahimi [3], and Sadeghian and Ekhteraei Toussi [4]. In more detail, Kalali and Hadidi-Moud have developed an analytical method for predicting elastic-plastic stress distribution in cylindrical and spherical pressure vessels made from a ceramic/metal functionally graded material, while the vessel was subjected to plane-stress conditions and von Mises yield criterion was considered. Also, small strains have been assumed and Hencky’s stress-strain relation was used to obtain the governing differential equations for the plastic region. Other study in this field was presented last year by Ansari Sadrabadi and Rahimi. They examined thick-walled cylindrical vessels made from functionally graded material under internal pressure with the presence of a temperature gradient, while material parameters have been modeled using power functions. They have shown that material distribution parameters and temperature gradient play an important role in FGM elastoplastic behavior. It should be noted that calculation of loading effect has been determined in the first yield point. Another study that was mentioned above has been done by Sadeghian and Ekhteraei Toussi in 2012. Their study includes an axisymmetric thermal elastoplastic stress analysis of FGM cylindrical vessels based on Tresca’s yield criterion and small deformation theory. The investigation of temperature distribution effect upon the evolution and growth of the plastic zone was their study uniqueness. They proved that the interface line between elastic and plastic regions may take shape in different radii while being dependent on the thermomechanical composition properties of the FG material.

Moreover, other structures of beam and spherical shapes have been examined by Eraslan and Akis [5], Nemat-Alla et al. [6], Akis [7], Kanlıkama et al. [8], and Chandel et al. [9], respectively. For instance, Eraslan and Akis have developed plane strain analytical solutions to functionally graded elastic and elastic-plastic pressurized tube under small deformation. Also, plastic behavior and Tresca’s yield criterion were considered. They also assumed radial change of tube material elasticity modulus based on a two-parameter model in a general parabolic form. Field equations exact solutions for elastic and plastic deformations have been obtained together with elastoplastic response which was proved to be affected by the radial variation of the modulus of elasticity. Moreover, nonhomogeneous solution was found to be sensitive to the choice of material parameters. In continuation to the latter study, Kanlıkama et al. [8] have investigated coupled thermoelastic phenomenon determining the stress-strain relations in thick-walled pressurized vessel and a reactor pressure vessel exposed to an inner moderator pressure and thermal loads. Good agreement was found between reactor and classical pressure vessels solutions. Furthermore, Chandel et al. [9] have presented recently a general analysis of thermal stresses and strains in a thin rotating circular FGM disk. For more information on their study, see [9].

In general, physical behavior of non-FGM thick-walled pressure vessels has been investigated in the last decade by several researchers, like Sinclair and Helms [10] who have performed a fundamental review study of elastic hoop stress formulas in cylindrical and spherical pressure vessels. Other researchers like Zhao et al. [11] have proposed a technique for elastic-plastic analysis of a thick-walled elastic-plastic cylinder under internal pressure. Their calculation was based on two parametric functions including piecewise linearization of the stress-strain curve. They have found that the required strain energy value of deformation is found to be dependent on initial or final geometry choice where boundary conditions are satisfied. Moreover, it was found that, in case of low work-hardening solid, the difference is significant and cannot be ignored. Finally, the researchers have shown that the new formulation is appropriate for elastic-plastic fracture calculations. Another research that would be mentioned concerns nonlinear kinematic hardening behavior of pressure cylinder and was studied by Nayebi [12]. He dealt with Bree’s cylinder which was used to simulate different material properties under constant mechanical and cyclic thermal gradient loadings. Nayebi reconsidered Bree’s theory by using nonlinear kinematic hardening material model. Two-dimensional model including Poisson’s effect was also assumed. After comparison with Bree’s model, it was found that Bree’s one-dimensional model is relatively conservative and the bidimensional diagram did not correspond to the complete model. However, calculation of stress-strain field in cylinder or other shapes using finite element method (FEM) is discussed broadly by Szabó et al. [13]. Briefly described, they developed FEM solution for small-strain elastic-plastic stress problems by using p-version elements.

