Synthesis of Monodisperse Walnut-Like SnO2 Spheres and Their Photocatalytic Performances

Abstract

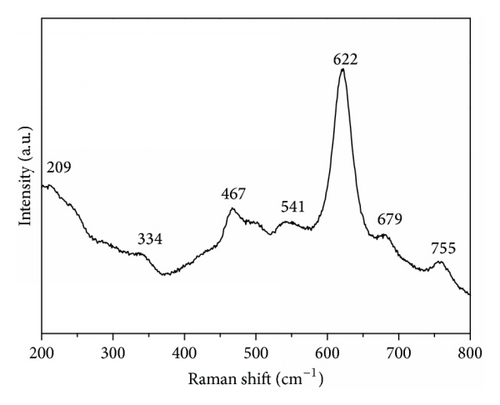

Novel walnut-like SnO2 spheres have been synthesized using a one-step hydrothermal reaction with SnCl2·2H2O and KOH as raw materials. The morphology, microstructure, and optical properties of the products were characterized by X-ray powder diffraction (XRD), Raman spectrum, scanning electron microscopy (SEM), transmission electron microscopy (TEM), selected area electron diffraction (SAED), and ultraviolet-visible (UV-Vis) absorption spectroscopy. The detailed studies revealed that these synthesized spheres are highly monodisperse and have a uniform size of approximately 250 nm. Photocatalytic activity of the prepared SnO2 spheres was evaluated by the degradation of methylene orange. The synthesized SnO2 spheres exhibited excellent photocatalytic degradation. In addition, a possible formation mechanism of the walnut-like nanostructures was proposed based on reaction time-dependent experiments.

1. Introduction

Textile industries produce large volume of colored dye effluents which are toxic and nonbiodegradable [1]. In the past years, the traditional techniques for the treatment of dye waste effluents are usually inefficient, costly, and nondestructive or just transferring pollution from water to another phase [2]. Recently, the purification of wastewater by photocatalytic degradation of dyes using semiconductor particles has proven to be a very effective method, which leads to complete mineralization of the pollutants [3]. Many oxide semiconductors, such as TiO2, ZnO, and SnO2 [4–6], have been widely studied due to their good potential for photocatalyst. Among the above semiconductors, SnO2 is a very important n-type oxide and wide band gap (3.6 eV) semiconductor [7]. Due to its excellent physicochemical properties, SnO2 is employed in a wide range of applications, including gas sensors [8] and photocatalysts [9]. Some researchers have reported that heterogeneous SnO2 showed enhanced photocatalytic activity for photodegradation of various organic dyes [10, 11]. However, use of SnO2 single-phase as a photocatalyst to decompose organic dyes still remains difficult and necessary [12]. It is well known that the size and morphology of nanomaterials can substantially affect their physicochemical properties and their applications [13–15]. Therefore, novel SnO2 morphologies may improve its performances in photocatalysis.

The hydrothermal method has been the most widely used method for synthesizing SnO2 materials due to its advantages of saving energy and convenient manipulation as well as excellent control over size and morphology [16]. However, various templates and surfactants, which are typically toxic and expensive, are often introduced into the hydrothermal process to control the morphology, uniformity, and dispersibility of SnO2 nanomaterials. The removal of these stabilizing molecules requires an additional thermal treatment or chemical etching. Alternatively, if SnO2 nanomaterials could be synthesized via a hydrothermal reaction without any organic additive or template, the manipulation would be convenient and the extraneous impurities would be avoided. In this paper, we present a one-step hydrothermal method to prepare walnut-like SnO2 spheres, using only SnCl2·2H2O and KOH as the raw materials. The products are investigated in detail for their structural characteristics and morphologies. A possible growth mechanism of the walnut-like nanostructure is proposed based on the reaction time-dependent experiments. Furthermore, compared with the commercial SnO2, the photocatalytic performance of the walnut-like SnO2 is improved toward methyl orange (MO) solution.

2. Experimental Section

2.1. Material and Methods

All of the chemical reagents used in this research are of analytical grade without any further purification. In a typical synthesis, 0.002 mol of SnCl2·2H2O was dissolved in 35 mL of deionized water. Then, KOH (4 M, 5 mL) was added to the above solution under vigorous stirring at room temperature. The resulting solution was transferred to a Teflon-lined stainless steel autoclave (50 mL), sealed, and maintained at 190°C for 15 h. After cooling to room temperature, the obtained precipitates were washed several times with distilled water and absolute ethanol followed by drying at 60°C for 12 h.