When dealing with plastic behavior of non-FGM pressure vessels, one cannot ignore the autofrettage phenomenon. Autofrettage is a process that is intended mainly to enhance pressure vessels fatigue life and to reduce the vessel weight. The method works by creating plastic expansion (yielding) of the inner wall thickness by overloading the vessel inner diameter or just a portion of it. As a result, compressive residual stresses are being created in the inner diameter (ID) region while in response residual tensile hoop stresses are being created in the outer diameter as was explained in detail by Gibson [14]. The idea of thick wall prestressing is aimed at having a beneficial distribution of tensile hoop stress and compressive stress on the outer diameter (OD) when the pressure is released, while Gibson has investigated autofrettage phenomenon with the appropriate processes. As mentioned in his study, two methods of autofrettage exist: hydraulic and swage. He has made a comparison between both methods using FE model of hydraulic autofrettage. He has found good agreement between the obtained solutions and existing analytical and numerical models. According to Gibson, bilinear material representation is preferred to be used for modeling over other materials since radial position is dependent on the nonlinear material behavior. In the second step, he has developed full model of swage autofrettage. One year later, Lee et al. [15] have published their own study on autofrettage process analysis of a compound cylinder based on the elastic-perfectly plastic material behavior and strain hardening stress-strain curve. They showed that compound cylinder resistance ability is higher than a one layer cylinder while both kinds of cylinders have the same size. Additionally, they found that shrink fit is a relatively efficient way to extend compressive residual stress. Moreover, they found that Bauschinger effect has significant impact on compressive residual stress of the strain-hardening model, such that the stress is smaller than elastic-perfectly plastic case. According to the last studies, an obvious question should be asked: what are the limits of autofrettage process or what is the optimum autofrettage process under a given pressure? An answer was given by Wahi et al. [16]. They performed a research about the influence of optimum autofrettage on the pressure limits of thick-walled cylinder. The tradeoff that researchers have dealt with was between strength-weight ratio increase and fatigue life extending. Their main target is to solve this apparent contradiction by using optimal autofrettage procedure while they have found the required autofrettage pressure for given various levels of allowable pressure. Consequently, three distinguished cases of thick-walled cylinders design have been created. It should be mentioned that, according to their study, the optimal autofrettage is achieved only if both minimum equivalent stress and maximum fatigue life conditions are fulfilled. During the years 2012–2014, various fresh studies have been published on the subject while only few researches among them will be pointed out here. For instance, Hu and Puttagunta [17] have presented numerical investigation study of thick-walled cylinder under overloading internal pressure involved in autofrettage process while the Bauschinger effect was considered inside the elastoplastic material. Moreover, they have found the optimal autofrettage pressure and the maximum reduction percentage of the von Mises stress under the elastic-limit working pressure. In addition, comparison between Bauschinger and the non-Bauschinger effect model has been made by the authors [17]. One year later, fresh study which includes most of the latter subjects together with new approaches has been presented by Trojnacki and Krasinski [18]. They have developed analytic expressions for calculating the autofrettage pressure based on both Tresca and von Mises yield criteria including the Bauschinger effect. The results have been compared with FEM and other analytical models whereas experimental data and analytical model were dealing with multilinear kinematic hardening. The authors have concluded that the autofrettage technique is the preferred technology to use over other technologies discussed. Thorough mathematical analysis of pressure vessel during autofrettage process which also concerns the optimum operation conditions has been published in 2013 by R. Zhu and G. Zhu [19]. Moreover, autofrettage compounded tube had been modeled according to Huang’s model which considers the Bauschinger effect as was introduced by Bhatnagar [20]. He has found that compounded tube advantages include maximum pressure, fatigue life, and manufacturing economy. In 2014, short review on autofrettage process in cylindrical pressure vessels was presented by Gupta and Vora [21]. During the past year of 2015, new studies and approaches have come out. For example, a new process to create autofrettage by applying thermal stresses on the cylinder wall has been performed by Kamal and Dixit [22]. Last fresh study on the autofrettage subject that would be mentioned here has been performed by Kumar and Moulick [23]. They made comparative stress analysis based on FEM for both elliptical and cylindrical pressure vessel with and without autofrettage. For more information relating to autofrettage process in FGM vessels one should read [2–4]. Buckling of FGM and non-FGM materials is summarized by Patil et al. [24]. Specifically, post buckling of FGM plate and shells has been investigated by Shen [25]. In 2006, Kadoli and Ganesan [26] have made analysis research of linear thermal buckling and free vibration of FG cylindrical shells with clamped-clamped BC based on temperature-dependent material properties. Two years later, Shariyat [27] has presented a study about dynamic thermal buckling due to temperature heat shock on FGM cylindrical shells, while a combination of axial compression and external pressure was applied. During his research he has found that buckling behavior is dependent on the volume fraction index and the differences between the thermal stresses in the outer and the inner surfaces. Moreover, he has revealed that temperature gradient and initial material imperfections effects are relatively small on the buckling phenomenon of a shell subjected to a pure external pressure. In 2009, Huang and Han [28] have performed nonlinear buckling and postbuckling examinations for axially compressed FG cylindrical shells by using the Ritz energy method and the nonlinear large deflection theory. One year later, Sofiyev [29] has presented buckling analysis of the simply supported truncated conical shell made of FGM. One of his main findings on this area relates to cylindrical shell stress-strain analysis including buckling analysis based on parametric examination. During the current year of 2015, another study has been published by Zhao and Liew [30, 31] on the subject of buckling response of FG ceramic-metal cylindrical shell panels while axial compression and thermal load are applied. Their model is based on the first-order shear deformation shell theory and element-free kp-Ritz method. One year later, Huang et al. [32] published their research on Buckling of FGM cylindrical shells subjected to pure bending load. Their findings under the appropriate assumptions indicate that the materials inhomogeneity is significant for buckling of FGM cylindrical shells.