2.2. Characterizations

X-ray powder diffraction (XRD) pattern was collected on a SmartLab X-ray diffractometer with Cu-Kα radiation (λ = 1.5406 Å). The Raman spectrum (inVia, Renishaw, Gloucestershire, UK) was excited by a 785 nm diode laser at room temperature. The morphologies of the samples were examined using Zeiss Supra 55 field emission scanning electron microscopy (FE-SEM) operated at 15 kV. Transmission electron microscopy (TEM, JEM-3010, Questar, New Hope, USA) was performed using an acceleration voltage of 300 kV. The optical absorption of the products was carried out using a UV-Vis double-beam spectrophotometer (UV-2450, SHIMADZU). The specific surface area was determined by the Brunauer-Emmett-Teller (BET) method using a surface area analyzer (Micromeritics, Gemini VII 2390).

2.3. Photodegradation Experiments

0.05 g of the SnO2 photocatalyst was dispersed in 50 mL of a 10 mg/L MO solution followed by stirring in the dark for 30 min to establish absorption equilibrium. Then, the suspension was irradiated by UV light (300 W mercury lamp) under continuous magnetic stirring. After irradiation for a certain time period, the reaction suspension was centrifuged and characterized using a UV-Vis spectrophotometer.

3. Results and Discussion

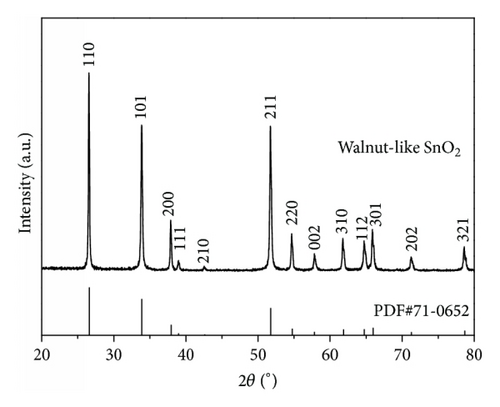

The XRD pattern of the walnut-like SnO2 spheres is shown in Figure 1. All of the diffraction peaks are able to index to the tetragonal rutile structure of SnO2 based on both the position and relative intensity (JCPDS Card number 71-0652). There is no other peak detected, which indicates that the as-prepared SnO2 product has high purity. The sharp diffraction peaks imply that the walnut-like SnO2 sphere in this work is highly crystalline. Based on the Debby-Scherer equation (d = kλ/Bcosθ, where d is the mean crystalline size of the powder, λ is the wavelength of Cu-Kα (λ = 1.5406 Å), B is the full width at half maximum (FWHM) intensity of the peak in radian, θ is Bragg’s diffraction angle, and k is a constant usually equal to ~0.9) [17], the average crystallite size of SnO2 calculated from the main diffraction peak is about 43 nm.