- (i)

FGM: elastic-plastic.

- (ii)

FGM: plastic-elastic.

- (iii)

FGM: plastic-elastic-plastic.

- (iv)

FGM: elastic-plastic-elastic.

- (v)

Non-FGM: elastic-plastic.

- (vi)

Non-FGM: plastic-elastic.

- (vii)

Non-FGM: plastic-elastic-plastic.

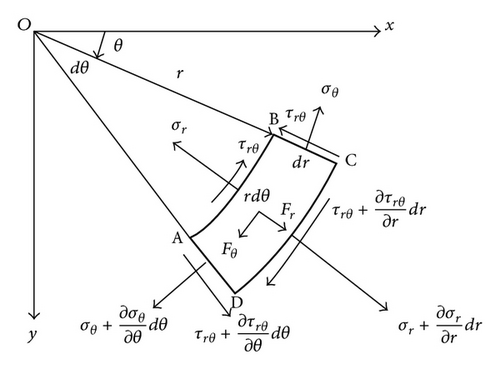

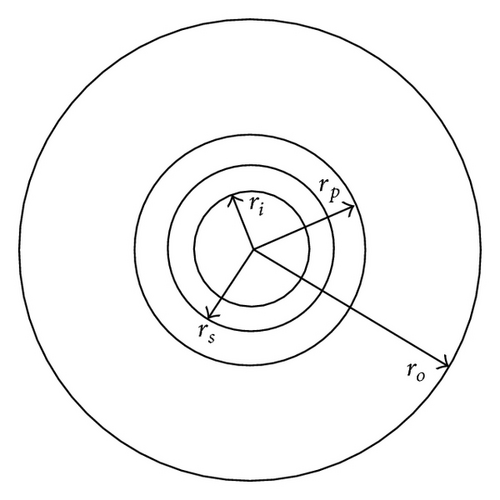

2. General Elastic Stress-Strain Relations with Thermal and Body Forces Influence of Non-FGM Pressure Vessels

In the next section, the elastic stress-strain relations of FGM pressure vessels including the body forces effect will be developed.