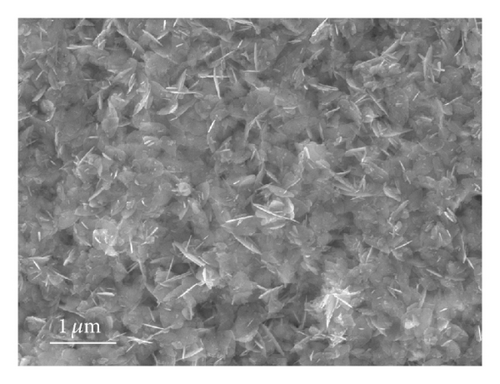

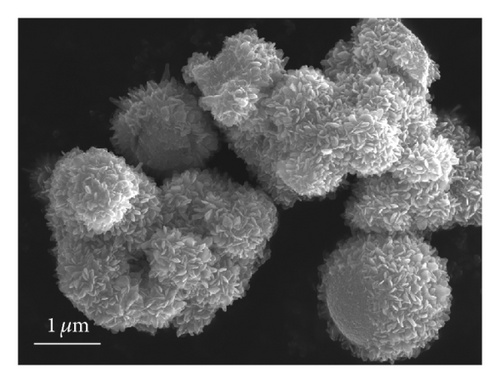

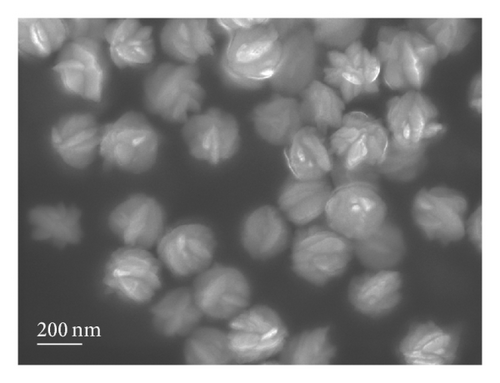

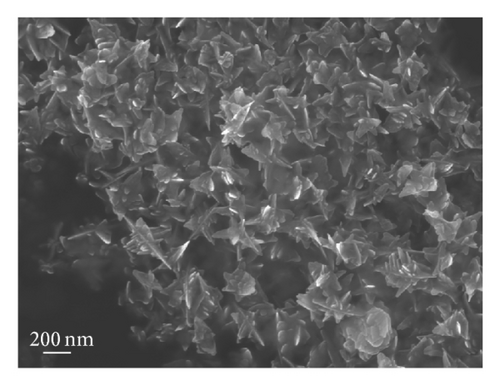

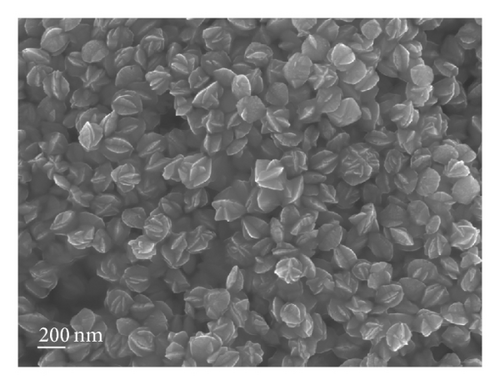

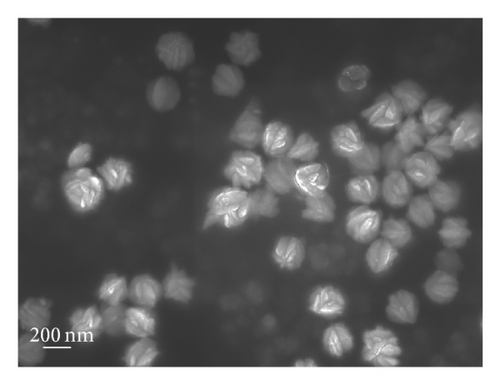

The images in Figures 2(a)–2(d) show the morphologies of the products prepared with different concentration of KOH. It is found that the concentration of KOH affects the morphology dramatically. When the KOH concentration was 2 M, the product consists of dispersed nanoplates (Figure 2(a)). The size of some nanoplates is about 400 nm. As the concentration increases to 3 M, some hierarchical structures begin to appear (Figure 2(b)). It can be seen from some broken hierarchical structures that the inner of the products consists of tiny nanoparticles and the surface of the products is covered with numerous nanoplates. Additionally, compared with the concentration of 2 M, the size of nanoplates of the hierarchical structures decreases to ~200 nm. With an increase of concentration to 4 M, walnut-like SnO2 spheres are obtained (Figure 2(c)). These SnO2 spheres are highly monodisperse and have a uniform diameter of approximately 250 nm. From the high magnification SEM image (Figure 2(d)), it can be seen that the surface of walnut-like SnO2 spheres has many edges, which interlaced with each other to form uniform walnut-like appearance. It denotes that the preferential adsorption of molecules and ions from solution on different crystal faces directs the anisotropic growth of nanoparticles by controlling the growth rate along different crystal axes [18]. Yang et al. proposed that OH− ions attached favorably to the specific facets of rutile SnO2 nanocrystals and accelerated the growth rate of these facets [19]. Our results indicate that the KOH influence the anisotropic growth of SnO2 and play an important role in the synthesis of walnut-like structure.

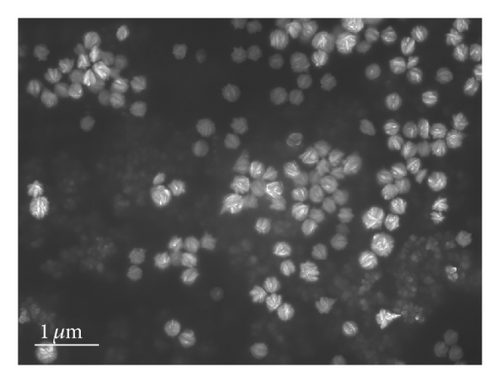

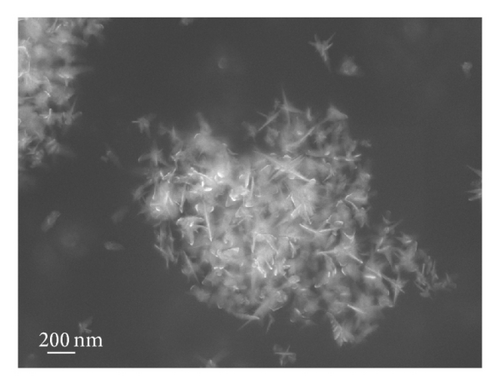

To investigate the growth process of the walnut-like SnO2 spheres and the possible growth mechanism, reaction time-dependent experiments were performed. The corresponding results are shown in Figures 3(a)–3(d). When the hydrothermal time is 4 h, the product consists of some aggregates with sharp corners (Figure 3(a)). When the hydrothermal reaction time is prolonged to 6 h, the nanostructure evolves into the irregular aggregates assembled by imperfect plates (Figure 3(b)). Additionally, the surface of these plates is rough, where some tiny nanoparticles are enchased. When the reaction time is further prolonged to 12 h, the structure evolves into spheres and ellipsoids with wrinkly surface (Figure 3(c)). Compared with the product obtained at 6 h, the edges of these spheres or ellipsoids become obviously smoother and thicker. After increasing the reaction time to 15 h, walnut-like spheres are obtained (Figure 3(d)).

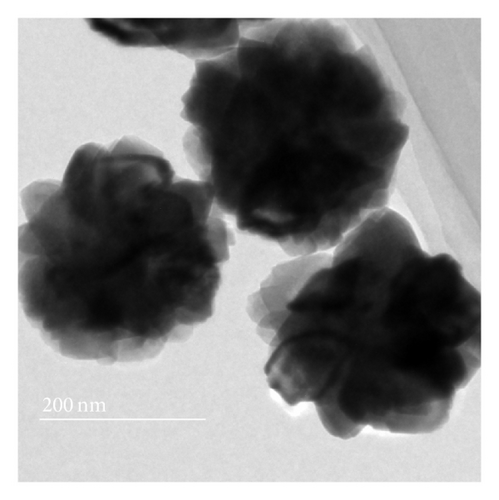

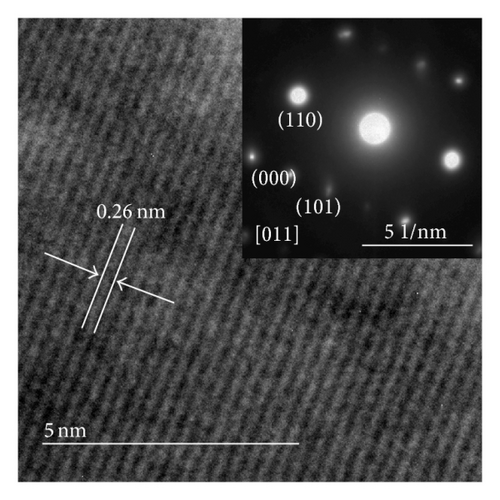

To obtain more details of the walnut-like SnO2 spheres, the structure is characterized by TEM and SAED. As shown in Figure 4(a), the products have a spherical appearance with an average size of ~250 nm, which agrees with the results from SEM. Furthermore, the as-prepared SnO2 spheres are solid and composed of some nanoparticles. Figure 4(b) shows high-resolution TEM (HRTEM) image and selected area electron diffraction (SAED) pattern (inset of Figure 4(b)), respectively. Based on the HRTEM image, the measured d-spacing is 0.26 nm, which corresponds to the (101) planes of the tetragonal rutile SnO2. The sharp diffraction spots observed in the SAED pattern indicate that the individual nanoparticles are highly crystalline. Furthermore, the spots can be easily divided into two sets, which are caused by the (101) and (110) crystal planes, and correspond to the [011] zone axis. These crystallographic results agree well with the XRD analysis.

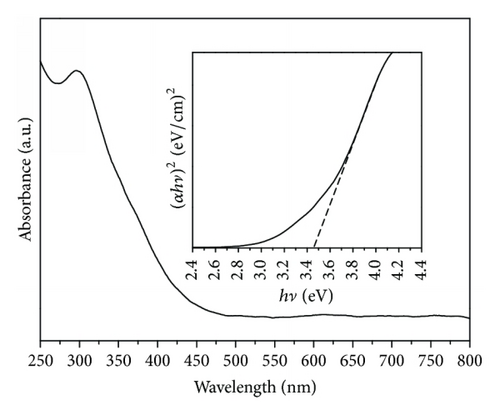

The UV-Vis absorption spectrum of the walnut-like SnO2 spheres is shown in Figure 6(b). The band gap can be determined by (αhν)2 = A(hν − Eg), where α, A, and hν are the absorption coefficient, a constant, and the photon energy, respectively [45]. According to the intercept of the tangent to the plot of (αhν)2 as a function of ν, the band gap is approximately equal to 3.46 eV (inset of Figure 6(b)), which is lower than that for bulk SnO2.