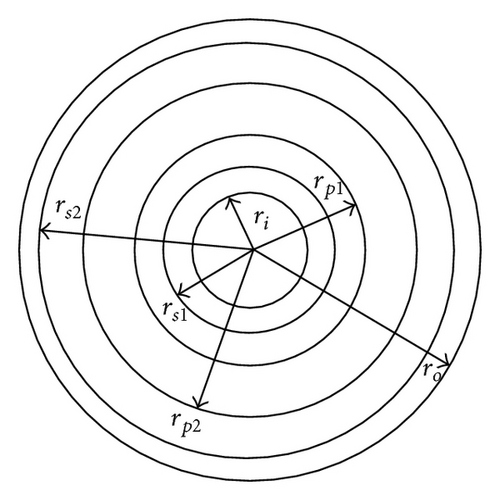

3. General Elastic Stress-Strain Relations with Thermal and Body Forces Influence of FGM Pressure Vessels

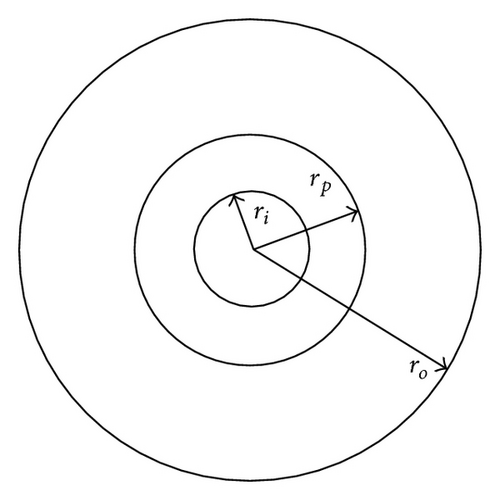

4. General Elastic-Plastic Stress-Strain Relations with Thermal and Body Forces Influence of FGM Pressure Vessels

| ni | u | Limitations |

|---|---|---|

| n = n3 + 2 |

|

|

| n = n4 + 4 |

|

|

| n = n4 + 1 |

|

|

| n = 2 − n5 |

|

|

| n = 2 |

|

|

| n1 = n2 − 2 |

|

|

| n1 = −2 |

|

|

- (i)

FGM qualities are variable and are dependent on the power n and radius r.

- (ii)

Stresses are also temperature dependent.

- (iii)

Body forces are not neglected.

| Case/conditions | B.C. | Representative equations | Constants to define |

|---|---|---|---|

| Plastic-elastic |

|

||

| Elastic-plastic |

|

|

|

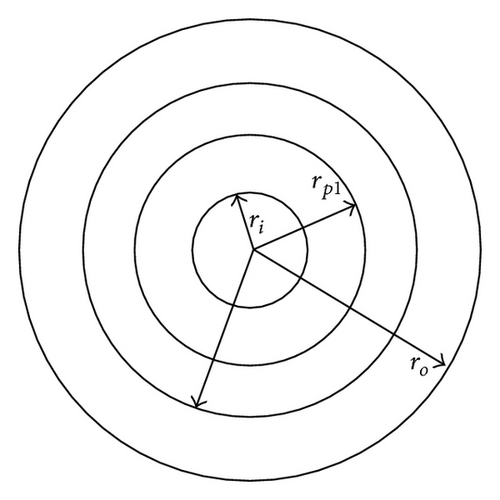

| Plastic-elastic-plastic |

|

|

|

| Elastic-plastic-elastic |

|

|

|

5. General Elastic-Plastic Stress-Strain Relations with Thermal and Body Forces Influence of Non-FGM Pressure Vessels

- (i)

Material properties are constants (E, α).

- (ii)

Stresses are temperature dependent.

- (iii)

Body forces are not neglected.

| Case/conditions | B.C. | Representative equations | Constants to define |

|---|---|---|---|

| Plastic-elastic |

|

||

| Elastic-plastic |

|

|

|

| Plastic-elastic-plastic |

|

|

|

6. Summary and Future Topics

During this study, stress-strain relations of FGM and non-FGM cylindrical vessels behavior in the presence of physical phenomena like magnetic, gravitation, rotational, and electrical charge were developed. In addition, a new power law model for FGM materials was suggested and discussed.

- (i)

FGM: elastic-plastic.

- (ii)

FGM: plastic-elastic.

- (iii)

FGM: plastic-elastic-plastic.

- (iv)

FGM: elastic-plastic-elastic.

- (v)

Non-FGM: elastic-plastic.

- (vi)

Non-FGM: plastic-elastic.

- (vii)

Non-FGM: plastic-elastic-plastic.

In the future, thorough examination including numerical and experimental aspects of the developed elastic-plastic states of FGM and non-FGM materials influenced by body force effect should be performed.

Competing Interests

The author declares that he has no competing interests.