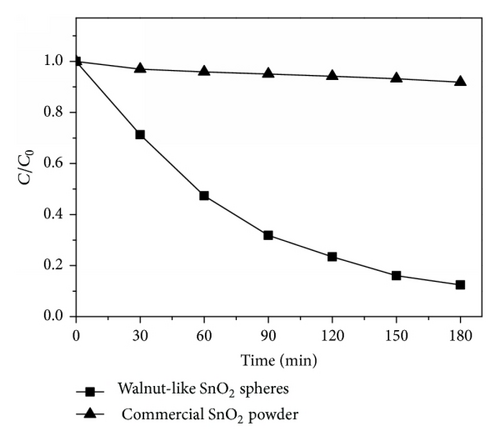

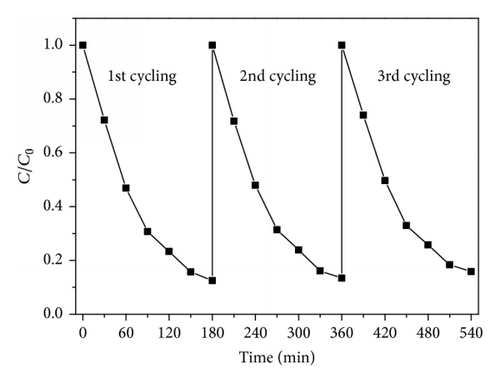

The experiments related to photocatalytic degradation of MO were carried out to demonstrate the photocatalytic properties of walnut-like SnO2 nanospheres. Figure 7(a) shows the photocatalytic rate of walnut-like SnO2 spheres and commercial SnO2 powders under UV light at different periods of time. After 180 min of illumination, in the case of walnut-like SnO2 spheres, the degradation of the MO concentration is about 88%, whereas in the case of commercial one, the degradation is lower than 9%. In order to evaluate the photostability, the cyclic photodegradation of MO over the walnut-like SnO2 spheres is also examined. As shown in Figure 7(b), after three cycles of photocatalytic degradation, no significant loss of activity is represented. It indicates that the photocatalysts with high photocatalytic activity could be easily recovered by sedimentation and would greatly promote their industrial application in eliminating organic pollutants from wastewater.

The basic photocatalytic principle relies on the photogenerated electrons (e−) and holes (h+) (when absorbed energy is equal to or higher than its band gap) [1]. The electrons and holes react with the adsorbed surface substances, like O2 and OH−, to form reactive species and OH∙, which are the major oxidative species for the decomposition of organic pollutants. Generally, the larger exposed surface can provide more surface sites, where OH∙ radicals can be generated by the reaction between the photogenerated charge carriers and react with MO molecule. The as-prepared SnO2 spheres possess the small size and rough surface, which benefit from improving their specific surface area. The BET surface area of the walnut-like SnO2 spheres is estimated by nitrogen sorption and is about 47.4 m2g−1, which is much higher than that of the commercial SnO2 (3.5 m2g−1). Moreover, the walnut-like SnO2 spheres are highly monodisperse without agglomeration in the solution. This good dispersion stability is of considerable importance in the practical water treatment applications.

4. Conclusions

Novel walnut-like SnO2 spheres have been synthesized successfully via a facile one-step hydrothermal method. The as-prepared SnO2 spheres are highly monodisperse and have a uniform size of approximately 250 nm. The formation mechanism of the SnO2 walnut-like structure has been proposed. In addition, these walnut-like SnO2 spheres exhibit excellent photoactivity for the degradation of MO. Our synthesis method is environmental-friendly and inexpensive. It provides SnO2 materials with a novel morphology that can be exploited for various applications.

Conflict of Interests

The authors declare that there is no conflict of interests regarding the publication of this paper.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (51172187, 51277138, 51402230, and 61405151), SPDRF (20116102130002), 111 Program of MOE (B08040), the Natural Science Foundation of Shaanxi Province (nos. 2014JQ8337 and 2013KW12-02), the Scientific Research Program of Shaanxi Education Department (nos. 15JK1325 and 15JK1578), the Doctorate Foundation (BS1436) of China, the SKLP Foundation (KP201421), and the Fundamental Research Funds for the Central Universities (3102014JGY01004) of China.